wire rope cable splicing in stock

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

Manufacturer of electric fencing for pasture, animal performance and health management applications. Products include EID (electronic identification) tag readers, data collectors, wireless water monitoring systems, battery energizers, solar panels, batteries, remotes and testers. Clamps, posts, strainers, insulators, offsets, electric gates, fence tools, wire, cables, reels, tapes, wires, braids and pigtails are offered. Other products such as netting, scale heads, weighing scales, load bars, pipe unions, floats, elbows, tees, adaptors, couplers, valves, automatic watering fittings, mouse traps and software are available. Repair, overgrazing and preventative management are provided as secondary services.

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

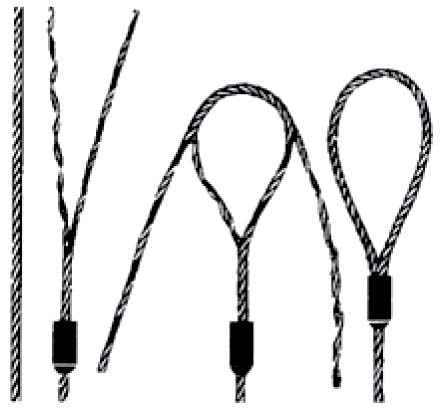

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

No one"s a tougher judge of our products and services than you. That"s why every product we manufacture or distribute meets or exceeds applicable national and international standards. Everyone involved has a dedicated resolve to meet the strictest quality and service standards you deserve. Why do we go the extra mile? Simple. We want to satisfy your needs and expectations, earn your trust, and win you back when your next requirement arrives.

Splicing Grips Model O series is traditionally used as a splicing grip to pull a new cable or wire rope with the existing cable/wire that is being replaced.

Additionally, as a bundle keeper, Splicing Grips Model O versatile series is also being used for cable management or wire management or for abrasion resistance or cut and/or nick protection of a cable, hose or bundling of cables and or hoses on a jobsite.

Really Quick Wire Rope Eye-splice.: This is a handy trick if you ever find yourself in need of an eye in a wire rope and you don"t have wire rope grips (bulldog grips) or the ti…

We stock a large variety of rigging gear and hardware. Our in-house services include inspection, test, and certifying of slings and rigging gear. We also offer on-site inspection of rigging, of rolex replica slings and rigging gear, on-site inspection of rigging, and pickup and delivery. We can have any of our experienced sales staff go on-site and assist with determining the best way to handle your lifting needs. We also offer an on site class on proper rigging gear inspection.

RF2A367AD–Electric wire connecter for fasten low-voltage electrical conductors. Connector splice wires together with a wire nut. Connecting end caps on electric

RFT5XDW6–Eye splice is the end of the rope is unlaid and the strands are bent upon the body of the rope, vintage line drawing or engraving illustration.

RF2A367A2–Splice electrical wires using wire connectors. Electric wire connectors are twist-on or wire nuts. End caps for electrical wires are wire caps or wire

RFT5YWT6–Short Splice is the most common description of splice is when a rope is lengthened by another of the same size, vintage line drawing or engraving illu

RF2A7N5R9–Splicing electric wires in a electrical box of a ceiling chandelier using a spring-loaded lever terminal block. An electrician mounts a wiring of a li

RFT5X4JH–Eye Splice in Three Steps which is a sort of eye or circle formed by splicing the end of a rope into itself, vintage line drawing or engraving illustr

RFMNXG3F–Technicians put it Optical cable and wire in fiber optic splice tray. Close up, selective focus. Modern and fast internet and network concept

RFT61FN3–Double Strop Made with one piece of rope the splice being brought as usual to the crown of the block, vintage line drawing or engraving illustration.

8613371530291

8613371530291