mud pump suction stabilizer in stock

The reciprocating pump’s cylinders pull its fluids from the suction manifold. When the suction manifold has trouble refilling with fluid, the cylinders will take in vapor and create a void in the cylinder. This is called cavitation, and it produces a very adverse reaction that is transferred into the fluids.

When you install a suction stabilizer off the suction manifold port, this gives the manifold extra capacity to pull fluid from and eliminates the manifold’s opportunity to lack fluids, thus eliminating cavitation.

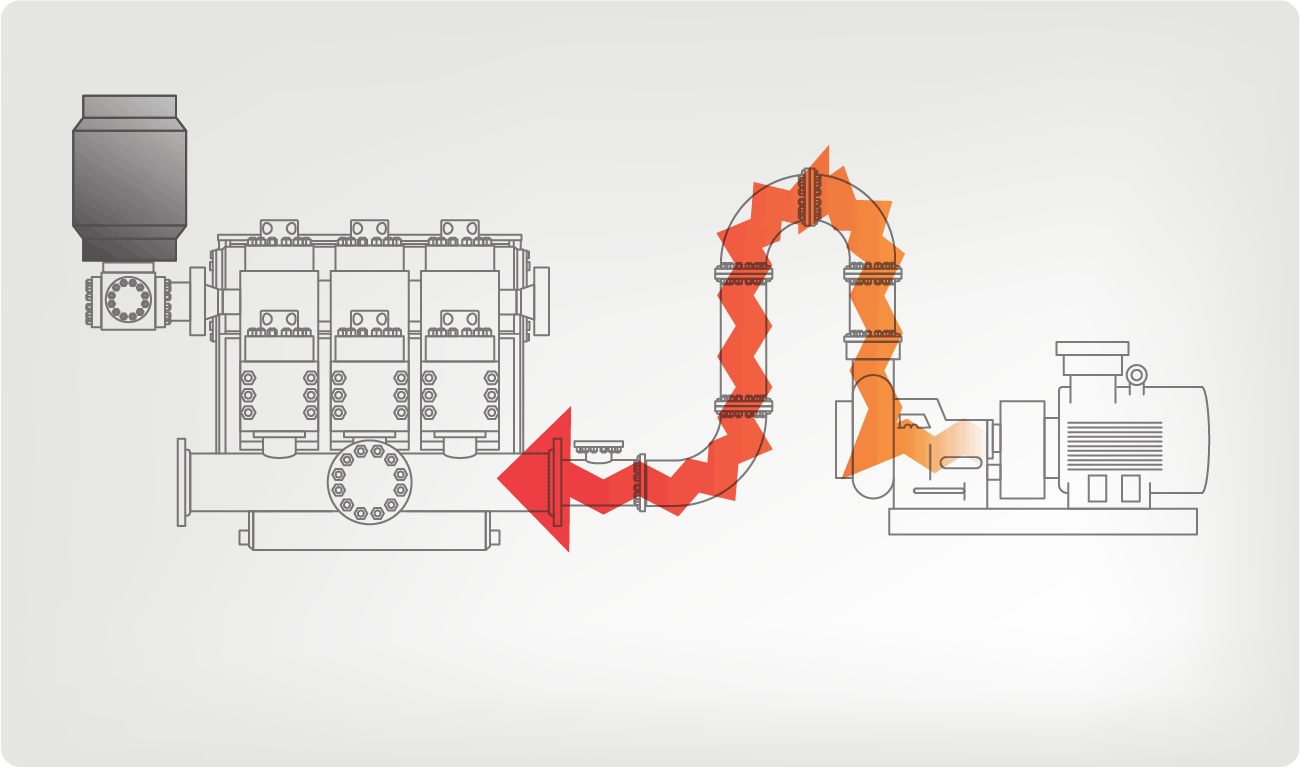

The second benefit the suction stabilizer offers is eliminating negative forces in the fluids produced by the pump’s valves opening and closing rapidly, creating a water hammer effect. The suction stabilizer’s compressible element is designed to absorb these energies and smooth out the fluid flow. This causes pump isolation or, in other words, the reciprocating pump is now isolated from the charge pump, and vice versa. The negative energies produced by the reciprocating pump never make it back to the charge pump, which extends the life of the pump expendables.

The Charge Free Dampening System™ combines the advanced technologies of Sigma’s Charge Free Dampeners™, Sigma’s Charge Free Conversion Kits®, Sigma’s Charge Free Stabilizer™, and Sigma’s Acoustic Assassin® to create the best available pulsation control solution. When it comes to performance and cost, Sigma’s Charge Free Dampening System™ will out perform more expensive dampeners while significantly reducing weight, size, and cost.

The Charge Free Stabilizer™ was designed to be installed directly before the suction manifold port between the mud pump and the charge pump. Maximizing mud pump performance by eliminating cavitation while isolating both the mud and charge pumps.

The Acoustic Assassin® was designed to be installed between the pump loop manifold and the production line. This fixture is a multi-chambered baffling system that will reduce damaging acoustic resonance generated by reciprocating pumps. The Acoustic Assassin® is an ideal addition to any pulsation control system.

The Charge Free Conversion Kit® is a high performance pulsation control kit that utilizes both compression and kinetic exchange for superior performance over traditional pulsation control methods of the past. With a gigantic increase in surface area, compression tuning, and a design to maximize energy exchange, the CFC Kits control pulsations from the pump while cleaning the signal for MWD tools.

Performance Pulsation Control is meeting the suction stabilizer needs of clients across the country. We can tailor a suction stabilizer and suction pulsation dampener to fit the specific output requirements of any commercial industry that relies on consistent and precise pump solutions. Some of the customization possibilities you’ll find for your business applications include:

Buy high-capacity pump suction stabilizer that are guaranteed to keep your appliances up and running in perfect condition from Alibaba.com. These pump suction stabilizer are offered from the best and most energy-efficient brands and provides users with an elevated experience. These pump suction stabilizer are designed to ensure safety and stability and are available in a number of variants.

pump suction stabilizer offered on Alibaba.com have many necessary and interesting features such as fail-safe circuit protection and cut-off points. These pump suction stabilizer have a high range and are likely to fit most home and commercial purposes. These pump suction stabilizer have finely crafted exteriors to ensure that there is no risk of shock or accidents. Some of these items even have LED displays for a smoother experience and greater transparency.

pump suction stabilizer are suitable for all sorts of large appliances and do not malfunction easily. They require very limited maintenance and not much has to be spent on their upkeep. pump suction stabilizer ensure that your expensive appliances and machines do not get damaged due to fluctuations and are inevitable for any home or commercial enterprise that engages multiple electronic items. pump suction stabilizer on the site offer optimal performance at economical prices.

Choose the pump suction stabilizer that best suit your needs, whether for home, office or industry. pump suction stabilizer suppliers are sure to want to snap up this attractive chance to buy quality items at discounted prices. Grab these amazing deals today.

Pulsation dampeners, also known as pulsation stabilizers, accumulators, arrestors and surge suppressors, are used to control and minimize the pulsations that result from a pressurized system’s pump stroking action. They increase system efficiency, performance, and pump life; decrease maintenance costs and down time; and protect pipes, meters, valves and instrumentation from pulsation, vibration, and hydraulic shock.

Most pulsation dampeners use a bladder, or bellows, to separate the process fluid from a compressible gas. During the pump’s discharge stroke, fluid pressure displaces the bladder or bellows and compresses the trapped gas. During the following cycle, the momentary interruption of fluid flow causes the compressed gas to expand, forcing the bladder or bellows to push the accumulated fluid back into the discharge line.

Generally, the majority of pump pulsation problems can be traced to and remedied on the suction side of a pump, even though some symptoms may show up on the discharge side In feeding the pump. It is extremely important to maintain a steady flow of fluid through the suction valves. Also, the fluid column must attach thoroughly to the face of the plunger to achieve complete cylinder fill on the suction stroke.

Determine the amount of fluid a pump will be moving, at what speed, and at what pressure. Indicators: Number of plungers, Bore, Stroke Length, RPM Suction & Discharge Pressure

The pulsation stabilizer opening should be the same size as the opening on the side of the pump on which it will operate. This will guard against unwanted acceleration or deceleration of fluid as it passes between the pump and stabilizer. Always defer to the next larger size should an exact match not be available.

Before installing any pulsation stabilizer or discharge dampener, be sure to consider the makeup of the overall system. Be aware of system characteristics that could effect a stabilizer decision, such as other pumps running in line, upstream/downstream pressure considerations, fluid composition and temperature, such as crude oil, salt water or drilling mud, or multiple pumps on a common header.

NOTE: The stabilizer opening should be the same size as the pump opening or larger. flanged and threaded Sizes are available from 1" to 8" - depending on the Series.

Pulsation problems often start on the suction side. Pulsation or cavitation is caused by the variation of fluid movement within a contained system. Since fluid is non-compressible, the energy produced by this pulsation or cavitation must be compensated for. With the introduction of pulsation equipment into a system this energy now has a place to expend itself. Without the pulsation equipment involved in your pumping system, the pulsation or cavitation that is present can lead to the following:

Since the NOV A1700-PT Triplex Mud Pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

NOV A1700-PT Triplex Mud Pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;They cost less to operate

One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

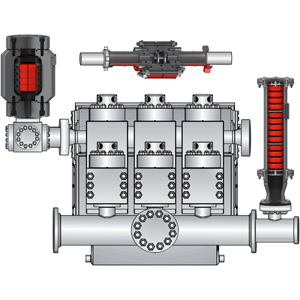

NOV A1700-PT Triplex Mud Pump is gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. NOV A1700-PT Triplex Mud Pump has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Single Acting Triplex pumps come with three cylinders and are commonly used for various applications requiring low to medium flow rates including mud pumping, cement pumping, salt water disposal, descaling, high pressure pumping, Frac pumping and pipeline systems for the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors. We have new, used and rebuilt API 674 triplex pumps of all leading manufacturers like Union, Gaso, Emsco, Apex and Wheatley.

Single Acting Triplex pumps come with three cylinders and are commonly used for various applications requiring low to medium flow rates including mud pumping, cement pumping, salt water disposal, descaling, high pressure pumping, Frac pumping and pipeline systems for the Oil & Gas, Agriculture, Mining, Municipal and Manufacturing sectors. We have new, used and rebuilt API 674 triplex pumps of all leading manufacturers like Union, Gaso, Emsco, Apex and Wheatley.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

Mouvex reciprocating triplex plunger pumps cover most applications in the oil and gas industry, both offshore and onshore, and in the petrochemical field, especially when high pressures are required. Other typical applications include those in the LPG and LNG field. Mouvex NL171 pumps are triplex plunger pumps designed according to API 674 norms.

Powerful, durable and lightweight, the GD-1600 is ideal for offshore applications, but features the versatility to be used in skid, or truck mounted configurations, even being staggered for a double pump unit within the road legal 102” limit. A patented connecting rod assembly allows for maximum thrust bearing area, and standard autofrettaged fluid end options provide exceptional fluid end life.

8613371530291

8613371530291