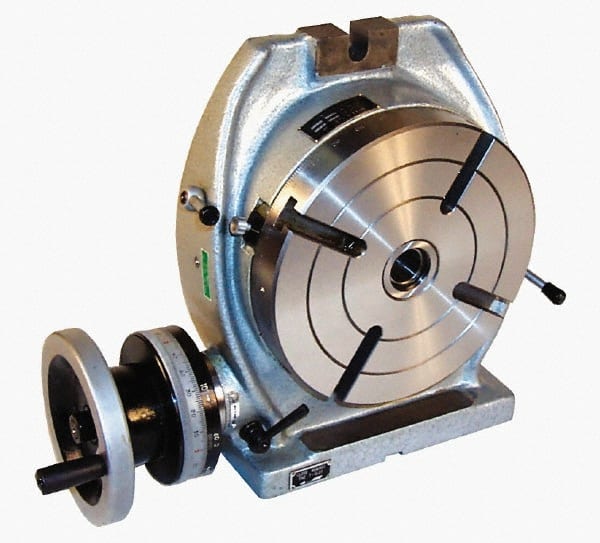

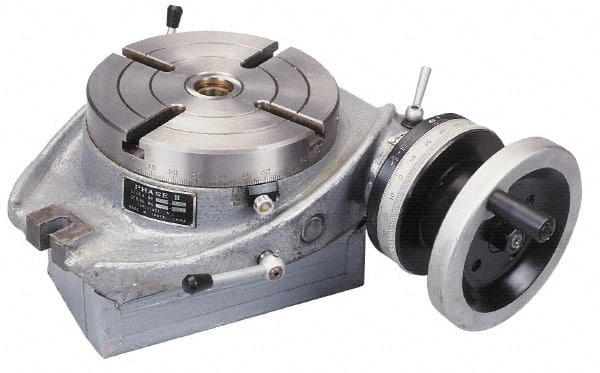

phase 2 rotary table quotation

Optional Accessories: Dividing plates have all divisions from 2 to 66 and all numbers from 68 to 132 that can be divided by 2, 3 and 5. Fits all except 6".

For assistance with finding the right tools or any other questions, please feel free to call our customer support team at 800-221-0270 or use our chat feature now.

Motorized worm gear driven rotary tables provide high angular resolution (the worm gear ratio directly multiplies the motor output torque and motor angle resolution) and holding torque. PI offers precision motorized worm gear rotary tables with both stepper motors and closed-loop servo motors with encoder feedback. While open-loop stepper motors are often used for their lower cost and ease of control, closed loop servo motors with encoder feedback provide higher speed, higher accuracy, and repeatability. PI also provides closed-loop stepper motor rotary stages, combining the best of both worlds. PI stepper motor rotation stages are provided with stepper motor controllers featuring a micro stepping mode for higher performance. For single axis applications, a compact and very cost effective single axis stepper motor controller is available.

For the best performance and highest velocity, direct-drive rotary stages with torque motors are recommended (link to new Rotary Stage Page with Direct Drive Torque Motors).

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

The Convex Rotating Table, unlike the Concavo rotating table, has the particularity of collecting the products deposited in the center of the tray, by means of a conveyor belt or slide, and convey them towards the outer edge. Located at the end of the packaging line, they act as an “accumulation tank”. They facilitate the unloading phase of the product leaving the packaging machine and facilitate the operations of picking up and boxing the operator.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

Waluj, Aurangabad D1 C 270, Udyog Bharati Estate C/o,Udyog Bharti Estate,Mahaveer Chowk, Near Hotel Dream Line Phase No-3, Plot No.-X340,Waluj,, Waluj, Aurangabad - 431136, Dist. Aurangabad, Maharashtra

Shivaji Udyam Nagar, Kolhapur A-249, Kagal Hatkanangale, Five Star MIDC Kagal, Village Halsawade, Shivaji Udyam Nagar, Kolhapur - 416203, Dist. Kolhapur, Maharashtra

The 60-1/2″ American Block Rotary Table is NEW Surplus with 3 sets of master bushings. The 60-1/2″ American Block Rotary Table includes a hydraulic motor drive. This is available for immediate sale. Please request a quote for further information.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

With proper selection and integration of high-performance brushless DC servo motors ABTech’s air bearing rotary tables provide ultra-smooth and precise rotary motion. With high torque, high performance motor drives, our motion experts will gather your specific requirements and work closely with our motor suppliers to create/select a motor drive that suits your specific application. Whether you need sub-micron position accuracy with minimal settle time and stringent following error specifications, high-speed constant motion, or a combination of both there is an ABTech rotary table that will meet your needs.

ABTech’s modular design approach facilitates multiple system configurations to optimize the price-for-performance required in your application. This approach allows the user to define the level of control desired for the most cost-effective solution. Our complete engineering services allow us to respond quickly to provide a solution to your O.E.M. requirements for ultra-precision rotary motion.

8613371530291

8613371530291