rotary table feeder factory

Global provider of vibratory feeders and other custom part feeding solutions, specializing in automated equipment that orients bulk parts by means of vibration and centrifugal feed systems, built to customers specifications. Products include custom tooled vibratory bowls, inlines, escapements, bulk hoppers, gravity tracks, sound enclosures, tables, base plates, PLC packages, IV sensors and cameras. Also offer custom centrifugal feeders, conveyors and bulk prefeeders. These feed systems use both mechanical tooling as well as vision or profile sensor integration. Systems are managed by either simple bowl and track level sensor monitoring to full PLC Logic with or without Ethernet capabilities. Engineering services from proof of principle to Solid Works modeling. Documentation/FAT approval via live streaming available. Serving the following industries: medical, medical devices, pharmaceutical, injection molding, packaging, labeling, aerospace, defense/munitions, electronics, cosmetics, fasteners, irrigation, automotive, and hardware.

Our Circle FeederTM Table Feeder is unique in that it prevents bridging in hoppers, bins, and silos. This is accomplished by properly sizing the round inlet of the feeder to exceed the critical arching diameter of the feed material.

Flat, slow-rotating vanes cause radial flow of material under the flow adjusting ring. Rotary vanes convey this material toward one or more discharge ports . The design allows for the widest range of applications including powders, fibers, flakes, wet cakes, etc.

Components of a Rotary FeederThe rotor shaft is a component found at the center of the electric motor. It produces a torque force, or motion, that causes movement of the material through the rotary feeder.Housing is the metal shell that contains and protects the electrical components of the rotary feeder. It forms the shape of the rotary feeder.

A rotary feeder works by separating pressure differences while allowing the passage of material into the processing system. To best illustrate how a rotary feeder works, it is best to imagine how a revolving door works. It permits the passage of material through while maintaining the difference of pressure in the building against the outside pressure.

Commonly known as ARFs, these feeders have varied speeds. They usually follow the direction of material flow and make use of a rotating member and the articulable gate to control the flow volume of material. There is also what is called drum rotation. This regulates and prevents the backflow of material and reduces overloading, product distraction, formation of fine dust, and ensures a uniform flow of material.

These feeders are usually set to feed material in a pneumatic conveying line. Rotation of the valve, coupled with the leakages between the rotor and the stator, cause gas from the conveying line to go upstream and be emitted.

Rotary tables are an incredibly useful piece of equipment as they can perform many functions. Rotary tables may be used to sort product into single-file, orientate product in a specific direction and as a quality control mechanism to reject product which does not meet specification. These tables can be customised to handle a large range of product shapes and sizes.

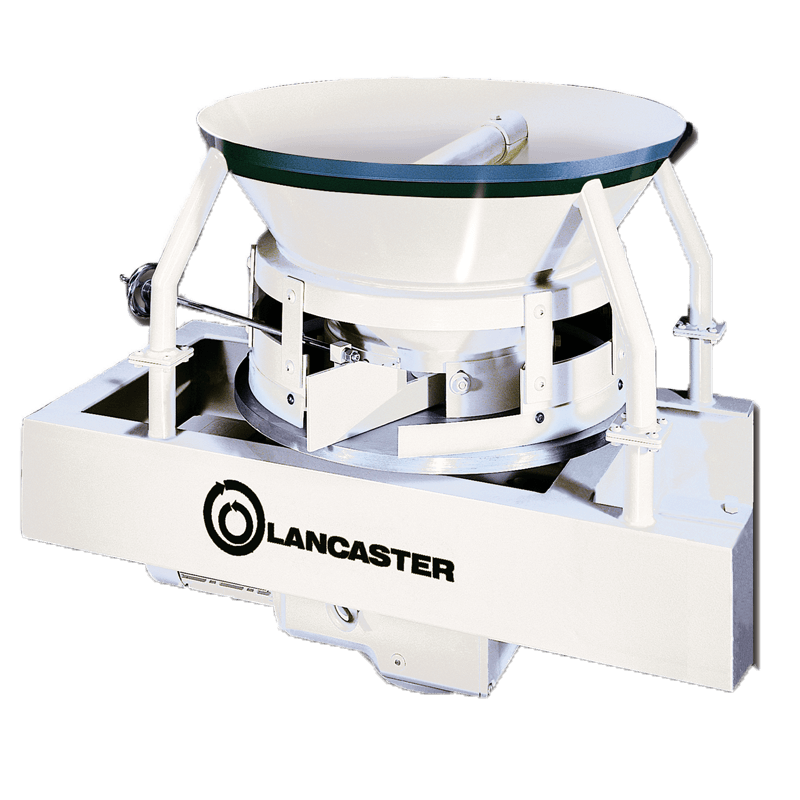

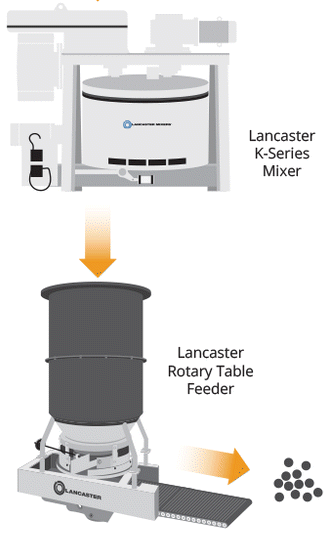

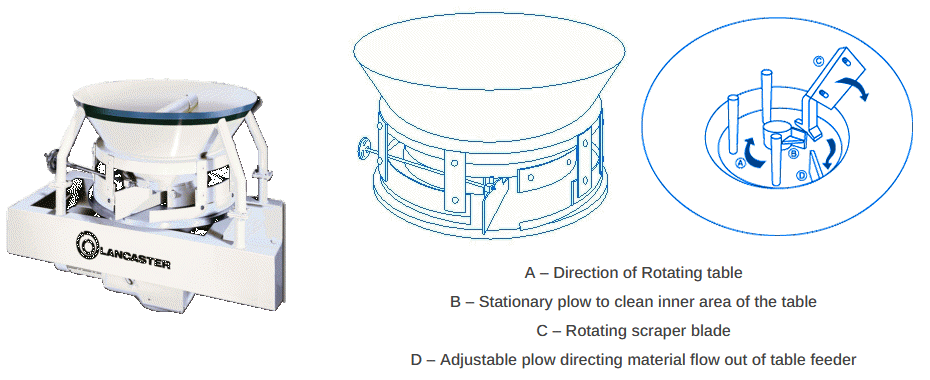

Rotary Table Feeder will consist of a power driven circulated plate rotating directly below a hopper / bunker. A feed collar located immediately above rotating table used in conjunction with an adjustable plough, determines the volume of material discharged.

The lower edge of the feed collar will be parallel to the table with a predetermined gap from table top. This arrangement permits equal quality of material to flow under the collar and spread over the table as it resolves. The material is then ploughed off into the discharge chute.

Let us be your one-stop supplier for all your rotary table, bar feeder, bar loader and high pressure coolant needs. Check out CNC Indexing & Feeding Technologies and you’ll see – no other supplier of CNC machine tool accessories can compare!

Manufacturers worldwide are always looking for the most reliable workholding devices on the market to accommodate their indexing and rotating needs. At CNC Indexing & Feeding Technologies, we are proud to carry the complete product line of Ganro Industrial Corporation’s workholding rotary tables and indexers

For more than 30 years, Ganro (Golden Sun) has been providing the world with a wide range of products to meet any manufacturing needs. To meet those needs, a manufacturer must know which table is the right choice and understand the proper use and capabilities of the different styles of equipment.

With sizes ranging from 120mm (4.72”) to 2500mm (98”), these rotary tables and indexers are capable of both vertical and horizontal mounting and have large thru-holes to offer maximum flexibility.

At CNC Indexing, you have the choice of three different types of Ganro standard tilting rotary tables that can accommodate most 4th/5th axis manufacturing needs. These include:

Standard Tilting Rotary Tables: With sizing available from 320mm (12.59”) to 630mm (24.8”), this table offers ample room for the workpiece while also providing clearance for the machine’s spindle and tool.

Compact Tilting Rotary Tables: Coming in 150mm (5.90”), 200mm (7.87”) and 250mm (9.84”) sizes, these tables are ideal for the smaller machining center and workpieces.

Manual Tilting Rotary Tables: Available in sizes from 200mm (7.87”) to 630mm (24.80”), this manual rotary table is designed with full 4th axis and manual tilting axis that is perfect when tilting capabilities are only occasionally needed.

With table tops ranging from 400mm (15.74”) to 300mm (118”) square, Ganro’s horizontal CNC rotary tables are useful in a wide range of manufacturing needs. The tables are designed for horizontal mounting only, and have the added benefit of withstanding extremely heavy workpieces. They are particularly suited to horizontal boring mill applications. These horizontal rotary tables can be used as a full rotating axis integrated into the machine’s CNC controller, or utilized as an indexer with Ganro’s M-Mate AC servo controller.

Our line of precision horizontal index rotary tables come in two different types, both of which use a two-piece Hirth coupling design that offers superior indexing accuracy while still maintaining a high level of rigidity during heavy cutting.

CNC Index Rotary Table: These index rotary tables are clamped and unclamped with hydraulics. They are designed to integrate into a machine’s CNC controls, but can also be operated with Ganro’s M-Mate AC servo control system.

Manual Index Rotary Table: This line of manual rotary tables can be clamped and unclamped either pneumatically or hydraulically. When unclamped, the table is manually indexed to the required degree and securely clamped into place.

Available in 250mm, 320mm, 400mm and 500mm sizes, these rotary tables are designed with a three-piece Hirth coupling for no-lift rotation. This design allows for mounting heavy workloads while still getting high rigidity and accuracy. These rotary tables are typically used in applications that incorporate a strong tailstock and tombstone or fixture plate, and can be integrated into the machine’s CNC controls or operated through Ganro’s AC servo controller.

From large to small workpieces, horizontal and vertical applications, 4th and 5th axis work, and manual or automated applications, CNC Indexing & Feeding Technologies has the right rotary tables and machine tools accessories to meet any needs.

Star Trace Rotary and Table Feeders or Valves are used to transfer the powder/dust/granular partical from the top storage bin or hopper to the discharge port of the bottom. Rotary Valves can feed materials uniformly or with variable speed motor. we can adjust the feeding quantity as your demands at any time. Rotary Valves used in chemical, cement, pharmacy, iron & steel and foodstuff industry etc.

The TJR AR-5C pneumatic collet rotary table is designed to provide an affordable alternative to three- or four-jaw chucks for workpieces requiring 5C collets.

PMTS 2017: CNC Indexing & Feeding Technologies’ Tracer Minibar hydrodynamic magazine bar feeder is able to feed bar diameters from 0.8 mm to 12 mm and up to 10 ft. in length.

The Tracer Vs-105XL bar feeder from CNC Indexing & Feeding Technologies is designed for heavy bars ranging to 41/8" (105 mm) in diameter and measuring as long as 72".

The Ganro HR-3030 rotary table available from CNC Indexing offers a table-top dimension of 3,000 mm (118.11"), a table-swing diameter of 3,905 mm (153.75") and a maximum workload capacity of 50,000 kg (110,230 lbs).

Distributed by CNC Indexing & Feeding Technologies, Ganro Industrial Corporation’s GCT series manual horizontal index table adds indexing capability to a horizontal boring mill.

CNC Indexing & Feeding Technologies says its GSI CNC-201R rotary indexing table is designed for companies that want to add fourth-axis productivity at minimal cost. According to the company, the table provides high clamping torque and indexing accuracy.

The GSI CNCT-321 tilt/rotary table is designed to add four- and five-axis productivity at a minimal cost. The table allows manufacturers to machine as many as five sides of a part while minimizing second and third operations and setups. The table also provides excellent clamping torque and indexing accuracy, the company says.

CNC Indexing Technologies says its GSI CNCT-321 tilt/rotary table is designed for adding fourth- and fifth-axis productivity at minimal cost. The table allows users to machine as many as to five sides of a part while minimizing second and third operations and setups. The table has a 12.

The GSI DNC-400 direct-drive rotary indexing table is suited for high-volume and aerospace manufacturers performing high speed, high-accuracy contouring operations. Compared to tables using a servomotor and worm gear, this direct-drive table offers higher accuracy, faster rotational speeds and higher torque, the co

Rotary feeders, also referred to as centrifugal feeders, utilize rotary force in order to orient and sort parts before feeding them to the next stage in automated processes. As a component of bulk and specialty material handling processes, rotary feeders are often utilized in industries such as agriculture, industrial, automotive, cosmetics, mining, food and chemical processing.

Ideal for air pollution control applications, rotary feeders provide quiet, subtle processes to separate materials in order to feed a wide variety of parts without the use of tracks or vibration. Typically constructed from cast iron, carbon steel or stainless steel, rotary feeders are often used for dry free-flowing powders. Offering high feed rates, rotary feeders are ideal for thick parts that are not inclined to tangle when pulled to the outside of the bowl at high speed. Offering efficient separation of both large and small parts, rotary feeders tend to mar parts less than any other feeder type and offer an ergonomic solution to monotonous and physically strenuous sorting tasks.

Primarily used to discharge production materials from hoppers and bins, cyclones and receivers, rotary feeders are constructed from components including a rotor shaft, housing, head plates, and packing seals and bearings. The rotors typically have large vanes that are cast or welded on and are often driven by either small internal combustion engines or electric motors. The parts are simultaneously stabilized as they accumulate on the outer edge in order to start orientation. After orientation, the parts exit the bowl and are conveyed to the next stage in the process. However, parts that are damaged or misaligned in any way will not be conveyed forward, but will be returned back to the feeder bowl to either be recirculated or discharged. Specialized custom tooling is often available in order to better suit certain types of parts and well as to achieve a desired rate of speed. For example, one special type of rotary feeder, referred to as a rotary airlock feeder, is best suited for pneumatic conveying systems and dust control equipment.

8613371530291

8613371530291