mud pump preventive maintenance pricelist

Everyone agrees that reactive maintenance is probably the worst pump reliability strategy. Maintaining equipment only after it breaks can mean unexpected downtime, emergencies, rush charges, overtime, and replacement of expensive parts.

The best pump reliability strategy is not either preventive or predictive maintenance, it’s a combination of the two, strategically applied. In this post, we’ll discuss the differences between predictive and preventive maintenance and when it’s best to use them.

Many operators rely heavily on “reactive” maintenance rather than preventing and planning for future repairs. As discussed in our eBook, 36 Ways to Kill Your Pump, “reactive” maintenance accounts for unplanned equipment downtime and increased costs.

Preventive and predictive maintenance programs extend the overall life of the equipment and result in fewer unplanned breakdowns. The choice is not one or the other, it’s a combination of the two.

Preventative maintenance is any variety of scheduled maintenance to a pump or other piece of equipment. Generally, it includes scheduled routine maintenance, such as equipment calibration, greasing, oil change, and analysis.

One of the biggest ways to prevent failures is to make sure your equipment is properly aligned and balanced. Misalignment and pump unbalance are the two most common reliability problems for rotating equipment. Laser alignment also fits within this category since its a service completed upon installation, setting the pump up for success.

These programs are designed to keep your maintenance costs low by preventing costly failures before they happen. If you need a preventative maintenance checklist, you can download one here.

Up to 50% of damage to rotating machinery is directly related to misalignment. Misalignment can cause increased vibration, premature seal and bearing failure, and increased power consumption. An unbalanced pump causes similar issues, such as vibration, which can be easily avoided with the right preventative maintenance measures.

Predictive maintenance services are used to monitor the condition of equipment over time. Vibration analysis, for example, measures the vibration of the equipment while it is still in service. This allows the technician to see the change in vibrations over time to predict when a problem may occur, and why.

Predictive maintenance should be part of routine maintenance for pumps and rotating equipment that absolutely can NOT go down. Operators and maintenance managers get a glimpse into the future life of the pump as it"s running today. This allows them to plan for repairs and avoid unexpected downtime.

Not all pumps are equally important in a manufacturing process, so not all pumps should receive the same maintenance plan. It wouldn’t make sense to spend time and money on vibration analysis for a pump in a non-essential application.

Before creating a maintenance plan, place the pumps into categories. This will help determine how much time and money to invest in each one. Use these categories to get started:

Regularly maintaining pumps will extend the life of your pump. When a pump is properly maintained, the parts that need replacing are usually the less expensive wear parts.

Check shaft alignment – believe it or not, shaft alignment can change! Thermal growth and machine movement due to load shifts can cause pumps to move out of alignment.

Up to 50% of damage to rotating machinery is directly related to misalignment. That’s huge. Machine vibration, bearing damage, premature seal wear, and coupling damage are all examples of issues pumps experience when misaligned.

For the most accurate alignment, we always recommend laser alignment. It’s the most accurate method available (to .0001), and once familiar, an operator can align a pump/motor very quickly. It is the most expensive method to get into if doing alignments in-house and can be difficult to learn at first. But when looking for long-term results, the laser align method is the better choice.

Precision rebuild or precision maintenance is the practice of rebuilding a pump as close to OEM specifications as possible. Attention to detail is required for precision rebuilds.

Precision rebuilds are proven to reduce failures and should be a central piece of a pump reliability strategy. If the team lacks capacity, tools, or expertise to rebuild pumps to OEM standards, look for a capable local shop.

Add taps with isolating ball valves into piping on the suction and discharge sides of the pump. Use these to mount pressure indicators to ensure the pump is performing properly.

Read the pump manual and follow each step in the procedure. The procedures therein give the best possible instruction for long and trouble-free life for the pump.

Upon start-up, record the pump performance baseline data – amps, suction pressure, discharge pressure. This is handy when troubleshooting issues, should they arise.

Vibration monitoring is a very helpful tool for predicting pump failures. Some manufacturing facilities have a vibration technician on staff to take readings on critical pumps. These technicians may read the results themselves or send them to a firm that can interpret the readings and provide a report.

Unfortunately, this is not a skill easily attained by a maintenance team. It requires expensive equipment and a great deal of training to be an effective vibration technician. Unless the facility has a large population of critical equipment, this is a service best hired out.

Arguably the most important piece of a preventative/predictive maintenance plan... The TRAINING! Training isn’t just for the maintenance team, it’s for everyone in contact with pumps, operators especially! Failure prevention is everyone’s responsibility.

The maintenance team is the keeper and protector of equipment in the facility. Train operators on the signs of failure so they can report it quickly. Show them how to properly start-up or shut down a pump and how their actions will affect other parts of the system.

If all these steps were do-able by a maintenance team alone, everyone’s reliability goals would be already met. Some of the steps we’ve laid out require specialized training, tools, or specialized training on tools to make them effective. It’s likely the team doesn’t possess all these as they’re expected to know how to fix every machine in the plant. Hire outside help where it makes sense.

Look to a preventative maintenance program and predictive maintenance measures to save on annual maintenance costs and unscheduled downtime. We recommend working with your local equipment supplier to schedule a preventative or predictive maintenance program for your pumps.

Need more information about our preventative and predictive maintenance services? We are happy to help businesses in Wisconsin and upper Michigan. Got a noisy, underperforming pump? Consider our FREE Bad Actor Pump Assessment!

Pumps are often designed to operate at a single point known as the Best Efficiency Point (BEP). As components begin to wear, a pumps performance begins to decline, with operation away from this point leading to issues such as accelerated bearing or seal wear, vibration, excess temperature rise or cavitation. Quite often declining performance can start gradually, before quickly accelerating until failure if performance issues are not addressed in a timely fashion.

Corrective Maintenance is undertaken when failure has occurred. The unit may be leaking, efficiency reduced, pump stopped or motor tripped, leading to loss of production resulting in an urgent situation where parts must be sourced and fitted quicky.

Preventative Maintenance is inspection and repair scheduled at specific intervals (daily, weekly, monthly, yearly) or based on the number of hours run. Visual inspections are made externally and internally by dismantling the unit, replacing seals such as gaskets and mechanical seals, with pump parts checked for wear.

Differential Pressure:Check the operating pressure by calculating the difference between the inlet and outlet pressure of the pump ensuring it is operating on curve.

The “6 to 1 Rule” discovered by John Day Jr, (Manager of Engineering & Maintenance at Alumax South Carolina stated that the ideal ratio of Proactive Maintenance (PM) to Corrective Maintenance (CM) should be 6 to 1 - 6 PM checks to 1 RM check. If your ratio is below this then according to his theory it is being inspected too infrequently, above and inspections are too frequent.

Although Proactive Maintenance can seem to avoid the urgent costs and downtime associated with reactive maintenance, PM maintenance costs can be high due to the cost of labour in dismantling of complicated designs such as Progressing Cavity, or Triplex Plunger pumps which are often time consuming to maintain with more than one person required to undertake work.

On dismantling units, some seals require replacing regardless of condition, and excess spares can be required in case of gasket entrapment during assembly. Rental of specialist lifting equipment may be required and there can be situations where when inspected, pump parts do not require replacement.

This can be achieved through a monitoring device, where when the right data is collected, pump failure can be anticipated between 3 and 12 months in advance with an 80-95% accuracy.

With the average lead time on DN100 pumps, and units over 5 years old being 3 months or more, it is essential that spares are either on the shelf or failure is anticipated through advance ordering.

There are hazards during any maintenance activity. Always ensure the correct PPE is worn before attempting repair, that sufficient expertise is on hand and chemical data sheets of any fluid being pumped are checked prior to undertaking work. A full risk assessment should be completed in advance.

Hazardous FluidsIrritation, Chemical burns, ignitionEnsure when pump is opened the unit is cool, not pressurized, ignition sources are not present, and any fluids spilt are contained.

If inspection has been neglected for some time, then additional parts may require replacing than had the unit been inspected earlier, with some pump parts becoming beyond economical repair.

Enables planned work to be undertaken during lower activity levels and at lowest cost & risk.Pump has to be crucial within a process or above a certain size for monitoring to be cost effective

Thread Sealant –The use of semi-permanent thread sealant will ensure vitality important threaded fasteners such as bolts or screws on shafts, couplings or pump casings do not self-loosen due to vibration and become disengaged.

Interchangeable Spares –Our range of pumps are modular in design utilizing interchangeable spares, meaning on site stock holding of parts can be reduced by up to 80% further reducing slow moving stock.

Repair & Replace –Choosing to repair an existing pump within a process of vital importance, as well as replace, is a strategy we recommend for maximizing plant efficiencies and reducing downtime. Should unexpected pump failure occur, your process can be restored quickly.

Checklists & Logs –The use of checklists and logs ensures a fully repeatable process ensuring important maintenance intervals are not missed. Logs can provide valuable insight and reveal a pattern before failure occurs enabling easier troubleshooting.

indicates which areas should be checked, but note that a units maintenance routine is dependent on several factors such as hours of operation, duty, aggressiveness of pump medium, rpm of motor, temperature, inlet conditions and location of equipment.

Pump maintenance is the process of keeping your pumps in good working condition. A thorough checklist that guides the maintenance engineer for pump maintenance can be very beneficial as pump maintenance is essential to keep your pumps running smoothly and prevent them from breaking down. This includes regularly checking and cleaning your pumps and replacing any parts that are worn out.

Modern pumps are essential equipment in the industrial and manufacturing sectors. These devices allow companies to move liquids and gases from one place to another, which can be crucial to operations. While modern pumps are reliable and rarely need maintenance, they require some attention over time.

The ideal way of classifying pump maintenance is through the method used for drawing out the maintenance plan. Based on this, the following are the four significant types of pump maintenance:

Corrective maintenance is the most reactive type of pump maintenance, and it involves repairing or replacing parts as needed to keep a pump functioning properly. While this approach may be necessary for some situations, it is often not ideal due to its high cost and disruption of operations.

Preventive maintenance is another common approach to pump maintenance that focuses on proactive measures such as regular inspections and adjustments. This can help avoid potential problems and keep pumps operating at peak efficiency. Using a reliable checklist for pump maintenance, engineers conduct a thorough checking and carry out the needful maintenance as and when needed. This approach is widely used in industries.

Predictive maintenance uses advanced sensors and equipment to monitor the condition of pumps and other components in real-time. This enables users to detect potential problems before they become serious issues that require extensive repairs or replacements. However, this type of maintenance is cost-intensive and unsuitable for small-scale pump systems.

This type of pump maintenance is a newer type of pump maintenance that uses data collected from sensors to assess the condition of pumps and other equipment. This information is then used to develop a customized maintenance plan tailored to the equipment’s specific needs. This approach can be more effective than traditional pump preventive maintenance plans and can help to reduce downtime and costs. But setting up a CBM system can prove to be a costly affair.

Whether you are using one of these approaches or a combination of them, it is essential to ensure that your pump maintenance program is adequately designed and implemented to optimize the performance and longevity of your pumps. Pump maintenance plans are also created based on the system they target, including mechanical, electrical, and hydraulic. Mechanical maintenance typically involves replacing parts that have worn out or broken down due to normal wear and tear. Electrical pump maintenance requires checking the wiring for any signs of damage and replacing fuses if necessary. And hydraulic pump maintenance may involve changing fluid levels or upgrading the oil viscosity depending on the level of use.

The strength and effectiveness of your pump preventive maintenance plan depending on how robust your checklist is. While you would want to include all possible checks in the plan, it is impractical and inadvisable for all routine checks. Therefore the checklist is divided based on the frequency of checks making it more sustainable and effective:

Please note that the pump preventive maintenance schedule for each pump would depend on its design and application, and hence you should always consult the pump manufacturer for the same. However, the above checklist is a general checklist that can guide the process of pump preventive maintenance. A well-maintained pump will last longer and perform better than one not correctly cared for.

Check the manufacturer’s recommendation for service interval schedules. Depending on the type of pump, different servicing may be required at different intervals.

Maintain the proper records for all pump maintenance activity. Good data collection will give you the correct information about the pump’s health and operational condition.

Based on the checklist, pump maintenance may seem a simple task that needs to be done regularly. However, this is not true. Understanding the pump behaviour and performing suitable maintenance activities requires years of experience. Therefore, it is always advisable to hire a qualified expert to carry out pump maintenance due to the following reasons:

Safety – Pump maintenance through a qualified expert, ensures that all safety hazards are identified and eliminated. This keeps you, your equipment, and your employees safe from harm.

Efficiency – Qualified experts know how to service and maintain pumps to operate at peak efficiency. This can save you money on your energy bills and help prolong the life of your pump.

Peace of Mind – Pump maintenance can be a complex task. By entrusting it to a qualified expert, you can rest assured that the job will be done correctly and on time.

Avoid Downtime – Downtime is costly, both in terms of lost productivity and repair costs. Pump maintenance through a qualified expert can help minimize the risk of unexpected downtime.

Compliance – Pump maintenance through a qualified expert can help ensure that your pump complies with all relevant safety and environmental regulations. This can save you from costly fines or penalties.

The majority of reliable pump manufacturers offer pump maintenance as a part of their service. Therefore, it is always a good practice to hire them to execute the pump maintenance of your site. They will also be able to create an effective schedule and an exhaustive checklist that your site engineers can follow for pump inspection. Ensuring that pump preventive maintenance is done at the right time in the right way will make your overall system more reliable and efficient.

Southwest’s Field Service Team is committed to providing customers with highly-trained personnel who can thoroughly inspect Mud Pumps and troubleshoot equipment issues. Our services are designed to provide customers with valuable information about their mud pump, along with providing cost-effective solutions to keep your equipment running trouble-free.

OEM trained technicians provide installation of fluid end modules ensuring equipment meets OEM standards and is aligned properly to reduce consumption of mud pump wear parts.

Drastically reduce mud pump equipment outages by installing a hydraulic liner retention system. This system decreases liner change-out time from hours to minutes.

Inspections allow you to address problems and issues before a failure occurs. Additional performance enhancements can also be achieved with our laser alignment pump service and customizable preventative maintenance program.

The system is lightweight and suitcase portable, thus eliminating the cumbersome and difficult-to-transport systems of the past. In addition, the Zero-N Laser Alignment system is a non-intrusive service requiring the removal of only the piston rod which allows for much quicker service and less downtime on the pump. Alignment inspections are performed worldwide by Southwest Oilfield trained service technicians.

Arun Chandrasekaran, Adam Avey and Corey Philipp, GD Energy Products, highlight the hidden cost of neglecting preventative maintenance of a pump’s power end.

Anyone with a vested interest in pressure pumping spends considerable time ensuring their pumps run efficiently with no unexpected downtime. A pump that is sitting in the repair shop is a harbinger of non-productive time, spiralling costs and operational headaches all-round. Since the repairs that are typically necessary on the power end component of the pump cannot usually be completed overnight, once a failure of a power end has occurred it can take several weeks to get a pump up and running again.

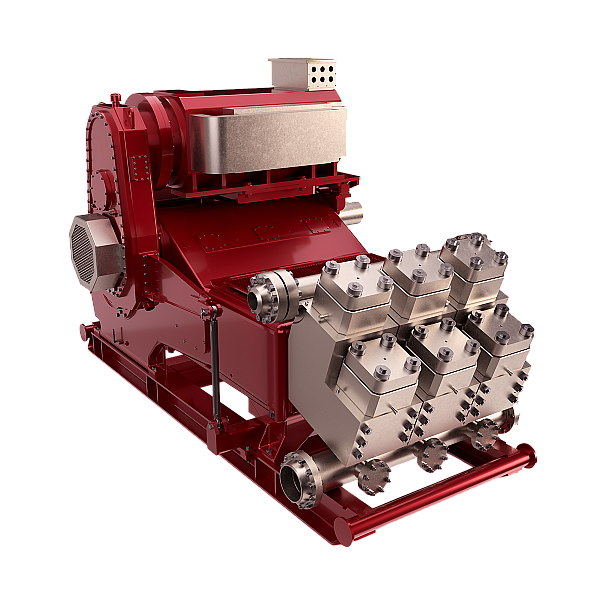

A frac pump is composed of a power end and a fluid end. The fluid end is the high pressure component of the pump that takes fluid into a chamber at low pressure and discharges it at higher pressure. As such, the fluid end is usually the component that receives frequent services in the field in-between frac stages. During preventive maintenance, the fluid end is periodically opened up to change wear components in order to keep it running efficiently. Conversely, the power end is the component that drives all the moving parts required to create the pressure in the fluid end. The moving components of a power end are contained within an enclosed steel frame and include a crankshaft, crossheads and connecting rods, similar to the rotating and reciprocating components found inside a car engine, but on a much larger scale. Unlike the fluid end, the power end rarely gets opened and serviced in the field. To run the pump, a driveshaft is hooked up to the power end from the transmission, which is turned by a diesel engine. The diesel engine and the transmission, at a certain gear, turn the power end. The power end turns the crankshaft and the connecting rod assembly, which moves the plungers to create the pressure in the fluid end. Ultimately, the goal for a pressure pumping company is to keep turning the power end and to keep the pump running.

Unfortunately, since the power end is not inspected periodically, the rate of unexpected failures for this component is rising. If a component is only looked at once a strange noise or even smoke is being emitted from it, the chances are that it is already too late to intervene to prevent significant damage to the power end. At this point, the only option would be to take it offline and send it to the repair shop. Typically, when a pressure pumping company goes to a site to perform a fracturing job, they will take some additional pumps with them. These extra pumps could be sitting idle, to serve as backup in case any of the major components, including the power end, breaks down unexpectedly. If customers are able to keep a good maintenance record, or perform preventative maintenance on the power end, they will only need to carry the pumps they require, resulting in lower operating costs and increased efficiency.

GD Energy Products helps pressure pumping customers actively maintain their equipment. By developing preventative maintenance plans for power ends, customers can better understand what to inspect for in the power end after set time intervals and take a proactive approach in replacing wear components as needed to prevent any unexpected downtime. This will also help to prevent catastrophic failures, which often results in very expensive repairs.

Pressure pumping companies should consider the following power end characteristics when developing a preventive maintenance plan. The company has helped customers in developing a maintenance plan specific to their operations and duty cycles.

As explained, the harder and longer a pump is run for, the sooner the bearings will wear out and need to be changed as part of a preventative maintenance cycle. ‘Duty cycle’ is a term used to characterise how hard a pump has been run and for how long. Duty cycle is determined by RL and ‘speed’ – that is how fast the pump is being run, and ‘time,’ meaning the number of pump cycles or run time. Preventative maintenance plans can be developed based on duty cycle. In the US, each different operating area/shale basin has different pressures that pumps are required to pump at. This can drastically change the required preventative maintenance intervals. Customers can provide a record of duty cycles and operating conditions in their area of interest and a preventative maintenance plan can be designed around those.

The company has performed studies to correlate improper mounting to the performance of the load-bearing components. Since the frame houses all the critical components and there are installed running clearances between the frame and the bearing components, stress from any unnecessary twist in the frame is transmitted to the bearing components. Results from studies showed pumps that were not mounted appropriately were subjecting the bearing components to additional stresses and even creating the potential for excess heat generation due to reducing clearances of bearing components below their minimum tolerance. It is recommended to place the pump on the skid and use shims to level the pump before it is bolted to the skid. As part of the preventive maintenance plan, all mounting bolts must be checked periodically for tightness and replaced as necessary.

Stroke length is a pump characteristic that is specific to each pump model and cannot be altered. It denotes the distance the plunger strokes for each revolution of the crankshaft. For each stroke of the plunger, a specific volume of fluid is displaced and the output volume can be increased or decreased by varying pump speed. This is a key piece of information for customers, as there are many pumps available with varying stroke lengths. When looking for a specific flow rate out of these pumps, the pumps must be operated at varying speeds to provide a uniform flow output. A longer stroke pump needs to be run slower than a short stroke pump in order to output the same flow rate.

However, it is important to remember that when pumps are run faster, they are accumulating fatigue cycles at a more rapid pace. Pump components are constructed with steel. By its very nature, at some point steel will reach its fatigue limit and start to develop a failure mode. How quickly it takes to reach the ultimate fatigue limit determines the life of the component. Ideally, pressure pumping companies operate their frac units at an optimal speed that does not result in too much load for the engine, transmission or pump. Overall, fatigue plays a major role in pump failure. Overall usable life of any component can be increased by managing accumulation of fatigue cycles more efficiently.

All power ends manufactured by the company are run through an extensive factory acceptance test where they are tested at their operating limits and have the temperatures of their critical components monitored prior to shipping to the customer to ensure the pump is receiving proper lubrication and ready for operation.

In April 2018, a pressure pumping company using GD Energy Products C-2500 pumps experienced several power end failures across their fleets due to overheating of internal power end components. In an effort to understand and further investigate the actual root cause of the failures, a frac unit from the same fleet was tested at GD Energy Products’ Fort Worth facility in Texas, US. Pressure gauges and flow meters were systematically installed at various locations in the lube system to better understand the system dynamics at various pump load conditions.

The unit was first operated as received, with the exception of the installation of the instrumentation. The power end oil was replaced with clean ISO 220 oil, as per the equipment manufacturer’s specification, and the oil filter was changed before operation. Significant issues were found with the amount of oil shown to be flowing through the gear pump relief line, as well as in the gear pump suction line. Additionally, the pressure relief valve at the power end was not adjusted correctly to maintain adequate (≥100 psi) pressure throughout the installed oil’s temperature/viscosity range. The decision was made to reroute the gear pump pressure relief valve relief line to the lube reservoir to improve the gear pump’s suction conditions. The unit was operated and the gear pump pressure relief valve was adjusted to increase flow to the power end. The power end pressure relief valve was also adjusted to maintain 145 psi at the power end. System performance was greatly improved with the modifications made.

A pump could cost tens of thousands or even hundreds of thousands of dollars to repair if one of its critical bearings fails and causes a power end failure on the jobsite. These unexpected expenses can be avoided, and total cost of ownership reduced by simply ensuring the bearing is changed at the right time. Fortunately, the cost of committing to a proactive maintenance schedule is modest, and can be planned and forecast for. A long-term outlook centered on preventative maintenance is essential in safeguarding a pressure pumping company’s ability to fulfill their customers’ demands and take on new work.

.jpg)

Repairing your pumps quickly and efficiently to get your operations back up and running is GD Energy Products’ top priority. If your pump requires immediate attention, our field engineers and service technicians can be deployed to your job site or facility. Our experienced technicians are trained to identify and inspect your pumping issue and conduct as-needed service, repairs and preventative maintenance at your preferred location.

GDEP offers a full range of 24/7 on-site pump maintenance and repair offerings tailored to your individual needs. We offer comprehensive repairs for fracking pumps, drilling pumps, well service pumps, fluid ends and modules. Additionally, our customers have access to 24/7 service, ongoing parts support and product maintenance.

GDEP’s inspection program offers a comprehensive and proactive approach to solving your pump issues. Our field service technicians can utilize advanced troubleshooting procedures to uncover various underlining issues with the capability of performing onsite repairs using genuine, high-quality OEM replacement parts to guarantee maximum performance

If you have a large fleet or pumps that simply require more attention, we can provide you with a dedicated field service technician with either half-day or full 24/7 coverage.

Our state-of-the-art repair facilities operate in a constant state of readiness to provide your pumps with the most comprehensive and cutting-edge repair and maintenance services. With facilities strategically located in all major shale plays throughout the United States, we are able to provide our customers with efficient service on a local level.

If you have a large-scale repair that cannot be completed in the field, bring your pump to any one of our repair facilities and expect the same level of service and expertise. A highly trained and experienced team of field engineers, service technicians and repair mechanics possess all the necessary skills and insights required to overhaul any pump, all under one roof. Backed by our satisfaction guarantee, you can have the confidence your pumps will operate at peak performance after it leaves our facility.

Our team of experts is available 24/7 to service and repair any brand of pump. Whatever your repair needs, GDEP will bring the proper experience, tools and equipment needed to get the job done.

Editor’s note: The following article is based on a Pumps & Systems webinar presented by Mr. Kernan in October 2012. Readers can register for the presentation slides and audio under the “Webinars” section of www.pump-zone.com.

Industrial facilities have the same fundamental goals, no matter the product they manufacture or the market they serve. From top executives to the plant floor, a common goal is to cut costs while improving reliability and process control. A recent poll confirmed that energy efficiency and maintenance were the top two concerns of industrial pump users in 2012. From an investment perspective, focusing on these concerns makes sense. More than 50 percent of the life-cycle costs of a typical chemical pump are made up of energy, maintenance and repair costs (see Figure 1). But what is actually being done to address these concerns?

When pressure is applied to maintain the steady pace of plant operations, the approach to maintenance could fulfill Albert Einstein’s definition of insanity, “...doing the same thing over and over again and expecting different results.” Getting caught in “firefighting” mode is common—fixing critical assets that have failed and putting them back into production as quickly as possible, and then moving to the next piece of problematic equipment. However, with the abundance of data on rotating equipment that are readily available, operators can implement different pump maintenance strategies to mitigate risks and optimize budgets.

This article addresses how to achieve a balanced maintenance approach, illustrating the pitfalls of a “one-size-fits-all” mentality. It describes the spectrum of maintenance philosophies and gives applicable advice on how to improve the bottom-line benefits of total pump system investments.

Above: A South American copper mine implemented a condition-based maintenance system to monitor 16 pumps and motors at four remote locations. The system gives mine operators real-time data on all pumps and motors, allowing them to monitor vibration levels, temperatures and more.

Smallest in volume, critical equipment failure can pose significant production losses and safety threats. Less important, balance-of-plant equipment generally represents more of the total assets, but failure will not result in substantial plant downtime. The balance-of-plant assets can quickly consume maintenance resources and budgets if not managed properly.

Before determining which maintenance philosophy to apply, end users should consider the equipment’s relative impact to the overall process and critically rank all assets. Four maintenance philosophies for consideration are:Reactive—Running a piece of equipment to failure and fixing it when it breaks

Figure 1. This breakdown of life-cycle costs highlights the importance of finding the right equipment for the right job. The combined cost of energy, along with maintenance and repair, makes up more than half the overall life-cycle cost for equipment. Cutting these costs down can lead to big savings. Source: Top 10 Global Chemical Manufacturer, FY 2006

Practicing predictive or proactive maintenance wherever possible seems ideal. However, this may not be cost effective for all equipment. For instance, balance-of-plant equipment that has a smaller impact on profitability may not be worth as much of an investment to closely monitor as critical or essential equipment. Reactive maintenance—otherwise known as “fix it when it breaks” mode—may suffice in these cases.

The bottom line is that end users should consider the costs to fix or replace a particular asset when determining what they are willing to spend on respective maintenance efforts.

Under normal circumstances, one could assume that the probability of equipment failure increases with time. In the 1960s, this maintenance paradigm prevailed. After the initial burn-in phase in which a high likelihood of infant mortality exists, the probability of failure evens out, followed by an eventual increase in probability of failure near the end of life. For preventive maintenance, the thought process is simple: if repaired before end of life, catastrophic failure can be prevented.

However, a famous 1978 reliability-centered maintenance report from Nolan and Heap revealed that 89 percent of failures are random. The incline in failure probability over time is an oversimplification. In fact, performing invasive preventive maintenance actually introduces a new burn-in phase prematurely and can increase the probability of failure. So if not time, what factor can be used to determine the best schedule for maintenance activities?

Fortunately, a benefit of rotating equipment like pumps is that they provide a signature of health. There are many opportunities to capture trendable and repeatable data, such as pressure, vibration and temperature. Performing predictive maintenance means using this data to end users’ advantage, keeping detailed records to capture baselines over time and then looking for overall increases that indicate a problem.

The root cause of the problem was a failed mechanical seal on a relatively small, overhung, inline API-style pump. This incident severely impacted the bottom line and created a dangerous situation for the refinery personnel.

In late 2009, the oil refinery made the decision to implement a wireless continuous monitoring system. With this technology, a data monitor examines the process and mechanical side of the pump, taking readings on bearing vibration, bearing temperature, suction pressure, discharge pressure and motor amps.

The data monitor wirelessly connects to a communications module that feeds this information to two sources:Pump key performance indicators—such as pump discharge pressure, pump suction pressure and motor amps—are fed to the refinery’s control room for operators to track where the pump is running on the pump performance curve and whether it has adequate net positive suction head to prevent cavitation.

Machine health data—such as tri-axial bearing vibration and bearing temperature—are sent to a Web-based condition monitoring platform, enabling the head reliability engineer to monitor the pump at all times, from any location, through the Internet or a mobile device.

The reliability engineer was able to track rapid upward trends with greater convenience, which helped catch a step change in the pump’s outboard bearing vibration.

Since implementing a predictive continuous monitoring system, the pump has increased mean time between failures (MTBF) and avoided catastrophic failure. In addition, the facility reported no unplanned maintenance activities on this pump for more than three years.

While predictive maintenance uses data to help foresee equipment issues, proactive maintenance takes this philosophy one step further. Also referred to as “precision,” it requires an understanding of why a failure occurred and a commitment to implementing change to prevent future failures and increase the MTBF.

Practicing proactive pump maintenance does not always require exhaustive root-cause analysis. Start with basic questions, such as:Where is the pump operating on the curve with respect to best efficiency point (BEP)?

By answering these questions, top targets for change will be identified. It starts with data integrity. Standardizing on a thorough set of failure codes is important. More important is setting and enforcing the policy to incorporate these codes into a computerized maintenance management system (CMMS).

When everyone is adamant about putting in fault codes that accurately describe the failure modes, bad actors are quickly identified. By proactively working through the bad actors, repeat maintenance activities caused by these machines can be eliminated, reducing costs and increasing productivity.

A 700-pump North American chemical plant was under extreme pressure to reduce pump maintenance costs and improve MTBF. Its plan was to embed a pump specialist as a full-time resource to transform the facility’s maintenance practices.

The first task was to reconcile the pump work order history because vague or generic failure codes made the data less useful. The specialist made procedural changes to ensure that the fault codes and job materials were correctly assigned in the CMMS for future trending.

With better data, the specialist created a “hot list” of pumps to target for root cause analyses. Cross-functional teams were formed from maintenance, operations and pump and seal OEMs to address problems.

While the solutions were simple, the results were powerful. In five years, pump MTBF increased by 108 percent. Annual operating costs per pump were reduced by 48 percent, saving the company more than $1.3 million per year.

In the world of industrial equipment, no two operations are the same. Since unplanned repairs can be 10 times as costly as scheduled maintenance, finding the right fit for each application—which may include taking a multifaceted approach—is important.

Consider a South American copper mine in which four pumping stations transported 16 million gallons of seawater 144 kilometers to its desert location every day.

Pump MTBF was low and mine operators were practicing firefighting maintenance—fixing failed equipment and putting it back into production as quickly as possible. The copper mine implemented both proactive and predictive maintenance strategies.

From a proactive standpoint, adjustments to check valves and control valves were made to slow response times, and pump starting and stopping procedures were implemented that helped mitigate water hammer effects.

The addition of a wireless condition monitoring system allowed maintenance to be predictive with the ability to monitor 16 pumps and motors at four remote locations over a span of 144 kilometers. The results included higher MTBF for the seawater pumping system and a 22 percent increase in annual production.

No matter the strategy or mix of strategies selected for industrial equipment maintenance, being aware of and responsive to data is key. Only when failures are fully understood and bad actors are targeted can meaningful change be effectively implemented. This requires being open and committed to change and following the path to improving reliability and optimizing maintenance budgets. P&S

Keeping pumps operating successfully for long periods of time requires careful pump design selection, proper installation, careful operation, the ability to observe changes in performance over time, and in the event of a failure, the capacity to thoroughly investigate the cause of the failure and take measures to prevent the problem from re-occurring. Pumps that have been: properly sized, are dynamically balanced, that sit on stable foundations with good shaft alignment, with proper lubrication, where operators start, run, and stop the machinery with care and where the maintenance personnel observe for unhealthy trends that begin to appear and act on them usually never experience a catastrophic failure.

This is true with a large percentage of pumping systems but, it is definitely not true with all of them. Frequently pumps are asked to operate way off their best efficiency point, or are perched on unstable baseplates, or run under moderate to severe misalignment conditions, or were lubricated at the factory and never see another drop until the bearings seize, and vibrate to the point where bolts come loose. When the unit finally stops pumping, new parts are thrown on the machine and the deterioration process starts again with no conjecture as to why the failure occurred.

If you work long enough in industry, you may get an opportunity to observe all the different “styles” of maintenance. How maintenance organizations operate usually fall into four different categories:

The disadvantages are that the maintenance department perpetually operates in unplanned / ‘crisis management’ maintenance activities with unexpected production interruptions and the plant must have a high inventory of spare parts to react quickly. Without a doubt, it is the most inefficient way to maintain a facility. Futile attempts are made to reduce costs by purchasing “cheap” parts and hiring “cheap” labor further aggravating the problem. Frequently the personnel are overworked and understaffed arriving at work each day to be confronted with a long list of unfinished work and a half dozen new “emergency” jobs that occurred while they were at home in the evening. It is not uncommon to send someone out to work on an emergency job first thing in the morning and by 10 o’clock, half way through the job, stop their progress and send them on a new “higher priority” emergency job.

This philosophy consists of scheduling maintenance activities at predetermined time intervals where you repair or replace damaged equipment before obvious problems occur. Done correctly, studies have shown that the costs to operate in this fashion are about $13 per horsepower per year. The advantages of this approach is that it works well for equipment that does not run continuously and the personnel have enough knowledge, skill, and time to perform the preventive maintenance work.

The disadvantages are that the scheduled maintenance may be done too early or too late. It is quite possible that reduced production could occur due to potentially unnecessary maintenance. In many cases there is a possibility of diminished performance through incorrect repair methods. I have witnessed perfectly good machines disassembled, good parts removed and discarded, and then new parts improperly installed. For some, squirting grease into bearings every month is their idea of a preventive maintenance program.

This philosophy consists of scheduling maintenance activities only if and when mechanical or operational conditions warrant by periodically monitoring the machinery for excessive vibration, temperature, lubrication degradation or observing any other unhealthy trends that occur over time. When the condition gets to a predetermined unacceptable level then the equipment is shut down to repair or replace damaged components in the equipment to prevent a more costly failure from occurring. In other words “DonÕt fix what is not broke”. Done correctly, studies have shown that the costs to operate in this fashion are about $9 per horsepower per year. The advantages of this approach is that it works very well if personnel have enough knowledge, skill, and time to perform the predictive maintenance work. The repairs to equipment can be scheduled in an orderly fashion and it allows you some lead time to purchase materials for the necessary repairs reducing the need for a high parts inventory. Since maintenance work is only performed when it is needed, there is a likely increase in production capacity.

The disadvantages are that maintenance work may actually increase if the personnel improperly asses the level of degradation in the equipment. To observe the unhealthy trends in vibration, temperature, or lubrication, this approach requires the facility to procure equipment to monitor these parameters and provide training to in-house personnel. The alternative is to outsource this work to a knowledgeable contractor to perform predictive / condition based duties. If an organization had been running in the breakdown / run to failure mode and / or the preventive maintenance style, the production and maintenance management must conform to this new philosophy which can be problematic if the maintenance department is not allowed to purchase the necessary equipment, provide adequate training to the people to learn the new techniques, are not given the time to collect the data, or are not permitted to shut down the machinery when problems are identified.

This philosophy utilizes all of the predictive / preventive maintenance techniques discussed above in concert with with root cause failure analysis to not only detect and pinpoint the precise problems that occur but to insure that advanced installation and repair techniques are performed including potential equipment redesign or modification to avoid or eliminate problems from occurring. Done correctly, studies have shown that the costs to operate in this fashion are about $6 per horsepower per year. The advantages of this approach is that it works extremely well if personnel have enough knowledge, skill, and time to perform all of the required activities. As in the predictive based program, repairs to equipment can be scheduled in an orderly fashion but then additional efforts are made to provide improvements to reduce or eliminate potential problems from repetitively occurring. Again, repairs to equipment can be scheduled in an orderly fashion and it allows lead time to purchase materials for the necessary repairs reducing the need for a high parts inventory. Since maintenance work is only performed when it is needed, and extra efforts are put forth to thoroughly investigate the cause of the failure and then determine ways to improve the reliability of the machinery, there can be a substantial increase in production capacity.

The disadvantages are that this requires extremely knowledgeable employees in preventive, predictive, and prevention/pro-active maintenance practices or to outsource this work to a knowledgeable contractor who works closely with the maintenance personnel in the root cause failure analysis phase and then assist in the repairs or design modifications. This also requires procurement of equipment and properly training personnel to perform these duties. If an organization had been running in the breakdown / run to failure mode and / or the preventive maintenance style, the production and maintenance management must conform to this new philosophy which again can be problematic if the maintenance department is not allowed to purchase the necessary equipment, provide adequate training to the people to learn the new techniques, are not given the time to collect the data, are not permitted to shut down the machinery when problems are identified, are not given the time and resources to conduct the failure analysis, and then do not modify the component or procedure to increase the reliability.

Effective problem identification and problem avoidance requires a rigorous investigation process. When a pump failure occurs, it is very tempting to remove the pump, replace the defective parts (or the entire pump), install the new or rebuilt unit, and get the unit back on line as quickly as possible. However if several checks are not made during the removal and disassembly process, important clues as to the cause of the problem will be overlooked. Below is a recommended checklist that should be done when any pump is removed from service to assist in identifying the source of the failure. In fact, it may not be a bad idea to preform many of these checks on an annual basis.

2. For mechanically flexible couplings (e.g. gear, metal ribbon, chain), is there grease or oil on the inside of the coupling guard and on the baseplate? If so, did it come from the coupling, the bearings on the motor or the pump, or someplace else?

4. Prior to disassembling the coupling, capture a set of shaft alignment measurements. It really does not matter what type of alignment method or tool is used to capture the measurements. What is the the amount of misalignment in mils per inch? Was the pump being subjected to run under a slight (0.1 to 2 mils/inch), moderate (2.1 to 10 mils/inch) or severe (10+ mils/inch) misalignment condition? Since a good Pro-Active maintenance program requires that you keep records of alignment on all the rotating machinery in your facility, compare the as found alignment to the last final alignment on the unit. Has the alignment shifted? If so, how much and what caused the shift? (easy question to ask, but usually quite difficult to answer).

6. Visually inspect the pump for any obvious problems such as loose foot bolts, loose pump casing bolts, cracked casing, low lubricant level, loose shim packs or missing shims, leaking mechanical seal, leaking oil seals, or discoloration in the shaft.

7. Determine if there is an excessive amount of shaft “freeplay”. This is fairly easy to do and can tell you if there are potential bearing problems in the pump or driver. Attach a fixture on the driver shaft, span across the coupling (engaged or disengaged) and place a dial indicator on the top of the pump shaft (or coupling hub) and zero the indicator. Lift the shaft from underneath and observe the dial indicator. If the pump shaft is supported in rolling element bearings, you should not see any more than 1 mil of movement (of course if you use too much force when lifting the shaft, it is quite possible to elastically flex the shaft giving you a false reading of the looseness of the assembly). If the pump is supported in sliding type bearings, the amount of shaft movement should be within the radial bearing clearance range.

9. Determine if there is an excessive amount of piping stress on the pump. There are several ways to determine this. One way is to attach a fixture on the driver shaft, span across the coupling (engaged or disengaged) and place a dial indicator on the top and one side of the pump shaft and zero the indicators. Loosen the pump base bolts one at a time observing the indicator as you loosen each bolt. If the pump shaft does not shift vertically or laterally more than 5 mils, there is probably not an excessive amount of piping stress on the pump. If the pump shifts more than that amount, you should seriously consider providing adequate piping supports on the suction and / or discharge piping to reduce or eliminate the stresses. If the movement is severe (i.e. 20+ mils either direction) you may have to cut and re-fit the piping. Sorry!

10. Disconnect the piping and check for excessive “soft foot” problems. Soft foot conditions can be detected fairly easily using magnetic bases and dial indicators placed near each tightened foot bolt and then successively loosening each bolt to see if the foot lifts up or drops away. If more than 2 mils of movement is observed at any foot, further investigation in warranted. The amount of lift (or drop) seen by the dial indicator is only an indication that a problem exists and is not necessarily an indication of how the soft foot should be corrected. Soft foot checks can also be made with just about any alignment measurement system by setting up the tooling on the shafts, zeroing the instruments in the 12 o’clock position, and loosening the foot bolts up one at a time, noting any changes that occur as each bolt is loosened. Again, the amount of lift (or drop) seen by the alignment measurement system is only an indication that a problem exists and is not necessarily an indication of how the soft foot should be corrected. Since many pumps are driven by motors and the personnel who install and align these system frequently call the motor as the movable machine in the alignment process, soft foot problems are often corrected on the motors but since the pump was named as the stationary machine, it is incorrectly assumed that it does not have a soft foot problem. Be aware that soft foot on pumps can be as severe as on any other piece of rotating machinery.

The above ten “pre-removal” steps can give you valuable information on the source of the problem with the pump you are about to overhaul or replace. A Pro-Active / Prevention based maintenance program requires that you thoroughly investigate each failure to determine the root cause of the problem. It also requires that steps be taken to prevent the problem from occurring again. Sometimes none of the steps above indicate a problem but frequently one or more than one of the checks can lead you to the source of the malady and provide you with valuable information to prevent the failure from occurring over and over. These may take some time to do, but it is always time well spent.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

.jpg)

Industrial plants, factories and vessels rely heavily on the reliability of their equipment and machinery; pumps being a core part of this. Downtime of a pump can costly in terms of loss of output and the cost of repairs. Imagine your pump plays a critical role in your production line; it is responsible for dosing a specific quantity of ingredient into a mix. If the pump unexpectedly fails, then the production of the mix comes to a halt. A pump failing on board a ship out at sea can have even worse implications, especially if it one required for the safety or operation of the vessel. Pump maintenance is therefore an integral operation within any plant to limit this costly downtime…

Maintenance is commonly split into two classifications; corrective and preventive maintenance. Corrective maintenance is essentially maintenance that is undertaken to cope with a pump failure that has already occurred. It has to be undertaken as quickly and efficiently as possible to get the installation up and running again with as little impact on operation as possible.

Relying on corrective maintenance however is an issue. It means that maintenance is only carried out once a problem has already arisen rather than preventing the problem from happening in the first place. To avoid downtime caused by unexpected problems with the pump, it is important to introduce a preventive maintenance schedule.

If you have a pump on site and you don’t already have a maintenance programme in place, then your first step should be to make someone responsible for this, maybe your inhouse engineer or operations team. Most pump engineers offer servicing contracts and can carry out any required maintenance then and there. However, it’s good practice to be able to inspect your pump yourself more regularly to catch any issues in between your services.

A pump maintenance programme would generally involve a periodic check of the pump performance, an inspection of the wearing parts and lubrication of bearings and joints. It is good practice to carry out a visual inspection of the pump installation on a daily basis. Spotting an issue early is one of the best methods of trouble shooting and preventing pump breakdown. Most of the things to look out for should be easily visible, these include:Leaks - Check the pump and pipework for any leaks that need to be dealt with, as they will result in reduced performance and loss of pump output as well as mess. Common leaking points are from the stuffing box or the mechanical seals. Mechanical seals are a wearing part and need to be routinely replaced.

Unusual noise -One of the first signs of a problem with your pump is noise. Like anything with a motor, a consistent hum when the pump is running is quite normal. However, abnormally loud noises or a clunking or crunching sound is likely to indicate an issue e.g. worn bearings. A popping sound, particularly if it is near the impeller, could mean the pump is experiencing cavitation which can cause a lot of damage.

Extreme vibration - A properly installed, well working pump should not overly vibrate, and therefore any level of vibration deemed excessive should be investigated. Common causes include impeller imbalance, damage and misalignment of the pump and motor.

Corrosion - Rusting, cracking or discoloration of the pump casing or pipework need to be acted on immediately as these are all signs of corrosion. Corrosion can not only result in pump failure through a weakening of the casing and components, but also contamination of the fluid being pumped.

Overheating - The pump, motor or bearings getting really hot is not something that should be ignored as it always indicates some form of problem. Some explanations may be internal rubbing/wearing of parts, that the wrong power has been put into the pump, the pump has been running against a dead head or that it has been running at a duty it cannot efficiently maintain.

Clogging - The presence of solids can result in the clogging of impellers or valves if the pump is not capable of handling the size of the solids that have attempted to pass through. You will usually notice clogging quite quickly as the pump will not be delivery the same quantities of fluid.

Whilst these are examples of typical daily checks, other checks however are required less regularly. One of the largest causes of pump downtime is pump owners not routinely replacing wearing parts and instead waiting for them to fail before changing them. It is recommended to replace certain components such as the mechanical seals and impellers every 1-2 years to prevent leaking and other issues. Best practice is to hold stock of typical wearing parts on site to prevent any delay in being able to maintain your pump if any components fail.

Just like the below, preventive pump maintenance should to be planned into a periodic maintenance schedule. By setting out when certain tasks should be carried out, maintenance becomes a smoother more efficient process and tasks don"t get "forgotten" about. Not only does it reduce the likelihood of unexpected pump failures and downtime, it also helps to reduce the cost of ownership as replacing wearing parts for example is a much cheaper process than replacing an entire pump.

The abrasiveness of the slurry wears on centrifugal pump components over time. The customer had to replace worn-out pumps every few months, and the replacements cost are over $30,000.

Fine MgO particles can stick together and harden, significantly reducing the diameter of the pipes or blocking them entirely. This affects the ability of a centrifugal pump to keep up the required flow.

The customer required relatively high pressure (over 100 psi) for their system to operate correctly, and their original pump—a Slurry duty centrifugal pump—couldn’t handle the service conditions without quickly wearing out. They approached John Brooks Company to consider an alternate pump option to notably increase runtimes while reducing costs.

The pump benefits from a constant targeted flow rate unaffected by process pressure changes because the customer can set the positive displacement pump’s speed. This differs from centrifugal pumps, which will move up and down the curve as pressures change.

The capability to tighten the stator in the Seepex SCT design when the customer notes a drop in efficiency significantly increases the stator life and acts as advance notice that they’ll need to replace parts soon (the customer can be proactive with maintenance and decrease downtime).

The Seepex SCT design also grants the ability to easily remove the top half of the stator to inspect the rotor and stator for signs of wear, eliminating the need to remove pipework and making maintenance simpler.

The SEEPEX pumps successfully achieved the customer’s goals of reducing maintenance downtime and costs between replacements and increasing the lifespan of their pumps: instead of replacing pumps every 3-4 months, the customer now had to do basic preventative maintenance every 9-12 months.

We worked out a “try and buy” plan with the customer to install the pump as a trial, and, based on a set of success criteria, they would either purchase or return it. Once the trial was complete, the client was happy to report that the Seepex pump notably outlasted their previous centrifugal pump by a factor of greater than 3:1, and, once it did wear out, the cost for mai

8613371530291

8613371530291