enco rotary table factory

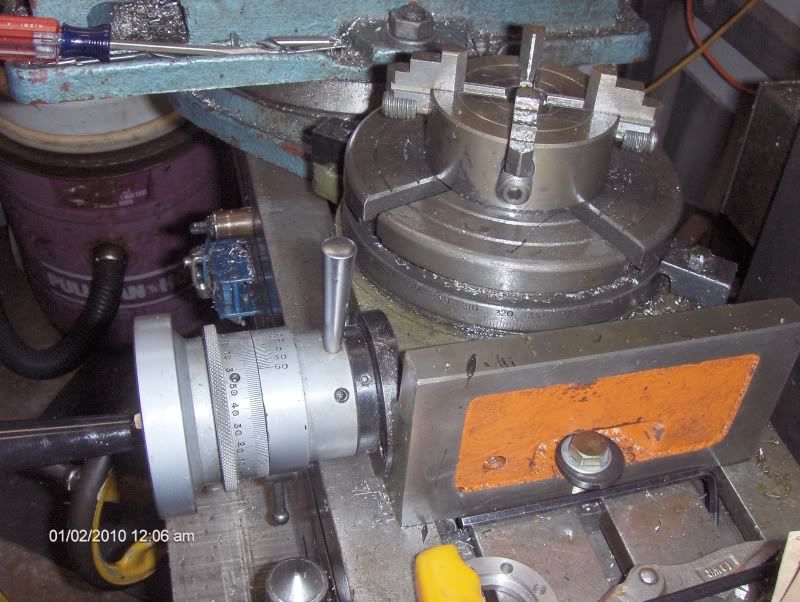

I have an eight inch that I ordered from Enco but it looks different (has two vertical mounting lugs and two horizontal lugs). Mine also came with the dividing apparatus and a 17 - 47 hole set of plates. It IS very heavy, as you mentioned, and I have made a small roll-around platform for mine so that I can move it around the bench during setup. I"m considering a crane to move mine, too, but in the meantime, here"s what I do:

After I get the table set up to my liking, I lower the mill table so that it is an inch or two lower than my workbench. Placing a plywood ramp between the workbench and the mill table, I roll the rotab down to the mill and carefully slide it off the little wheeled platform onto the table. To get it back on the workbench, reverse the process only raising the mill table an inch or two above workbench level.

Mine hasn"t seen extensive use but works well ... I"ve made a couple of large milling cutters from 1-1/2 diameter drill rod and a number of smaller projects. (I even used it for a couple of woodworking projects with my home-made router spindle attached to the mill quill.) The cool thing about it is that the backlash in the worm can be completely adjusted out. Frankly, I"ve thought about a smaller table (for convenience) but the argument for the bigger table is that more mass prevents chatter and makes for a smoother cut. If yours doesn"t come with dividing plates, you might consider that as one of your first projects.

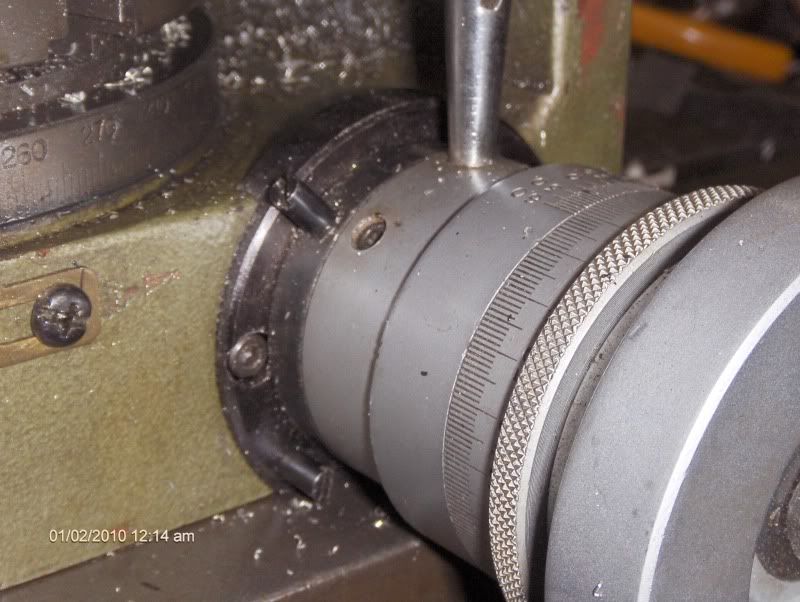

Unfortualy im not completely sure if its the set screws in the silver part or black part. And if that black "knob" part that sticks out has anything to do with it. But basicly the operation is getting that handle to freely move (its locked in place by SOMETHING, and will freely rotate once that is removed), rotate it about 90~180 degrees and the table should spin freely (Well, with a really strong nudge, but no need to beat on it with a hammer)

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

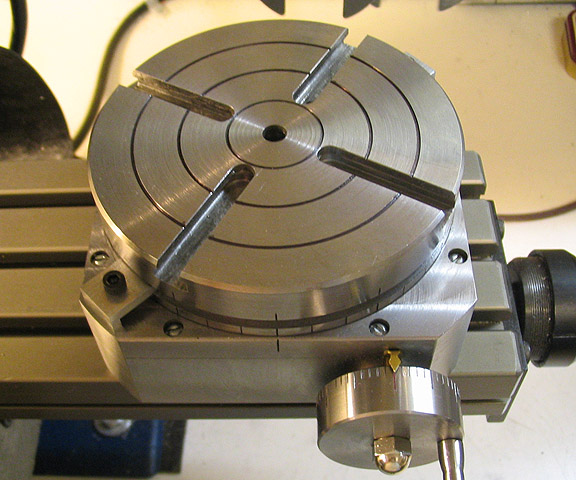

You could bolt a larger plate to the rotary, then secure your work-piece to it ( to get the larger radius cuts) since you won"t need the locking mechanism to mill the radius on the part. If you work it correctly, you might be able to mill both radii with one set-up.

I am thinking of adding an 8" horizontal/vertical rotary table to my PM935 mill setup and need some suggestions. The candidates I have seen so far are Yuasa, Vertex, and Phase II. Their are other but these seem to be the most readily available in 8".

Turret tool posts, magnetic tools, centers, boring and facing heads, drilling and tapping heads, measuring tools, cutting tools, milling machine vises, clamping kits, safety shields, and accessories. Rotary tables ; arbors ; boring bars ; calipers ; cam locking toolposts ; centers ; chuck block parallels ; collets ; compound replacement toolposts ; demagnetizer ; diving heads ; end mills ; flange nuts ; granite surface plates ; magnetic base lights ; magnetic vise ; plain clamps ; radius and angle dresser ; shields; guards ; step clamps ; studs ; t-nuts ; toe clamps ; turret quick change toolposts ; etc.... this comprises the uncataloged portion.

Many rotary table manufacturers outsource gear fabrication to lower costs. While that strategy may offer short term cost savings, Index Design’s American made rotary tables are built with gears cut in house. This is the only way to closely monitor and control tolerances, consistency and performance.

Our rotary tables incorporate large diameter high tensile bronze worm gears mated against hardened steel drive shafts. The combination of metal gives superior wear properties for long lasting operation. As the rotary table is run, the properties of a tin bronze gear develops a low friction deposit on the mating steel drive shaft. These deposits fill in microscopic pores of the mating surface. Over time, as these deposits are embedded on the surface, wear decreases followed by a reduction in frictional forces within the gear assembly.

In addition, the data gathered from our automated calibration procedure allow our engineers to assess, monitor and improve the static and dynamic performance of prototype rotary tables during the design phase.

Our engineers have a long and rich history in the machine tool business, they combine decades of both CNC machine tool and rotary table manufacturing experience with the latest design tools to produce rotary tables with superior performance and dependability.

Our CAD/CAM software is used to analyze displacement and stress for each component, sub-assembly and total assembly. However, the best software and technology is worth next to nothing if no one understands the craftsmanship. This is particularly true when manufacturing precision rotary tables which involves many steps. Despite all the modernization and automation available, a large part of the manufacturing process is still completed by hand. At Index Designs, we understand and appreciate craftsmanship, It is designed and built into our products.

Fully Factory Rebuilt, Factory Refurbished Rotary Tables, to as new factory specifications: Horizontal, Weight approx 2100kg, Loading capacity approx 18,000kg/39,600lbs, . Refurbished October 2017 by Rusach International. Fanuc Alpha 30 motor, Heidenhain ROD800C +/-3.5 Arc Second encoder, Siemens hydraulic pump. Table Top is set up for a pallet receiver. Need it modified, please let us know!

8613371530291

8613371530291