mud agitator pdf factory

Comes Complete with a "C" Face Explosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Derrick Mud Agitator

MUD AGITATOR All Derrick agitators feature a "C" face motor coupled to a rugged oilfield gearbox, which eliminates misalignment and troublesome couplings. This configuration promotes longer motor and gearbox bearing life. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. Helical-Bevel gearboxes are preferred over worm gear arrangements because of their power efficiency, reliability, and lower operating temperatures.

The Derrick agitator is available in both horizontal (model DE-AG-H) and vertical (model DE-AG-V) configurations sizes range from 5 to 30 HP. Derrick agitators carry a two year warranty.

Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller (size, type and quantity), and shaft length to meet your requirements.

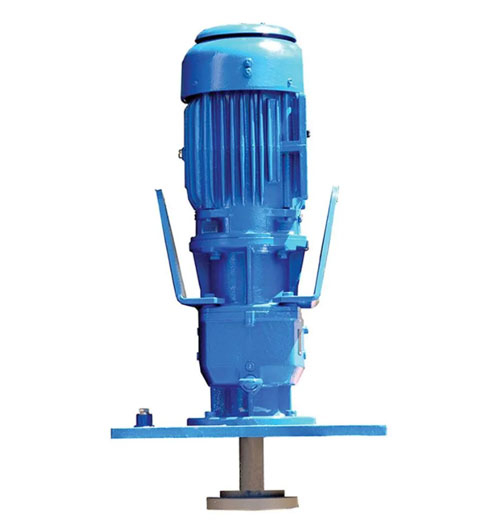

Vertical Mud Agitator Model DE-AG-V (shown with a turbine impeller)

DE-AG / SSCP 9/03 Copyright 2003 Derrick Corporation. All products indicated by trademark symbols are trademarked and/or registered by Derrick Corporation. DE-AG Mud Agitator

Comes Complete with a "C" FaceExplosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Mud Agitator

Derrick DE-AG mud agitators come complete with an explosion proof "C" faced motor, a highly efficient gear box, impeller and shaft complete with bushing. Available motors range from 5 HP to 30 HP. The motor is attached directly to the gear box assembly, which helps prevent premature bearing failure due to misalignment. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. This allows the DE-AG to do the same amount of work with less horsepower. The noise level of the DE-AG has been reduced to less than 75 dBA. Agitator model, horsepower, impeller diameter, and shaft length are customized to specific tank dimensions and maximum mud weights. Available horsepowers: 5, 7.5, 10, 15, 20, 25, and 30. Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller diameter and shaft length to meet your requirements. The DE-AG gear box has a two year warranty.

DIMENSIONS (IN,MM) WEIGHT WHEN ORDERING SPECIFY: MODEL HP Minimum Shaft Dia. Shaft Agitator (lbs / kgs) 1) Model Number Impeller Dia. (lbs/ft / kg/m) (Less Shaft & Impeller) 2) Motor Voltage DE-AG 3 3 24 610 2 1/4 57 13.5 / 20 350 / 159 3) Shaft Length DE-AG 5 5 28 711 2 1/4 57 13.5 / 20 450 / 204 DE-AG 7.5 7 1/2 32 813 2 1/4 57 13.5 / 20 575 / 261 4) Impeller Size DE-AG 10 10 40 1016 3 1/4 83 28 / 42 875 / 397 5) Impeller Orientation DE-AG 15 15 40 1016 3 1/4 83 28 / 42 1000 / 454 (Straight or Canted) DE-AG 20 20 44 1118 3 1/4 83 28 / 42 1300 / 590 DE-AG 25 25 48 1219 3 5/8 92 35 / 53 1800 / 816 6) Tank Depth DE-AG 30 30 48 1219 3 5/8 92 35 / 53 1850 / 839

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

North AmericaUnited States of AmericaTel:1-847-967-2400Fax:1-847-967-3915EuropeUnited KingdomTel:44-1753-224000Fax:44-1753-224224Latin AmericaBrazilTel:55-11-3371-2500Fax:55-11-3371-2599Middle East & AfricaUnited Arab EmiratesTel:971-481-27800Fax:971-488-62830Asia PacificSingaporeTel:65-6518-1800Fax:65-6518-1803If the products featured will be used in a potentially dangerous and/or hazardous process, your John Crane representative should be consulted prior totheir selection and use. In the interest of continuous development, John Crane Companies reserve the right to alter designs and specifications withoutprior notice. It is dangerous to smoke while handling products made from PTFE. Old and new PTFE products must not be incinerated. ISO 9001 andISO14001 Certified, details available on request.©2020 John CraneJC368 Revised 03/20www.johncrane.comAN-PULPPAPERAGITATORSSealing RecommendationsType 37FS Heavy-duty Split SealsThe seal most frequently used for this equipment is theJohn Crane Type 37FS non-pusher elastomer bellow splitseal or Type 3740 split seal which is often fitted with theType 73 inflatable seal. Since the equipment is large anddifficult to remove, split seals are easily used and theType 37FS effortlessly handles any shaft movements. Theaddition of the Type 73 inflatable seal allows the split sealto be serviced by holding back the product all the while thetank is full reducing downtime and eliminating lost product.However, the Type 73 inflatable seal is not split. Most oftenthe Type 37FS split seal is flushed but during shut downsthe seal water can fill the tank. Therefore, a split bushingoften made of PTFE is inserted into the stuffing box toreduce water entering the tank.Additionally, for Sulzer (Ahlstrom) Salomix SL and ST modelagitators, the Safematic Type SE2 seal is used. It is appliedin both single (SE1) and dual (SE2) seal versions dependingon the severity of the service. However, this version’sadaptive hardware differs from the pump seal design.If the shaft deflection is not an issue Standard Cartridgeseals can be used.Standard Cartridge SealsTYPE SB2/ SB2ASafematic SB2/SB2A is a dual cartridge seal. Its doublebalanced design ensures the reliability and longevity ofthe seal in the most demanding conditions. The SB2/SB2Aseal is ideal for use with environmentally hazardous andabrasive fluids, most often used in pumps in pulp mills,minerals processing and other slurry duties up to 40%solids by weight and a solids hardness of 8 Mohs.Materials: Seal faces SiC/SiC, SiC/CarbonO-rings: PTFE, EPDM, FFKMMetals parts: AISI 329 and 316 or higher a standard requirementPiping PlansThere is a growing demand for reducing seal water usageand seal-related costs. Environmental issues are aconcern, and high seal reliability is also required.Safematic Safeunit is a unit construction pressure andflow control device. These units control and monitor sealwater flow and pressure. Safeunit permits seal conditionmonitoring both visually and electronically. Low sealwater flow alarms sensors are typically used to preventseal failures and interlock agitators if flow is lost. Safeunitdetects internal seal leakage by avoiding uncontrolled sealwater leaks into the process, improving product quality andreducing energy costs.PLAN 32Type SFP for Packings or Plan 321.Inlet and outlet connections2.Check valve3.Flow gauge and valve4.Pressure gaugePLAN 54Type SFD for Dual Seals Plan 541.Inlet and outlet connections2.Connections to seal and from seal3.Check valve4.Flow gauge and valve5.Pressure gauge and valve112323445

8613371530291

8613371530291