wire rope cable splicing factory

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

Manufacturer of electric fencing for pasture, animal performance and health management applications. Products include EID (electronic identification) tag readers, data collectors, wireless water monitoring systems, battery energizers, solar panels, batteries, remotes and testers. Clamps, posts, strainers, insulators, offsets, electric gates, fence tools, wire, cables, reels, tapes, wires, braids and pigtails are offered. Other products such as netting, scale heads, weighing scales, load bars, pipe unions, floats, elbows, tees, adaptors, couplers, valves, automatic watering fittings, mouse traps and software are available. Repair, overgrazing and preventative management are provided as secondary services.

No one"s a tougher judge of our products and services than you. That"s why every product we manufacture or distribute meets or exceeds applicable national and international standards. Everyone involved has a dedicated resolve to meet the strictest quality and service standards you deserve. Why do we go the extra mile? Simple. We want to satisfy your needs and expectations, earn your trust, and win you back when your next requirement arrives.

Factory Wholesale Stainless Steel Wire Rope Cable With Eyelet Terminal Tube Crimp Cable Lug Wire Rope Sling - Buy 316 Stainless Steel Cable,High Tensile Steel Cable,Wire Rope Assembly Cable Product on Alibaba.com

Splicing Grips Model O series is traditionally used as a splicing grip to pull a new cable or wire rope with the existing cable/wire that is being replaced.

Additionally, as a bundle keeper, Splicing Grips Model O versatile series is also being used for cable management or wire management or for abrasion resistance or cut and/or nick protection of a cable, hose or bundling of cables and or hoses on a jobsite.

As Sling Manufacturers, Hanes Supply"s sling production now includes chain slings, nylon slings, SlingMax slings and wire rope slings. Hanes Supply, Inc., has over 80 years experience splicing wire rope and manufacturing slings, as well as providing quality products to industry and the construction trades. Our expert staff is here to help you create lifting solutions for your lifting needs.

Our structural ropes are produced and assembled in accordance with the EU harmonization directives and are certified with CE approval. The CE certification guarantees that the marked products can be traded in the EU without restrictions. Fatzer guarantees that all requirements necessary for CE approval have been met in accordance with the relevant directives.

If ropework were not a popular pastime, then "The Art of the Sailor" by Hervey Garrett Smith would not be such a popular book, nor would "The Ashley Book of Knots" be in its umpteenth printing. There"s also a book called "The Marlinspike Sailor".

But the most practical book, for you "Practical Machinists" is "Handbook of Seamen"s Rope Work. The author was an old-time Scandanavian sailor and this one has all the techniques for working with big lines and wires.

I have an application for spliced wire that does not involve lifting. The luff wire in the jib on my old gaff-rigged sailboat is a phosphor-bronze wire rope with spliced eyes. This jib is "set flying" - it is not "hanked" to a forestay.

To get the job done, your equipment has to live up to your expectations. It needs to function properly and do what it was made to do -- be strong, secure, safe, and work under any condition. Mill Valley Splicing"s expertise ensures your equipment holds up its end of the bargain, so your focus can remain on the job at hand.

From chain slings and boom pendants, to wire rope hoist and winch lines, we apply more than 175 combined years of wire rope fabrication and industryexperience to every order, providing custom-made or off-the-shelf solutions to your on-the-job-challenges.

In stricter senses, the term wire rope refers to a diameter larger than 9.5 mm (3⁄8 in), with smaller gauges designated cable or cords.wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically, wire rope evolved from wrought iron chains, which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. While friction between the individual wires and strands causes wear over the life of the rope, it also helps to compensate for minor failures in the short run.

Wire ropes were developed starting with mining hoist applications in the 1830s. Wire ropes are used dynamically for lifting and hoisting in cranes and elevators, and for transmission of mechanical power. Wire rope is also used to transmit force in mechanisms, such as a Bowden cable or the control surfaces of an airplane connected to levers and pedals in the cockpit. Only aircraft cables have WSC (wire strand core). Also, aircraft cables are available in smaller diameters than wire rope. For example, aircraft cables are available in 1.2 mm (3⁄64 in) diameter while most wire ropes begin at a 6.4 mm (1⁄4 in) diameter.suspension bridges or as guy wires to support towers. An aerial tramway relies on wire rope to support and move cargo overhead.

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany.chains, such as had been used before.

Wilhelm Albert"s first ropes consisted of three strands consisting of four wires each. In 1840, Scotsman Robert Stirling Newall improved the process further.John A. Roebling, starting in 1841suspension bridge building. Roebling introduced a number of innovations in the design, materials and manufacture of wire rope. Ever with an ear to technology developments in mining and railroading, Josiah White and Erskine Hazard, principal ownersLehigh Coal & Navigation Company (LC&N Co.) — as they had with the first blast furnaces in the Lehigh Valley — built a Wire Rope factory in Mauch Chunk,Pennsylvania in 1848, which provided lift cables for the Ashley Planes project, then the back track planes of the Summit Hill & Mauch Chunk Railroad, improving its attractiveness as a premier tourism destination, and vastly improving the throughput of the coal capacity since return of cars dropped from nearly four hours to less than 20 minutes. The decades were witness to a burgeoning increase in deep shaft mining in both Europe and North America as surface mineral deposits were exhausted and miners had to chase layers along inclined layers. The era was early in railroad development and steam engines lacked sufficient tractive effort to climb steep slopes, so incline plane railways were common. This pushed development of cable hoists rapidly in the United States as surface deposits in the Anthracite Coal Region north and south dove deeper every year, and even the rich deposits in the Panther Creek Valley required LC&N Co. to drive their first shafts into lower slopes beginning Lansford and its Schuylkill County twin-town Coaldale.

The German engineering firm of Adolf Bleichert & Co. was founded in 1874 and began to build bicable aerial tramways for mining in the Ruhr Valley. With important patents, and dozens of working systems in Europe, Bleichert dominated the global industry, later licensing its designs and manufacturing techniques to Trenton Iron Works, New Jersey, USA which built systems across America. Adolf Bleichert & Co. went on to build hundreds of aerial tramways around the world: from Alaska to Argentina, Australia and Spitsbergen. The Bleichert company also built hundreds of aerial tramways for both the Imperial German Army and the Wehrmacht.

In the last half of the 19th century, wire rope systems were used as a means of transmitting mechanical powercable cars. Wire rope systems cost one-tenth as much and had lower friction losses than line shafts. Because of these advantages, wire rope systems were used to transmit power for a distance of a few miles or kilometers.

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The very high strength of the rope wires enables wire ropes to support large tensile forces and to run over sheaves with relatively small diameters.

In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbors along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

In principle, spiral ropes are round strands as they have an assembly of layers of wires laid helically over a centre with at least one layer of wires being laid in the opposite direction to that of the outer layer. Spiral ropes can be dimensioned in such a way that they are non-rotating which means that under tension the rope torque is nearly zero. The open spiral rope consists only of round wires. The half-locked coil rope and the full-locked coil rope always have a centre made of round wires. The locked coil ropes have one or more outer layers of profile wires. They have the advantage that their construction prevents the penetration of dirt and water to a greater extent and it also protects them from loss of lubricant. In addition, they have one further very important advantage as the ends of a broken outer wire cannot leave the rope if it has the proper dimensions.

Stranded ropes are an assembly of several strands laid helically in one or more layers around a core. This core can be one of three types. The first is a fiber core, made up of synthetic material or natural fibers like sisal. Synthetic fibers are stronger and more uniform but cannot absorb much lubricant. Natural fibers can absorb up to 15% of their weight in lubricant and so protect the inner wires much better from corrosion than synthetic fibers do. Fiber cores are the most flexible and elastic, but have the downside of getting crushed easily. The second type, wire strand core, is made up of one additional strand of wire, and is typically used for suspension. The third type is independent wire rope core (IWRC), which is the most durable in all types of environments.ordinary lay rope if the lay direction of the wires in the outer strands is in the opposite direction to the lay of the outer strands themselves. If both the wires in the outer strands and the outer strands themselves have the same lay direction, the rope is called a lang lay rope (from Dutch langslag contrary to kruisslag,Regular lay means the individual wires were wrapped around the centers in one direction and the strands were wrapped around the core in the opposite direction.

Multi-strand ropes are all more or less resistant to rotation and have at least two layers of strands laid helically around a centre. The direction of the outer strands is opposite to that of the underlying strand layers. Ropes with three strand layers can be nearly non-rotating. Ropes with two strand layers are mostly only low-rotating.

Stationary ropes, stay ropes (spiral ropes, mostly full-locked) have to carry tensile forces and are therefore mainly loaded by static and fluctuating tensile stresses. Ropes used for suspension are often called cables.

Track ropes (full locked ropes) have to act as rails for the rollers of cabins or other loads in aerial ropeways and cable cranes. In contrast to running ropes, track ropes do not take on the curvature of the rollers. Under the roller force, a so-called free bending radius of the rope occurs. This radius increases (and the bending stresses decrease) with the tensile force and decreases with the roller force.

Wire rope slings (stranded ropes) are used to harness various kinds of goods. These slings are stressed by the tensile forces but first of all by bending stresses when bent over the more or less sharp edges of the goods.

Technical regulations apply to the design of rope drives for cranes, elevators, rope ways and mining installations. Factors that are considered in design include:

Donandt force (yielding tensile force for a given bending diameter ratio D/d) - strict limit. The nominal rope tensile force S must be smaller than the Donandt force SD1.

The wire ropes are stressed by fluctuating forces, by wear, by corrosion and in seldom cases by extreme forces. The rope life is finite and the safety is only ensured by inspection for the detection of wire breaks on a reference rope length, of cross-section loss, as well as other failures so that the wire rope can be replaced before a dangerous situation occurs. Installations should be designed to facilitate the inspection of the wire ropes.

Lifting installations for passenger transportation require that a combination of several methods should be used to prevent a car from plunging downwards. Elevators must have redundant bearing ropes and a safety gear. Ropeways and mine hoistings must be permanently supervised by a responsible manager and the rope must be inspected by a magnetic method capable of detecting inner wire breaks.

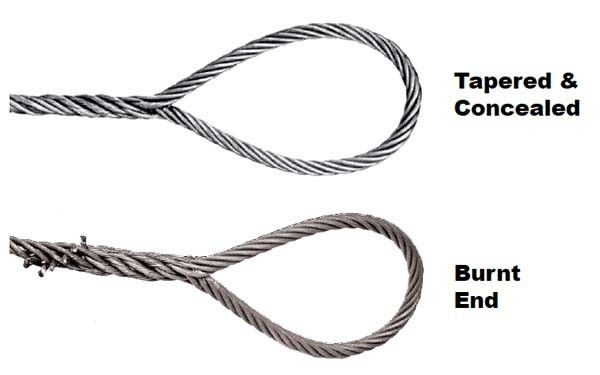

The end of a wire rope tends to fray readily, and cannot be easily connected to plant and equipment. There are different ways of securing the ends of wire ropes to prevent fraying. The common and useful type of end fitting for a wire rope is to turn the end back to form a loop. The loose end is then fixed back on the wire rope. Termination efficiencies vary from about 70% for a Flemish eye alone; to nearly 90% for a Flemish eye and splice; to 100% for potted ends and swagings.

When the wire rope is terminated with a loop, there is a risk that it will bend too tightly, especially when the loop is connected to a device that concentrates the load on a relatively small area. A thimble can be installed inside the loop to preserve the natural shape of the loop, and protect the cable from pinching and abrading on the inside of the loop. The use of thimbles in loops is industry best practice. The thimble prevents the load from coming into direct contact with the wires.

A wire rope clip, sometimes called a clamp, is used to fix the loose end of the loop back to the wire rope. It usually consists of a U-bolt, a forged saddle, and two nuts. The two layers of wire rope are placed in the U-bolt. The saddle is then fitted to the bolt over the ropes (the saddle includes two holes to fit to the U-bolt). The nuts secure the arrangement in place. Two or more clips are usually used to terminate a wire rope depending on the diameter. As many as eight may be needed for a 2 in (50.8 mm) diameter rope.

The mnemonic "never saddle a dead horse" means that when installing clips, the saddle portion of the assembly is placed on the load-bearing or "live" side, not on the non-load-bearing or "dead" side of the cable. This is to protect the live or stress-bearing end of the rope against crushing and abuse. The flat bearing seat and extended prongs of the body are designed to protect the rope and are always placed against the live end.

The ends of individual strands of this eye splice used aboard a cargo ship are served with natural fiber cord after splicing to help protect seamens" hands when handling.

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound a certain distance, then bent around so that the end of the unwrapped length forms an eye. The unwrapped strands are then plaited back into the wire rope, forming the loop, or an eye, called an eye splice.

A Flemish eye, or Dutch Splice, involves unwrapping three strands (the strands need to be next to each other, not alternates) of the wire and keeping them off to one side. The remaining strands are bent around, until the end of the wire meets the "V" where the unwrapping finished, to form the eye. The strands kept to one side are now re-wrapped by wrapping from the end of the wire back to the "V" of the eye. These strands are effectively rewrapped along the wire in the opposite direction to their original lay. When this type of rope splice is used specifically on wire rope, it is called a "Molly Hogan", and, by some, a "Dutch" eye instead of a "Flemish" eye.

Swaging is a method of wire rope termination that refers to the installation technique. The purpose of swaging wire rope fittings is to connect two wire rope ends together, or to otherwise terminate one end of wire rope to something else. A mechanical or hydraulic swager is used to compress and deform the fitting, creating a permanent connection. Threaded studs, ferrules, sockets, and sleeves are examples of different swaged terminations.

A wedge socket termination is useful when the fitting needs to be replaced frequently. For example, if the end of a wire rope is in a high-wear region, the rope may be periodically trimmed, requiring the termination hardware to be removed and reapplied. An example of this is on the ends of the drag ropes on a dragline. The end loop of the wire rope enters a tapered opening in the socket, wrapped around a separate component called the wedge. The arrangement is knocked in place, and load gradually eased onto the rope. As the load increases on the wire rope, the wedge become more secure, gripping the rope tighter.

Poured sockets are used to make a high strength, permanent termination; they are created by inserting the wire rope into the narrow end of a conical cavity which is oriented in-line with the intended direction of strain. The individual wires are splayed out inside the cone or "capel", and the cone is then filled with molten lead-antimony-tin (Pb80Sb15Sn5) solder or "white metal capping",zincpolyester resin compound.

Donald Sayenga. "Modern History of Wire Rope". History of the Atlantic Cable & Submarine Telegraphy (atlantic-cable.com). Archived from the original on 3 February 2014. Retrieved 9 April 2014.

Andrew Hallidie is considered the father of the cable car, although he was not the only inventor to dabble in the use of cable as a means of transportation. Hallidie and his father both held several patents for the manufacture and use of cable, or wire rope as it was called. Wire rope served a number of purposes in the mines of California, Nevada and other western mining centers in the latter half of the 19th century. Woven much like hemp rope but much stronger, it ranged in gauges from the thickness of a hair to a finger, and was used to transport ore from the mines, equipment and supplies to the mines, and occasionally passengers as well, who both trembled and wondered at the breathtaking views they saw from the aerial trams operating on the wire ropes.

The first commercial success of wire rope was in England when, in 1830, George Binks convinced the Royal Navy to replace hemp rope on its fleet of ships with wire rope. Binks was joined shortly after by Andrew Smith, a Scot, who held patents on several improved varieties of wire rope and was incidentally the father of young Andrew, who took the name Hallidie from his godfather Sir Andrew Hallidie, royal physician to the court of Queen Victoria.

Across the water in the United States, John A. Roebling, who would later build the Brooklyn Bridge, was manufacturing wire rope at his factory in Pennsylvania, in 1840. Roebling"s company expanded, as did the demand for wire rope, until it became one of the largest producers of iron and steel rope used in building bridges during the 19th century. One of Roebling"s friends and competitors, Peter Cooper, began dabbling in aerial tramways to transport materials for factories on the East Coast.

Hallide developed the first successful aerial tramways in the West, after a few years of drifting from camp to camp working claims, narrowly avoiding disasters both natural and manmade, and briefly running a restaurant at Michigan Bluff in the Mother Lode. Then in 1855, young Hallidie built a wire suspension bridge and aqueduct 220 feet long at Horse Shoe Bar on the Middle Fork of the American River. A year later he built a flume near Gray Eagle Bar that transported ore to a quartz mill 1100 feet up a hill. The cars operated along Hallidie"s wire rope, which replaced regular rope, by gravity, the loaded cars pulling empty ones up to the mill as they went down. Hallidie manufactured rope for this project consisting of three spliced pieces one-eighth of an inch thick, 1200 feet long, which lasted for two years as opposed to 75 days for the previous type used.

In 1857 Hallidie left the Mother Lode and returned to San Francisco where he set up a factory on the corner of Mason and Chestnut Streets to manufacture wire rope. In addition to aerial tramways, his rope was used to build suspension bridges across creeks and rivers throughout northern California. He was often away from the City on his bridge projects until in 1865 he returned to San Francisco and focused his energies entirely on manufacturing and perfecting wire rope. The discovery of the Comstock Lode in Nevada increased the need for wire rope. The City became a major industrial center for mining operations in the 1860s and Hallidie prospered, becoming a leading entrepreneur, citizen, and in 1868 President of the prestigious Mechanic"s Institute.

It was also about this time that Hallidie began to implement a scheme for urban transportation he had been pondering for some time, based upon his use of wire rope for aerial tramways transporting material up steep mountainsides and across gorges. He worked on improving the tensile strength and flexibility of his wire to develop an "endless" wire rope that could be would around large pulleys, which could then provide continuous underground propulsion for a car that could be attached or released at will from the cable. Hallide took out a patent for this "Endless Wire Ropeway" and for the next decade or so dominated the construction of tramways at mines across the west. However, it was the implementation of his Endless Wire Ropeway for moving streetcars in San Francisco that brought him lasting fame and a place in the history books.

The cable used in the present system measures 1 1/4 inches in diameter, is made of steel with a hemp center to increase flexibility, and varies in length - the California (21,700 feet), Hyde (16,000 feet), Mason (10,300 feet), and Powell (9,300 feet).

The cable itself is composed of six steel strands of 19 wires each that are wrapped around the sisal rope center. It has an average life of 6 to 8 months, and if it becomes worn, the system is shut down at night and a splice is made in the powerhouse.

If a cable should break, which is very rare, the splice is made temporarily out along the line, then run back into the powerhouse where a permanent splice is made. The cable is lubricated to reduce wear and friction; for over a century pine tar was used, giving the cable car lines a distinctive and now nostalgic smell, but after the 1982 restoration a synthetic lubricant was substituted.

“Tough-Lock™” and “Cable-Flex™” slings are uniquely constructed unlike various return wire loop types. Note that our five step manufacturing process, commonly

All “Tough-Lock™” slings adhere and comply with current specifications of OSHA, ASME B30.9c-2000 Wire Rope Technical, and Associated Wire Rope Fabricators.

8613371530291

8613371530291