mud pump working animation for sale

This animation was done for a sales presentation highlighting every single function of o.r Triplex Mud Pump. Originally I was going to include text and information into the original animation but the requester decided that he wanted to explain all the functions himself

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features Power End The power pump shell is the structure of steel plate welding and has been tested with its intensity by authority. The crankshaft is a composed structure of straight shaft and eccentric wheel. Its airproof part of elastic ripple tube has been awarded a patent certificate by the state. The...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

Product Features ● Its compact structure, lighter weight, and small size with high efficiency can be matched with kinds of pump devices according to drilling rig`s requirement and different conditions. ●Its durable and compact structure can ensure the smooth operation of pump, and meet the specific requirements of...

AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCabo VerdeCambodiaCameroonCanadaCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos IslandsColombiaComorosCongoCongo, Democratic Republic of theCook IslandsCosta RicaCroatiaCubaCuraçaoCyprusCzechiaCôte d"IvoireDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEswatiniEthiopiaFalkland IslandsFaroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly SeeHondurasHong KongHungaryIcelandIndiaIndonesiaIranIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People"s Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People"s Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorth MacedoniaNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRomaniaRussian FederationRwandaRéunionSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint MartinSaint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint MaartenSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSurinameSvalbard and Jan MayenSwedenSwitzerlandSyria Arab RepublicTaiwanTajikistanTanzania, the United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkmenistanTurks and Caicos IslandsTuvaluTürkiyeUS Minor Outlying IslandsUgandaUkraineUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVenezuelaViet NamVirgin Islands, BritishVirgin Islands, U.S.Wallis and FutunaWestern SaharaYemenZambiaZimbabweÅland Islands

Our team of animators and SMEs has spent hours studying equipment and well control concepts to create industry leading animations for all of our online drilling and well servicing courses. Every concept in every course is illustrated through a custom created graphic or animation.

Bullheading, Reverse Circulation, Lubricate and Bleed Method, Bringing Pump Online with constant BHP, Successful Flow Check, Adjustable Choke being fully closed, Trapped Pressure at Choke, BOP Control System, Choke Backpressure, Opening Choke Balances BHP And FP, Choke Manifold, Oil Blowout, Formation Pressure Gradient, U-Tube Effect, Slug Causing U-Tube Effect, Lost Circulation, Fluid Level Dropping, Lost Circulation Causing A Kick, Gas Kick, Sustained Gas Kick, Gas Migration After Shut In, Mudgas Separator, Surging, Surging Effect, Fast Swabbing, End of the Volumetric Stripping process, Opening Choke To Reduce Pressure, Increase In Choke Backpressure, Drillers_Method_1st_Circulation, Drillers_Method_2nd_Circulation, Wait and Weight Method, Volumetric Stripping Pressure Decrease Portion, Volumetric Stripping Pressure Increase Portion, Gas Pumped Into Accumulator Bottle, 3D To 2DView Of Accumulator Bottle, Liquid Pumped Into Accumulator Bottle, Single Accumulator Bottle 3D Panning, Mud Level Rising And Decreasing, Mud Level Rising, Mudtank360, Volumetric Method Animation, Choke Backpressure, Slug causing Utube Effect

Drill Bit, Drill Bit Nozzles, Drill Collar, Drill Pipe, Drill String In Drilling, Rock Cuttings, Rock Cuttings With Mud, Mud Pump, Mud Transfer From Trip Tank To Strip Tank, Pump Manifold, Mud Pushed Down, Mud Circulating System, Flow Paddle, Shale Shaker, Degasser, Standpipe Manifold, Adjustable Choke, Oil Kick In Circulating Well, Oil Kick In Static Well, Sustained Oil Kick, Friction Losses During Circulation, Annular Friction Loss With Choke Back Pressure, Shut-In, Annular Preventer, Pipe Ram Preventer, Blind Ram Preventer, Blind Shear Ram Preventer, Blind Ram Accidentally Closing On Pipe, Tripping Out Without Trip Tank, Tripping Out With Trip Tank, Tripping In With Trip Tank, Swabbing, Drilling Stopped And Bit Off Bottom, Circulation Stopped, Well Flowing During Flow Check While Tripping Out, Well Not Flowing During Flow Check While Tripping Out, 2D Well Flowing During Flow Check While Tripping Out, Sustained Flow Check End, Fluid Through HCR Valve With Annular Preventer Closed, Fluid Through HCR Valve With Annular Preventer Opened, Animation Of Mud Pressure Shown Using Pump And Gauge, Animation Of Mud Pressure Shown Using Pump And Gauge While Drilling, Depth Of Drilling, Desander360, Desilter360, Driling Spool, Leak Off Test Pumps Being Started, ROP Decrease Animation, ROP Increase Animation, Triptank Level Increase, Paddle Inset

Flow By Passing Diverter, Heave Of The Drill Ship Only, Drill Bit, Drill Collar, Drill Pipe, Drill String In Drilling, Mud Pushed Down, Mud Pushed Up, Oil Blowout, AFL In Annulus Plus Riser, AFL In Choke Line, U Tube Effect, Lost Circulation, Fluid Level Dropping, Lost Circulation Causing A Kick, Gas Kick, Sustained Gas Kick, Gas Migration After Shut In, Shut In Full, Annular Preventer, Pipe Ram Preventer, Blind Ram Preventer, Blind Shear Ram Preventer, Pipe Ram Preventer Without Inset, Tripping Out With Trip Tank, Tripping In With Trip Tank, Tripping Out Without Trip Tank, Swabbing, Surging, Gas Flow Due To Improper Casing, Drilling Stopped And Bit Off Bottom, Well Flowing During Flow Check, Well Not Flowing During Flow Check, HCR Valve, Side Outlet Valves, Increase In Choke Backpressure, Driller"s Method, Wait and Weight Method, Hydrates, Driller"s Panel 3D Panning, Fluid Circulated To Surface Through Riser Animation, HPU Unit & Solenoid Valve, ROV Operation, Gas Circulation Through Choke Line, Subsea System Panning, Subsea Water Depth, Sweeping Subsea Stack, Heave and Kick Detection, Roll and Kick Detection, Pitch and Kick Detection, Gas In The Riser Concept And Danger, Removal Of Gas In The Riser, BOP Control System

Coiled Tubing Shear Process, Coiled Tubing Mud Circulation, Coiled Tubing Deployment, Reel Winding, Tubing and Levelwind, Injection Bend Cycle, Ejection Bend Cycle, Shear Ram, Pipe Ram, Blind Ram, Coiled Tubing Travelling From Service Reel To Injector Head, Ovality, Injector Head Chains, Tubing Shear Process

Wireline Operation, Wireline Lowered into well, Wireline Being Pulled Out Of The Well, Wireline Blind Ram Pipe Ram, Wireline Blind Ram Pipe Ram, Grease being pumped into the greasehead, Lubricator Testing, Panning downwards over lubricator, Stuffing Box Internal View, Stuffing Box Tightening, Wireline Blind Ram and Shear Ram closed in succession, Wireline lowered through Stuffing Box, Wireline run into the well, Wireline Shut In With Inset

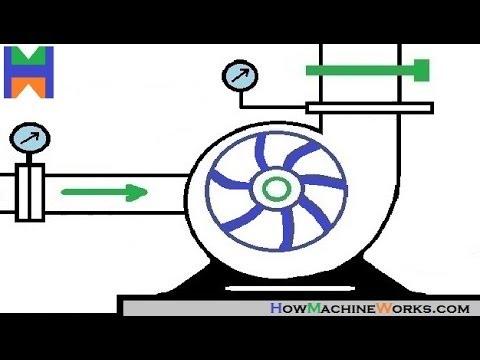

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Progressive cavity pumps, also known as PC pumps, progressing cavity pumps, eccentric screw pump and mono pumps are a type of rotary positive displacement pump designed for the conveying of liquids and sludges from 1cst to 1Million. They handle not only viscous fluids and solids but also gassing or multiphase liquids containing gas slugs typical during crude oil extraction.

The volume of liquid pumped is proportional to speed providing a linear predictable pumping rate across a range of pressures. This technology delivers one of the highest flow and pressures available from a positive displacement pump being up to 600M³H and 48bar, with efficiency ranging from 55% to 75%. This technology is most suited for fluids more viscous than 5cst.

The design consists of a motor at the drive end which is connected to a gearbox as pc pumps operate at low rpm compared to centrifugal pumps. The output shaft from the gearbox connects to a rotor via a universal pin joint which rotates a metallic rotor within a rubber stator. Stators contain cavities, and the rotor pushes fluids through the cavities in a slow rotating fashion.

A pumps pressure generating ability will depend on the number of cavities within the pump, with high pressure designs often consisting of more than one stator and rotor. Each rotor will typically produce 6 bar enabling pressures up to 48 bar to be achieved through its modular design.

This design of pump is better suited for viscous lubricating fluids, which can contain solids. Short stator life can be experienced with abrasive slurries at which point a peristaltic pump can be a preferred option. Eccentric Screw Pumps viscosity handing is unrivalled, and they are usually specified when there are no other suitable options.

Stator designs consist of two types - equal and non-equal walled. Equal walled stators ensure a lower starting and running torque, lower pulsations and reduced power consumption, high volumetric pumping efficiency, and lower replacement costs. Materials are usually types of rubber being NBR, FKM but not PTFE meaning solvents cannot be handled.

·Oil & Gas – Cutting Transfer, Drilling Mud transfer and recovery, Separator Feed, Crude Oil Transfer, MOL (Main Oil line Pump), Multiphase transfer and injection in remote areas.

Low shear -Ensures gentle handling of the most difficult to pump fluids such as resins, viscous foods, oil and water emulsions without change in consistency to the liquid. They are often use in oily water separators as the design ensures oil droplets remain intact and was rated by SPE (Society of Petroleum Engineers) in Paper SPE18204 as the preferred pump to use for oil droplets which were disturbed the least during handling and a comparison of lobe, vane and screw technology.

Reversible – Units are reversible with reduced output pressure as standard meaning hoses can be emptied, or if blockages are encountered pump can be reversed to assist with clearing. It also enable the pump to be versatile for situations such as tanker loading and offloading.

Wide fluid handling capabilities –Designs can handle viscous liquids, large solids, abrasive materials, fibrous solids and gas slugs without issue making it one of the most versatile pumps available. This design has Unparalleled Viscosity handling viscosities from 1cst to 1Million means there are no comparable pumping technologies.

High Accuracy –Due to flow being directly proportional to pump speed, and due to its cavity design, it enables flows to be very predictable enabling it to be used in metering and dosing applications

Hopper Pump –A pump is fitted with a hopper of various designs, designed for viscous liquids, materials containing high amounts of dry matter, large solids requiring breaking up and materials which plasticise

Multiphase Design -Baseplate mounted unit for multiphase boosting, with accessories allowing pump to handle viscous oil, gas slugs, sand and water, with automatic remote operation.

Bridge Breaker –For the breaking up of large solids within dehydrated sludge. Motorised paddles rotate within the hopper ensuring particles are broken into sizes which can be accommodated by the pump preventing blockages

Motorised wheel – Feeding of liquids with high dry solid content and materials which plasticize into the main pump. When materials such as liquid mortar, resins, mud, blocks of fat, or butter are pumped they can plasticise meaning they change shape rather than break up. To ensure they are fed into the rotor and stator, a motorised wheel ensures materials are broken up when other technologies may mean materials clog.

Liquid injection port –Typically used for the biogas sector, this unit has a separate injection port for accepting liquid manure which is combined with materials in the inlet containing high dry solids content (such as digestate, straw, corn, grass, rye, vegetable and food waste ) ensuring pumpability.

PC Pump curves are different to a centrifugal curve as it is linear demonstrating the units ability to handle liquids of varying viscosities with little impact on pump performance, with the bottom axis being speed rather than flow as flow is proportional to speed. Unit speed is much lower than centrifugal, operating from as little as 50rpm

Not suitable for solventsAll metal parts means solvents can be transferred, although some designs may have bearings within liquids and should be avoidedAll metal parts means solvents can be pumped.

8613371530291

8613371530291