mud pump working animation quotation

The drilling industry has roots dating back to the Han Dynasty in China. Improvements in rig power and equipment design have allowed for many advances in the way crude oil and natural gas are extracted from the ground. Diesel/electric oil drilling rigs can now drill wells more than 4 miles in depth. Drilling fluid, also called drilling mud, is used to help transfer the dirt or drill cuttings from the action of the drilling bit back to the surface for disposal. Drill cuttings can vary in shape and size depending on the formation or design of the drill bit used in the process.

Watch the video below to see how the EDDY Pump outperforms traditional pumps when it comes to high solids and high viscosity materials commonly found on oil rigs.

The fluid is charged into high-pressure mud pumps which pump the drilling mud down the drill string and out through the bit nozzles cleaning the hole and lubricating the drill bit so the bit can cut efficiently through the formation. The bit is cooled by the fluid and moves up the space between the pipe and the hole which is called the annulus. The fluid imparts a thin, tough layer on the inside of the hole to protect against fluid loss which can cause differential sticking.

The fluid rises through the blowout preventers and down the flowline to the shale shakers. Shale shakers are equipped with fine screens that separate drill cutting particles as fine as 50-74 microns. Table salt is around 100 microns, so these are fine cuttings that are deposited into the half-round or cuttings catch tank. The drilling fluid is further cleaned with the hydro-cyclones and centrifuges and is pumped back to the mixing area of the mud tanks where the process repeats.

The drill cuttings contain a layer of drilling fluid on the surface of the cuttings. As the size of the drill cuttings gets smaller the surface area expands exponentially which can cause rheological property problems with the fluid. The fluid will dehydrate and may become too thick or viscous to pump so solids control and dilution are important to the entire drilling process.

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator that must move the contents of the waste bin or roll-off box. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Using the excavator method explained above, the unloading of 50 barrels of drill cuttings from the half round can take as long as two hours. This task is mostly performed by the solids control technicians. The prime duty for the solids control technicians is to maintain the solids control equipment in good working order. This involves maintenance for the equipment, screen monitoring and changing, centrifuge adjustments, and retort testing to prepare a daily operational summary of the solids control program.

Offshore drilling rigs follow a similar process in which the mud is loaded into empty drums and held on the oil platform. When a certain number of filled drums is met, the drums are then loaded onto barges or vessels which take the drilling mud to the shore to unload and dispose of.

Oil field drilling operations produce a tremendous volume of drill cuttings that need both removal and management. In most cases, the site managers also need to separate the cuttings from the drilling fluids so they can reuse the fluids. Storing the cuttings provides a free source of stable fill material for finished wells, while other companies choose to send them off to specialty landfills. Regardless of the final destination or use for the cuttings, drilling and dredging operations must have the right high solids slurry pumps to move them for transport, storage, or on-site processing. Exploring the differences in the various drilling fluids, cutting complications, and processing options will reveal why the EDDY Pump is the best fit for the job.

The Eddy Pump is designed to move slurry with solid content as high as 70-80 % depending on the material. This is an ideal application for pumping drill cuttings. Drill cuttings from the primary shakers are typically 50% solids and 50% liquids. The Eddy Pump moves these fluids efficiently and because of the large volute chamber and the design of the geometric rotor, there is very little wear on the pump, ensuring long life and greatly reduced maintenance cost for the lifetime of the pump.

plumbed to sweep the bottom of the collection tank and the pump is recessed into a sump allowing for a relatively clean tank when the solids are removed. The Eddy Pump is sized to load a roll-off box in 10-12 minutes. The benefit is cuttings handling is quicker, easier, safer, and allows for pre-planning loading where the labor of the solids control technician is not monopolized by loading cuttings. Here, in the below image, we’re loading 4 waste roll-off bins which will allow the safe removal of cuttings without fear of the half-round catch tank running over.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Options vary depending on whether the company plans to handle drill cuttings treatment on-site or transport the materials to a remote landfill or processing facility. If the plan is to deposit the cuttings in a landfill or a long-term storage container, it’s best to invest in a pump capable of depositing the material directly into transport vehicles. Most dredging operations rely on multiple expensive vacuum trucks, secondary pumps, and extra pieces of equipment.

Using an EDDY Pump will allow a project to eliminate the need for excavators/operators to load drill cuttings, substantially lowering both labor and heavy equipment costs. The EDDY Pump also allows a company to eliminate vacuum trucks once used for cleaning the mud system for displacing fluids. Since the pump transfers muds of all types at constant pressure and velocity throughout a system of practically any size, there’s little need for extra equipment for manual transfer or clean up on the dredge site.

The EDDY Pump can fill up a truck in only 10 minutes (compared to an hour) by using a mechanical means such as an excavator. For this reason, most companies can afford one piece of equipment that can replace half a dozen other units.

This application for the Eddy Pump has the potential to revolutionize the drilling industry. Moving the excavator out of the “back yard” (the area behind the rig from the living quarters) will make cuttings handling a breeze. Trucking can be easier scheduled during daylight hours saving on overtime and incidences of fatigued driving. Rig-site forklifts can move the roll-off boxes out of the staging area and into the pump loading area. The operator can save money on excavators rental, damages, and keep the technician operating the solids control equipment.

The EDDY Pump is ideal for drilling mud pump applications and can be connected directly onto the drilling rigs to pump the drilling mud at distances over a mile for disposal. This eliminates the need for costly vacuum trucks and also the manpower needed to mechanically move the drilling mud. The reasons why the EDDY Pump is capable of moving the drilling mud is due to the hydrodynamic principle that the pump creates, which is similar to the EDDY current of a tornado. This tornado motion allows for the higher viscosity and specific gravity pumping ability. This along with the large tolerance between the volute and the rotor allows for large objects like rock cuttings to pass through the pump without obstruction. The large tolerance of the EDDY Pump also enables the pump to last many times longer than centrifugal pumps without the need for extended downtime or replacement parts. The EDDY Pump is the lowest total life cycle pump on the market.

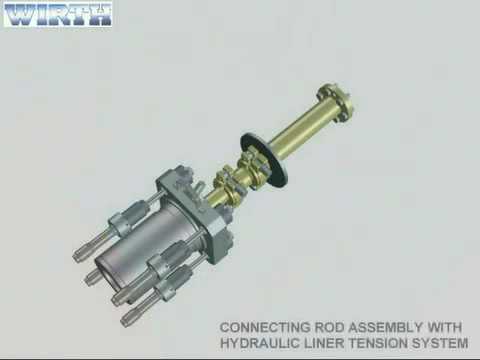

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Progressive cavity pumps, also known as PC pumps, progressing cavity pumps, eccentric screw pump and mono pumps are a type of rotary positive displacement pump designed for the conveying of liquids and sludges from 1cst to 1Million. They handle not only viscous fluids and solids but also gassing or multiphase liquids containing gas slugs typical during crude oil extraction.

The volume of liquid pumped is proportional to speed providing a linear predictable pumping rate across a range of pressures. This technology delivers one of the highest flow and pressures available from a positive displacement pump being up to 600M³H and 48bar, with efficiency ranging from 55% to 75%. This technology is most suited for fluids more viscous than 5cst.

The design consists of a motor at the drive end which is connected to a gearbox as pc pumps operate at low rpm compared to centrifugal pumps. The output shaft from the gearbox connects to a rotor via a universal pin joint which rotates a metallic rotor within a rubber stator. Stators contain cavities, and the rotor pushes fluids through the cavities in a slow rotating fashion.

A pumps pressure generating ability will depend on the number of cavities within the pump, with high pressure designs often consisting of more than one stator and rotor. Each rotor will typically produce 6 bar enabling pressures up to 48 bar to be achieved through its modular design.

This design of pump is better suited for viscous lubricating fluids, which can contain solids. Short stator life can be experienced with abrasive slurries at which point a peristaltic pump can be a preferred option. Eccentric Screw Pumps viscosity handing is unrivalled, and they are usually specified when there are no other suitable options.

Stator designs consist of two types - equal and non-equal walled. Equal walled stators ensure a lower starting and running torque, lower pulsations and reduced power consumption, high volumetric pumping efficiency, and lower replacement costs. Materials are usually types of rubber being NBR, FKM but not PTFE meaning solvents cannot be handled.

·Oil & Gas – Cutting Transfer, Drilling Mud transfer and recovery, Separator Feed, Crude Oil Transfer, MOL (Main Oil line Pump), Multiphase transfer and injection in remote areas.

Low shear -Ensures gentle handling of the most difficult to pump fluids such as resins, viscous foods, oil and water emulsions without change in consistency to the liquid. They are often use in oily water separators as the design ensures oil droplets remain intact and was rated by SPE (Society of Petroleum Engineers) in Paper SPE18204 as the preferred pump to use for oil droplets which were disturbed the least during handling and a comparison of lobe, vane and screw technology.

Reversible – Units are reversible with reduced output pressure as standard meaning hoses can be emptied, or if blockages are encountered pump can be reversed to assist with clearing. It also enable the pump to be versatile for situations such as tanker loading and offloading.

Wide fluid handling capabilities –Designs can handle viscous liquids, large solids, abrasive materials, fibrous solids and gas slugs without issue making it one of the most versatile pumps available. This design has Unparalleled Viscosity handling viscosities from 1cst to 1Million means there are no comparable pumping technologies.

High Accuracy –Due to flow being directly proportional to pump speed, and due to its cavity design, it enables flows to be very predictable enabling it to be used in metering and dosing applications

Hopper Pump –A pump is fitted with a hopper of various designs, designed for viscous liquids, materials containing high amounts of dry matter, large solids requiring breaking up and materials which plasticise

Multiphase Design -Baseplate mounted unit for multiphase boosting, with accessories allowing pump to handle viscous oil, gas slugs, sand and water, with automatic remote operation.

Bridge Breaker –For the breaking up of large solids within dehydrated sludge. Motorised paddles rotate within the hopper ensuring particles are broken into sizes which can be accommodated by the pump preventing blockages

Motorised wheel – Feeding of liquids with high dry solid content and materials which plasticize into the main pump. When materials such as liquid mortar, resins, mud, blocks of fat, or butter are pumped they can plasticise meaning they change shape rather than break up. To ensure they are fed into the rotor and stator, a motorised wheel ensures materials are broken up when other technologies may mean materials clog.

Liquid injection port –Typically used for the biogas sector, this unit has a separate injection port for accepting liquid manure which is combined with materials in the inlet containing high dry solids content (such as digestate, straw, corn, grass, rye, vegetable and food waste ) ensuring pumpability.

PC Pump curves are different to a centrifugal curve as it is linear demonstrating the units ability to handle liquids of varying viscosities with little impact on pump performance, with the bottom axis being speed rather than flow as flow is proportional to speed. Unit speed is much lower than centrifugal, operating from as little as 50rpm

Not suitable for solventsAll metal parts means solvents can be transferred, although some designs may have bearings within liquids and should be avoidedAll metal parts means solvents can be pumped.

The design of self-priming pumps reduces pump efficiency, due to the separation chamber within the pump head which works when fluid is retained within the pump head.

Slurry pumps are mainly used in industrials of mining, metallurgy, dredge, power, coal and other solid slurry transport. Mud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

The slurry pump is mainly used in the mining industry, its wear resistance is strong. So It conveys slurry that containing slag, but it can conveys mud. The mud pump is usually made of cast iron, the wear resistance of the pump is low. So the mud pumps often used for conveying mud or slurry containing suspended particles. When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

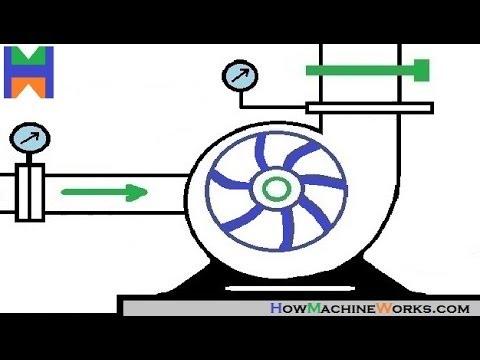

The mud pump is the motor driving the piston move through the link mechanism. Then causes the change of the volume of the sealed chamber of the mud pump. and the pressure difference between inside and outside of the pump change. Finally, the process of absorbing water and draining water is complete. When slurry pump working, which is the motor drives the impeller rotation. That is the impeller on the slurry work which increases the kinetic energy of the slurry. At the same time, the slurry flows to the edge of the impeller due to inertia and is discharged from the discharge pipe at a high speed.

The Mud pumps need to be equipped with auxiliary equipment, but slurry pumps not. They often need to use with high-pressure water pump when mud pump working. The high-pressure pump sent the water that larger than the mud pump pressure to the leakproof packing. Then protect the packing. Otherwise, it is easy to make the seal part wear. But the wear-resistant slurry pumps can complete the transportation work independently, which not need to equip other auxiliary equipment.

In a word, the wear-resistant properties of the slurry pumps are stronger, and the ability to convey particles is also stronger. Generally, the capacity of the slurry pump is larger than the mud pump, which is mainly used for coal and metal ore washing. The mud pumps are more suitable for abrasive slurry is not very strong.

1. The two types of pumps are all centrifugal pumps in the working principle. They are machines that increase the energy of solid and liquid mixtures by means of centrifugal force (the rotation of the impeller of the pump). A device that converts electrical energy into kinetic and potential energy of a medium.

Mud Pump Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump.

Mud Pump Pulsation Dampener is a pneumatic device built into the outflow line of each UUD pump to dampen the pressure fluctuations resulting from the action of the pump. Although presented as a surge tank, this device is really a device that can be tuned to greatly diminish the output pulsations transmitted downstream from the mud pump. Unfortunately, the effectiveness of the pulsation dampener is a function of both output pump pressure and frequency of the pump pulsations.

8613371530291

8613371530291