mud agitator gearbox quotation

The direct-drive shaft assembly featured on our agitators maximizes motor efficiency which results in reduced energy consumption and greater performance. Available in vertical or horizontal configurations, all of our agitators are completely customizable and or to meet your specific tank dimensions and mud weight range.

When you need to gain rapid access to the essential wholesale gear box for agitator supplies that your business relies on, head to Alibaba.com where you"ll find thousands of Chinese wholesalers ready to provide the equipment, materials, consumables and products that you need to run your business. From gear box for agitator supplies that cover all technical specifications through to associated products and office consumables, you can buy everything that your business needs in one place at Alibaba.com.

Simply use the search filters and categories to swiftly find details of gear box for agitator prices, specifications, order volumes, lead times, discounting arrangements and more. See what other customers thought of individual wholesalers with the customer review feature and see images of operations, markets served and more. You can even chat instantly with sales and support or send an email at any time of day.

Ready to make your gear box for agitator order? Just do so in a few clicks in your private account area and you"ll receive regular updates on your shipment so that you know exactly where it"s at in the world until it arrives at your business! It"s swift, convenient and cost-effective to shop at Alibaba.com where you"ll find everything that your business needs to operate smoothly and without delay.

Fluid Systems mud agitators are designed to mix and suspend the solids using axial flow, promoting low particle size degradation and effective polymer shear. Unlike mud guns, the FSI mud agitator is relatively a low energy device, easy to operate and inexpensive to maintain. Our standard horizontal and vertical mud agitators range in 5 to 30 horsepower with an explosion proof motor and gear reducer. We size mud agitators according to the configuration and maximum mud weight.

• The Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high

• Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the Agitator is the lower bearing, which can

pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

• An external oil sight glass has been provided, so the oil level can be checked at a glance. Vent plugs are supplied and installed in the gearbox housing to maintain a homeostatic internal pressure, which prevents a pressure build-up that could blow out an oil seal.

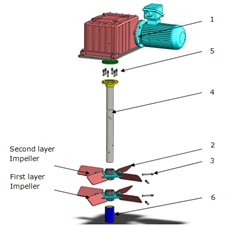

Our agitators feature the new dracomet coated corrosion resistant keyless coupling for easy installation and impeller adjustment. The units come complete with base plate, motor, gearbox, impeller, shaft & couplings.

There are different models APMA3, APMA7.5, APMA11, APMA15, PMA18,PMA22,etcetera. Presently, the helical bevel geared ones are usually APMA7.5. While the APMA15 is geared with a helical worm reducer. For mud agitators, we produce gearbox driven by 5.5kw, 7.5kw, 11kw, 15kw, 18.5kw, 22kw, and 30kw motors.

And the agitators can be the horizontal type or the vertical type. According to users’ preferences, we’ll provide different customization services. The impellers can be a single layer or double layer. The blades are the canted type for better agitation performance.

Drilling mud agitators are popular auxiliary equipment used in drilling mud systems. In oilfields, mud tanks are the platform for a whole solids control system. On tanks, there are shakers, mud cleaner, centrifuge, pumps, agitators, and so on

Mud tanks are used to reserve drilling fluids. During whole well drilling, we need drilling mud and we maintain and process drilling mud for better property and to save drilling costs. Mud agitators will help us to mix or agitate the drilling fluids. Under the impellers’ rotation, the useful solids will suspend without sediment

We know the agitator is consisting of a motor and reducer. Combining them together will get a proper turn speed. Under proper TOR the drilling fluids will be at a high property for better circulation throughout the mud system

A horizontal worm gear type agitator is the most popular agitator used in oil and gas mud tanks because it’s cost-effective. There are coupler options for agitator to protect gear or options without a coupler for saving cost.

A horizontal bevel gear type agitator is a very good option for larger torque and minimum footprint. The bevel gear is much higher in torque compared to the worm gear. Better performance, higher cost.

AIPU supplies mud agitator for the above options as per the buyer’s request and cost budget. Other than the agitator, AIPU supplies a series of equipment for mud tanks or a whole tank with all tank attachments.

Sharpe Mixers gear drives portable mixers are the best choice for volumes up to 3000 USG with higher solids concentrations. The slower speed provides the higher torque that is necessary to mix the higher apparent viscosity associated with drilling mud. Large diameter Hyflo 218 impellers produce much more flow per horsepower than other impellers on the market.

Established in the year 2021, Agiterio Stirrer Manufacturing Co. is the leading Manufactureof Industrial Agitator, Laboratory Stirrer, High Speed Stirrer, Surface Aerators and many more.

An Agitator is a equipment used in a tank for mixing various process media together. Media include all liquid types, gases & solids (such as salts, powders, granules etc). In summary, it works by rotating an impeller to impart energy to the media which interact and mix. The components of an agitator in general are the motor & gearbox, shaft & impellers selected for the duty.

An Agitator is used for mixing different process media – liquids, gases and solids in chemical addition or Pharmaceutical Ingredients. The agitator imparts energy through mechanical mean by rotating a shaft on which there is an impeller designed specifically for the duty. This could be axial pumping, gas induction, flocculating, high viscosity products, high & low shear mixing etc. An agitator is also used in the Water Industry for adding various chemicals to bring the source water up to drinking water standards

An Agitator is generally made up of a three main components – a shaft with impellers, a mechanical seal and motor with option of gearbox for lower RPM duties.

The agitator is mounted onto the vessel or via a supporting bridge in the water industry. The mechanical seal has a number of options depending on the duty – single/double mechanical seal, dry or wet mechanical seal, gas lift off mechanical seal that is related to the duty involved.

An agitator shaft is connected to the drive unit (motor & gearbox) and where the impellers used for the mixing are welded or bolted onto. There are options for magnetic driven units where there is a hermetic seal as opposed to mechanical.

Agitators can be simplified into Bottom Entry Agitator, Side Entry Agitator and Top entry Agitator Mud Agitator, depending on the duty & scale of the application to be mixed.

90% of Agitators are a Top Entry Agitatorin API / Chemical / Water industries. The main advantages of a Top Entry Agitator is that it can handle a larger variance in viscosities and specific gravities and also the fact that the mechanical seal is not in the liquid.

The remaining 10% include Bottom Entry Agitator, Side Entry Agitator and Bottom Entry Mag Drive Agitator. Milk silos & very large holding tanks use side entry agitators not necessarily for mixing but to keep the process media moving and keep the milk cool while bottom entry agitators are more common in the Biotechnology sector, where it is a magnetic driven unit (see below).

A slurry agitator is often used to keep the solids in suspension to prevent settling out and forming on the base of the vessel or bulk tank before being transferred to the next stage of processing.

RCI (Retreat Curve Impellers): can be used on Glass Lined Tank/Agitators, they offer lower shear than the Straight Blade Turbines with lower power requirements. They are usually used as a Bottom Impeller because they can be positioned very close to the curve of the bottom dish of the Tank, the blades curve upwards and they are also curved towards the end of the blades.

Generally, there are different versions or models of mud agitators that are being offered to fulfill various customers’ needs more effectively. However, here are some of the most amazing features of these mud agitators’ range that you must know:

However, the impeller speed of these mud agitators is 60/72RPM. While, on the other hand, the shaft length of the mud agitator will depend on the size of the mud tank completely.

Excellent capacity, longer service life, and high-quality materials along with sturdy construction are making these mud agitators highly durable and reliable.

The entire range of these mud agitators is highly demanding. It is mainly because of the state of art technology and quality of basic materials that is used in these. The fabrication used on these mud agitators makes this high corrosion resistant and can help you to enjoy a longer service life of mud agitators with ease.

Do you want to know what makes these mud agitators most amazing? Let’s have a look at the key benefits below to get a better idea about the things in this regard:

A Mud Agitator is equipment that is used for a specific purpose – the mixing and agitation of mud. While doing so, it prevents the settlement of the solid phase particles in the tank, which is crucial for the recycling process. The Mud Agitator is basically a speed reducer that is combined with an explosion-proof motor. The motor is horizontally placed for a convenient installation. These elements of the Mud Agitator are basically what makes everything tick. Also, they are robust and easy to maintain, allowing the Mud Agitator to be used in harsh conditions.

The impellers in the Mud Agitator are responsible for ‘taking in’ the drilling fluid. There are single-layer and double-layer options that one can go for. A centering guide is also added if the tank depth increases to handle mixing and agitation of a high quantity of drilling fluid. This equipment also has a worm wheel and worm gear reducer drive for smooth and reliable operation. The mug agitator comes with a speed reducer and you can use it as per your needs.

Drilling mud agitator is a device mounted on mud tank for agitating the drilling mud to prevent the drilled cuttings and fine solids from sedimentation. Nearly every large compartment of mud mixing and storage tank should be equipped with mud agitators to maintain the proper properties of drilling mud that will pump back to the borehole. The oilfield mud tank agitator is configured with an explosion-proof motor, reduction gearbox, impeller, and shaft with assembly bushings. Canted blade impeller are commonly used. Horsepower, mechanical configuration, impeller diameter, number of impeller and shaft length are customized to tank dimensions and maximum mud weights. Here is a list of our recommended configuration. Bothhorizontal / vertical drilling mud agitator available for option.

Mud Agitator is usually used n mud mixing tank to keep mud uniformity. The Mud Agitator is featured by compact construction, light weight, low noise and strong agitating power. We provide mud agitators in different motor power from 5 HP to 30 HP or as per customers requirements.

Mud Agitator is used in mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor,coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation. The objective is to obtain a uniform suspension of all solids.

Mud Agitator features a “C” face motor couple to a rugged oil field gearbox, which eliminates misalignment and troublesome couplings. This configuration promotes long motor and gear box bearing life.

8613371530291

8613371530291