what pressure do you set pop off on mud pump factory

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

In any cases if you don’t know/ clearly understand how to do it don’t do it, ask your supervisor. Do not start or later on , stop the job if you feel to do so .

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

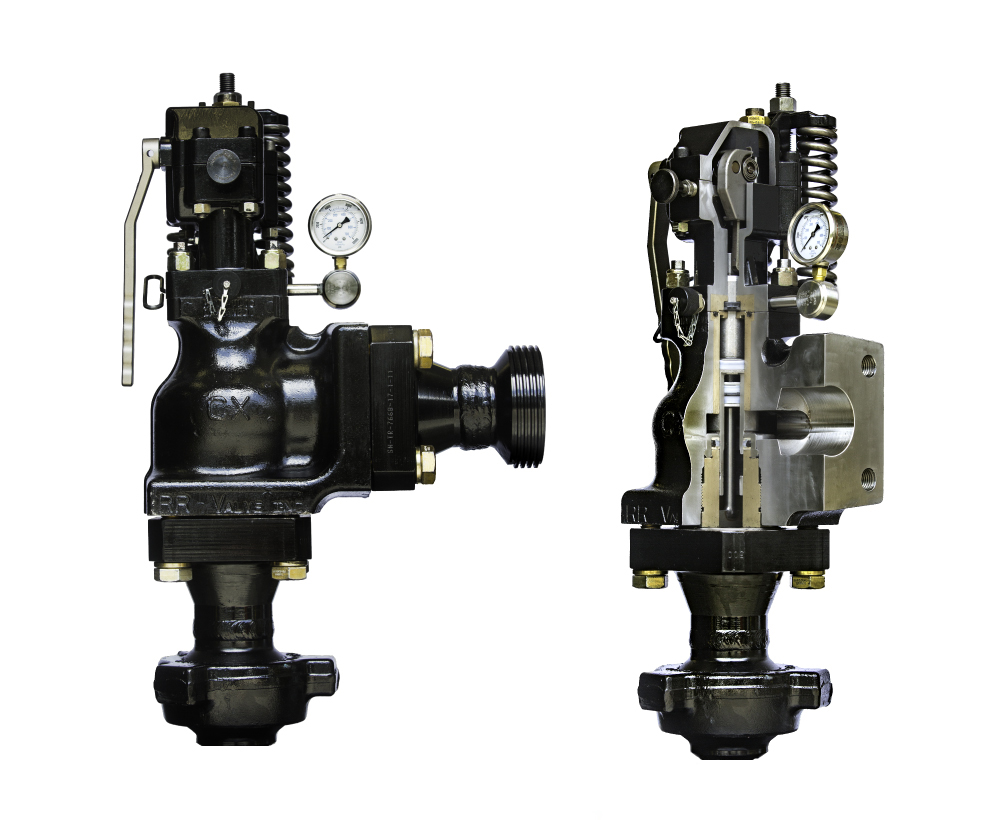

With a low pressure setting, ie, 1000psi, by adjusting the top nylon self lock nut to move on the vertical scale to get the same setting than the scale.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

1.1 OBJECTIVE.A key objective of ADC Procedures is to set up a step by step way of handling thejob. It is also an analysis of associated hazards pertaining to the jobs and measures tominimize the risks.This procedure has developed to be applied and discussed before each job listed inthe contents.1.2 SCOPE.This procedure applies to Rig AD-321.3 RESPONSIBILITY.It is the responsibility of the Tool-pusher and Rig Manager to insure all listedoperations are executed in a safe and efficient manner. It is their responsibility toconduct a Pre-job Safety Meeting and discuss and review the related JSA, prior tostarting each operation.Tool-pusher is responsible to ensure that each work permit has its dedicated JSAattached to.JSA to be reviewed and updated at least annually or When equipment is modified When processes are changed When material are changed When changing people/contractors When there is an accident or near miss.The Rig Sup. is accountable for keeping this document up-to date.The JSA date and the crew should be same as Work Permit date and crew.

Table of ContentsTASK ANALYSISIs Procedure relevant for the operation?What can interfere with the operation (Simops)?Who is going to be in charge, position?Who is giving instructions/signals, who replace him?How many people are required to do the job?-

Do you need a PTW/ Isolation (lockout, Tag out)?What is the PPE required?What tools/equipment do you need?Do you need a third party, crane, and forklift?Who else needs to know what you are doing?Do you need to barrier off the area?What are the safest access/escape routes?-

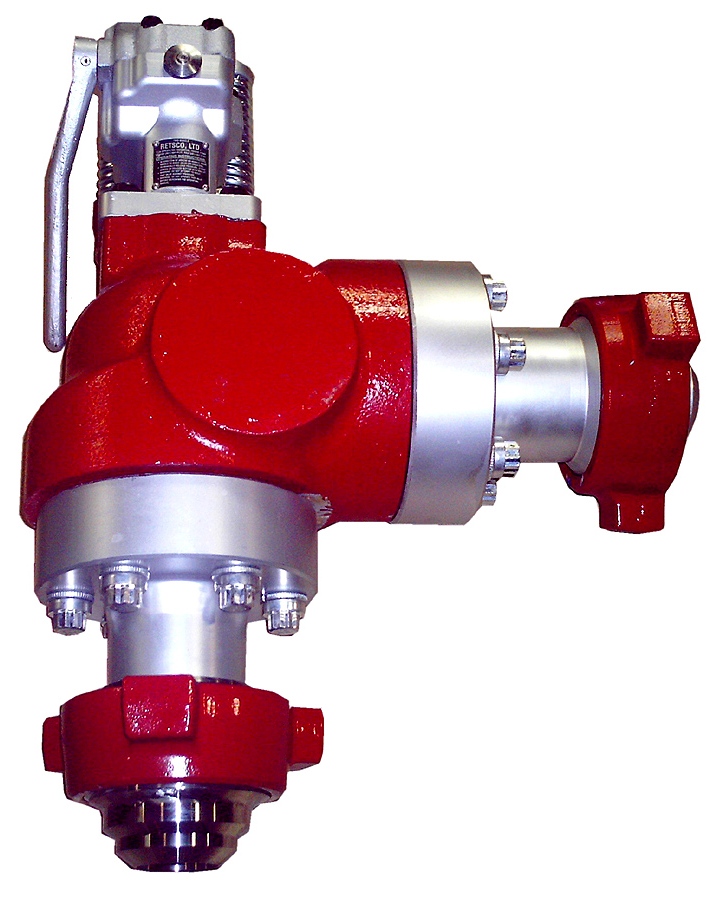

Pressure relief valves are installed on mud pumps in order to prevent an overpressurewhich could result in a serious damage of the pump and serious or fatal injury topersonnel.The discharge pressure is routed to the closer mud tank, via a 2 line minimum clamped allthe way along. Mud is flowing into the mud tank until 0 pressure in the line.Read carefully manufacturer instructions regarding setting, handling, refurbishing of suchequipment.In any cases if you dont know/ understand how to do it dont do it, ask your supervisor.1) Pressure relief valves are set usually to 90% of the maximum working pressure ofthe liners in use. Read carefully manufacturer chart for pressure setting versus sizeof liners.2) The most commonly used pressure relief valve is RETSCO, 500 and 750, whichstands for mud pumps maximum working pressure 5000psi and mud pumps7500psi.3) Prior to installing a pressure relief valve it needs to be tested on a bench.

nut to move on the vertical scale. If the pop off pressure matches the setting, then screw to the pressurerequired on the mud pump (check liner chart) and test again.

When the pressure test has been successful, put a tag on the pressure relief valve, whereit is mentioned:-The date of the test.-The pressure of the test.-If the pressure relief valve was reconditioned.Store it properly away from dust and adverse weather.

1) When/if the pressure relief valve activates due to: I_Bop kept closed and pump started. Build up pressure close to the maximum preset pressure.The pressure relief valve can be reset, if not damaged during the release of pressure.The Pressure relief valves are usually installed on a upper point of the discharge side ofthe mud pumps.Special care should be taken if no working platform available to access the PRV.A safety harness may be necessary in some places.1) Pull round button toward you.2) Pull handle towards you to reset / reposition the knuckle joint inside.3) The handle should have a hard point then come freely.4) If you cannot exert enough force due to position a 1 ID pipe can beused to pull the handle. DO NOT FORCE on the handle if nothingmoves, that means that the discharge piston inside is jammed.

7) Replace PRV by the one ready tested in the store.8) Restore the power on the mud pump.9) Start the pump slowly; check on the discharge pipe above the mudtanks if there are no leaks.10)If everything ok, close work permit, recondition worn pressure reliefvalve, with original parts, pressure test it and store it with a tag asmentioned earlier.

If you run a mud rig, you have probably figured out that the mud pump is the heart of the rig. Without it, drilling stops. Keeping your pump in good shape is key to productivity. There are some tricks I have learned over the years to keeping a pump running well.

First, you need a baseline to know how well your pump is doing. When it’s freshly rebuilt, it will be at the top efficiency. An easy way to establish this efficiency is to pump through an orifice at a known rate with a known fluid. When I rig up, I hook my water truck to my pump and pump through my mixing hopper at idle. My hopper has a ½-inch nozzle in it, so at idle I see about 80 psi on the pump when it’s fresh. Since I’m pumping clear water at a known rate, I do this on every job.

As time goes on and I drill more hole, and the pump wears, I start seeing a decrease in my initial pressure — 75, then 70, then 65, etc. This tells me I better order parts. Funny thing is, I don’t usually notice it when drilling. After all, I am running it a lot faster, and it’s hard to tell the difference in a few gallons a minute until it really goes south. This method has saved me quite a bit on parts over the years. When the swabs wear they start to leak. This bypass pushes mud around the swab, against the liners, greatly accelerating wear. By changing the swab at the first sign of bypass, I am able to get at least three sets of swabs before I have to change liners. This saves money.

Before I figured this out, I would sometimes have to run swabs to complete failure. (I was just a hand then, so it wasn’t my rig.) When I tore the pump down to put in swabs, lo-and-behold, the liners were cut so badly that they had to be changed too. That is false economy. Clean mud helps too. A desander will pay for itself in pump parts quicker than you think, and make a better hole to boot. Pump rods and packing last longer if they are washed and lubricated. In the oilfield, we use a petroleum-based lube, but that it not a good idea in the water well business. I generally use water and dish soap. Sometimes it tends to foam too much, so I add a few tablets of an over the counter, anti-gas product, like Di-Gel or Gas-Ex, to cut the foaming.

Maintenance on the gear end of your pump is important, too. Maintenance is WAY cheaper than repair. The first, and most important, thing is clean oil. On a duplex pump, there is a packing gland called an oil-stop on the gear end of the rod. This is often overlooked because the pump pumps just as well with a bad oil-stop. But as soon as the fluid end packing starts leaking, it pumps mud and abrasive sand into the gear end. This is a recipe for disaster. Eventually, all gear ends start knocking. The driller should notice this, and start planning. A lot of times, a driller will change the oil and go to a higher viscosity oil, thinking this will help cushion the knock. Wrong. Most smaller duplex pumps are splash lubricated. Thicker oil does not splash as well, and actually starves the bearings of lubrication and accelerates wear. I use 85W90 in my pumps. A thicker 90W140 weight wears them out a lot quicker. You can improve the “climbing” ability of the oil with an additive, like Lucas, if you want. That seems to help.

Outside the pump, but still an important part of the system, is the pop-off, or pressure relief valve. When you plug the bit, or your brother-in-law closes the discharge valve on a running pump, something has to give. Without a good, tested pop-off, the part that fails will be hard to fix, expensive and probably hurt somebody. Pop-off valve are easily overlooked. If you pump cement through your rig pump, it should be a standard part of the cleanup procedure. Remove the shear pin and wash through the valve. In the old days, these valves were made to use a common nail as the shear pin, but now nails come in so many grades that they are no longer a reliable tool. Rated shear pins are available for this. In no case should you ever run an Allen wrench! They are hardened steel and will hurt somebody or destroy your pump.

One last thing that helps pump maintenance is a good pulsation dampener. It should be close to the pump discharge, properly sized and drained after every job. Bet you never thought of that one. If your pump discharge goes straight to the standpipe, when you finish the job your standpipe is still full of fluid. Eventually the pulsation dampener will water-log and become useless. This is hard on the gear end of the pump. Open a valve that drains it at the end of every job. It’ll make your pump run smoother and longer.

Rig pump output, normally in volume per stroke, of mud pumps on the rig is one of important figures that we really need to know because we will use pump out put figures to calculate many parameters such as bottom up strokes, wash out depth, tracking drilling fluid, etc. In this post, you will learn how to calculate pump out put for triplex pump and duplex pump in bothOilfield and Metric Unit.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.)

Priority date (The priority date is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the date listed.)

F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

Method and device for preventing a primary relief valve (12) in a mud system (1) from opening at a pressure lower than a nominal opening pressure, and where the mud system (1) includes a mud pump (2), wherein the method includes: - installing an flow restrictor (16) between the mud pump (2) and the primary relief valve (12); and -providing a cavity (20) between the flow restrictor (16) and the primary relief valve (12).

There is provided a method for preventing a primary mud re¬ lief valve from incorrect opening. More precisely there is provided method for preventing a primary relief valve in a mud system from incorrect opening, where the mud system includes a mud pump.

Mud systems, as known from drilling rigs, normally include a mud pump, a pulsation dampener and a relief valve, the latter herein termed "primary relief valve". The main pump is typi¬ cally a triplex pump. This kind of pump delivers a flow rate which is far from constant but fluctuates much because of i) variable piston speed - the pump is crank shaft driven, ii) mud compressibility and iii) valve and fluid inertia. The pulsation dampener is therefore included to smoothen the flow rate and mitigate the resulting pressure fluctuations. The primary relief valve may be of a design known as a "pop-off valve" in the industry, or a rupture disk. Other types of re¬ lief valves are also known.

The primary relief valve is a safety valve that is designed to prevent excessive pressure and possible hazards in the case the pump pressure exceed the certified pressure limit for the system. Normally the so-called trip pressure, at

which the primary relief valve shall switch from a closed to an open state, is set slightly higher that the system pres¬ sure of typically 5000 psi (345 bar) .

It is a well-known problem in the industry that the primary relief valve sometimes trips frequently even though the rec¬ orded pressure levels never reached the nominal trip pressure level .

Tripping of a primary relief valve represents a costly and highly undesired disruption of the drilling process, both because of the time it takes to refit a new rupture disk or to reset a resettable primary relief valve and because the well can be damaged during long periods of no circulation. To lower the risk for primary relief valve tripping one can therefore reduce maximum working pressure to say 80 per cent of the system pressure limit. This is also a costly solution be¬ cause flow rate and pressure is often a limiting factor that can lead to slower drilling and even cause well stability problems. The opposite solution of increasing the nominal trip pressure to compensate for the dynamic effect is also a highly undesirable solution that may lead to damage in other parts of the mud system. It may even be illegal to raise the nominal relief valve pressure to more than a few per cent over the certified system pressure.

According to a first aspect of the invention there is provid¬ ed a method for preventing a primary relief valve in a mud system from opening at a pressure lower than a nominal open-

A field study of above stated problem has revealed that the reason for the tripping of the primary relief valve at a pressure lower than the nominal opening pressure, most likely is relatively large pressure fluctuations in a pop-off line. Despite of the damping action of a pulsation dampener, there are substantial residual pressure fluctuation present in a discharge pipe between the pump and the dampener. The pop-off line itself represents a hydraulic resonator that can signif¬ icantly amplify these residual fluctuations at frequencies close to resonance frequencies. This explanation is supported by special pressure measurements just below the primary re¬ lief valve showing that the peak dynamic pressure can some¬ times exceed 115 per cent of the mean pressure.

These pressure fluctuations can lead to undesired primary re¬ lief valve trips, both because the peak pressure are really higher than seen on the standard pressure sensors, and be¬ cause they can lead to fatigue and lowering of the real trip pressure. This fatigue effect is especially relevant if the primary relief valve is a rupture disk.

It has thus been found that the opening of the primary relief valve is related to pressure variation at higher frequencies, typically in the region of 40Hz. Pressure fluctuations at this frequency has been measured to be up to 40 bars. Such fluctuations are superimposed on the mean pressure and are believed to cause the tripping of the primary relief valve at a pressure lower than the nominal opening pressure.

The high frequency pressure fluctuation components appear to be generated by the mud pumps and are related to the pump valve action. Both mud compressibility and pump valve inertia tend to cause sudden changes in the pump flow rate when the pump discharge valves open and closes. The changes give rise to a pressure pulse that is enhanced at frequencies close to the resonance frequencies of the closed primary relief valve line .

By installing a flow restriction between the mud pump and the primary relief valve in combination with a cavity positioned between the flow restriction and the primary relief valve, these higher frequency pressure fluctuations are dampened. The pressure acting on the primary relief valve is then the mean operating pressure of the mud system. The relation between the size of the flow restrictor and the cavity volume should be calculated according to known principles, or it should be found experimentally by testing different

The flow restrictor may be in the form of a tubing having a diameter much smaller than the so called characteristic di¬ mension of the cavity, say smaller than the cubic root of said cavity, and a length much longer than the diameter of the flow restriction.

Said flow restrictor may be in the form of an opening in a plate where the opening has a diameter much smaller than the characteristic dimension of the cavity.

The method may include placing a second relief valve in par¬ allel with the flow restrictor, preferably with a lower nominal trip pressure than the primary relief valve.

This second relief valve will normally only experience the dynamic pressure difference as it receives the mud pump pres¬ sure on one side and the smoothed pressure at the cavity on the other side.

According to a second aspect of the invention there is pro¬ vided device for preventing a primary relief valve in a mud system from opening at a pressure lower than a nominal opening pressure and where the mud system includes a mud pump, wherein a flow restrictor is positioned between the mud pump and the primary relief valve, and where a cavity is provided between the flow restrictor and the primary relief valve.

In a practical embodiment of the invention, the primary re¬ lief valve, the flow restriction, the second relief valve and the cavity may be produced as one unit that is fairly compact and suitable for installation in a mud system.

The method and device according to the invention render it possible to overcome the long felt problem of incorrect open¬ ing of the primary relief valve of a mud system.

On the drawings the reference number 1 denotes a part of a mud system that includes a mud pump 2 that draws mud from a mud reservoir 4 and discharge the mud via a discharge pipe 6 into a so-called stand pipe 8. A pulsation dampener 10 is connected to the discharge pipe 6. A primary relief valve 12 is connected to the discharge pipe 6 via a so-called pop-off line 14. In this exemplary embodiment, the primary relief valve 12 is a pop-off valve. However, in other embodiments, the primary relief valve 12 may be a rupture disk or another suitable valve.

According to the present invention a flow restriction 16 is provided between the mud pump 2 and the primary relief valve 12, or more precisely between the discharge pipe 6 and the primary relief valve 12.

A second relief valve 18, which may be of a type similar to the primary relief valve 12, is positioned in parallel with the flow restriction 16. A cavity 20 is closed off in the pop-off line 14 between the primary relief valve 12 and the second relief valve 18. The cavity 20 communicates with the discharge pipe 6 through the flow restriction 16.

As stated in the general part of the description, the cavity 20 in relation to the size of the flow restriction 16 should be determined according to well known principles in order to dampen the dynamic frequency pressure at the actual frequen¬ cies .

This done, as the mud pump 2 operates, the high frequency pressure fluctuation components are dampened in the flow re¬ striction 16/cavity 20 dampener system. Thus, the primary relief valve 12 only experiences the average pressure present in the cavity 20.

The second relief valve 18 has the pressure from the mud pump 2 acting on the side facing the discharge pipe 6, while the average pressure is acting on the side of the second relief valve 18 facing the cavity 20. The resultant pressure across the second relief valve 18 equals the dynamic pressure fluc¬ tuations in the discharge line 6, normally with zero mean.

Then, as the flow through the flow restriction 16 is minute compared to that of the primary relief valve 12, the pressure over the second relief valve 18 will equal the full pressure from the mud pump 2. The second relief valve 18 will then al¬ so open if the high average pressure is still present. To en¬ sure tripping of the second relief valve 18, its trip pres¬ sure may preferably be slightly lower than the trip pressure of the primary relief valve 12.

In an alternative embodiment, see fig. 2, the pressure sens¬ ing component of the second relief valve 18 is a rupture disk 22. A flow restriction 16 is incorporated in the rupture disk

22, see fig. 3. Aside from the second relief valve 18 being a rupture disk in this embodiment, rather than a pop-off valve, mud system 1 and its functioning are as previously described.

1. Method for preventing a primary relief valve (12) in a mud system (1) from opening at a pressure substantially lower that a nominal opening pressure, where the mud sys¬ tem (1) includes a mud pump (2) , c h a r a c t e r i z e d i n that the method includes:

i n that said restrictor (16) constitutes a tubing hav¬ ing a diameter much smaller than a characteristic dimension of said cavity (20) and a length much longer than the flow restrictor" s (16) diameter.

i n that said restrictor (16) constitutes an opening in a plate, where the openings diameter much smaller than a characteristic dimension of said cavity (20) .

5. A device for preventing a primary relief valve (12) in a mud system (1) from opening at a pressure lower than a nominal opening pressure and where the mud system (1) in¬ cludes a mud pump (2), c h a r a c t e r i z e d b y that a flow restrictor (16) is positioned between the mud pump (2) and the primary relief valve (12), and that a cavity (20) is provided between the flow restrictor (16) and the primary relief valve (12) . Device according to claim 5, c h a r a c t e r i z e d i n that a second relief valve (18) is placed in paral¬ lel with the flow resistor (16) .

Mud pump is one of the most critical equipment on the rig; therefore personnel on the rig must have good understanding about it. We’ve tried to find the good training about it but it is very difficult to find until we’ve seen this VDO training and it is a fantastic VDO training about the basic of mud pumps used in the oilfield. Total length of this VDO is about thirteen minutes and it is worth to watch it. You will learn about it so quickly. Additionally, we also add the full detailed transcripts which will acceleate the learning curve of learners.

Powerful mud pumps pick up mud from the suction tank and circulate the mud down hole, out the bit and back to the surface. Although rigs usually have two mud pumps and sometimes three or four, normally they use only one at a time. The others are mainly used as backup just in case one fails. Sometimes however the rig crew may compound the pumps, that is, they may use three or four pumps at the same time to move large volumes of mud when required.

Rigs use one of two types of mud pumps, Triplex pumps or Duplex pumps. Triplex pumps have three pistons that move back-and-forth in liners. Duplex pumps have two pistons move back and forth in liners.

Triplex pumps have many advantages they weight 30% less than a duplex of equal horsepower or kilowatts. The lighter weight parts are easier to handle and therefore easier to maintain. The other advantages include;

• One of the more important advantages of triplex over duplex pumps, is that they can move large volumes of mud at the higher pressure is required for modern deep hole drilling.

Triplex pumps are gradually phasing out duplex units. In a triplex pump, the pistons discharge mud only when they move forward in the liner. Then, when they moved back they draw in mud on the same side of the piston. Because of this, they are also called “single acting.” Single acting triplex pumps, pump mud at a relatively high speeds. Input horsepower ranges from 220 to 2200 or 164 to 1641 kW. Large pumps can pump over 1100 gallons per minute, over 4000 L per minute. Some big pumps have a maximum rated pressure of over 7000 psi over 50,000 kPa with 5 inch/127 mm liners.

Here is a schematic of a triplex pump. It has three pistons each moving in its own liner. It also has three intake valves and three discharge valves. It also has a pulsation dampener in the discharge line.

Look at the piston at left, it has just completed pushing mud out of the liner through the open discharge valve. The piston is at its maximum point of forward travel. The other two pistons are at other positions in their travel and are also pumping mud. But for now, concentrate on the left one to understand how the pump works. The left piston has completed its backstroke drawing in mud through the open intake valve. As the piston moved back it instead of the intake valve off its seat and drew mud in. A strong spring holds the discharge above closed. The left piston has moved forward pushing mud through the now open discharge valve. A strong spring holds the intake valve closed. They left piston has completed its forward stroke they form the length of the liner completely discharging the mud from it. All three pistons work together to keep a continuous flow of mud coming into and out of the pump.

Crewmembers can change the liners and pistons. Not only can they replace worn out ones, they can also install different sizes. Generally they use large liners and pistons when the pump needs to move large volumes of mud at relatively low pressure. They use a small liners and pistons when the pump needs to move smaller volumes of mud at a relatively high pressure.

In a duplex pump, pistons discharge mud on one side of the piston and at the same time, take in mud on the other side. Notice the top piston and the liner. As the piston moves forward, it discharges mud on one side as it draws in mud on the other then as it moves back, it discharges mud on the other side and draws in mud on the side it at had earlier discharge it. Duplex pumps are therefore double acting.

Double acting pumps move more mud on a single stroke than a triplex. However, because of they are double acting they have a seal around the piston rod. This seal keeps them from moving as fast as a triplex. Input horsepower ranges from 190 to 1790 hp or from 142 to 1335 kW. The largest pumps maximum rated working pressure is about 5000 psi, almost 35,000 kPa with 6 inch/152 mm linings.

A mud pump has a fluid end, our end and intake and the discharge valves. The fluid end of the pump contains the pistons with liners which take in or discharge the fluid or mud. The pump pistons draw in mud through the intake valves and push mud out through the discharge valves.

The power end houses the large crankshaft and gear assembly that moves the piston assemblies on the fluid end. Pumps are powered by a pump motor. Large modern diesel/electric rigs use powerful electric motors to drive the pump. Mechanical rigs use chain drives or power bands (belts) from the rig’s engines and compounds to drive the pump.

A pulsation dampener connected to the pump’s discharge line smooths out surges created by the pistons as they discharge mud. This is a standard bladder type dampener. The bladder and the dampener body, separates pressurized nitrogen gas above from mud below. The bladder is made from synthetic rubber and is flexible. When mud discharge pressure presses against the bottom of the bladder, nitrogen pressure above the bladder resists it. This resistance smoothes out the surges of mud leaving the pump.

Here is the latest type of pulsation dampener, it does not have a bladder. It is a sphere about 4 feet or 1.2 m in diameter. It is built into the mud pump’s discharge line. The large chamber is form of mud. It has no moving parts so it does not need maintenance. The mud in the large volume sphere, absorbs this surges of mud leaving the pump.

A suction dampener smooths out the flow of mud entering into the pump. Crewmembers mount it on the triplex mud pump’s suction line. Inside the steel chamber is a air charged rubber bladder or diaphragm. The crew charges of the bladder about 10 to 15 psi/50 to 100 kPa. The suction dampener absorbs surges in the mud pump’s suction line caused by the fast-moving pump pistons. The pistons, constantly starts and stops the mud’s flow through the pump. At the other end of the charging line a suction pumps sends a smooth flow of mud to the pump’s intake. When the smooth flow meets the surging flow, the impact is absorbed by the dampener.

Workers always install a discharge pressure relief valve. They install it on the pump’s discharge side in or near the discharge line. If for some reason too much pressure builds up in the discharge line, perhaps the drill bit or annulus gets plugged, the relief valve opens. That opened above protects the mud pump and system damage from over pressure.

Some rig owners install a suction line relief valve. They install it on top of the suction line near the suction dampener. They mount it on top so that it won’t clog up with mud when the system is shut down. A suction relief valve protects the charging pump and the suction line dampener. A suction relief valve usually has a 2 inch or 50 mm seat opening. The installer normally adjusts it to 70 psi or 500 kPa relieving pressure. If both the suction and the discharged valves failed on the same side of the pump, high back flow or a pressure surge would occur. The high backflow could damage the charging pump or the suction line dampener. The discharge line is a high-pressure line through which the pump moves mud. From the discharge line, the mud goes through the stand pipe and rotary hose to the drill string equipment.

The pressure setting is limited by two things: the horsepower available and the lowest pressure rating of any given component. This means that the lowest rated component is the highest rating of the system.

There are several factors that determine which components to use on a pressure washer. In choosing an unloader you must consider the intended purpose, operating conditions, and additional accessories. Doing so will help ensure that the unloader will last and give you the intended results.

A basic pressure washer system consists of a drive, pump, regulator/unloader, hose, gun, wand, and a nozzle. The motor and pump convert horsepower to water flow to be delivered to the nozzle. Ultimately, the pressure in the system is created at the nozzle as water is forced through the orifice, which is controlled by the unloader. The unloader regulates pressure by either sending water to the nozzle or to bypass, depending on the setting of the unloader. The unloader acts like a traffic cop for the system by reacting to the system pressure and directing flow either toward or away from the nozzle. The more water through the nozzle, or the smaller the orifice, the more pressure you get. Conversely, less water through the nozzle or a larger orifice yields lower pressure. When the trigger gun is shut off the traffic cop puts up barricades and directs the flow through the detour we call bypass. Just like drivers on the road, the water circulating in bypass heats up if it is left there too long.

If the spring tension on the unloader is set low, pump pressure will be low because water is bypassing the nozzle. Increasing spring tension on the unloader will direct the flow to the nozzle and increase the operating pressure until there is no more flow to go to the nozzle. Can you guess what happens as the nozzle wears? A worn nozzle has an oversized orifice, so pressure will drop. What do you think happens if you adjust the unloader to a higher pressure setting with a worn nozzle? Remember that the unloader directs flow and that all of the flow was already going to the nozzle. In this case the operating pressure won’t increase but the amount of pressure it takes for the unloader to unload (traffic cop to put up the barricade) will.

To illustrate this idea: a low pressure setting is similar to everyone wearing roller skates, which can change direction very easily. As you increase the pressure setting the vehicles change from roller skates to bicycles to compact cars to buses to semi-trucks to freight trains. Imagine how hard it would be to stop or redirect a freight train compared to a compact car. This is the concept of pressure spike.A spike of pressure occurs when the unloader shifts modes (changes the direction of the water) from spraying to bypass. The spike pressure increases with the unloader setting until it becomes so great that damage begins to occur in the system—broken hoses, blown valve caps, leaking unloaders and so on. The spike pressure increases with the size of the ‘vehicle.’ The pipeline is the same and the flow is the same but the roller skates have become freight trains.

A proper unloader setting allows a small amount of continuous bypass (approximately 5% of total flow) to minimize the pressure spike and compensate for nozzle wear. As the nozzle wears, the 5% bypass will be redirected from bypass to the nozzle, allowing for a longer operational period before pressure begins to drop. As soon as a pressure drop is noticed the nozzle should be replaced. Once an unloader is set it should never have to be adjusted again unless there are modifications done to the system. There are two main types of unloaders used on pressure washing equipment—pressure trapping and flow-actuated. Pressure trapping unloaders react only to pressure in the system and give you instant pressure when you open the trigger gun. Flow-actuated unloaders react to both flow and pressure and give you a gradual build in pressure, sometimes referred to as a ‘soft start.’

Speaking in terms of intended use (application), a pressure trapping unloader is most appropriate when you are working on very durable surfaces, i.e. metal, concrete, brick, and asphalt. The sudden burst of pressure is less likely to damage these surfaces, but beware if you are working on a ladder as you could lose your balance. The flow-actuated style is appropriate for more delicate surfaces such as glass, wood, limestone, asphalt, plastic and so on. Also the soft start is better for working in precarious locations. The pressure builds gradually (over about one second) so you have a better chance to maintain your balance. Follow OSHA guidelines when working in elevated situations.

Operating conditions affect the unloader because water quality, temperature, and time in bypass effect life and reliability. The conditions affect both types of unloaders equally, inasmuch as poor water quality and extended bypass will wear them both out. Note that, on average, a pressure-trapping unloader is about one quarter the cost of a flow actuated to repair or replace. Another consideration is that the pressure-trapping unloader is more forgiving as it wears out. It will usually continue to operate to some degree even as it is near complete failure. Flow-actuated unloaders are slightly more finicky and may cease to function if they wear too much out of tolerance.

Finally, additional accessories such as more discharge hose, injectors, speed controllers, burners, telescoping wands and certain types of nozzles affect the unloaders differently. Pressure trapping unloaders respond to the pressure in the system. Additional accessories increase the apparent pressure and a pressure-trapping unloader will just bypass more water to regulate pressure. With a flow-actuated unloader, changes to the system can affect the operation of the unloader. Any line restriction downstream of the unloader will change the flow-actuated unloader’s operating characteristics.

Flow-actuated unloaders tend to be easier on the system overall. Pressure-trapping unloaders offer a little more reliability over flow-actuated, but once the system is set up correctly a flow-actuated unloader is as reliable, if not more so, than a pressure trapping.

Look at the ZK7 series unloaders and the Pulsar3 unloaders. Both are excellent in design and operation and will provide you years of use if properly installed and maintained.

This stainless steel pop-off valve is designed as a secondary pressure relief and should be used with a primary pressure regulating valve. It is set approx 200 PSI above the primary valve and will only go into by-pass should the primary valve fail.

This article series describes how to repair a water pressure control switch that sticks on, off, or chatters or is otherwise not working properly, causing loss of water pressure or irregular in cycling on and off.

We discuss how to diagnose problems with the water pump control and how to fix them by correcting an underlying problem, by replacing a bad pressure control switch, or by replacing switch parts such as bad contacts or diaphragm.

This article explains inspecting, cleaning, and possibly repairing a typical Water Pump Pressure Control Switch or other controls or problems when a water pump or well pump won"t start or won"t run.

For most well water or water pressure boosting systems, a pump pressure control switch, usually found close to the water pressure tank, senses the water pressure and when necessary, turns the water pump on.

a submersible water pump is in use), this switch may operate a physically separate (usually wall-mounted) heavier-duty pump relay which turns on the water pump itself.

If water pressure shown on the water pressure gauge falls below the pressure switch CUT-IN pressure and the pump won"t turn ON there could be several causes and fixes that we will describe in this article.

Then turn on water in the building and watch for a pressure drop at the pressure gauge - as pressure falls below the control switch CUT-IN setting, the water pump should turn on.

Watch out: it is possible to use a DMM or VOM or a simple voltage tester to confirm that electrical power is being delivered to the pump relay or control switch.

But if you are not trained in basic electrical work and testing you could be shocked or killed - it"s best to leave that step to a licensed electrician.

The voltage tester we show here is one of the more-safe instruments as you do not need to actually touch an electrical wire or contact to confirm that it is carrying current.

In our water pressure gauge photo at left we show a pressure of about 17 psi. Since this is below our water pump cut-in pressure which was set to a little over 20 psi, the pump should have cut on. Something was wrong.

If the water tank pressure gauge reads a low number, say below the pump"s cut-in pressure, try tapping the gauge gently to see if the indicator needle moves.

In that case, run some water in the building, watch the gauge pressure fall to below the pump"s cut-in pressure, and then we should hear the pump turn on.

you won"t hear it running, but you can hear the pump relay click in and out (close or open) and you can see the water pressure change at the gauge when the water pump is running.

So water pressure can fall as you use water but the pump may fail to turn on when it should (when pressure falls below the CUT-IN setting) or it may fail to turn off when it should (CUT-OUT setting) or it may fail to respond just sometimes.

It could be a dirty or burned electrical contact, a loose electrical connection, or debris clogging the diaphragm of the pressure sensor (or something else we haven"t thought of).

Just as a connection in a pressure switch may be loose or dirty or bad, the same could be true of a pump motor. If tapping on the water pump makes it start, it needs repair or replacement.

Lifting this lever from its horizontal (off) position upwards towards vertical (on) position, will "force" the pump switch to turn the water pump on. We explain the intended function of this lever-switch just below.

In our pump control drawing (left) the red arrow points to a pump pressure control switch bypass lever. Most pump pressure control switches do NOT have this feature, however.

Some manufacturers such as Square-D call this the "Maintained Manual Cut-in Lever or Manual Cut Out Lever" (depending on the switch model and application).

Watch out: Do not leave the manual cut-in switch on (up). Turn the switch back off and proceed to diagnose why the switch was not turning the well pump on and off automatically.

On Square-D pump control switches that contain the lever you describe, includes a low-pressure cut-off feature intended to protect the pump from damage should the well run out of water.

The model involved might be, for example, the Square D by Schneider Electric FSG2J24M4CP 40-60 PSI Pumptrol Water Pressure Switch with Low Pressure Cut-Off.

If there is no water pressure and the pump has shut off - or is not running - in response to the fall of pressure below the pump switch cut-in pressure, then the switch may have tripped OFF to protect the water pump from damage that can be caused if the pump runs dry - without water. In that case do the following:

B. Where Form M4[the side lever and pump protection feature] is not present, check the water source. The well may be low. Turn off the power to the pump until source has recharged (the well has water in it)

The document cited just below offers a brief maintenance and troubleshooting guide for class 9103F and 9103G pressure control switches, including how to use the manual over-ride side-lever on a Pumptrol switch.

You can see the small diameter mounting pipe that connects the bottom of this pressure switch to the building water supply piping right at the bottom of the water tank.

Other pressure control switches may be bolted right to the pump motor and may use a flexible plastic or copper tube to transmit water pressure to the switch.

If this pipe (usually ¼” or 1/8” IPT diameter) is clogged with debris, you might be successful in getting the pressure control switch working again by removing the control switch, confirming that the line is packed with debris, and replacing it.

In our experience often when there is enough debris to clog the pressure control switch mounting pipe then the same debris also clogs the still smaller opening in the bottom of the pressure switch itself.

It’s this small opening that permits water to press against a diaphragm in the bottom of the pressure switch and thus allows the switch to sense the water pressure.

Watch out: the pressure sensing diaphragm on the bottom of the pump pressure switch is the mechanism that senses water pressure. If the diaphragm has developed a tear or old the switch may leak water and it certainly won"t work.

Debris can clog the tubing connecting (or mounting) the pressure control switch to the water tank or water piping, preventing the pressure switch from responding properly to changes in water pressure.

Our photo shows a copper tube running from a two-line jet pump (photo center) to the bottom of a pressure control switch (the gray box at lower left). This is the tube that carries water pressure (pressurizing air in the tubing) to the bottom of the pressure control switch.

that the tubing or piping connecting the pump pressure switch to the pump or water piping, or the pump switch bottom orifice through which the pressure switch senses the water pressure in the system has become clogged.

The small diameter of this tubing and still smaller diameter of the pump switch orifice makes clogging easy if your well water is high in sediment or minerals.

I ended up calling the pump service company to come over. There was an extreme amount of mineral buildup inside the pump where the copper tubing initially comes out to travel to the pressure switch.

Now I know why - ever since that date when they come do their yearly check up they knock out this sediment [using the awl to open the tubing so that the pressure switch can accurately sense the water pressure in the system]. -- Jeff Crosby

We see a similar problem affecting water pressure gauges on private water systems: debris or mineral deposits can clog the pressure sensing orifice on the water pressure gauge, causing it to fail to respond at all, or to respond inaccurately to changes in water pressure.

When we find a clogged water pump pressure switch or the tubing connected to it, or a clogged water pressure gauge, we replace those items. A well pump pressure gauge that does not respond to pressure changes is potentially unsafe as it could lead to excessive pressurization of the water tank and building piping.

Thanks to reader Bob Hartman-Berrier for explaining a more subtle problem with pressure control switch tubing - wrong (too-small) diameter, causing a leaky fitting, preventing the pressure control switch from properly responding to changes in water pressure.

The tubing connecting a pressure switch may be steel (a rigid small-diameter mounting pipe), flexible copper (connected with flare fittings), or flexible plastic (connected using special brass connectors. Changing the tubing, especially plastic tubing, can get cause trouble.

Mr. Hartman-Berrier diagnosed this problem by observing that the pressure control switch would turn the water pump on if the override lever on the pressure switch were moved to the "on" position, but otherwise the switch did not work.

The pressure switch was not turning on the water pump even though the water pressure was below the "cut-in" pressure setting. Because the pressure control switch was a new one, investigation eventually turned to a possible problem with the plastic tubing connecting the switch to the water tank.

... the pump would not come on by itself but it would come on if I used that over-ride switch. The replacement tubing between the pump pressure sensing diaphragm and the pump body was not small enough on its inside diameter to make a tight seal on the nipples of the switch and the pump body.

The seal was tight, but not tight enough; the hose didn"t blow off, but it wouldn"t allow the pressure to build up in the tube and on the pressure sensor.

For a proper fit and thus for the pump pressure switch to sense the water pressure in the plumbing system, the internal diameter of the pressure tube must match the fittings to which it attaches.

I was also worried about "priming" the pressure sensing tube and the pressure switch diaphragm, thinking that because any air in the tube is compressible and that the diaphragm wouldn"t be activated because the air would keep compressing.

I changed the hose (more-or-less proper ID), plugged in the pump and - miracle of miracles - the switch turned on. Its been running fine since then, and we"ve had plenty of water and pressure.

We do this by unscrewing the connecting pipe from the bottom of the pressure switch, and looking inside of the opening into which that pipe was connected.

Be careful about poking anything into the threaded opening which connects the pressure switch to the water pump or water tank. It"s tempting to just jam a paper clip into the little sensor hole and wiggle it around. But if you puncture the switch diaphragm you"ll certainly need a new switch.

It"s possible to remove all of the phillips-head screws you see in this photo of the underside of a pump pressure control switch, to expose the diaphragm, and to clean out the whole mechanism. Don"t tear the diaphragm

Since a new pressure switch is not very costly, and since we have to take the switch off to diagnose it anyway, if on removing and inspecting the pump pressure switch we think it was clogged, I’ll often just replace it.

If the pump pressure control switch contacts are burned we can sometimes get it working again for a while by first, turning off electrical power as we described above, and then using a file, carefully cleaning all touching-surfaces the switch contacts.

We sometimes use fine sandpaper anyway, but in either case be careful not to leave grit and debris in the switch or it’ll fail again that much sooner.

If after inspecting the pump pressure control switch or its mounting fittings you decide that you"ve repaired it or that you need to replace it, follow the instructions

While we have heard a report of the pump pressure control switch failing to turn "off" blamed on burned contact points, we think that when a pump won"t turn off other causes are more likely.

If the pump has run continuously for hours it may be overheated. Some water pumps, particularly submersible (in-well) pumps include a thermal overload switch that will turn the pump off if it overheats.

Submersible pump overload switches will re-set automagically when the pump motor cools down. Try waiting half an hour. if water pressure returns this might be the problem. (Or your well was also running out of water.)

If there is electrical power to the pump controls but the pump does not turn on, wiring between the pump control and the pump motor could be cut, damaged or open.

Watch out: damaged electrical wiring is unsafe, risking fire, electric shock, or even death. Get help from a licensed electrician to test wiring to the pump for continuity, resistance, unusual current draw, or other damage.

I had a power failure today and now that the power has returned I still don"t have water. I reset the breakers just in case with no effect. The pressure gauge next to the switch still says 50psi but no water is coming out of the taps. Never had a problem with this system before.

Have square D pressure switch 9013FSG2M4 on 1 hp elect pump; water from aerator to house through 35gal pressure tank (rubber diaphragm). works fine normally ( 35psi to 55psi) except when lose electricity.

If pressure drops below 20psi before the electricity returns; when elect. returns pump appears to start but switch contacts open. I have to hold contacts closed until pressure builds to 30 psi for them to stay costed. Why? What is solution?

Following a power failure or a lightning strike there are a number of possible sources of well and pump trouble. Starting with the clues in your question.

As your gauge says your system is at 50 psi but yet you have no water coming out of the taps, I wonder if the pressure gauge (and thus potentially the pressure control switch too) are dirt clogged and not registering pressure changes

- try tapping on the gauge to see if it moves; replace a clogged gauge, pressure switch, or mounting pipe nipple or plastic line feeding water pressure to the switch sensor.

If your power outage was caused by a lightning strike the pump or pump wiring could have been damaged. Some well pumps that intend to run at 240V might limp along at low voltage. So I"d start by asking your electrician to check the voltage being supplied to the pump and its controls.

Private water bore - We had a power outage for several hours (electricity company updating their system) and since resumption, the water pressure is lower.

I noticed it because the hot water pressure is half of what it was before the outage, the cold is always strong and is more than adequate (but not strong enough to push the hot water at a reasonable flow).

I know virtually nothing about how this all works except I have a submerged pump located several meters from the house in the garden. in the loft I have a large plastic storage rank, a large 3" pressurised metal tank with a gauge on it, and an electric box with LEDs that cycle on and off;

in a cupboard I have a pump on and off switch, a pump isolator switch, and switch labelled by the previous occupier as "overload switch".... so where do I start to diagnose the problem? Thanks

Usually those deposits are because of minerals or sediment that are in the water supply itself. But you might at least want to check that you"ve got an adequate height above the bottom of the well at which your pump is suspended.( pardon my grammar )

@InspectApedia (Editor), Yeah, that"s what I did. I had power going to the pressure switch, then I check power at the top of the well, under the cap and had power. Pulled the pump and it was busted. Replaced the pump and I"m back in business.

BTW the pic is the top of the pump. This sediment was hard and black when I broke it off of there. Any idea what that is or how to prevent it in the future?

@InspectApedia-911, It"s below ground. I"m going to check if it"s getting 240 to the switch then go pull the cap on the well and see if it"s getting it there. If it is, then it has to be the pump right?

I have a "common" well setup. Everything was working fine. I had a pinhole leak in a pipe. I shut off the pressure switch power at the box, fixed the leak, and went to turn the power to the switch back on and got nothing. I have opened all the shutoff valves back open, but still no switch kicking on.

I even removed the old switch and replaced it with a new back up switch. The pipe leading to the pressure switch is clean and there is water dribbling out of the pipe from the pump.

Since it was working before I shut the power off I haven"t tested that the switch is getting 240v (to be honest I don"t really want to). Any thoughts?

I have a Davey well booster pump 33076NPT that doesn"t turn on when the water line pressure falls. It"s hooked to the main water line and a storage tank. (The tank and pump on the right are on a closed line)

I’m getting power to switch but no power to the pump side if I hold switch in the start position I get power but when I put it in run position no power

Please Help! I changed the control box, pressure switch and tank with a orecharged one at 38psi. The well pump won"t engage. The capacitor makes a click but the pump won"t engage. Any ideas?

My son just moved into a house that has been boarded up for 8 yrs. He lived here when he was little. Well there"s no water. What should he check first with the Well and is it because there hasnt been anyone here for so many years?

He said it worked when they moved. Thats all he knows and he"s 21 and knows nothing about Wells so when responding just know neither of us know about Wells lol. Thank you.

An example of how this can happen that one might miss: over-tightening a strain relief clamp where the electrical wire passes into the switch - cutting into the wire and shorting hot to neutral or to ground.

@Inspectapedia Com Moderator, I dismantled the electrical side of things (after turning the circuit breaker off), cleaned the wires (slight corrosion) and put it back together.

Turned breaker back on and all is once again working. I was hoping it wasn"t pump issue. The tank and pressure switch were replaced within the past year so I figured they were ok.

Even when you"re not running water (though you might be without realizing it, such as a running toilet), the well pump might try to turn on in order to re-pressurize the system.

A trained service tech can make some simple tests of the current draw of your pump that might tell us if the motor is seized, running but pumping air, or off completely.

My well/pump just quit during the day with nothing using water. Had to reset the control box reset switch, unit came on ran for a few moments with lots of air and then shut off again.

Checked the pressure switch and the contacts are closed, the gauge reads 0 psi and there is 216VAC going to the pump wires. The pump is submerged at 187 feet. Everything appears to be correct, but no pump operation.

I don"t think this is exactly a pressure tank problem - though if condensation reaches near the top of the tank, indeed it"s water-logged ( a condition that can cause pump short-cycling).

Your tank might have the right "pressure" of air but not the right air volume. You want the tank air pre-charge to be 2 psi below the CUT-IN pressure when the pump has been turned off and all water pressure has been drained from the system.

Rather when the pump turns off before reaching the cut-off pressure I suspect the well is running out of water and the pump is being shut off by a pump protection switch OR the pump itself is overheating or failing.

When I start my pump, it builds pressure to about 30psi and then shuts off and will not cut on again and I have to restart it and ends up same results. I"ve tried 3 different pressure switches.

My pressure tank has the correct air pressure in it. There"s a lot of condensation on my pressure tank that I have never noticed before. Any suggestions on what to do

Examples excerpted from above: even a new well pump installation can have a leak that loses prime or debris that temporarily blocks the sensor port on the pressure control switch. Of course check also for a poor electrical connection.

Deep well 265", New pressure tank, tee, gauge and pressure switch. System worked fine several cycles after installation. Next morning, no water, 0 pressure.

Manually started pump at pressure switch, Pressure restored to set pressure of 50psi. Pump shut off as expected. No leaks detected. Why didn"t pump cut on at 30psi automatically?

I don"t know, of course, being so far away and just seeing a brief text, but I"m guessing that your system has a leak in well piping or a leaky foot valve.

When you lost electrical power for sufficient time for the water to drain back enough to lose pump prime, when the pump returned to service it had lost prime so ran dry until it was damaged, or shut down by a pump protection device. (Assuming your pump is above ground?)

If there is a small leak in a water system and there is a power cut then the water pressure continues to drop during the power cut and eventually drops below the switch on point of the pressure switch. When power is restored the pump will not start because the water pressure is too low. Any solution for this?

Having fouled up the pump pressure control settings in the switch myself, we"ve now got an article on how to get back to a reasonable starting point: factory settings.

While adjusting a pressure switch there as a small spark and the pump stopped running, There is power to all the wires to the pump but its not starting.

@BB, could be a leaky foot valve if what"s happening is the pump reaches cutoff and then when no water is being run in the building you see the tank pressure falling again.

No water.... yikes.... Replaced old pump, primed the pump for multiple hours, pump just cycles and does not fully run. Pressure builds, but pump just cycles. What next? Could this be the foot valve?

When a pressure control switch responds by turning on when it is tapped I suspect debris clogging of the sensor port on the control or occasionally a loose electrical connection or a corroded one. Maybe a good time to replace the control

water pressure control switch works well at all times except after I have drained tank, re-pressurized it to 18 psi, and then turned the line valves back on to refill it. It the doesn"t turn the pump back on.

A light tap to the contacts starts it back up, and then it continues to work well with no further action. Historically, it always would start back running on its own.

I"m wondering what the problem might be with it, and if there is anything I can do to correct this issue. The pressure control switch (a Square D model) is now about thirty years old. Any feedback you can provide would be welcomed. Thank you.

Some well pumps have a pump protection switch that protects the pump from running dry (which ruins it) - a lever on the side of the pressure switch or a button in a larger 240VAC relay box.

My list of reasons that the water pump won"t turn on, given on the page above, is more-complete than if I try to make it up again off-the-cuff here. Please take a look and ask further question or make comments as needed.

I suspect your system lost prime; if the pump runs but no water is delivered, prime the pump (see our ARTICLE INDEX for "how to") and asap you"ll also need to replace a leaky check valve or foot valve that"s the underlying cause.

Your pump may be getting switched off by a pump protection switch if it"s running the well dry, or your pump"s pressure control switch may be debris-clogged and not responding to a drop in water pressure. If the pump power is on and pressure is below the pressure control switch CUT-IN pressure setting, and then the pump isn"t turning on, if you tap the switch gently and it turns on the pump, that"s a confirmation of debris clogging or perhaps burned switch points.

Hi we have a new pump not even a year old stopped getting water so we change the pressure switch then we had water for a day or so and now it’s not working again

Possibly a debris-clog in the pressure control switch pressure sensor port or the small diameter pipe or tube bringing water pressure to the switch. Replace the switch and clean the tube or

8613371530291

8613371530291