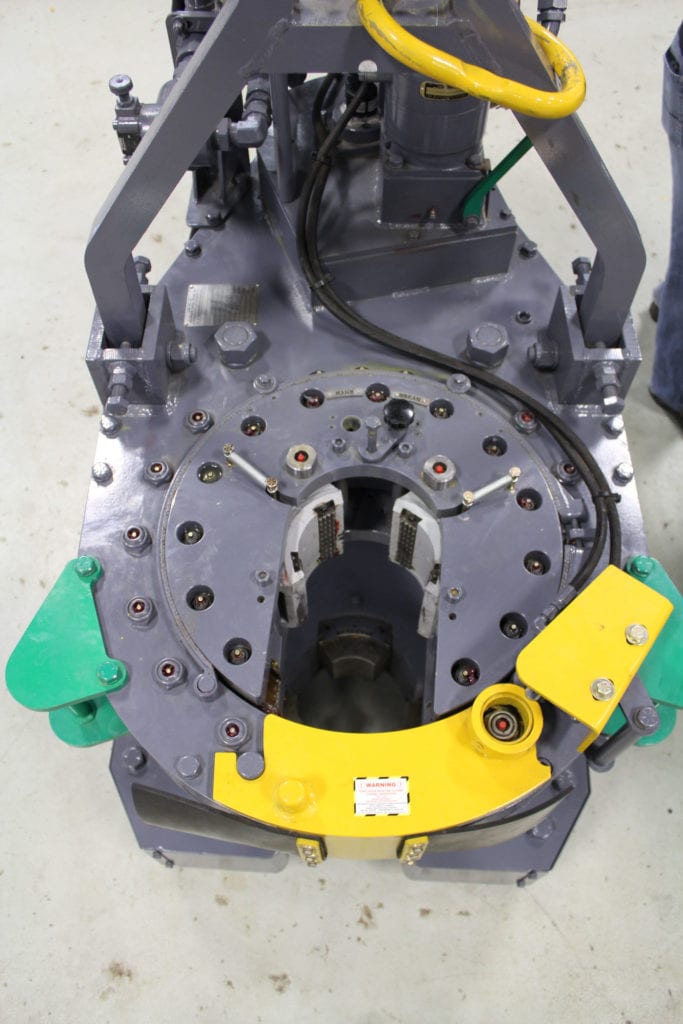

power tong frame top view brands

Special applications and tough requirements demanded that we respond with a new tong designed and built with today"s pipe handling challenges in mind, the 8⅝ Hydra-Shift® HT. By utilizing a two-speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies, which provides evenly applied pressure to the pipe and a greater pipe gripping coverage, which reduces tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufacturers and oil companies, but it also has the option of speeds of 100 RPM"s when required. Available torque: 40,000 ft-lb

The Tri-Grip® Backup is the industry standard for reliable make-up and break-out of tubular connections that are optionally supplied with Eckel tongs. Utilizing two hydraulic cylinders and a three head arrangement ensures a slip-free operation. The backup is suspended at an adjustable level below the power tong employing three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for the connection"s thread travel. The Tri-Grip® uses two pivoting heads and one stationary. The Eckel Tri-Grip® Backup has exceptional gripping capabilities with Rig Die

Eckel"s power units provide maximum power output from a compact and rugged design. Electric or diesel power units are available to provide reliable power (65 GPM and 2,500 psi) to tubing tongs and other applications. Hydraulic power units are available in standard or custom-designed configurations. Our units meet the industry"s highest standard through every step of design, manufacture, and quality control. Expendable parts are specially selected from the best-recognized brands for easy replacement in any part of the world.

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

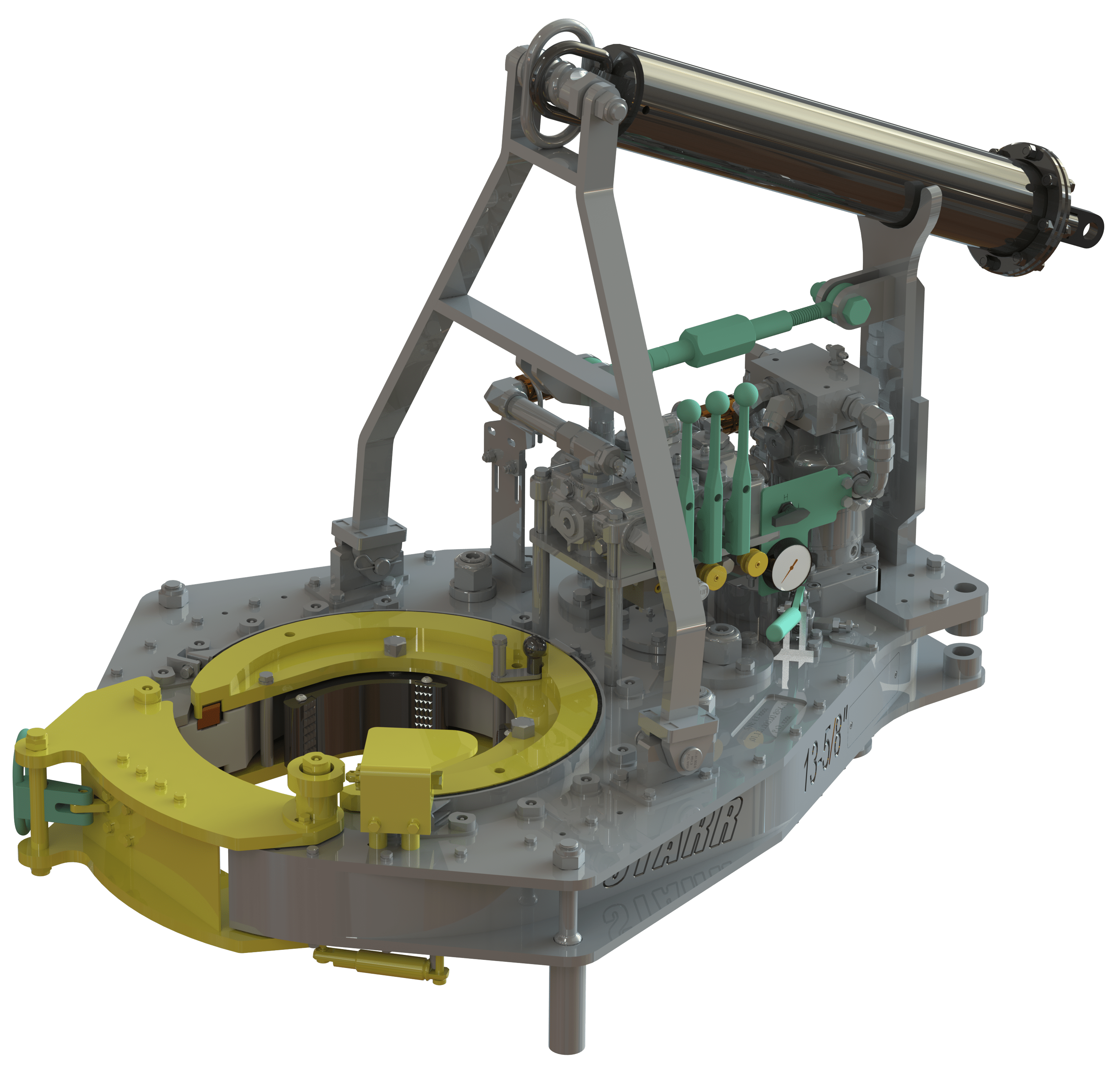

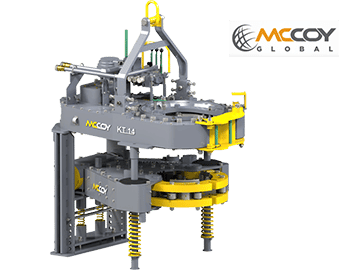

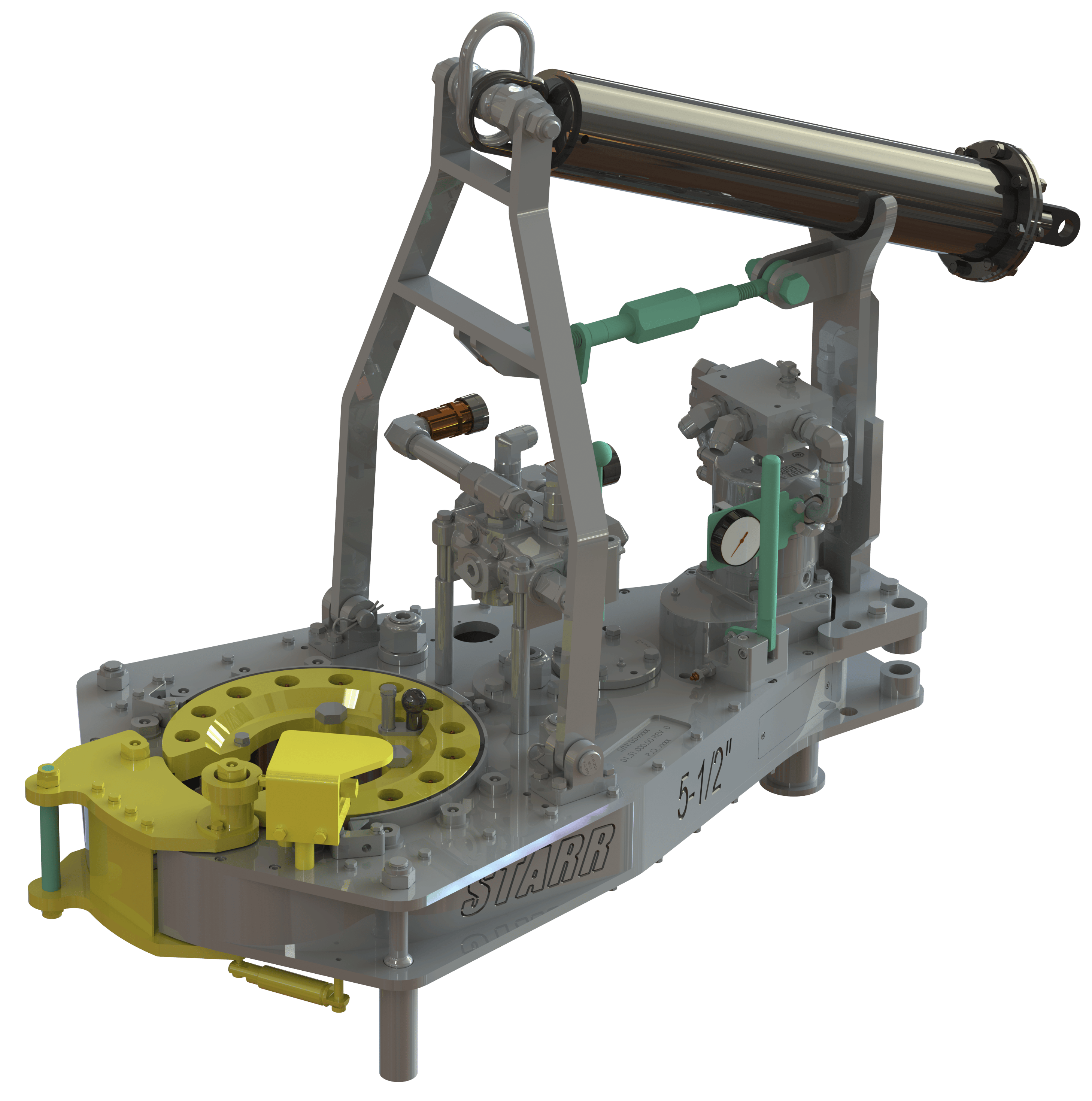

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

XQ140 micro-marking and no-marking hydraulic power tongs is a special equipment and open power tongs which is applicable to make up or break out 41/2"-51/2" casing during oil field work over operation. Master and back tong device adopts jaw plate type multi-point clamping mechanism.Can choose contour coated rig dies or pyramid tooth , to ensure the column minimum damage, and can improve the pipe thread connection quality, reduce due to improper work over pipe accident etc..

1. The tongs head is the open structure which is quick and convenient for entering and retreating working position. The integral tong head has good hardness and rigidity.

2. Master tong is roller climbing two jaw plate structure,can install arc tooth die ,the contact surface is more larger and clamp no deformation, The assembly and disassembly is very convenient. The optimum tangent-diameter ratio design ensures reliable clamping and easy slope retreating.The back tong is the three-jaw-plate structure pushed by hydraulic cylinder. The structure is simple and the clamping is reliable; The minimum damage to the tubular column can be ensured, and the main body of the pipe string can be clamped.

6. Master and back tong adopt integral frame structure,back tong is floating connection,The master and back tong adjustable distance, reduce the damage of pipe string shackle;

8. Matching torque and speed test system,can accurately control the torque of makeup,can timely display, control, storage, print torque parameters(Suitable for FOX、VAM TOP、BGT1、3SB、NSCC、WSP etc special threaded bushing).

We offer a full range of specialized equipment for casing and tubing running, including the Derrickman™ stabberless system, Casing Running Tools (CRT), the Leadhand™ tong positioning systems, Fill-and-Circulate tools (FAC), pickup and laydown systems, and flush-mounted spiders. A specialized sand-screen completion running system ensures sand screens are run in your well in optimum condition with no restriction to production flow. The field-proven ChromeMaster™ chrome-running system for tongs and handling tools is a fully integrated package that enables handling and makeup of chrome tubulars without damage and minimal marking. The Salvo™ torque-turn system minimizes cost by ensuring correct torque application through the control, monitoring, and recoding of every make-up, immediately detecting faulty connections.

Our rigorous QHSE&S system standards include a “Stop Work Authority” program that ensures every employee is fully aware of his or her right and duty to stop an unsafe job, along with risk management/assessments for all our equipment.

As the first and leading exhibition manufacturer who specialized in researching, developing, and producing exhibition system products in China, Lingtong Exhibition System Co., Ltd has more than 35 years of history and experience in the exhibition industry and worked with more than 10,000 customers all over the world.

8613371530291

8613371530291