phase 2 rotary table brands

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

The ultra-compact HRT100 rotary table provides high-speed, accurate positioning and full 4-axis motion for machining small parts on the Haas CM-1 Compact Mill, and other small machines. The unit’s very ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

The HRTA5 is a single-axis rotary table based on the HRT160 model. It has an A1-5 spindle nose instead of the T-slot platter. This allows manual A5 chucks to bolt directly to the rotary ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

... fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

Our extra-large HRT Series rotary tables are perfect for holding large workpieces or fixtures for 4-axis machining. These high-capacity, heavy-duty tables mount vertically, and feature ...

... models is available to make the whole range of HMCs complete. The rotary tables dedicated to the Spark line match the 5000 kg max load with excellent dynamics whereas the hydrostatic tables ...

The tilting tables are designed and produced for 5-axis operations on complex work-pieces requiring accessibility to the most unreachable surfaces thus ensuring fast swarf removal at the same time.

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

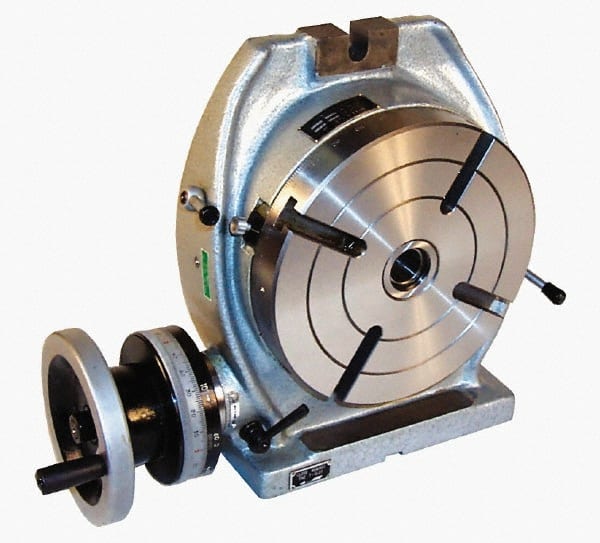

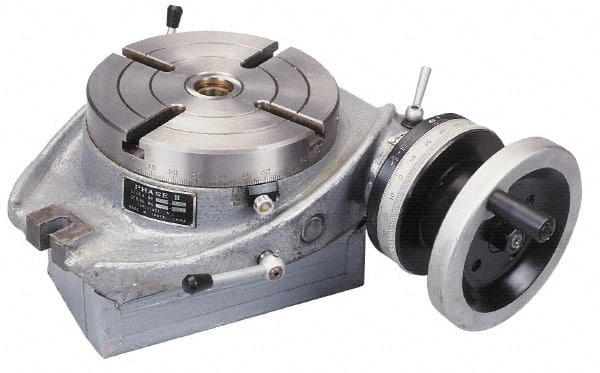

What are some of the best Rotary table brands you can buy? I only buy tools once so quality of the most important thing. I’ll happily buy vintage if people truly think they are better. I have a Bridgeport (pictured below)

Here"s a mystery for all you hobby milling machine enthusiasts. Help me ID this rotary table. I"m considering purchasing it, but can"t figure out who made it.

Finally complete. The casting came out very nice, little if any hydrogen bubbles or oxide inclusions. 11" diameter x 1" thick, 6 T slots, referencing rings 1/2" apart. See if I can get a photo to post.

So, here"s what I"m wondering. About half the time I use the rotary table I find the hand wheel interferes with where I"d like to clamp it down. Looking at other tables this seems to be the common configuration, where the handwheel interferes with the mounting plane(s) of the table. Why would...

not getting any feedback to a previous post I gotta wonder if there isn"t something wrong with an Advance Rotary Table. I see lots of posts regarding "what to buy" and "I settled for a Chinese knockoff". Just wondering what is the problem? This seems to be an extremely well built and accurate...

I have a vertex 10" Rotary table with mounted chuck, I use it often. There are quite a few occasions I wish it was motorized. Has anyone done a DIY motor on their rotary table and not spent a fortune ? I"ve seen pretty expensive motors so i"m looking for DIY options. I think I may have even...

I have barely enough room left to get tooling in. Had to use a short 3" boring bar. I can see another 2 inches of shiny ways below where the knee is stopped by the limit switch.

I"ve become a (happy) owner of a new-to-me 8" Phase II horizontal rotary table. Unfortunately it came with the dividing plate setup and no handwheel, so I need to make one. If you have this model of the table, I would really appreciate if you could post a picture and/or dimensions of...

So I need a rotary table for a couple of projects I have in mind, making round things on my Jet 15 mill/drill. I don"t have a lathe. I"m thinking 6" would be a reasonable size both for the things I need to make and the size of my mill. I see cheap imports on ebay starting around $160, Phase...

8613371530291

8613371530291