mud agitator pdf manufacturer

Derrick mud agitators include an explosion-proof, “C” faced motor, reduction gearbox (helical-bevel gears for horizontal agitators or all helical gears for vertical units), impeller, and shaft with assembly bushings. Motors range from 5 to 30 HP and may be supplied in several power configurations.

Attaching the motor directly to the gearbox protects correct alignment that can increase bearing life and provides 95 percent efficiency in power transfer to the impeller. Using this superior design surpasses standard worm drive gear assemblies by 30 percent, allowing Derrick agitators to do the same work at far less horsepower. By unitizing the motor and gearbox, weight and space requirements are reduced. Horsepower, mechanical configuration, impeller diameter, and shaft length are customized to tank dimensions and maximum mud weights. Available horsepower ratings* are: 5, 7.5, 10, 15, 20, 25, and 30.

Comes Complete with a "C" Face Explosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Derrick Mud Agitator

MUD AGITATOR All Derrick agitators feature a "C" face motor coupled to a rugged oilfield gearbox, which eliminates misalignment and troublesome couplings. This configuration promotes longer motor and gearbox bearing life. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. Helical-Bevel gearboxes are preferred over worm gear arrangements because of their power efficiency, reliability, and lower operating temperatures.

The Derrick agitator is available in both horizontal (model DE-AG-H) and vertical (model DE-AG-V) configurations sizes range from 5 to 30 HP. Derrick agitators carry a two year warranty.

Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller (size, type and quantity), and shaft length to meet your requirements.

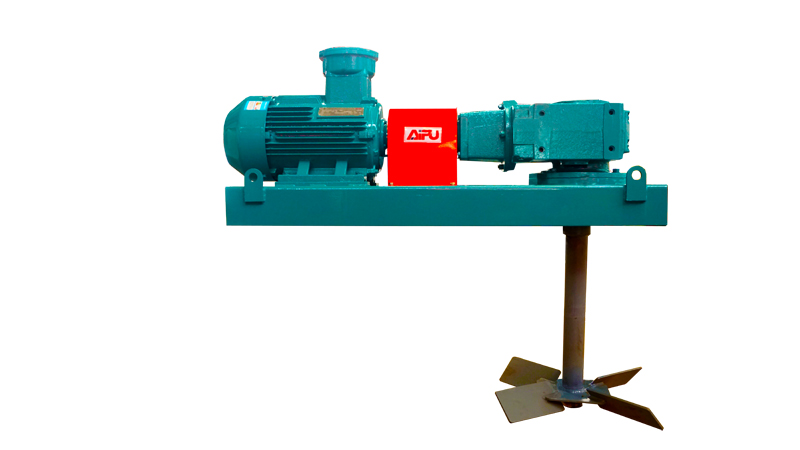

Vertical Mud Agitator Model DE-AG-V (shown with a turbine impeller)

DE-AG / SSCP 9/03 Copyright 2003 Derrick Corporation. All products indicated by trademark symbols are trademarked and/or registered by Derrick Corporation. DE-AG Mud Agitator

Comes Complete with a "C" FaceExplosion Proof Motor, Helical-Bevel Gearbox, Mounting Plate, Impeller, Shaft and Necessary Couplings Mud Agitator

Derrick DE-AG mud agitators come complete with an explosion proof "C" faced motor, a highly efficient gear box, impeller and shaft complete with bushing. Available motors range from 5 HP to 30 HP. The motor is attached directly to the gear box assembly, which helps prevent premature bearing failure due to misalignment. Derrick uses a Helical-Bevel gear unit to turn the impeller. This highly efficient gearbox offers a 95% power transfer, which is approximately 30% more than a worm drive gearbox. This allows the DE-AG to do the same amount of work with less horsepower. The noise level of the DE-AG has been reduced to less than 75 dBA. Agitator model, horsepower, impeller diameter, and shaft length are customized to specific tank dimensions and maximum mud weights. Available horsepowers: 5, 7.5, 10, 15, 20, 25, and 30. Please contact a Derrick Equipment representative with your tank dimensions and maximum mud weights for the correct agitator model, horsepower, impeller diameter and shaft length to meet your requirements. The DE-AG gear box has a two year warranty.

DIMENSIONS (IN,MM) WEIGHT WHEN ORDERING SPECIFY: MODEL HP Minimum Shaft Dia. Shaft Agitator (lbs / kgs) 1) Model Number Impeller Dia. (lbs/ft / kg/m) (Less Shaft & Impeller) 2) Motor Voltage DE-AG 3 3 24 610 2 1/4 57 13.5 / 20 350 / 159 3) Shaft Length DE-AG 5 5 28 711 2 1/4 57 13.5 / 20 450 / 204 DE-AG 7.5 7 1/2 32 813 2 1/4 57 13.5 / 20 575 / 261 4) Impeller Size DE-AG 10 10 40 1016 3 1/4 83 28 / 42 875 / 397 5) Impeller Orientation DE-AG 15 15 40 1016 3 1/4 83 28 / 42 1000 / 454 (Straight or Canted) DE-AG 20 20 44 1118 3 1/4 83 28 / 42 1300 / 590 DE-AG 25 25 48 1219 3 5/8 92 35 / 53 1800 / 816 6) Tank Depth DE-AG 30 30 48 1219 3 5/8 92 35 / 53 1850 / 839

LIGHTNINΒs unrivaled, patented, Hydrofoil high-flow, high-efficiency style impellers are used to develop the highest flow achievable for solid suspension and blending. LIGHTNIN guarantees the performance of the mixer as well as the mixing result. Equal power is not equal mixing LIGHTNIN֒s axial flow impellers provide more mixing at the same motor power than competitive impellers. LIGHTNIN mud mixers are designed and engineered to provide complete suspension of the mud and cut- tings. This provides a uniform feed to the mud cleaning equipment regardless of the mud weight. This results in...

Exclusive helical gear construction minimizes gear wear that often plagues worm gear designs. Some mud systems require a low profile mixer to accommodate headroom requirements. LIGHTNIN right angle drives have a very low vertical profile. Oversized bearings and shafts increase life and decrease maintenance. > Splash lubrication provides constant, worry-free flow to all critical areas. Integral foot-mounted or flange-mounted configurations. Dry well construction. One piece shafts as standard. Optional couplings with rabbet/spigot fit to assure alignment. No steady bearings. Special paint and...

The MAX2000® Agitator features a rugged cast iron gearbox that houses helical bevel gearing. The gear sets are precisely ground to prevent all but the slightest amount of backlash in the gear sets. This feature promotes longer life by eliminating the high impact forces generated when the unit is energized at start-up. Each helical bevel gear stage is 98% efficient. A typical worm gear set is only 85% efficient, since it loses most of its efficiency through the generation of heat.

Internal gears and bearings are lubricated with mineral oil. When the ambient temperature drops below 23ºF or rises above 140ºF, a synthetic lubricant should be substituted. A unique feature of the MAX2000® Agitator is the lower bearing, which can be maintained from the top of the tank. This feature eliminates the need for in-tank inspections of the lower bearing, and also provides a barrier of grease that can be expunged out the lower seal. The lower seals are arranged to accommodate the grease pocket and make for a four-tier layer of protection for the gearing. The end result means the lower bearing stays in contact with good, uncontaminated lubricant at all times. All four of these levels must be breached prior to loss of oil in the gearbox.

DEL"s Agitators and Mixers have been the standard for the mobile mix tank industry since 1985. Our mixers are designed to withstand the rigorous wear and tear of transportation, the extreme environments of the remote job sites of the oilfield, and the harsh duty of plants and refineries. Our units utilize a hollow bore gearbox design with c-face motors, eliminating coupling alignment problems and downtime. Each mixer is designed based on the customer’s specific requirements. Common horsepower outputs range from 3 to 30hp and a wide variety of output speeds are available based on application.

HJBL series vertical mud agitator is mainly used for deep mixing and mixing in the mixing tank. The mixing shaft is longer than 1 meter and equipped with a stainless steel base to ensure that the mixer runs stably and does not shake during the mixing process.

Vertical mud agitator can be widely used in chemical industry (fine chemicals, pharmaceutical chemicals and daily chemicals), environmental protection (sewage treatment), pharmaceuticals, cosmetics, metallurgy, food, heat treatment cooling, leather processing and other industries.

8613371530291

8613371530291