mud agitator pdf supplier

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

LIGHTNINΒs unrivaled, patented, Hydrofoil high-flow, high-efficiency style impellers are used to develop the highest flow achievable for solid suspension and blending. LIGHTNIN guarantees the performance of the mixer as well as the mixing result. Equal power is not equal mixing LIGHTNIN֒s axial flow impellers provide more mixing at the same motor power than competitive impellers. LIGHTNIN mud mixers are designed and engineered to provide complete suspension of the mud and cut- tings. This provides a uniform feed to the mud cleaning equipment regardless of the mud weight. This results in...

Exclusive helical gear construction minimizes gear wear that often plagues worm gear designs. Some mud systems require a low profile mixer to accommodate headroom requirements. LIGHTNIN right angle drives have a very low vertical profile. Oversized bearings and shafts increase life and decrease maintenance. > Splash lubrication provides constant, worry-free flow to all critical areas. Integral foot-mounted or flange-mounted configurations. Dry well construction. One piece shafts as standard. Optional couplings with rabbet/spigot fit to assure alignment. No steady bearings. Special paint and...

The VMAI series mud agitators are a vertically mounted motor with ahelical inline gearbox. They are heavy duty mechanical mixers used forviscous fluids such as drilling fluids. The gearbox utilizes a parallel helicalgear drive system that reduces the rotational speed of the motor to drivemounted impeller to maintain a homogeneous mixture of liquids and solidswithin a tank. Impeller are available with flat blades (radial flow), contourblades (axial flow), and canted blades (radial/axial flow). Blades may beinstalled in single or multiple configurations to provide desired results.Multiple sizes and locations of impeller configurations are available. Theseagitators are sized to meet all drilling rigs needs and have a large andsuccessful install base worldwide.

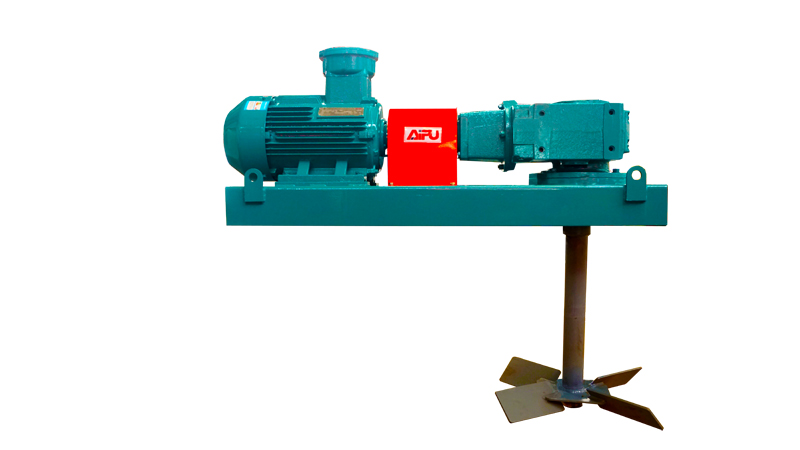

The MA-RG series mud agitators are horizontally mounted motor with ahelical-bevel gearbox. They are heavy duty mechanical mixers used forviscous fluids such as drilling fluids. The gearbox utilizes a helical-bevelgear drive system that reduces the rotational speed of the motor to drivethe impeller(s). MA-RG series agitators are very compact. Their low profilereduces headroom requirements and provides more layout space on top ofthe tanks. The 1:1 height to width ratio results in a lower center of gravity,providing stability and safety should the impeller encounter a sudden shockload. MA-RG agitators use a mounting skid for robust installation. Theybeing the size and mounting configuration. Multiple sizes and locations ofimpeller configurations are available. MA-RG agitators are sized to meet alldrilling rigs needs and have a large and successful install base worldwide.

motor with a helical-bevel gearbox. These agitators are considered highpurpose design for trouble free mixing. The 20BRGT Series are backed byto allow for optimal mixing with lower HP requirements. These agitatorsdesign and testing at our mixer facility to allow NOV to create more mixingwithout consuming a lot of power due to low shear and velocities. Theseand are being installed globally today along with BRANDT solids controlequipment.

Mud gun are meant to provide supplemental or primary mixing in mud tanks depending on the number being used and the pit size. They are best used in tank corners to keep solids from settling and a mud agitator is placed in the tank center.

The mud agitators are high-efficiency mud-mixing units offered in a wide array of custom sizes and configurations to accommodate virtually any mud tank. Both horizontal and vertical drive configurations are available for all sizes of mud agitators. The horizontal drive is designed for installations having limited space above the mud tank.

The mud agitator stirs a mud slurry to maintain suspension of solids. The agitator is mounted on top of the mud tank and has one or two impeller(s) immersed in the mud slurry. The impeller shaft is directly coupled to an electric drive motor that is available in several horsepower ratings from 3 (50Hz only) to 30 (60Hz). Impellers are available in diameters ranging from 20″ to 52″ to meet the needs of various size mud tanks.

The mud agitator is operated by a 3-phase induction motor. Drive motors range from 5 to 30 horsepower for the 230/460Vac 60Hz power configuration and 3 to 25 horsepower for the 190/380 50Hz power configuration.

Though there are mud guns and mud agitator‘s, to activate the mud, there is certain portion in the mud tank which is not influenced by these activating devices. Hence this portion of mud tank is having in-activated mud. This in-activated mud promotes in settling of the chemicals at the bottom of the tank creating a differential chemical composition throughout the tank. This in-activated mud is carried to the drill string followed to the drill bit, where its functioning is severely affected. On observation, in mud tank there‘s a provision to run a horizontal shaft-blade assembly through the length of the tank. Such an arrangement at proper elevation can activate that portion of the tank which is generally a dead zone. This assembly runs horizontally along the length of the mud tank with three bearing supports at the partition. Each blade assembly consists of four blades and four such assemblies are located through out the length of the shaft.

On economic considerations, the amount of chemicals wasted due to this in-active mud is primarily calculated. The cost of chemicals wasted per tank for a location is amounting to around Rs.51,000/- (Rs. Fifty one thousand). If the drilling rig, works at least for a span of one year in five locations, the total cost of chemicals lost amounts to Rs.2,55,000/- (Rs. Two lakh fifty five thousand). To reduce this wastage of mud it is proposed in this paper to design a horizontal shaft-blade assembly

Mud with density 1668.1 kg/m3 is chosen in order to design the project for high mud weight. The Standard D.C Motor with speed reduction gear box used to mud-agitator is selected for calculation towards failure criterion.

8613371530291

8613371530291