enco rotary table supplier

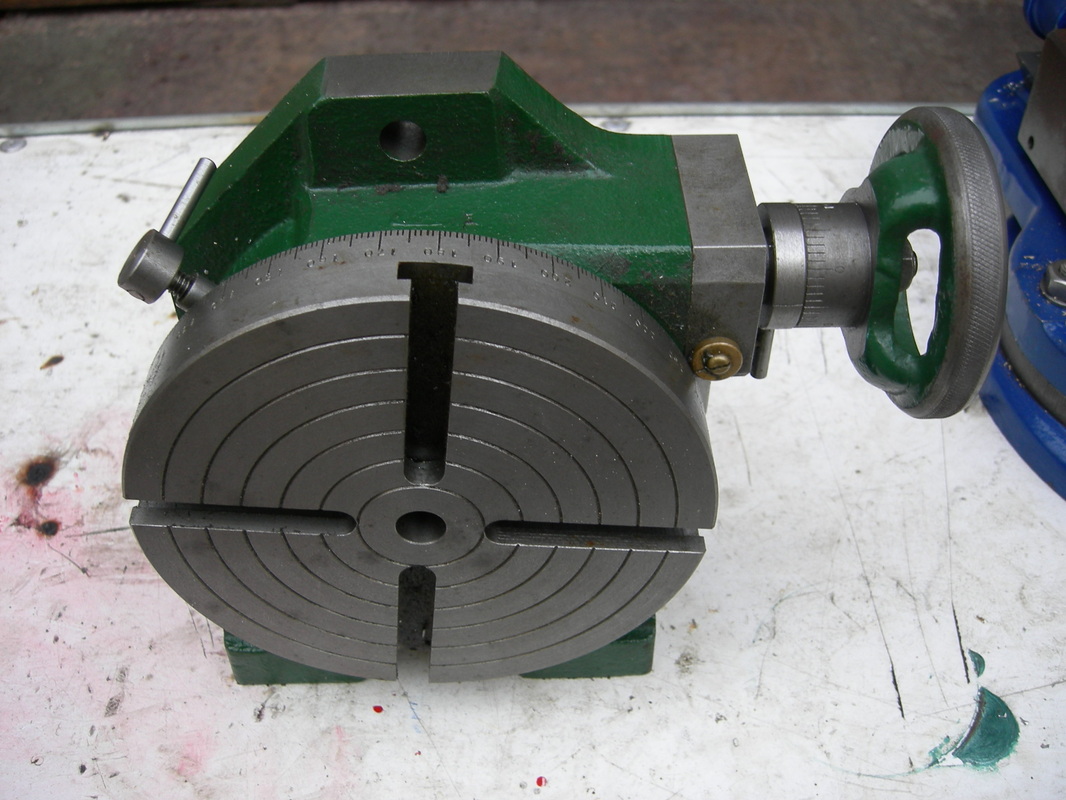

Im in the market for a 10-12" rotary table, and while I was at a local machine and tool supply house, I noticed a brand new, but older, Enco 12" H/V rotary table. The tag on the table said $600. The owner noticed my interest, and struck up a conversation, long story short, they said they"d take $300 for it because they had it for about 15 years now and really need to clear out some inventory. It says made in Taiwan, and it turns very smooth, and generally looks good, but there is a lot of backlash, but the handle felt like it had some loose bolts. What Im wondering:

3. What should I do to check out the accuracy of it? Can I put a mag-base dial indicator on the table base and spin the table to check flatness and runout?

I have an eight inch that I ordered from Enco but it looks different (has two vertical mounting lugs and two horizontal lugs). Mine also came with the dividing apparatus and a 17 - 47 hole set of plates. It IS very heavy, as you mentioned, and I have made a small roll-around platform for mine so that I can move it around the bench during setup. I"m considering a crane to move mine, too, but in the meantime, here"s what I do:

After I get the table set up to my liking, I lower the mill table so that it is an inch or two lower than my workbench. Placing a plywood ramp between the workbench and the mill table, I roll the rotab down to the mill and carefully slide it off the little wheeled platform onto the table. To get it back on the workbench, reverse the process only raising the mill table an inch or two above workbench level.

Mine hasn"t seen extensive use but works well ... I"ve made a couple of large milling cutters from 1-1/2 diameter drill rod and a number of smaller projects. (I even used it for a couple of woodworking projects with my home-made router spindle attached to the mill quill.) The cool thing about it is that the backlash in the worm can be completely adjusted out. Frankly, I"ve thought about a smaller table (for convenience) but the argument for the bigger table is that more mass prevents chatter and makes for a smoother cut. If yours doesn"t come with dividing plates, you might consider that as one of your first projects.

This will be a bit convoluted but...that Enco table looks very much like an "Advance" table (there is one for sale here, w an X-Y slide on top but still...) anyway, there is some discussion here

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

Today I decided to buy myself an 8" rotary table for Christmas. As this is strictly a hobby for me, it will most likely be Chinese made. So I looked at a few sites, Grizzly, Shars, CDCO, even Enco (their site is still up), and then I tried Ebay, now I"m really confused. There are many 8" tables on Ebay being sold by this or that seller (who knows who they really are) for a lot less than the internet supply places that I checked, AND ALSO, looking at the pics, I would swear they are all the same chinese made RT. So just how is a guy supposed to figure out what to do???? Well, I"m hoping that the great members here will chime in with any and all advise, whether its first hand advise from using any of these import tables, or especially general advise from you more experienced guys about all rotary tables. Thanks, and Happy Thanksgiving, JR49

8613371530291

8613371530291