mud pump preventive maintenance quotation

Envirep provides excellent service before, during, and after the sale. To maintain and protect your Gorman-Rupp equipment, our Service Department offers Gorman-Rupp preventative maintenance agreements. Regular preventive maintenance will uncover emerging problems and help to avoid costly and inconvenient breakdowns while keeping your pumping system working at peak efficiency.

Our service staff is factory-trained in the operation, maintenance, and troubleshooting of Gorman-Rupp pumping equipment and electrical controls. They are equipped with proper tools and testing instruments and arrive at your site with common replacement parts enabling them to solve potential problems quickly and economically. We will work with you to keep your pumping equipment operating reliably and efficiently.

If you or your customer would be interested in receiving a proposal for a Gorman-Rupp preventative maintenance agreement, please send an email to JPPRICE@Envirep.com

Envirep distributes Gorman-Rupp’s extensive line of products including Self-Priming Pumps, Packaged Wastewater Pumping Systems, Water Booster Stations and Submersible Pumps for the Municipal market. Envirep is a factory-trained, stocking distributor for Gorman-Rupp and provides local support and inventory.

Gorman-Rupp is the industry leader and innovator in high-quality pump design. At Envirep/TLC, we will help you choose the best Gorman-Rupp® pump parts for your needs. Our goal is to provide you with easy to operate, low maintenance pump parts to ensure you are being as cost-effective as possible

Envirep/TLC is an authorized distributor of Gorman-Rupp pump products and we carry a huge inventory of spare parts so our customers receive the best service possible.

When repairing a Gorman-Rupp pump, it is always best to use genuine Gorman-Rupp parts. Gorman-Rupp builds their parts to exact tolerances and exact material specifications. Not having the right part can reduce the service life and affect the pump’s life and efficiency. Only genuine Gorman-Rupp parts can guarantee that your part will fit perfectly, and deliver reliable service for many years.

Envirep/TLC is a leading manufacturer’s representative and service provider for municipal and industrial water and wastewater treatment and pumping systems. We represent manufacturers of quality products, serving Eastern Pennsylvania, Maryland, New Jersey, Delaware, Washington D.C., Northern Virginia, and part of West Virginia.

Envirep’s staff of application engineers and field service technicians have decades of experience in equipment selection, design, and operation and maintenance. We are committed to providing our customers with prompt and professional service. We assist consulting engineers and end-users with technical support, from new plant design and plant upgrades to equipment replacements and service. Our experienced team is here for you, to recommend the right product, part, and service for your application.

STH has been selling and servicing Booster, Fire and Sump/Sewage pumps in the Maryland, DC, & Northern VA market since 1973. We have Factory-Trained and Certified Service Technicians and we currently manage over 850 Preventative Maintenance (PM) Agreements for various property management companies and owners. Routine annual or bi-annual maintenance of your pumping system will help to minimize any “unbudgeted” emergencies and reduce costly downtime. Weekly, monthly and quarterly maintenance programs are also available. STH also offers extended warranty options.

Everyone agrees that reactive maintenance is probably the worst pump reliability strategy. Maintaining equipment only after it breaks can mean unexpected downtime, emergencies, rush charges, overtime, and replacement of expensive parts.

The best pump reliability strategy is not either preventive or predictive maintenance, it’s a combination of the two, strategically applied. In this post, we’ll discuss the differences between predictive and preventive maintenance and when it’s best to use them.

Many operators rely heavily on “reactive” maintenance rather than preventing and planning for future repairs. As discussed in our eBook, 36 Ways to Kill Your Pump, “reactive” maintenance accounts for unplanned equipment downtime and increased costs.

Preventive and predictive maintenance programs extend the overall life of the equipment and result in fewer unplanned breakdowns. The choice is not one or the other, it’s a combination of the two.

Preventative maintenance is any variety of scheduled maintenance to a pump or other piece of equipment. Generally, it includes scheduled routine maintenance, such as equipment calibration, greasing, oil change, and analysis.

One of the biggest ways to prevent failures is to make sure your equipment is properly aligned and balanced. Misalignment and pump unbalance are the two most common reliability problems for rotating equipment. Laser alignment also fits within this category since its a service completed upon installation, setting the pump up for success.

These programs are designed to keep your maintenance costs low by preventing costly failures before they happen. If you need a preventative maintenance checklist, you can download one here.

Up to 50% of damage to rotating machinery is directly related to misalignment. Misalignment can cause increased vibration, premature seal and bearing failure, and increased power consumption. An unbalanced pump causes similar issues, such as vibration, which can be easily avoided with the right preventative maintenance measures.

Predictive maintenance services are used to monitor the condition of equipment over time. Vibration analysis, for example, measures the vibration of the equipment while it is still in service. This allows the technician to see the change in vibrations over time to predict when a problem may occur, and why.

Predictive maintenance should be part of routine maintenance for pumps and rotating equipment that absolutely can NOT go down. Operators and maintenance managers get a glimpse into the future life of the pump as it"s running today. This allows them to plan for repairs and avoid unexpected downtime.

Not all pumps are equally important in a manufacturing process, so not all pumps should receive the same maintenance plan. It wouldn’t make sense to spend time and money on vibration analysis for a pump in a non-essential application.

Before creating a maintenance plan, place the pumps into categories. This will help determine how much time and money to invest in each one. Use these categories to get started:

Regularly maintaining pumps will extend the life of your pump. When a pump is properly maintained, the parts that need replacing are usually the less expensive wear parts.

Check shaft alignment – believe it or not, shaft alignment can change! Thermal growth and machine movement due to load shifts can cause pumps to move out of alignment.

Up to 50% of damage to rotating machinery is directly related to misalignment. That’s huge. Machine vibration, bearing damage, premature seal wear, and coupling damage are all examples of issues pumps experience when misaligned.

For the most accurate alignment, we always recommend laser alignment. It’s the most accurate method available (to .0001), and once familiar, an operator can align a pump/motor very quickly. It is the most expensive method to get into if doing alignments in-house and can be difficult to learn at first. But when looking for long-term results, the laser align method is the better choice.

Precision rebuild or precision maintenance is the practice of rebuilding a pump as close to OEM specifications as possible. Attention to detail is required for precision rebuilds.

Precision rebuilds are proven to reduce failures and should be a central piece of a pump reliability strategy. If the team lacks capacity, tools, or expertise to rebuild pumps to OEM standards, look for a capable local shop.

Add taps with isolating ball valves into piping on the suction and discharge sides of the pump. Use these to mount pressure indicators to ensure the pump is performing properly.

Read the pump manual and follow each step in the procedure. The procedures therein give the best possible instruction for long and trouble-free life for the pump.

Upon start-up, record the pump performance baseline data – amps, suction pressure, discharge pressure. This is handy when troubleshooting issues, should they arise.

Vibration monitoring is a very helpful tool for predicting pump failures. Some manufacturing facilities have a vibration technician on staff to take readings on critical pumps. These technicians may read the results themselves or send them to a firm that can interpret the readings and provide a report.

Unfortunately, this is not a skill easily attained by a maintenance team. It requires expensive equipment and a great deal of training to be an effective vibration technician. Unless the facility has a large population of critical equipment, this is a service best hired out.

Arguably the most important piece of a preventative/predictive maintenance plan... The TRAINING! Training isn’t just for the maintenance team, it’s for everyone in contact with pumps, operators especially! Failure prevention is everyone’s responsibility.

The maintenance team is the keeper and protector of equipment in the facility. Train operators on the signs of failure so they can report it quickly. Show them how to properly start-up or shut down a pump and how their actions will affect other parts of the system.

If all these steps were do-able by a maintenance team alone, everyone’s reliability goals would be already met. Some of the steps we’ve laid out require specialized training, tools, or specialized training on tools to make them effective. It’s likely the team doesn’t possess all these as they’re expected to know how to fix every machine in the plant. Hire outside help where it makes sense.

Look to a preventative maintenance program and predictive maintenance measures to save on annual maintenance costs and unscheduled downtime. We recommend working with your local equipment supplier to schedule a preventative or predictive maintenance program for your pumps.

Need more information about our preventative and predictive maintenance services? We are happy to help businesses in Wisconsin and upper Michigan. Got a noisy, underperforming pump? Consider our FREE Bad Actor Pump Assessment!

Pumps are often designed to operate at a single point known as the Best Efficiency Point (BEP). As components begin to wear, a pumps performance begins to decline, with operation away from this point leading to issues such as accelerated bearing or seal wear, vibration, excess temperature rise or cavitation. Quite often declining performance can start gradually, before quickly accelerating until failure if performance issues are not addressed in a timely fashion.

Corrective Maintenance is undertaken when failure has occurred. The unit may be leaking, efficiency reduced, pump stopped or motor tripped, leading to loss of production resulting in an urgent situation where parts must be sourced and fitted quicky.

Preventative Maintenance is inspection and repair scheduled at specific intervals (daily, weekly, monthly, yearly) or based on the number of hours run. Visual inspections are made externally and internally by dismantling the unit, replacing seals such as gaskets and mechanical seals, with pump parts checked for wear.

Differential Pressure:Check the operating pressure by calculating the difference between the inlet and outlet pressure of the pump ensuring it is operating on curve.

The “6 to 1 Rule” discovered by John Day Jr, (Manager of Engineering & Maintenance at Alumax South Carolina stated that the ideal ratio of Proactive Maintenance (PM) to Corrective Maintenance (CM) should be 6 to 1 - 6 PM checks to 1 RM check. If your ratio is below this then according to his theory it is being inspected too infrequently, above and inspections are too frequent.

Although Proactive Maintenance can seem to avoid the urgent costs and downtime associated with reactive maintenance, PM maintenance costs can be high due to the cost of labour in dismantling of complicated designs such as Progressing Cavity, or Triplex Plunger pumps which are often time consuming to maintain with more than one person required to undertake work.

On dismantling units, some seals require replacing regardless of condition, and excess spares can be required in case of gasket entrapment during assembly. Rental of specialist lifting equipment may be required and there can be situations where when inspected, pump parts do not require replacement.

This can be achieved through a monitoring device, where when the right data is collected, pump failure can be anticipated between 3 and 12 months in advance with an 80-95% accuracy.

With the average lead time on DN100 pumps, and units over 5 years old being 3 months or more, it is essential that spares are either on the shelf or failure is anticipated through advance ordering.

There are hazards during any maintenance activity. Always ensure the correct PPE is worn before attempting repair, that sufficient expertise is on hand and chemical data sheets of any fluid being pumped are checked prior to undertaking work. A full risk assessment should be completed in advance.

Hazardous FluidsIrritation, Chemical burns, ignitionEnsure when pump is opened the unit is cool, not pressurized, ignition sources are not present, and any fluids spilt are contained.

If inspection has been neglected for some time, then additional parts may require replacing than had the unit been inspected earlier, with some pump parts becoming beyond economical repair.

Enables planned work to be undertaken during lower activity levels and at lowest cost & risk.Pump has to be crucial within a process or above a certain size for monitoring to be cost effective

Thread Sealant –The use of semi-permanent thread sealant will ensure vitality important threaded fasteners such as bolts or screws on shafts, couplings or pump casings do not self-loosen due to vibration and become disengaged.

Interchangeable Spares –Our range of pumps are modular in design utilizing interchangeable spares, meaning on site stock holding of parts can be reduced by up to 80% further reducing slow moving stock.

Repair & Replace –Choosing to repair an existing pump within a process of vital importance, as well as replace, is a strategy we recommend for maximizing plant efficiencies and reducing downtime. Should unexpected pump failure occur, your process can be restored quickly.

Checklists & Logs –The use of checklists and logs ensures a fully repeatable process ensuring important maintenance intervals are not missed. Logs can provide valuable insight and reveal a pattern before failure occurs enabling easier troubleshooting.

indicates which areas should be checked, but note that a units maintenance routine is dependent on several factors such as hours of operation, duty, aggressiveness of pump medium, rpm of motor, temperature, inlet conditions and location of equipment.

The best safeguard against unplanned shut-down or system failure is a good preventive maintenance plan. Cat Pumps triplex pump design offers easy maintenance without the use of special tools, making routine maintenance achievable without difficulty. Every installation differs, so a unique maintenance schedule may be required.

The service life of pumps and wear parts vary by application based on duty-cycle, pumped liquid, temperature, inlet conditions, location of installation and system accessories. It is important to monitor the system carefully. At the first sign of low pressure, make a thorough system examination. Low pressure may be caused by system components other than the pump, such as:

Please consult the pump Data Sheet, Service Manual or Service Video to verify service procedures. If no problems are found with the system components, shut the system down and inspect the pump. Check for contamination in valves. Change seals and record hours for your preventive maintenance schedule. Typically valves should be replaced at every other seal replacement.

Preventative maintenance is critical to your Mud Sucker® Diaphragm Pump investment. We have added video tutorials to help you perform regular maintenance procedures for your specific Mud Sucker make and model. Above all, have spare parts kits on hand will help keep your diaphragm pump operating at its peak performance levels while extending the service life of your pump.

MCOR 2555 can prevent this type of pump impeller deterioration. Read more about this pump impeller project by Mech-Chem Engineers, a licensed and exclusive distributor of MCOR products in India.

The maintenance checklist, implemented a few months ago, covers equipment to monitor on a daily, weekly, and monthly basis. An area is devoted to tracking service truck miles, rig miles and hours, as well as welder hours to know when an oil change is needed. The goal is to not let any maintenance task fall by the wayside.

“It’s kind of brought about them (drilling crews) thinking of other things, recognizing other things, and having a mindset towards maintaining their equipment,” says Baker, owner of Apex Drilling LLC in Burley, Idaho, “and that’s the most important thing—having that mindset towards maintenance.”

Baker, president of the Idaho Ground Water Association, worked as a maintenance mechanic for nearly nine years at a potato processing plant before entering the water well industry. He worked at the plant under the supervision of a 20-year Air Force veteran who previously was a maintenance manager of intercontinental ballistic missile sites in the Midwest. Baker credits those years for helping him get keyed in on being proactive with equipment maintenance.

“I learned a lot about preventative maintenance and things you start looking for,” Baker says. “If you know about some of these small things before they become big things, then you don’t have downtime on the jobsites.”

Months into implementing the maintenance checklist, Baker is seeing his drill crews take ownership by noticing minor issues on their four drill rigs and making note of them. The crews then look at the list and fix the issues during half a day in the shop while they’re in between jobs, or at a jobsite when time allows for it.

Factoring into the maintenance of his equipment is the fact that Baker is using a higher-grade oil and additives package rather than what the manufacturer recommends. Also, every 200 to 300 hours of use, he has equipment oil samples (engine, hydraulic, and compressor oils) sent and analyzed by a lab in Salt Lake City, Utah. The lab runs an International Organization for Standardization (ISO) cleanliness analysis and designates a code to how clean the oil is and the results dictate when Baker needs to change the oil in his equipment.

“Hydraulics, pumps, and motors have an ISO cleanliness code on the oil,” Baker explains. “If you run that hydraulic system within that cleanliness code at 70 degrees in a controlled environment, you’re going to get 10,000 hours out of your pumps.

“When putting the pumps on mobile equipment, it cuts it in half, so you get 5000 hours on pumps because they’re working in the extreme heat, cold, and dirt. As long as you maintain that cleanliness code in your oil, you can expect 5000 hours, but as soon as you go one code dirtier in your oil, you cut that in half. If you can operate one code cleanlier you can double it, and so we’re trying to operate in a manner that is not necessarily normal in an effort to try and get our equipment to last longer. Ultimately, it reduces our cost of maintenance.”

Sprowls, president of the Ohio Water Well Association, also shared how hydraulic oil in the GEFCO 40K came back with elevated metal content. He says nothing indicated that the hydraulics were acting up, but the oil sample prompted further investigation which revealed a hydraulic pump failed prematurely.

Sprowls stresses that maintenance needs to be intentional where time is made for it. He makes a point that being proactive is less stressful than reacting to an engine replacement in a customer’s front yard. After all, it’s much easier to work on the machines in a climate-controlled shop or gravel lot with no mud.

“What I’ve done for routine items is put a value on them that is relevant to our industry,” he shares. “Most drilling is accounted for by the foot, so I will analyze what kind of drilling I’m doing and put a footage on it. For example, I grease the rig every so many feet of overall drilling. If I’m mud drilling, the mud pump and swivel get greased very well, no matter the footage. Air drilling may be more frequent on the swivel due to the temperatures.

“The main reason Layne is dedicated to a robust equipment inspection/maintenance program is the safety of our employees,” Snelten says. “If we can keep our equipment safe to operate, it reduces the hazards to our employees and helps prevent injuries. They go home to their families at the end of the day in the same condition they came to work.

“We’ve made incredible strides in our safety performance over the past four years, and we see equipment maintenance as a required component to our continued safety evolution to not just maintain industry leading safety performance, but achieve true world-class safety.”

Beyond improved safety, Layne sees additional benefits of an aggressive maintenance and repair program achieving increased employee engagement, client appreciation and recognition, decreased maintenance costs, decreased downtime, increased productivity and profitability, and differentiation from the competition.

Layne rolled out a new maintenance program in 2021 for its several thousand pieces of equipment—drill rigs, pump rigs, trucks, trailers, and support equipment—and for the roughly 350 field staff who operate them.

The program consists of daily, monthly, and annual inspections of the drill rigs, pump rigs, and service trucks. Inspection items include fluid levels, wire ropes, sheaves, frame welds, controls, emergency stops, etc. A copy of the inspection goes to the field superintendent and mechanic and repairs

The program also presents Layne with information to determine action steps for a piece of equipment. If a piece of equipment continues to have persistent maintenance issues, and its records show maintenance costs are excessive, the question becomes: Is it better to perform a mid-life rebuild where another seven to 10 years can be gained, or is it better to replace it?

Pumps are vital to industries including water treatment and wastewater facilities, power generation, oil and gas, food processing and more. In the oil and gas industry, the uptime of industrial pumps is especially critical. The total world consumption of global petroleum and other liquid fuels averaged 92.30 million barrels per day in 2020, according to the U.S. Energy Information Administration. That total has risen by approximately 5 million in 2021 and will continue to grow in 2022. Any unplanned downtime can impact the ability to meet this growth.

There are three basic types of pumps, and they are classified by how they transport fluid: positive-displacement, centrifugal and axial-flow. Pumps can experience several different types of failures, including cavitation, bearing failures and seal failures, among others. In oil and gas, conditions in which pumps operate are often challenging, dirty and hazardous, resulting in wear and tear. Failure of these pumps not only results in unexpected operation delays and increased costs, but it can lead to dangerous oil and gas leaks, impacting labor safety and the environment. To avoid these unexpected failures, many companies increase preventative maintenance and create aggressive inspection schedules. These practices, however, can sometimes lead to unnecessary part replacement, maintenance costs and labor.

Others may rely on condition-based maintenance, which focuses on maintenance performed after monitoring real-time data and detecting unacceptable condition levels. However, this may not come with the advanced warning needed to prevent impending failure events or avoid downtime. By taking a predictive approach, past maintenance data and current sensor measurements can be used to determine early signs of failure, allowing companies to perform maintenance only at the exact time it is needed.

Developing and deploying a predictive maintenance solution for pumps is challenging. It requires a combination of sensing and instrumentation expertise, domain knowledge, and a practical perspective on applying machine learning and analytics for predictive monitoring. The instrumentation aspect is crucial since this data will be analyzed and will serve as the foundation of the actionable information. The decisions made from this information include what maintenance actions are needed and when they should be taken given the current pump health, as well as any trends or patterns that could emerge.

Vibration is typically the most crucial signal to use for monitoring the condition of a pump, but information on the rotating or reciprocating motion is also useful, especially for performing the more advanced signal processing methods. In addition, pressure and flow rate measurements are important for understanding pump operation and providing context for understanding the vibration data. A balance must be struck between the benefit of including these important measurements versus the hardware and implementation costs of doing so. This challenge is especially true for vibration sensors. Domain expertise is needed to place a minimal set of sensors to keep the hardware cost down and monitor the pump properly and accurately.

When handling the analytics, it is challenging to apply machine learning for this application without any domain-specific preprocessing and signal processing steps. Typically, pump failures are rare, so using a supervised machine learning model is not typically practical. Instead, a combination of domain-specific feature extraction methods for the vibration signals coupled with a baseline-based anomaly index machine learning algorithm is a more reasonable approach. The deployment and user interface should be closely aligned with the industrial use case and expected user, as well as the problem being solved. For some applications, it is not feasible to transmit the data to a remote monitoring center or central server, requiring the analytics and deployment to be performed closer to the data source.

A global oil and gas contractor with a specialty in automated drilling equipment and rig components wanted to develop a health monitoring solution for its mud pumps in the field. The contractor wanted to reduce unplanned downtime and unexpected failures. Not only did the company want to prevent these failure events, but they also wanted to distinguish between anomalies caused by maintenance issues and anomalies due to sensor issues.

By working with a predictive analytics company, this client sought to differentiate these anomalies, address the pump failures, and validate the solution by utilizing the induced fault data collected on its test rig.

The user provided the analytics company with a year’s worth of historical data from test bed data sets and sensors on the piston, suction and discharge mechanisms on two pumps in the field. The team of analytics experts was able to pull crucial features from the data by considering vibration patterns in the frequency and time-frequency domain. These features were integral to the development of health assessment models. The models then helped determine key indicators of pump seal failure, as well as establish the accuracy and necessity of the sensors.

By using advanced signal processing and vibration-based pattern recognition, the health monitoring system was able to detect and diagnose pump failures. This solution provided a baseline health assessment, failure identification and pattern recognition diagnosis capabilities.

The predictive analytics company was able to identify potential issues, as well as establish the best locations for sensor placement. The final solution predicted mud pump failure at least one day in advance, providing the data needed to take action and proactively perform maintenance. This approach helped reduce downtime, increase productivity, improve safety and prevent leaks.

1.Criticality analysis is essential in order to select the pumps for which predictive maintenance solutions can best be applied and to choose a solution that can provide the most value.

2.After determining the target pumps, the most critical failure modes should be identified, along with any relevant maintenance records for unplanned and planned downtime.

4.Based on the data and common failure modes, determine sensor placement and what, if any, additional sensors need to be added to the monitored pumps for the predictive solution.

These initial steps are essential when partnering with a technology provider and can help companies develop and adopt a predictive maintenance solution for their pumps that is robust and accurate.

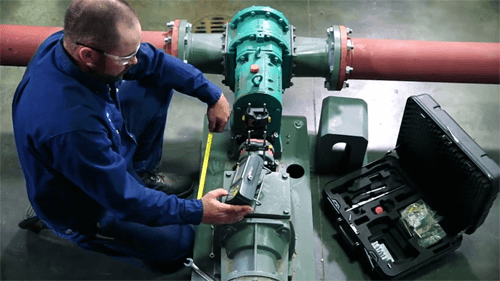

Whether onshore or offshore, well drilling sites rely on a multitude of systems to successfully perform the drilling operation. The mud pump is a key component tasked with circulating drilling fluid under high pressure downhole. The mud pump can be divided into two key sections: the power end or crosshead and the fluid end. Proper alignment of the pump’s crosshead to the fluid end liner is necessary to maximizing piston and liner life. Misalignment contributes to

accelerated wear on both the piston and the liner, and replacing these components requires downtime of the pump. Traditional methods of inspecting alignment range from using uncalibrated wooden rods, Faro Arms and micrometers to check the vertical and horizontal alignment of the piston rod OD to the piston liner ID. These are time consuming and cumbersome techniques that are ultimately not well suited to troubleshoot and solve alignment issues.

A “Mud Pump Laser Alignment Kit” enables you to measure where the piston will run through the liner at various positions along the pump’s stroke. It will also project a laser centerline from the fluid end back towards the rear power end of the pump that can be used to determine how much shimming is required to correct any alignment issues. The kit can include either a 2-Axis receiver or a 4-Axis which accepts the laser beam and documents where it falls on the active surface of the receiver. The 4-Axis receiver can decrease alignment time by as much as 50% as it will measure angularity as well as X and Y while the 2-Axis does not and will need multiple measurement locations to get the same information. In addition, the alignment system is a non-intrusive service requiring the removal of only the piston rod which allows for much quicker service and less down time on the pump. As the mud pumps in question are located globally both on and offshore, having a small, portable system is another great advantage. Our recommendation would be Pinpoint laser System’s “Mud Pump Alignment Kit”. They are being used by many of the leading repair service companies and have been their main alignment tool for over 15 years. Manufacturers are also utilizing these for new pump set-up.

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

Blackmer sliding-vane pumps stand ready to meet the needs of the rapidly growing oil and gas industry in the United States. Photo courtesy of Blackmer, a brand of PSG, a Dover company.

In some parts of North America, you can still clearly see the oil and gas pumping industry hard at work. Fly over Texas and see a checkerboard of sucker-rod “donkey” pumps, nodding in unison, pulling up millions of barrels of oil from deep beneath the surface.

At hydraulic fracturing sites, gigantic “frac” pumps dominate the landscape and shake the earth—splitting the mud, shale, and rock into bits with enormous pressure. That’s how oil corporations and service companies capture the elusive black gold buried deep inside—the material that literally fuels the multi-billion dollar oil and gas industry.

You can’t see the pumps that dive thousands of feet below the ocean’s surface from offshore rigs, and the pumps that transport the oil and gas are not visible, either. Hidden inside about 140 huge refineries throughout the U.S. there are even more pumps that keep the oil and gas industry functioning. It is up to the experienced maintenance professionals to make sure all of these pumps are hard at work every second of every day.

The massive oil and gas industry relies on a wide variety of pumps to perform every stage of the process—including upstream, midstream, and downstream functions. According to The Freedonia Group, Cleveland, the United States demand for oil and gas infrastructure equipment is forecast to hit $12.1 billion through 2016, which makes this a market that is vitally dependent on equipment that runs efficiently.

Different pumps present different obstacles, especially within a market as diverse as oil and gas. Mark Dufrene is the general manager for Pump & Process Technologies, a division of CastleOak LLC in Longview, TX—a distributor of Blackmer, Pentair, EnviroGear, Aurora, Fairbanks, Myers, and other centrifugal, rotary-gear, positive-displacement, and reciprocating pump brands for oil and gas applications. Each pump for each application must be treated differently.

According to Dufrene, a 27-year veteran of the pump industry, “There is a tendency to treat centrifugal and positive-displacement pumps the same. Some people use a control system on centrifugal pumps and just throttle back on the valve to control the flow. You can’t do this with a positive-displacement pump because, when you throttle back on the discharge valve, you create more pressure. It becomes self-defeating.”

One of the biggest problems contributing to excessive pump maintenance in the oil and gas space involves having a pump that is improperly sized or misaligned, Dufrene said. “People sometimes think bigger is better, but this is not always the case,” he said. “This can be a system issue.”

Advancements in technology, such as variable-frequency drives (VFDs), have contributed greatly to the longevity of most oil and gas pumps and have helped keep the maintenance manageable. A VFD is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage.

VFDs can optimize impeller diameter, which slows down the equipment and gives it longer life and less wear. “Instead of running the equipment at 1,800 rpm, with a maximum impeller diameter it can run at 1,400 rpm,” Dufrene explained. “This doesn’t sound like much, but it makes a big difference. It can extend the life of the pump and prevent it from running dry and cavitating. VFDs and other PLC controls can help to eliminate some of the misapplied and improperly sized equipment because you can use the speed control to compensate for errors made in pump selection.”

Changes are inevitable, and each change presents new maintenance concerns. “Every day is different,” Dufrene said. “If a guy has a mission to pump liquid from Point A to Point B, that is pretty simple—but it is not reality. When you dive into someone’s process and discover they want to pump from Point A to Point B to Point S to Point Z, it becomes more complicated. Every time they make a change, the system curve changes. Therefore, the pump curves change, but they may be using a fixed-speed piece of equipment to do all of the applications. This is not realistic, and it leads to problems. The pump does not always operate at the one design point. This is a dynamic system as opposed to a static system.”

A Griswold 811 series pump installed in a Lease Asset Custody Transfer (LACT) unit located in the Eagle Ford play in Texas. A LACT unit automatically measures, samples, and transfers the oil from a lease location in the oilfield into a pipeline. Photo courtesy of Griswold, a brand of PSG, a Dover company.

Odessa Pumps, a DistributionNOW Company, has been providing equipment to the oil and gas market for more than 30 years with a full range of applications, including chemical injection and high-pressure injection pumps. Joe Lewallen, Jr. is the general manager of Applied Pumping Solutions for Odessa Pumps’ Irving, TX operation, and Brian Verdehem is director of sales. They describe their five most common maintenance problems and solutions for oil and gas pumping applications.

Improperly sized and installed equipment. “It’s a fact that the majority of centrifugal pumps installed today are oversized.” Verdehem said.Pumps are often oversized for an application then operated in an unstable region of the centrifugal pump performance curve. “Operating in these unstable regions of the pump curve can result in lower mean time between repair (MTBR) on the seal and bearings, as well as the turned and cast components,” Verdehem said. “This is especially prevalent in pumps with higher suction specific speeds (>11,000 Nss), where the stability window on the curve is less forgiving. These factors can often be avoided by properly sizing the pump and configuring the pump package with a VFD. Operating in variable speed can ‘right size’ the pump performance curve to the current system variables. Having a pump supplier who knows pump hydraulics and who can evaluate the system head variables is essential to implanting a successful VFD system into a pump installation.”

Contamination of lubrication leads to bearing failure. Bearing failure is the biggest cause of maintenance issues in pumping applications. Proper lubrication of the bearing is the simplest way to avoid it. “Changing and maintaining an optimal environment for the lubrication fluid by investing in labyrinth or magnetic type bearing isolators, can provide great benefits on extending the machine life on oil-sump designs, and avoiding unexpected failures. Investments in oil-mist systems are often an efficient way of lubricating multiple pump assets within a consolidated production or process unit,” Verdehem said.

Improper mechanical-seal selection results in premature seal failure. Centrifugal pump units in the oil and gas sector also require an extensive knowledge of mechanical seals. “New sealing technology and proper material selection leads to longer operation before service is required,” Lewallen said. “Many customers and equipment providers omit this important part of pump application. Misapplication of the seal design is one of the most common areas of centrifugal pump failure, and once the seal fails, that can lead to loss of product, environmental contamination, and other maintenance issues.”

Incorrect material selection on pump material and gasket/elastomers, resulting in premature failure. “Liquid compatibility with the gaskets and elastomers in a pump’s construction are often overlooked by customers and inexperienced pump suppliers,” Verdehem said. Taking the extra time to ensure that your metallic and non-metallic pump components are compatible with the liquid during the pump-proposal stage, can help decrease the onset of premature and costly downtime. There are plenty of publications and compatibility charts available online for use in confirming compatibility on metallic and polymer based components. An experienced pump supplier will take a conservative approach on material selection if they have full transparency on the customer’s liquid properties and process conditions. It’s important that customers provide the pump supplier with this information at time of quote request.

Preventive maintenance in oil and gas pumping applications is much the same as in other industries, Lewallen said. “On larger horsepower equipment a baseline vibration reading is taken when the equipment is commissioned. Our technicians provide a PM service for many of our customers. With an initial vibration reading by our technicians, subsequent readings can identify a problem early.”

“Shaft alignment to the manufacturer’s specification is also crucial,” Lewallen said. “The proper use of shaft sealing technology is another important factor for equipment reliability. Preventive maintenance performed by properly trained personnel will ensure long run times and prevent premature failure.”

Another best practice, according to Verdehem, is a proactive maintenance culture. “It’s no different than changing the oil in your car as instructed by the owner’s manual,” he said. “Most centrifugal-pump failures are a result of bearing and seal failure, so it is important that these two areas are given the most concentration.”

Monitoring vibration on a regular basis and identifying changes in the vibration spectrum can warn of a pending failure. “This way you can plan the maintenance and shutdown of the equipment. Proactive machine-health monitoring can have tremendous benefits for most types of rotating equipment,” Verdehem said.

VFDs at a Blending Facility. VFDs were used to optimize positive-displacement pumps for two different functions at a blending facility—loading trucks and loading totes and drums. “We use the VFD systems and run them at different settings,” CastleOak’s Mark Dufrene said. “To load the truck involves pumping 150 gpm. To load drums and totes the pump should run at about half speed. The VFD switches on, slowly fills up the drum to a certain level, then it ramps down and shuts off the unit. Instead of having someone over there with a trigger, it’s all automated. To improve the life of the pump, over time we are regulating the speed to slow the unit down and match application conditions. This increases reliability and MTBF.”

Refinery Condition-Monitoring System. Dufrene said his refinery customer had a boiler system that would run effectively most of the time. But, in certain circumstances, the pump would cavitate and fail. “No one could pinpoint the problem,” he said. “You could stand there for two or three days and nothing would happen. But as soon as you went home, the upset condition would occur. So we added a monitoring system to measure the suction pressure, discharge pressure, and temperature.”

Dufrene’s team placed a probe on the bearing frame to measure the product temperature and discovered that when certain systems in the plant were running, the pump was oversized for the application. The plant was running at maximum capacity most of the time.

VFDs for Centrifugal Pumping Systems. In most pumping applications, trimming the impeller reduces pump efficiency, sometimes by as much as 20% to 25%, Dufrene said. Running the system at the optimum impeller diameter and controlling the speed dramatically increases efficiency. “As conditions like head and pressure change, the VFD can speed up and match the system, as opposed to running to the right or to the left, which actually causes more maintenance problems,” he said. “If you use a VFD, you can match the system you have and improve efficiency.”

Centrifugal Pump Running Dry. A centrifugal pump running dry can be a challenge in many applications, and especially in the oil and gas industry. This is particularly an issue in tank or rail car unloading applications, as well as

“Dry run is the Achilles heel for pumps that have metal-to-metal wear ring designs on the rotary and stationary ring configuration,” Verdehem said. “Failures in this mode can often cost as much or more than a new pump unit. In these applications, customers can move to a stationary wear-ring insert constructed of a fiber-reinforced fluoropolymer material, with low creep and high thermal resistance. These materials on the stationary ring will not allow excessive heat build up during dry-run anomalies. This saves the pump from catastrophic damage due to dry run.”

Verdehem said that investing in a quality and reliable alignment device can provide long-term benefits for installed equipment. “Without proper alignment, one is installing a bad actor at the time of installation,” he said. “A vibration analyzer capable of generating a full spectrum can be a worthy investment from a predictive-maintenance perspective.”

Also, partnering with pump suppliers who have the experience with proper pump selection, installation, operation, and maintenance can provide long-term benefits to the end user, the experts agree. “Many pump suppliers have implemented a business model of only selling the new equipment and parts at a low price,” Verdehem said. “Those who can do that, plus provide the field and consultative services after the sale, are the partners that reliability-savvy customers value the most.”

Hydraulic fracturing pumps used in oil and gas service work are highly engineered, expensive pieces of equipment that can generate pressures as high as 20,000 psi and can weigh as much as 9 tons. Today’s multi-stage frac jobs mean longer pumping times, according to Kevin Hunter, Equipment Builder Group Engineer, Global Products Technology, ExxonMobil.

Shale reservoirs are the driver of much of the fracking work today and often require extremely high pressures, Hunter said. These factors have combined to force hydraulic fracturing pumps to work harder than ever.

“These critical pumps have to pump abrasive fluid in multiple stages on each job and there may be 15 or more frac trucks and pumps on a single frac job,” Hunter said. “Frac pumps have to operate almost continually for several days before moving to the next job. Uptime is critical as the locations are often several hours driving time from their support site, and they may have a series of consecutive jobs scheduled.”

Pump builders are constantly working to update designs to improve reliability. Optimum lubrication can also improve uptime and extend maintenance intervals.

Frac pumps are comprised of two key components—the power end and the fluid end. The power end includes a gear set that takes the power from an engine and transmits it to the crankshaft in the power end used to drive the plungers that push the frac fluid.

The other key component of a frac pump is the fluid end where the plungers apply pressure to the frac fluid. One key maintenance issue for fluid ends is maximizing plunger-packing life. In addition to good design and manufacturing processes, lubrication contributes to maximum plunger packing life.

Traditionally, rock drill oils delivered by a centralized lubrication system have been used in most pump designs. With ever-increasing environmental concern and reducing spills, many operators are migrating to grease for plunger lubrication.

“This requires a grease that can readily be pumped via the centralized lubrication system, which has relatively long lines leading to the fluid end of the frac pump,” Hunter said. “This requires a grease that pumps well while still providing good lubrication at the packing.”

8613371530291

8613371530291