mud agitator vs desander in stock

Fluid Systems uses an impeller to mix and suspend the solids using both axial and radial flows, and by utilizing low shear mixers to suspend and mix mud additives particle size degradation and polymer shear. Unlike centrifugal pumps or mud guns. The FSI Agitator is relatively low shear and low energy device, so it’s easy to operate and inexpensive to maintain.

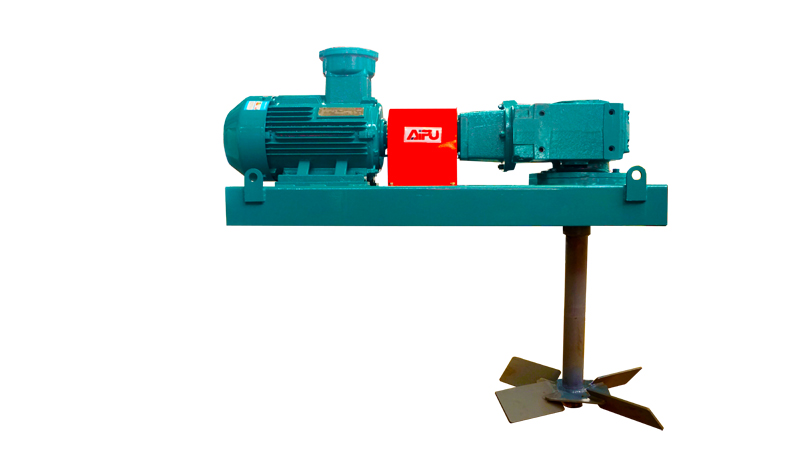

GearBox is a crucial part of mud agitators. Mud agitators are used in surface mud system to suspend solids and maintain homogeneous mixture throughout the system.

Mud agitator was one of solids control equipment and has two main type: verticle agitator and horizontal agitator. It is very important to select optimum gearboxes for various applications of drilling project or other mud treatment.

In the past, horizontal agitators mainly use worm gear unit for cost reason. But worm gear easy to broken and mantainance is difficult. you have to open shell to grease gear. Now horizontal mud agitator use helical-bevel gears ( like derrick agitator ). Helical gears have a smoother operation due to the angle twist creating instant contact with the gear teeth. Rigid tooth flank helical gear unit are advanced of helical gears. Rigid tooth flank means more wear resistant and long life to use. So it’s trend to use rigid tooth flank gearbox.

Mud agitators are fluid mixing equipment that keeps solids in drilling fluid suspending, no deposit in the mud tank bottom. It uses its impeller to agitate and mix the drilling mud to prevent solid particles from depositing in the tank or mud pit.

There were many types of mud agitator, depending on purpose demand, gearbox type, and working conditions. But the basic structure of the mud agitator is all the same: Motor, gearbox [Speed reducer], shaft, and impeller.

Yes. Some clients prefer the hydraulic drive for some specific use. Some clients need a vertical agitator. And some clients prefer the stainless steel shaft and impeller. Different applications and industries will request equipment much different If you have questions or demand on mud mixers, please let us know and we’ll help you to get the ideal solution.

For oil and gas drilling, there are different configurations on tanks number, tanks size, so it’s not easy to confirm. But we can take a system as an example. One mud system laying with 6 tanks, and tanks size are 9 m X 2.2 m X 2.3 m. The normal proposal is 3 sets of agitator per tank. But there is a shaker tank, then we deduct 1 set. So, probably we need 17 sets of the agitator. And the agitators are APM 7.5 driven by 7.5 kw motor.

The most important factor was the power of the mud agitator, 5.5 Kw agitator is cost far lower than 22 KW. There is apparently a different price between the explosion-proof type and Non-proof type. Higher explosion-proof grade means higher cost.

Worm gearbox type mud agitator is a common type, durable, and easy maintenance. But its efficiency lower than the bevel gearbox. so bevel gearboxes are generally more expensive than worm gearboxes for the same HP and gear ratios. Helical-worm and helical-bevel are advanced generation type of worm and bevel gearbox. They produce less vibration and noise. The planetary gearbox is mainly used in vertical agitator.

GN Solids Controlis a world famous turnkey provider of solids control equipmentfor oil and gas drilling fluids. GN Solids Control has rich experience on design, development, and manufacture solids control equipment includes but not limited to shale shaker and shaker screen, decanter centrifuge, desander, desilter, mud cleaner, mud agitator, cuttings dryer, centrifugal pump, screw conveyor and mud tank etc.

Last month, GN Solids Control finished manufacturing of one batch mud agitators for one offshore drilling rig platform. Consider the heavy duty mud, GN Solids Control provides helical bevel gerabox reducer for these mud agitators.

GN Solids Control manufactures mud agitator with single impeller, double impellers or multiple impellers. The shaft length of the mud agitator is customized based on customer’s mud tank depth.

GN mud agitator keeps the drilling mud from sediment, and plays a very important role in mud mixing, preparing and storage. GN Solids Control also provides control boxes to match the mud agitators, explosion proof includes IEC Ex, ATEX, CNEX etc.

In order to use in the offshore platform, GN Solids Control use PPG painting to cover the mud agitators with 3 layers which can keep sea moisture rusty from long time usage.

Besides the mud agitators, GN Solids Control has also been providing the other types of solids control equipment like decanter centrifuges and shale shakers for offshore drilling platforms. GN Solids Control made DNV lifting certified equipment is able to move safely and conveniently, the DNV lifting pad and supporting frame can be added optionally.

Now GN Solids Control has many solids control equipment in stock, once we received the order, we can just buy the motors and put the control boxes, tested and get it to delivery very fast. Welcome to connect with GN Solids Control for any drilling mud solids control and drilling waste management equipment inquiries.

For desander desilter,mud gas separator,mud agitator,and other drilling mud solids control equipments,This order is the first order for GN in Argentia.Like other overseas countries,We all believe this is just a good start for our business in Argentia,GN Solids Control will keeps going faster and faster there.

AIPU received an order for 20 sets of mud agitator from an Indian drilling contractor last month, the order finished packing yesterday and ready delivery. The mud agitators will be installed on client’s current storage mud tank for clean drilling mud storage. The clients purchased these new mud agitators for replace of old agitators from another China supplier because of AIPU good reputation and after sales service in India. AIPU set an service agent in New Delhi with shaker screen stock and sales service and after sales team for local clients.

AIPU build mud agitators with horizontal or vertical options. The horizontal option is the most popular one because of height limit. Anyway, vertical agitators can be supplied as per request. Other than agitator, AIPU supply mud gun also for a same application to stop solids build up.

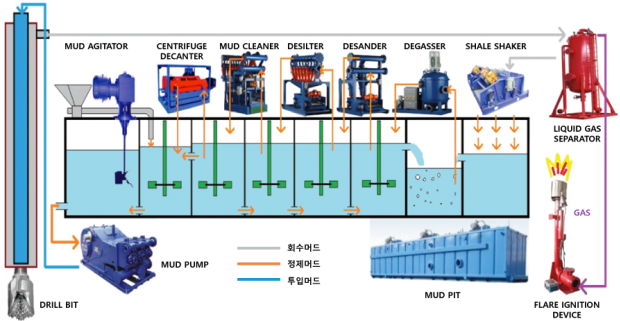

Drilling mud serve as lubricant that keep the drilling bit operate smooth. The consequence of drill bit overworked by temperature heading up will lead to hard work of engine and transmission that lead to breakdown and halt the whole operation. It is a very costly operation halt that leads cost of extra ten thousand of dollars and more. Plus, the drilling fluid is also a very costly lubricant and to keep the drilling cost under control, solids controlmachinery is need for filter the debris that contain in the drilling mud for many times of cycle of use the drilling mud. The 5 filtration machineries that will completely perform filter the solids from the drilling mud areshale shaker, vacuum degasser, Mud Gas Separator, desander, desilter and decanter centrifuge.

The drilling mud feed enter the feeding box of shale shaker. The mud contains various size of the solids return to the ground surface and shale shaker is filtering the biggest solid by use high G force of shaking. The box of shale shaker contain panels of mesh screen that is different number of mesh depend on solids contents analyze by drilling mud engineer

. The muds that return to ground surface not only contain solids but also gas from the earth core. This gas that change density of drilling mud leads result change the viscosity of drilling mud. Vacuum degasser removes the gas in the drilling mud to keep the mud in balance and continue the future solids filter process.

The drilling fluids now that contain medium size solids enter the liquid feeding pump and enter the desander, which contain large hydrocyclone(s). The solids diameter above 40-60um will be filtered and bottom of desander is pair with shale shaker contain finer mesh compare with first shale shaker to complete the filtering. T

This machinery’s function of work is just as same like desander in last step before. It contains multiple smaller hydrocyclones that can remove solids that measure diameter above 15-40um. It is also pair with shale shaker like desander and completes this step of filtering.

The drilling fluid feed through centrifugal pump that feed into decanter centrifuge that rotate in High speed of G force. The rotating bowl will separate solids from the mud and exit in one for solids and other one is for filtered mud. The drilling mud now will feed back to the rig for next cycle of usage.

A mud tank is an open-top container that is made of square-shaped steel tubes and plates with a cone-shaped bottom. These are used to mix and store drilling fluid on a drilling rig or for boring operations. The earliest concept of a mud tank was made by digging pits into the earth and using them to store products. For that reason, they can also be referred to as mud pits.

Mud tanks are able to mix, treat, and store drilling fluids, which makes them extremely important to the oil and gas industries. They are also used in applications to remove unwanted solids and sediments from the drilling and boring systems.

Mud tanks have different capacities for different storage functions attached to the oil and gas industries. For land rigs, mud tanks have an estimated capacity of 240 barrels.

The shale shaker is used to separate big solids while the desander separates relatively smaller solids. The desilter also segregates smaller kinds of solids from the drilling fluid. The vacuum degasser separates air from the drilling fluid. The centrifugal pump is used to move this drilling fluid from one component into another for further purification. The vertical slurry pump is used to pump the drilling fluid up to the centrifuge. The mud pump is used to pump the drilling fluids from the mud tank into the borehole after it is treated by centrifuge.

This circulation process repeats as a cycle. Normally the shale shaker, the vacuum degasser, and the desander are mounted together on the same mud tank. The desilter and the centrifuge are mounted on the second tank.

Adler Tank Rentals provides 10,080 gallon (240 bbl) open-top mud storage tanks, which are the top-performing solution for the oil and gas industries. With their sloped V-shaped bottoms for easy drainage, smooth interiors, top-mounted sidewall support braces, and durable one-quarter-inch steel-plate floors, these mud tanks make solids control extremely reliable and convenient.

All our mud tanks meet the highest standards of safety inspections and offer highly efficient containment and treatment solutions for your drilling projects.

Some of the parts we provide are for shale shakers, centrifugal pumps, mud pit agitators and more. Call us at281-409-0018to learn more about our spare part options and inventory. CONTACT US TODAY

A shale shaker is a vibrating device used in a rig solid control system to remove drill cuttings from mud. Shale shakers are a vital component of drilling equipment in many industries and can be costly when they break down. At Specialty Solids Control we provide spare parts for shale shakers so that you can start the first phase of your solid separation efficiently.

Mud Agitators are used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. Specialty Solids Control understands that equipment can break down from time to time which is why we provide spare parts. Schedule a call to learn more about how you can continue operations with our spare parts. Spare parts that we provide for mud pit agitators include but are not limited to: Motors & Gearboxes

Degassers are devices that remove entrained gas from drilling mud. Degassing is a crucial step after solids separation. This is an important step to reduce and eliminate the formation of gas cut mud. Learn more about how you can purchase degasser parts from Specialty Solids Control. Spare parts that we provide for degassers include but are not limited to: Compressors & Motors

A desilter is a device at the surface which removes very small particles from drilling mud. This equipment is great for removing very fine particles or silt from drilling fluid to keep the amount of solids in the fluid at the lowest possible point. We understand that these machines are important to your operations, which is why we provide desilter parts in order for you to quickly fix your desilter.

A desander is a type of mud recycling equipment designed to remove harmful solids particles ranging in size from 40 to 50 microns from your drilling mud. Specialty Solids Control provides desander parts at an affordable price. Contact us to learn how you can save.

Centrifuges are devices that rotate the mud in a bowl to generate high centrifugal forces causing solids to move toward the outside for removal. Specialty Solids provides centrifuges and centrifuge parts at an affordable price. CONTACT US TODAY

The primary separation plant is for the separation of solids of up to 45 microns. It uses double deck shale shakers, desander cleaner, mud tanks with attachments, centrifugal pumps and a mud agitator.

Later, a centrifugal pump pushes fluids from the mud tank first compartment to the 3-inch by 10-inch desander cones on the GNZJ703E-3S shale shaker. This is the third phase separation for solids bigger than 45 microns. After the desander, the fluids go to the second compartment of the mud tank.

The double chamber flocculation unit mixes chemicals for the flocculation of the drilling mud taken from the second compartment. Then the slurry and polymer are mixed and fed to the big bowl, big volume decanter centrifuge.

The VFD decanter centrifuge has g-force up to 2000 g, which separates the fine solids in the drilling mud and discharges clean water for reuse in the TBM project.

HJBL series vertical mud agitator is mainly used for deep mixing and mixing in the mixing tank. The mixing shaft is longer than 1 meter and equipped with a stainless steel base to ensure that the mixer runs stably and does not shake during the mixing process.

Vertical mud agitator can be widely used in chemical industry (fine chemicals, pharmaceutical chemicals and daily chemicals), environmental protection (sewage treatment), pharmaceuticals, cosmetics, metallurgy, food, heat treatment cooling, leather processing and other industries.

Leading Manufacturer of Drilling Mud Cleaner, Hydrocyclone Desander, Mud Agitator, Balanced Elliptical Motion / Linear Motion Shale Shaker and Shale Shaker Screen from Jodhpur.

JOT manufacture Mud Cleaner which is the first-stage solids control equipment in the drilling fluid solids phase control system, and separates a large amount of cuttings carried by mud from wellhead, facilitating mud to enter the second-stage separation equipment. JOT manufacture both two stage (Shale Shaker + Desilter) and three stage (Shale Shaker + Desander + Desilter) mechanical process Mud Cleaner.

Desanders are solid control equipment with a set of hydrocyclones that separate sand and silt from the drilling fluids in drilling rigs. Desanders are installed on top of the mud tank following the shale shaker and the degasser, but before the desilter.

A Mud Agitator is used in surface mud systems to suspend solids and maintain homogeneous mixture throughout the system. A mechanical agitator is driven by an explosion-proof motor, coupled to a gear box that drives the impeller shaft. The impellers (turbines) transform mechanical power into fluid circulation or agitation.

8613371530291

8613371530291