mud agitator vs desander free sample

The shale shaker mechanically takes out the large cuttings from the mud. It does not however remove very fine cuttings and other small solid particles. These solids can be fine sand particles and other very fine materials often called silt. Good drilling practice requires removing these undesirable solids. If not removed, the solids can increase the weight of the mud more than required, reduce the bits penetration rate and significantly increase the rate of wear on circulating equipment. The rig uses mechanical solids removing equipment. Such as hydrocyclones and decanter centrifuges to remove the fine solids.

This gas gets into the mud becomes entrained in it and must be removed before the pump recirculates the mud back down hole. A degasser removes and trained gas from a mud. The shale shaker has rapidly shaker screens. The modern cuttings from the return line fall onto it. The shaker screens catch the larger cuttings. These cuttings fall into the reserve pit, the sea or other container for disposal.

The liquid mud goes into the sand trap, which is a special mud tank. Shale shakers look simple, in fact, though shaker manufacturers carefully designed them to make the screens vibrate in a very controlled way. Sometimes the crew sends mud through a vacuum degassing. The degasser removes gas from the mud. If the gas were not removed, it could make the mud too light, not dense enough. As a result the well could kick. Formation fluids can enter the wellbore and have to be controlled to prevent a blowout. Another problem, if the driller recirculates gas in cut mud. The gas could cause the mud pumps to gas lock. Gas Locked pumps. Pump gas and mud instead of just mud which is highly inefficient. So, to remove gas in slurry. Crew members use a degasser. In a vacuum degasser, mud with gas in it (drilling fluid / mud), enters at the top and spills out over several baffle plates. A spreader spreading out the mud presents a large surface area for the gas to break out. Also the vacuum pump creates a vacuum, pressure lower than the surrounding atmosphere inside the degasser. This vacuum makes it very easy for the gas to escape from the spread out mud. The removed gas leaves through a vent which sends the gas a safe distance away from the rig. The gas free mud falls to the bottom and goes back into the mud tanks downstream from the degasser.

A hydrocyclone system consists of several cones. Mud enters through a signed opening at the large end of each cone. It swirls around inside the cone. This centrifugal force or cyclone motion throws the larger particles to the side of the cone there. The particles move to the bottom of the cone and drop out clean mud goes out the outlet. At the top a desander has large cones it removes particles as small as about 40 microns. A micron is one millionth of a meter which is very small.A desilter has smaller cones than a descender. Desilter’s remove particles down to about 20 microns.

A mud cleaner has still smaller cones. It removes particles down to about seven microns. Since barite that desirable solid which gives weight to the mud is also about seven microns. Screens are included on mud cleaners to retrieve the barite. So it can be returned to the system. Inside the cone mud enters from the side and spirals down. This movement flings the solids to the side. the spiraling action creates a vortex in the center somewhat like a tornado. It is an area of lower pressure. So the vortex sucks the liquid mud up through the center and out through the top of the cone. Meanwhile the solid slide down the side and out the bottom of the cone. The smaller the cone, the smaller is the particle it can remove but more cones are needed to handle a given volume of mud.

A decanting centrifuge spins mud at high speed. This creates centrifugal force. Centrifugal force throws the particles to the side of the centrifuge where they are removed. Decanting centrifuge removes particles as small as 2 to 5 microns which includes barite. Sometimes crew members run a centrifuge at a specific speed to remove barite. So the rig can use it again on the next rig hole. Occasionally the rig owner runs 2 decanting centrifuges, the first removes the barite and the second the finer particles. Crew members then re-add the barite to the mud system.

The mud system normally has several centrifugal pumps. A centrifugal pump puts out relatively low pressure but it can move a large volume of mud. Crew members, therefore, use them in several ways. One job a centrifugal pump often does is supercharge the mud intake of the main mud pump. The small pump takes the mud from a suction tank, moves it through a line connected to the main pump suction line, and keeps the suction line full of mud at all times. If the system does not use a charging pump the force of gravity alone feeds the pump suction line. Sometimes gravity cannot keep the pumps intake completely full of mud. The pump Pistons suck in the mud so fast that gravity cannot keep the suction line full of mud. The crew also uses a centrifugal pump to mix some mud components.

A hopper (mud mixing hopper) is like a big funnel. Crew members put sacks of mud material into it. They do not however use the hopper to mix caustic soda. The hopper(mud mixing hopper) can blow dry caustic back into the face of the worker mixing it. In addition to being dangerous adding caustic through the hopper can flocculate the mud, cause it to clump up. A crew member opens the sack of material at the top of the hopper and feeds the material into the funnel. At the same time a jet of mud from a centrifugal pump goes through a nozzle at the bottom of the funnel.

In some cases, if the job site country does not have strict request for waste water discharge and for environment protection, clients do not use separation system trenchless machines. They only use mud mixing tank system. GN Solids Control makes different sizes compact design mixing tank system for different trenchless machine:

1. GNMX-05A: usable capacity of the mixing tank system is 5m3 / h; a hopper and a 11KW centrifugal pumpis used in the system for mixing. There is a T-pipe at the outlet pipe of mixing pump. In this case, the mixing pump can also be used as transfer pump to feed mud from mixing tank to HDD or trenchless machine

2. GNMX-10A: usable capacity of the mixing tank system is 10m3 / h; a hopper and a 22KW centrifugal pump is used in the system for mixing. There is a T-pipe at the outlet pipe of mixing pump. In this case, the mixing pump can also be used as transfer pump to feed mud from mixing tank to HDD or trenchless machine

3. GNMX-15A: usable capacity of the mixing tank system is 15m3 / h; a hopper and a 30KW centrifugal pump is used in the system for mixing. There is a T-pipe at the outlet pipe of mixing pump. In this case, the mixing pump can also be used as transfer pump to feed mud from mixing tank to HDD or trenchless machine

4. GNMX-20A: usable capacity of the mixing tank system is 20m3 / h; a hopper and a 37KW centrifugal pump is used in the system for mixing. There is a T-pipe at the outlet pipe of mixing pump. In this case, the mixing pump can also be used as transfer pump to feed mud from mixing tank to HDD or trenchless machine

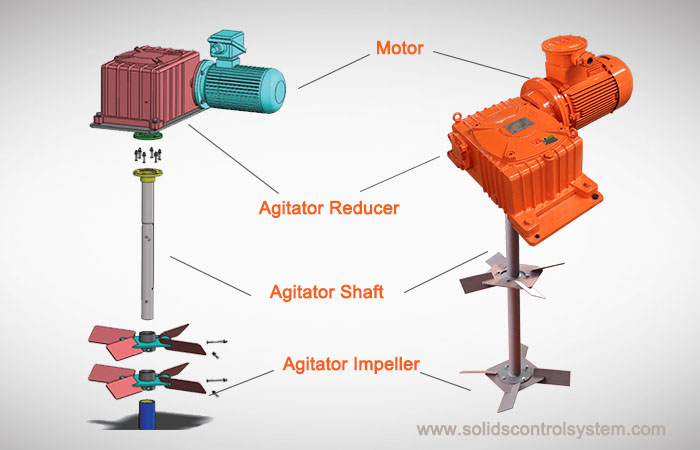

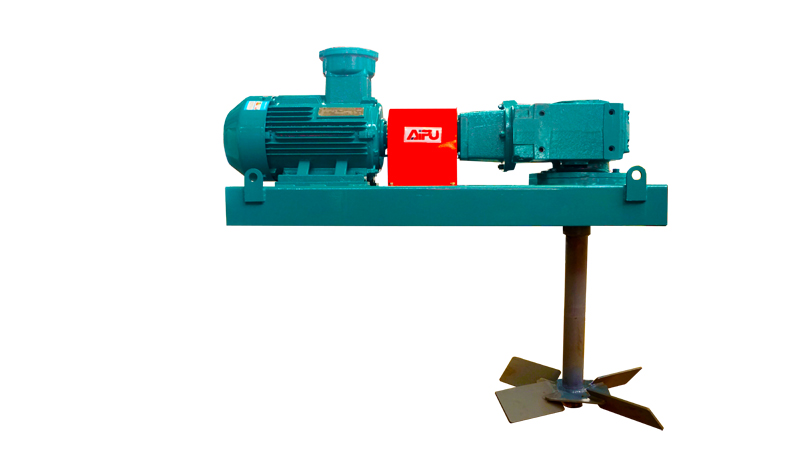

mud tanks are important rig components that are used for storing mud for oil and gas drilling operation. We will discuss about mud tanks miscellaneous components .

Used to shear/mix mud in the mud tank it is usually installed near toCorner of mixing tank. It enhance agitation of mud, Where agitation byagitator is limited, as agitator is installed in the middle of tank.It can be used to transfer mud between the mud tanks.

Trailer Mounted Mud Tank System for 1500 HP Rig & 1000 HP Rig includes Shale Shakers, Vacuum Degasser, Mud conditioner 3 in 1 ( desander, desilter & mud cleaner), Mud Agitators, Mud Mixing System,Water Tankstrailer mounted,Trip Tank trailer mounted, Pill tanks, Mud lab on mud tanks for mud tester (air conditioned preferred).

All mud tanks of 1500 HP Rig & 1000 HP Rig mud system is designed Trailer Mounted-Trailer Mounted Mud Tank System. The design details of Trailer Mounted Mud Tanks as follow:

complete set of mud system should include the following equipment, such as theShale Shaker, Desilter, Desander, Centrifuge, Centrifuge Pumps, Agitators, Mud

XBSY desander and desilter are widely used in the triplex process of drilling fluids. Desanders can effectively remove solid-phase particles from 40 to 150 μm in diameter from drilling mud. And the desilter can effectively remove solid-phase particles of 20 ~ 65 μm in diameter from the drilling mud.

1. The models in the table are only examples, desander cyclone specifications(250/300) and quantities(2/3) can be configured according to user requirements.

Explore the various well drilling desander products available for wholesale at Alibaba.com. Get a well drilling desander for drilling water wells, water exploration holes, geological exploration, coal mines, and other kinds of mining. Some well drilling desander options use caterpillar tread to move. Others use rubber tires, while others require a separate means of transport. Caterpillar tread propulsion can climb up to 25 degrees inclination. Some products in the range are capable of drilling over 200 meters, while others are only used for open-pit mining with depths of around 3 meters. Drilling can be done vertically downwards, horizontally, or in a slanting direction. Drilling speed depends on the power of the machine and the general hardness of the surface. The hole diameter can vary from 90mm to 200mm.

well drilling desander options also include an air compressor, a mud pump, drilling rods of various sizes, connectors, and a drilling tower. Drilling is done using drill bits of various shapes, sizes, and compositions. You can choose between diamond bits, alloy ring-shaped bits, 3-wing alloy bits, PDC bits, and hammer bits. Each drill bit uses different drilling methods, including rotary, percussion, blast hole, and core drilling.

Smaller products have a lifting power of around 25 kilonewtons and weigh about 2,500kgs. They’re ideal for small-scale drillings such as farms and homes. Larger ones are faster with more power, making them ideal for commercial use. Browse through Alibaba.com and find a well drilling desander that’s ideal for your work scope. Buy mine drilling rigs for your wholesale business at competitive prices. Chinese wholesalers provide you with customization options and great after-sales services.

Global solid control equipment market segmentation by type: Mud agitator, Shale shaker, Desander, Centrifuge, Others. Global solid control equipment market segmentation by application: Onshore, Offshore

Brightway Solids Control Company (Xi"an Brightway Energy Equipment Co., Ltd.) is the professional manufacturer for the solids control equipment and complete set of solids control system. Brightway solids control equipment and system is widely used in the oil and gas drilling, HDD (Horizontal directional drilling), CBM drilling, Underground drilling, river silt cleaning, geothermal drilling., etc. Brightway solids control main equipment: Shale Shaker, Vacuum Degasser, Mud Cleaner, Desander Cleaner, Desilter Cleaner, Decanting Centrifuge, Centrifugal Pump, Submersible Slurry Pump, Screw Pump, Shear Pump, Mud Agitator, Jet Mud Mixer, Mud Gas Separator, Flare Ignition Device, Mud Gun, Oil Tank, Water Tank, Mud Tank etc. Brightway Slogan is Good Attitude, Active Action, Bright Future. Brightway provide value to customer all over the world.

In the oil and gas drilling, efficiency of operation is impaired owing to mud handling problems. To avoid such problems, mud handling equipment are used during the drilling operation. The main purpose of mud handling equipment is to manage losses due to waste without effecting the process and to maintain drilling fluid properties.

Mud handling equipment and systems include shale shakers, vacuum degasser, desilter/desanding, mud cleaner, decanter and centrifuges, among others. Generally, in the drilling operation, the pit system is incorporated with the mud handling system in order to get higher yield.

The mud handling equipment are designed to yield less cutting to reduce mud dumping, which helps to reduce the cost of the operation. While designing the system, mud handling equipment must have sufficient capacity to process the sand at required drilling rates without overloading, which will help to maintain the efficiency of the system.

Use of mud handling equipment varies with the application areas. For instance, if the drilled area is comprised of coarse sand then the shale shaker is used as a mud handling equipment.

Thus, with the growing exploration and drilling activities across the globe, the demand for mud handling equipment is expected to increase over the forecast period. In various industries, corrosion is a major issue that cause disastrous effects. In the U.S., corrosion costs around US$ US$ 180 Bn each year.

In the oil & gas industry, oxygen, and sulfur often cause corrosion loss during upstream operation. During drilling operation, untreated drilling mud and oxygen contaminated fluid corrodes the pipeline, well casing and drilling equipment as well as the mud handling equipment. Thus, losses due to corrosion lead to frequent repair and replacement of mud handling equipment or its parts. This replacement of mud handling equipment and its added cost is expected to dent the growth of the market.

With this significant growth in oil & gas exploration activities, the demand for mud handling equipment is expected to increase in North America. North America mud handling equipment market is expected to register healthy CAGR growth over the forecast period. In terms demand, Middle East ranked second and is expected to grow significantly over the forecast period. This growth of mud handling equipment market is mainly attributed to growing exploration and drilling activities in GCC Countries, which is expected to drive the demand for mud handling equipment.

Currently, around 300+ rigs are present in GCC countries and rig counts are expected to increase with rising demand for oil & gas across the globe. In terms of production, Europe is expected to dominate the global mud handling equipment market. It is expected that the China mud handling equipment market is expected to grow at a healthy CAGR over the forecast period. In Latin America, Mexico is expected to dominate the mud handling equipment market

8613371530291

8613371530291