mud agitator gearbox for sale

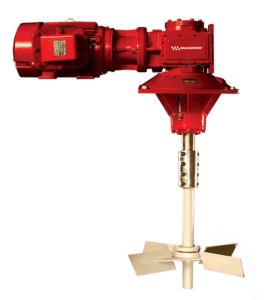

The Agitator provides rugged reliability along with the flexibility to meet your specific needs. Design features include a rugged cast iron gearbox housing helical bevel gearing which runs more smoothly than standard worm gears for cooler, more efficient operation and longer life. The unit’s unique lower bearing configuration allows maintenance from to top of the tank, eliminating the need for in-tank inspections. Lower bearing seals are arranged to maintain a grease pocket supplemented by four rings that ensure the gears are continually bathed in uncontaminated lubricant. Our unique shaft coupler is the strongest, most reliable in the industry. Available in vertical and horizontal configurations with a choice of canted or hydrofoil impellers in carbon or stainless steel.

• The Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high

• Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the Agitator is the lower bearing, which can

pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

• An external oil sight glass has been provided, so the oil level can be checked at a glance. Vent plugs are supplied and installed in the gearbox housing to maintain a homeostatic internal pressure, which prevents a pressure build-up that could blow out an oil seal.

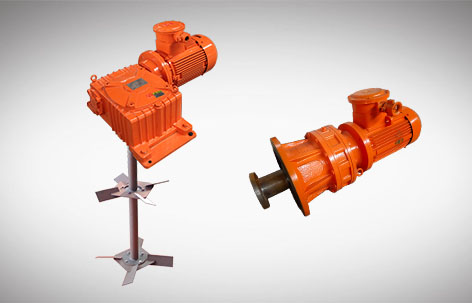

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

If your manufacturing processes involve mixing liquids, promoting chemical reactions or increasing heat transfer, you need agitators. At Federal Equipment Company, we pride ourselves on providing a large selection of used manufacturing equipment for virtually any manufacturing application. That"s why we offer reliable used agitators. These agitators are fully functional and reliable, but better yet, they"re also affordable.

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

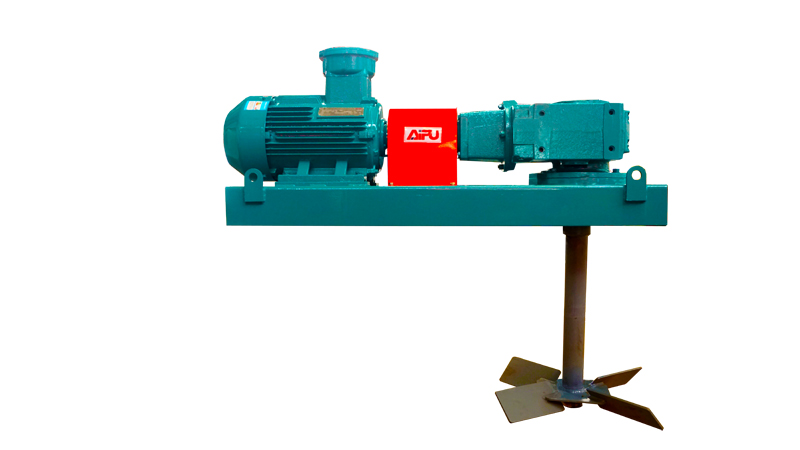

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

As Mud Agitator Manufacturer, Brightway can supply BWJBQ 5.5-22kw Mud Agitator for mud tank and mud system. including: Horizontal Mud Agitator or Vertical Mud Agitator. Brightway mud agitator can be customized once we get the detailed requirements. Buying mud agitator from Brightway will be your best choice for drilling mud circulation system.

1. Brightway mud agitator equips with a motor couple to a rugged oilfield gearbox, which can eliminates troublesome couplings, misalignment and have a longer bearing life. And it is driven by the explosion-proof motor, coupled to a gearbox which will drive the impeller shaft. Due to the simplex turbine structure of shaft,

2. Brightway mud agitator is featured by compact construction, light weight, balanced transmission, small footprint, low noise and high efficiency. And its impeller turbines can transform the mechanical power into drilling fluid agitation as well as circulation.

3. Brightway mud agitator can be designed per customer’s requirement to choose the helical-bevel design or worm design for reduction gearbox. Its motor can be horizontal or vertical. As for the shaft and impeller, compared with painting process, the galvanizing treatment is usually adopted to create a better anti-rust performance.

Electrical motor, agitator gear box, coupler, shaft and impeller. Worm gear is the most popular used gear for cost effective but larger footprint. Bevel gear is better working performance and small footprint but higher cost which is the reason for not popular. Coupler is not a necessary part but coupler type agitator is better to protect motor and gear. Today we"ll main introduction helical gearbox agitator

APMA series mud Agitator with the helical gearbox is one of the most popular solids control equipment, helical gearboxes are ideal for a wide variety of applications and functionally scalable. Thanks to Elecon’s modular design and high power density, space-saving compact construction makes it possible for it to function in tight industrial spaces.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients prefer the stainless steel shaft and impeller. Different application and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we"ll help you to get the ideal solution.

Moreover, the APMA series agitator is flexible on gearbox and motor configuration. Such as worm and worm wheel reducer, helical bevel reducer. The motor certified by IEC, ATEX, and so on

Cuttings in drilling mud as the main harmful solids will affect the performance of the drilling fluids during the drilling process. It will make the drilling mud density, viscosity, abrasiveness, glutinousness, dynamic resistance increased. In addition to this, cuttings is harmful to the oil & gas layer, such as reducing the drilling speed, increasing the rotary torque, leading to well leakage and blowout. So we must adopt some measures to solve t above problem, drilling fluids shale shaker as first stage equipment for purifying drilling mud is widely used in many industries.

There are different models APMA3, APMA7.5, APMA11, APMA15, PMA18,PMA22,etcetera. Presently, the helical bevel geared ones are usually APMA7.5. While the APMA15 is geared with a helical worm reducer. For mud agitators, we produce gearbox driven by 5.5kw, 7.5kw, 11kw, 15kw, 18.5kw, 22kw, and 30kw motors.

And the agitators can be the horizontal type or the vertical type. According to users’ preferences, we’ll provide different customization services. The impellers can be a single layer or double layer. The blades are the canted type for better agitation performance.

Drilling mud agitators are popular auxiliary equipment used in drilling mud systems. In oilfields, mud tanks are the platform for a whole solids control system. On tanks, there are shakers, mud cleaner, centrifuge, pumps, agitators, and so on

Mud tanks are used to reserve drilling fluids. During whole well drilling, we need drilling mud and we maintain and process drilling mud for better property and to save drilling costs. Mud agitators will help us to mix or agitate the drilling fluids. Under the impellers’ rotation, the useful solids will suspend without sediment

We know the agitator is consisting of a motor and reducer. Combining them together will get a proper turn speed. Under proper TOR the drilling fluids will be at a high property for better circulation throughout the mud system

A horizontal worm gear type agitator is the most popular agitator used in oil and gas mud tanks because it’s cost-effective. There are coupler options for agitator to protect gear or options without a coupler for saving cost.

A horizontal bevel gear type agitator is a very good option for larger torque and minimum footprint. The bevel gear is much higher in torque compared to the worm gear. Better performance, higher cost.

AIPU supplies mud agitator for the above options as per the buyer’s request and cost budget. Other than the agitator, AIPU supplies a series of equipment for mud tanks or a whole tank with all tank attachments.

Sharpe Mixers gear drives portable mixers are the best choice for volumes up to 3000 USG with higher solids concentrations. The slower speed provides the higher torque that is necessary to mix the higher apparent viscosity associated with drilling mud. Large diameter Hyflo 218 impellers produce much more flow per horsepower than other impellers on the market.

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

Mud agitator is one of the most popular equipment for drilling mud systems. It is mainly used to keep both the mud uniformity and the suspension of solids. The mud agitator is used to agitate the mud consecutively and reliably. This agitator agitates the mud to make the cuttings silt and sand pass the solids control system without being precipitated onto the tank bottom.

The worn and gear reducer mud agitator is an economic standard mud agitator. The mud agitator is equipped with explosion proof motor, worn and gear reducer. The worn and gear reducer is working stable and cost effective. It is also easy for maintenance.

The mud agitator is equipped with heavy duty helical bevel gearbox. Compared with traditional worn and gear gearbox, the helical bevel agitator is with a bigger torque. It is more powerful for heavy mud. The heavy duty helical bevel mud agitator save also power, for the same motor power, the helical bevel mud agitator is with a big torque compared with worn gearbox. So a smaller power helical bevel mud agitator can reach the performance of a bigger power worn gearbox agitator.

2) Impeller: There are double layer and single layer impeller for mud agitators. The impeller size is also designed to suit for the tank depth and width for a better agitating performance.

3) Tank bottom stabilizer to fix the shaft. For mud tank depth over 1800mm. GN will recommend Tank bottom stabilizer to fix the shaft and avoid is swaying during rotating.

For contour impeller applications, values must be significantly faster (i.e., smaller numbers) to achieve the same results, but because of the impeller design, air entrainment is less probable. In symmetrical compartments, the fluid has a nearly equal distance to travel from the center of the impeller shaft or from the impeller blade tip before it contacts the vessel wall. Agitators should be placed where the shaft is centered in the tank or compartment.

8613371530291

8613371530291