mud pump assembled piston brands

Tired of changing mud pump pistons? We have your solution. The TD will work in all types of drilling mud including oil based, synthetic and water based. It was specifically designed to work in applications where water based mud is used or in situations where WBM is used on the top side & OBM is used on the bottom end. This eliminates the need for changing the piston midway through the drilling program. The “TD” or “Total Depth” name reflects our commitment to make a single piston that will last from “spud” to “TD”. This piston has been engineered with a unique friction reducing material bonded into the urethane of the sealing lip. Because the TD is built to withstand friction in the liner, wear on your parts is minimized and savings is maximized. The Patriot™ TD is also designed to meet pressures of 7500 psi as well as temperatures up to 220 degrees.

Tired of changing mud pump pistons? We have your solution. The TD will work in all types of drilling mud including oil based, synthetic and water based. It was specifically designed to work in applications where water based mud is used or in situations where WBM is used on the top side & OBM is used on the bottom end. This eliminates the need for changing the piston midway through the drilling program. The “TD” or “Total Depth” name reflects our commitment to make a single piston that will last from “spud” to “TD”. This piston has been engineered with a unique friction reducing material bonded into the urethane of the sealing lip. Because the TD is built to withstand friction in the liner, wear on your parts is minimized and savings is maximized. The Patriot™ TD is also designed to meet pressures of 7500 psi as well as temperatures up to 220 degrees.

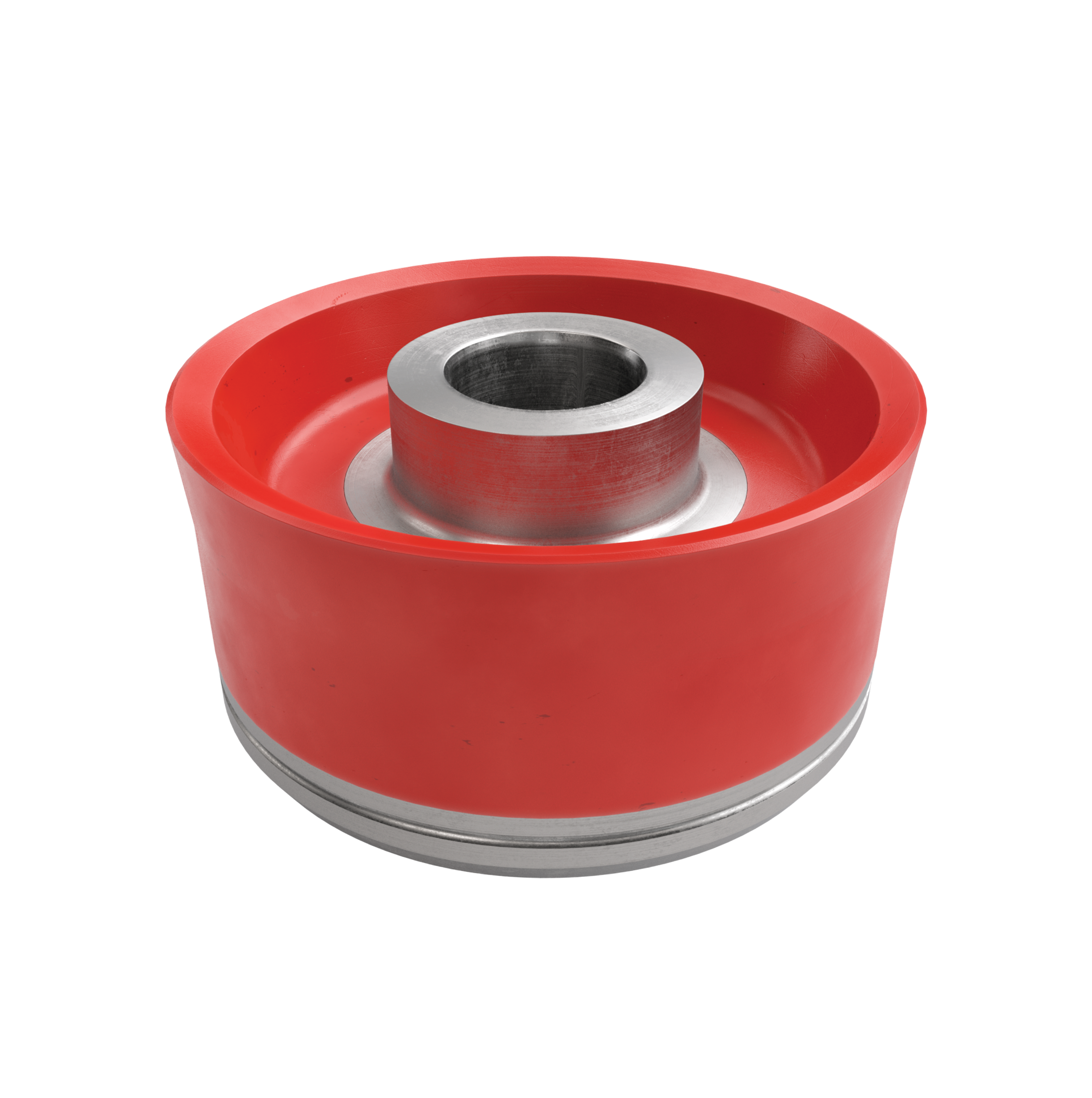

Mud Pump Pistons are made of high hardness alloy steel, and they are wear-resistant, anti-corrosive and anti-distortion after heat treatment. The seal of the piston can be made of polyurethane, polyether material and it can be also made of thiakol rubber.

Customers said they wanted long-lasting, easy-to-use pistons, and we delivered. Made from domestically sourced steel, GD Energy Products’ pistons feature proprietary bonded inserts and innovative geometry to deliver significantly longer life. This field proven design meets API Standards, and comes with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our pistons, along with our new valves and seats, are designed for use in GD Energy Products PZ, F-Series, Bomco, HHA, Emsco and National 12P lines of triplex drilling pumps. Let GD Energy Products be your one-stop shop for your whole fleet of pumps.

Full traceability is provided with all products sold, including pistons. Traceability markings include: operators ID, packers ID, date of urethane pour, part number of piston, work order number, Made in USA brand, and SWOP logo.

Our replaceable rubber pistons and inserts are based off of the industry standard “Mission-Supreme” style; our inserts will ft all competitors’ piston hubs that are interchangeable with the OEM.

Material: The piston assembly is constituted by the piston core, rubber, spring, clamp, etc. Pistoncore is made of 42CrMo and the piston rubber is made of nitrile rubber or polyurethane rubber.

Application: Piston assembly is one of the main parts of mud pump hydraulic system, but also th e vulnerable part of drilling work. Mud pump discharge pressure is through the piston assembly by the piston reciprocating linear motion.

For drilling companies with the need to pump slurries with bentonite, concrete, and other thick mud, Elepump triplex, high pressure piston mud pumps are the ideal choice for long life and minimal maintenance.

Featuring superior construction and high quality materials, Elepump mud pumps are built to last. They require minimal maintenance, so your costs stay low so and your drilling operations stay profitable.

The KT-45 mud pump is the most compact of the whole range of Elepump pressure pumps. This small capacity pump is still mighty enough to pack a big punch, with enough flow for drilling up to HQ sizes. It is very light and very maneuverable, making it a great choice for geotechnical drilling, fly jobs or heliportable jobs. Elepump mud pumps can be configured for diesel, gas, electric and air power.

The KF-50M is the pump to choose if you want a pump you can count on to keep pumping without missing a beat. This powerful pump is a standard size and can handle all slurries including bentonite, concrete and more. With its stainless steel ball and seat style valves, it is the ideal choice for pumping grit, cement, chunks of rock and other hard material, without the worry of damage to fragile parts. Elepump mud pumps can be configured for diesel, gas, electric and air power.

Mud pump is the "heart" of oil drilling system while mud pump liner an important disposable quick-wearing part of the fluid end. Therefore, the quality of mud pump liner will directly affect the normal operation of the drilling rig and thus the drilling costs.

Bi-metal liner is one of the most widely used types of liner. Our product combines the virtue of high strength forged steel shell and the advantage of anti-abrasive corrosion-resistant high-chromium sleeve together. The shell, including lip sleeve, is forged with high-quality carbon steel. The inner sleeve made of high-chromium cast iron is processed by centrifugal casting, the hardness of which is up to HRC 62 after heat treatment, could withstand a mud pressure of 7000 psi.

Ceramic liner is applied to well drilling operations for deep reservoir and complicated geologic situations, and is also used for offshore oil and gas development. The hardness of the working surface of the inner sleeve can reach HRC89 or more while the bending strength can be up to 1000-1200Mpa. Our ceramic liner is able to withstand a maximum pump pressure of 70Mpa. It is anti-abrasive, corrosion-resistant, heat-resistant, pressure-resistance, and is of high strength and high rigidity.

Piston assembly is one of the main parts of the fluid end of the mud pump. The volume of the working chamber alters with the reciprocating of piston, and thus realize a liquid suction and discharge through the pump valve. We are able to provide superior replaceable rubber piston and bonded piston.

Piston assembly, as a vulnerable part, is mainly composed of piston hub, rubber etc. Forged with alloy steel according to strict processing control and heat treatment, the piston hub is of high strength and rigidity, and of long lifespan. In addition, there are several selections for piston rubber under different operating conditions, like Nitrile Rubber, Polyurethane (PU) and Hydrogenated Nitrile (HNBR) etc.

Piston assembly, as a vulnerable part, is mainly composed of piston hub, rubber etc. Forged with alloy steel according to strict processing control and heat treatment, the piston hub is of high strength and rigidity, and of long lifespan. In addition, there are several selections for piston rubber under different operating conditions, like Nitrile Rubber, Polyurethane (PU) and Hydrogenated Nitrile (HNBR) etc.

Valve and seat make up a valve assembly that is the major component of the fluid end of the mud pump. It is also one of the most consumed vulnerable part during drilling.

Explore a wide variety of mud pump piston on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump piston are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump piston is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump piston for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump piston to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

The RRP PINNACLE ASSEMBLED PISTON also known as Replaceable Rubber Piston or Supreme Piston is designed for use in the most demanding applications. The replaceable seal element is manufactured from a specially formulated elastomeric compound designed to be resistant to most chemical fluid found in the drilling industry today. These pistons can also be used in conditions where elevated temperatures can be problematic to other types of pistons in the market. The fabric anti-extrusion device on the piston is constructed from proprietary materials utilizing well researched process to reduce the extrusion of the rubber even at the pump’s maximum pressure rating.

Mud Pump Pistons are made of high hardness alloy steel, and they are wear-resistant, anti-corrosive and anti-distortion after heat treatment. The seal of the piston can be made of polyurethane, polyether material and it can be also made of thiakol rubber.

American Mud Pumps LLC: warrants its products to be free from defects in material and/or workmanship under normal use and service for a period of one(1)year from the date of shipment. The liability for any defects shall be limited to the repair or replacement of such products, or at the option of American Mud Pumps LLC the refunding of purchase price. This warranty is expressly in lieu of all other warranties and representations, expressed or implied, and all other obligations or liabilities on the part of American Mud Pumps LLC, which shall not be liable for consequential damages for any breach of warranty."

American Mud Pumps LLC is a quality independent company. We are neither a licensee, nor affiliated with any other original equipment manufacturer (OEM) which may be named throughout. The manufacturers" names or trademarks used herein are solely for identification purposes and are not intended by American Mud Pumps LLC to cause confusion as to the source, sponsorship or quality of the parts provided by American Mud Pumps LLC. The OEMs named throughout this catalog do not sponsor, promote, warranty or endorse American Mud Pumps LLC products. Part number usage is for identification purposes only."

8613371530291

8613371530291