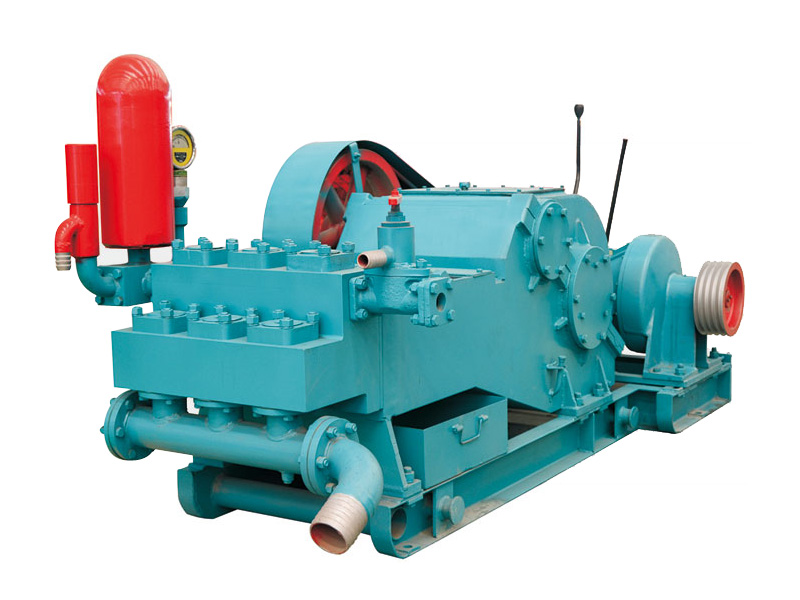

triplex mud pump design made in china

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

Manufactured by Long Shine Plant, F-1300 and F-1600 mud pumps can meet the requirements of the same manufacturing technique and quality level as those of F series mud pumps .They feature advanced structural design, reliable use, easy maintenance and compact occupied area. To reduce drilling workers" labor intensity and make the operation easy on site, liners are designed to be fitted into the frame from the frame top. A mini hoist with 500Kg lifting capacity is mounted on the frame for disassembling and changing liners.

Suction inlets of F-1300 and F-1600 mud pumps are fitted with 12"flanges, F-1300 and F-1600 mud pumps are fitted with API#7 valve pots. The suction valve and the discharge valve are interchangeable. Cylinders are made of forged alloy steel and nickel plated to improve their corrosion resistance. Three cylinders of each pump are interchangeable. Valve-over-valve (through type cylinder) design reduces the cylinder volume and promote the volumetric efficiency.

Notes: Cylinders, liners, pistons, valve and seats, valve springs, seal rings, valve covers and cylinder covers at the fluid end of F-1300 and F-1600 mud pumps are all interchangeable.

We have been focusing on producing triplex single-action mud pump and its accessories since we built our company. So far, we can offer two series products that are respectively the F-series and 3NB-series. Our F-series drilling pumps including models of RLF-500, RLF-800, RLF-1000, RLF-1300, RLF-1600 and RLF-2200 are designed and manufactured strictly in accordance with the API 7K specification (Certificate No.: 7K-0130) based on the American Emsco F-series drilling pump. Our products of the 3NB-series cover models of 3NB-350, 3NB-500, 3NB-600, 3NB-800, 3NB-1000A/D, 3NB-1300A/D and 3NB-1600. They are designed and produced following the standard formulated by Ministry of Petroleum Industry of China and can meet the needs of different customers.

Our F-series triplex mud pumps are designed and manufactured based on the American Emsco F-series mud pump strictly in accordance with API 7K specification. All of the expendable parts are interchangeable with any other similar spare parts produced according to API specification.

The optimized design helps to improve the suction performance of our products and extend the service life of the expendable parts. Triplex mud pumps of the RL3NB series are produced and tested strictly in accordance with the SY5138 standard formulated by Ministry of Petroleum Industry of China.

Customized Mud PumpWe can design and manufacture customized pump used for mud drilling according to customer"s requirement. We provide not only the mud pump itself, but also the power system and transmission system to make a pump package. After being assembled on the well site, the pump package is ready to work.

Since all the expendable parts are compatible with other similar parts made in accordance with the API specification, F-series mud pumps are easy to maintain all over the world.

Due to compact solid structure and small size, the F-series products have excellent performance to meet the drilling technological requirements of high pumping pressure and high displacement. Designed with longer stroke for lower working stroke rate, these products have fine water filling performance and buffering performance in suction pipelines. Meanwhile, the service life of the expendable parts in the fluid end will be extended as well. The power end of this series product is durable since its lubricating system combines forced lubrication and splash lubrication together.

Because of limited parts supply, the 3NB-series mud pumps mainly sell domestically. In resent years, due to cheaper price, they become more and more popular in oversea countries, especially in Kazakhstan and Russia.

We can also design mud pump package mainly composed of the power system, transmission system and the pump itself, according to customer’s environment. Other facilities like filling system, manifolds and control system are also available. Diesel engine driving and electric motor (DC/AC variable frequency motor) driving are optional. As to transmission mode, we provide gear reducer, hydraulic coupler and hydraulic torque converter for your selection. After being assembled on the well site, the pump package will go into operation.

Our F-series triplex mud pumps are designed and manufactured based on the American Emsco F-series mud pump strictly in accordance with API 7K specification. All of the expendable parts are interchangeable with any other similar spare parts produced according to API specification.

The optimized design helps to improve the suction performance of our products and extend the service life of the expendable parts. Triplex mud pumps of the RL3NB series are produced and tested strictly in accordance with the SY5138 standard formulated by Ministry of Petroleum Industry of China.

Customized Mud PumpWe can design and manufacture customized pump used for mud drilling according to customer"s requirement. We provide not only the mud pump itself, but also the power system and transmission system to make a pump package. After being assembled on the well site, the pump package is ready to work.

With advanced technology, relentless pursuit for innovation and dedicated engineers, we have become the professional Filter for Discharge Manifold, Hydraulic Valve Lifter Puller, Mud Pump Needle Valve manufacturer with a full range of products line. We aspirate to do cooperate with all different manufacturers, then create a beautiful future! Desire to collect requests of your stuff and produce the long-term co-operation partnership. The rapid and steady development of our company is inseparable from our excellent partners.

Triplex Mud Pumps is one of the most important equipments in the drilling operation which discharge high viscosity,heavy density and low sand contented fluid to well bottom in order to cool drill bit,flush well ,crush the rock and take out debris.

Mud pump is designed and manufactured in compliance with API Speck 7K"Specification for Drilling Equipment".All wearing parts of fluid end(valve,valve seat,liner and ect) can be interchanged acc to API specification.F-500F-800F-1000F-1300FB-1300F1600

All of our China 4 Inch Duplex And Triplex Mud Drilling Pump For Sale are independently researched and acquired by our unique technology to make sure that they can be upgraded and updated constantly. Through modern management philosophy, all our employees can display their creative enthusiasm, and push the company to a continuous and rapid development track. Our existence is to pursue a harmonious atmosphere of mutual help, mutual encouragement and common progress, to help employees continuously improve their quality, and to work together to build a better business.

1. Usage and Application Range SB series Centrifugal Sand Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipment work efficiently. The SB10×8×14...

SB Series Centrifugal Sand Pump 1. Application Range SB series Centrifugal Sand Pump mainly supplies to solids control circulating system of oilfield drill rig,and be used to provide drilling liquid with a certain discharge capacity and pressure to sand, desilter and mud mixer,to assure these equipment work...

Carbon/Stainless Steel Triplex 2250HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 4”,4.5”,5”,5.5”,6” Load Weight: 3,350LB Approx. Size: 36”x19”x23”(LXWXH)

Carbon/Stainless Steel Quintuplex 1000HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 2,500LB Approx. Size: 46”x12”x20”(LXWXH) We manufacture and provide Fracturing Pump Fluid Ends. Our high pressure pump fluid ends mainly cover...

Carbon/ Stainless Steel Triplex 600HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 1,550LB Approx. Size: 28”x12”x19”(LXWXH) We manufacture and provide Fracturing Pump Fluid Ends. Our high pressure pump fluid ends mainly cover...

Carbon/Stainless Steel Quintuplex2700HHP Basic Parameters: Stroke: 10” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 5,500LB Approx. Size: 59”x24”x26”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Y block Quintuplex 2800HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 3.75”,4”,4.5”,5” Load Weight: 6,300LB Approx. Size: 63”x20”x24”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Carbon/Stainless Steel Quintuplex 2500HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 4”,4.5”,5”,5.5”,6”, 6.5” Load Weight: 4,800LB Approx. Size: 52”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the...

Carbon/Stainless Steel Triplex 2250HHP Basic Parameters: Stroke: 8” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 4”,4.5”,5”,5.5”,6” Load Weight: 3,350LB Approx. Size: 36”x19”x23”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing job....

Carbon/Stainless Steel Quintuplex 1000HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 5 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 2,500LB Approx. Size: 46”x12”x20”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Carbon/ Stainless Steel Triplex 600HHP Basic Parameters: Stroke: 6” Material: Carbon Steel/Stainless Steel Plunger No.: 3 Plunger size: 2.75”,3”,3.5”,4”,4.5” Load Weight: 1,550LB Approx. Size: 28”x12”x19”(LXWXH) We provide and manufacture high pressure triplex/ quintuplex plunger pump fluid ends for the fracturing...

Sub-surface sucker rod pump Sub-surface sucker rod pump is one of main equipment in oil production. The pumps are made through advanced surface nickel and phosphate plating, carbonitriding and carbonnitroboriding featured in corrosion resistance, wear resistance, reliability, durability, and high efficiency. In 2011,...

Trailer Concrete Pump LV-HB-20S Product Advantages: One machine with multi-purpose, it can transport mortar/fine stone concrete and spray mortar/fine stone concrete. It is small but flexible. It is mostly used for exterior wall spraying, slope protection spraying, etc. Technical Specification Maximum vertical...

Trailer Concrete Pump LV-HB-50S Product advantages: Hydraulic control equipment. One-key switch between high and low pressure, one-key return piston. Ultra-stable performance, no need for proximity switches. External junction box, wiring is more convenient. The speed is adjustable, 5-50m3 can be adjusted arbitrarily....

Trailer Concrete Pump LV-HB-45S Product advantages: Hydraulic control equipment. One-key switch between high and low pressure, one-key return piston. Ultra-stable performance, no need for proximity switches. External junction box, wiring is more convenient. The speed is adjustable, 4-45m3 can be adjusted arbitrarily....

Mud Pump Spare Parts We can offer the mud pump spare parts covers the liners, valves and seats, pistons etc to match the most types of mud pumps in the market, like Emsco, Gardner Denver, National, Oil well, Continental, Ideco, and China 3NB etc Brand Model Emsco F-350 F-500 F-650 F-800 F-1000

Mud Pump Spare Parts We can offer the mud pump spare parts covers the liners, valves and seats, pistons etc to match the most types of mud pumps in the market, like Emsco, Gardner Denver, National, Oil well, Continental, Ideco, and China 3NB etc Brand Model Emsco F-350 F-500 F-650 F-800 F-1000

Trailer Concrete Pump LV-HB-40S Product advantages: One-piece stamping hopper, no material accumulation. Electric double lubrication, no distributor, point-to-point lubrication. Panel operation and wireless remote control dual control. Super air cooling, no water cooling required. Technical Specification

Triplex plunger-type mud pumps feature a reciprocating, positive displacement pump design utilizing three plungers to safely transfer high-viscosity fluids under high pressure over an extended depth. Although they have many industrial applications, these pumps have become an essential part of oil well drilling rigs where they’re used to provide smooth discharge of mud and debris from oil wells.

In addition to their use in drilling and well service operations, mud pumps are also frequently used to handle corrosive or abrasive fluids, as well as slurries containing relatively large particulates, in applications like commercial car washes, wastewater treatment, cementing, and desalination operations.

DAC Worldwide’s Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations.

For example, mud pump assembly is used on well sites maintain downhole backpressure, to lubricate the rotating drill bit, and to help recycle and remove rock debris resulting from drilling activities. These heavy-duty, high-pressure pumps require regular refurbishment, inspection, and repair in the field.

DAC Worldwide’s dissectible mud pump assembly is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job. DAC Worldwide chooses popular name-brand pumps for its dissectibles to ensure industrial and oil and gas training relevancy.

Using the dissectible mud pump, learners will gain hands-on experience with the operating principles, regular maintenance activities, and nomenclature/parts identification at a more convenient scale in the classroom or lab.

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Representative Triplex, Plunger Mud Pump Dissectible features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Representative Triplex, Plunger Mud Pump Dissectible is a sturdy unit with a complete triplex, reciprocating, 20+ bhp plunger pump with .75" plunger, 1.5" stroke, and 3" cylinder sleeve. The unit allows for complete disassembly, assembly, and inspection, including removal of plungers, packing, and valves.

The dissectible mud pump comes with a formed-steel, powder-coated baseplate. It can also be mounted on a compatible DAC Worldwide Extended Electromechanical Workstation (903). Each unit comes with the manufacturer’s installation and maintenance manual.

Schäfer Pumpen & Hydraulik heavy-duty triplex mud pumps are built for continuous operation for boring fluids operating at pressures of up to 530 bar and with maximum pumping rates of 230 m³/h.

With high volumetric efficiency and superlative running smoothness, these pumps are extremely low maintenance – and thanks to their rigid construction, they are lightweight and easily transportable.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

We are a large drilling tools, Drilling rig spares, Water well drilling and mining pump part, Drilling mud pumps and Fluid End Expendables and mud pump spare parts manufacturer in China.

We make all fluid end modules, Ceramic liners, Hy-chrome liners, rubber replaceable and bonded urethane pistons and all spares for popular brand mud pumps.

8613371530291

8613371530291