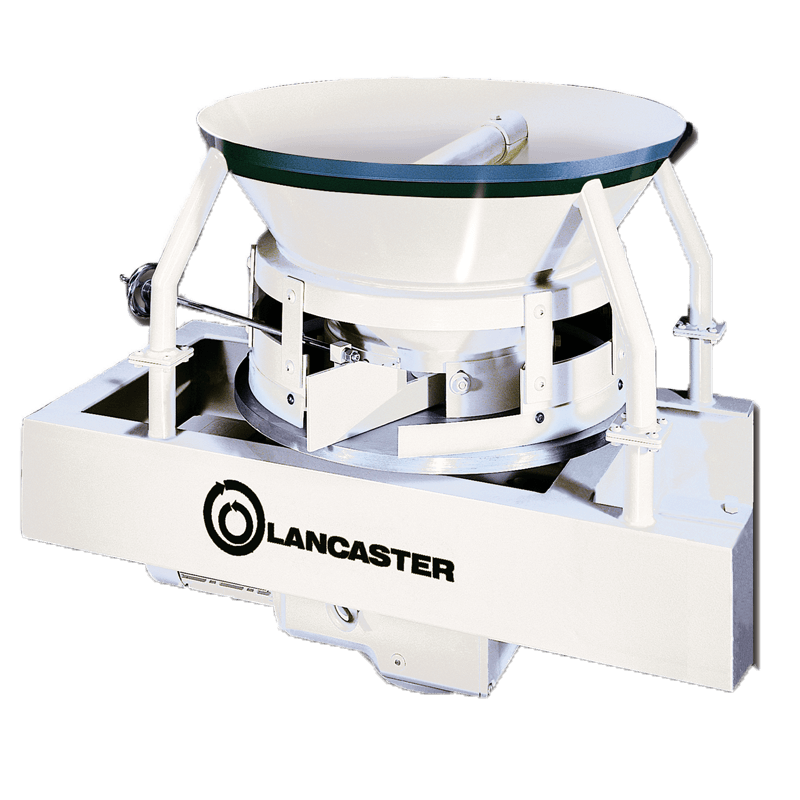

rotary table feeder in stock

Our Circle FeederTM Table Feeder is unique in that it prevents bridging in hoppers, bins, and silos. This is accomplished by properly sizing the round inlet of the feeder to exceed the critical arching diameter of the feed material.

Flat, slow-rotating vanes cause radial flow of material under the flow adjusting ring. Rotary vanes convey this material toward one or more discharge ports . The design allows for the widest range of applications including powders, fibers, flakes, wet cakes, etc.

Global provider of vibratory feeders and other custom part feeding solutions, specializing in automated equipment that orients bulk parts by means of vibration and centrifugal feed systems, built to customers specifications. Products include custom tooled vibratory bowls, inlines, escapements, bulk hoppers, gravity tracks, sound enclosures, tables, base plates, PLC packages, IV sensors and cameras. Also offer custom centrifugal feeders, conveyors and bulk prefeeders. These feed systems use both mechanical tooling as well as vision or profile sensor integration. Systems are managed by either simple bowl and track level sensor monitoring to full PLC Logic with or without Ethernet capabilities. Engineering services from proof of principle to Solid Works modeling. Documentation/FAT approval via live streaming available. Serving the following industries: medical, medical devices, pharmaceutical, injection molding, packaging, labeling, aerospace, defense/munitions, electronics, cosmetics, fasteners, irrigation, automotive, and hardware.

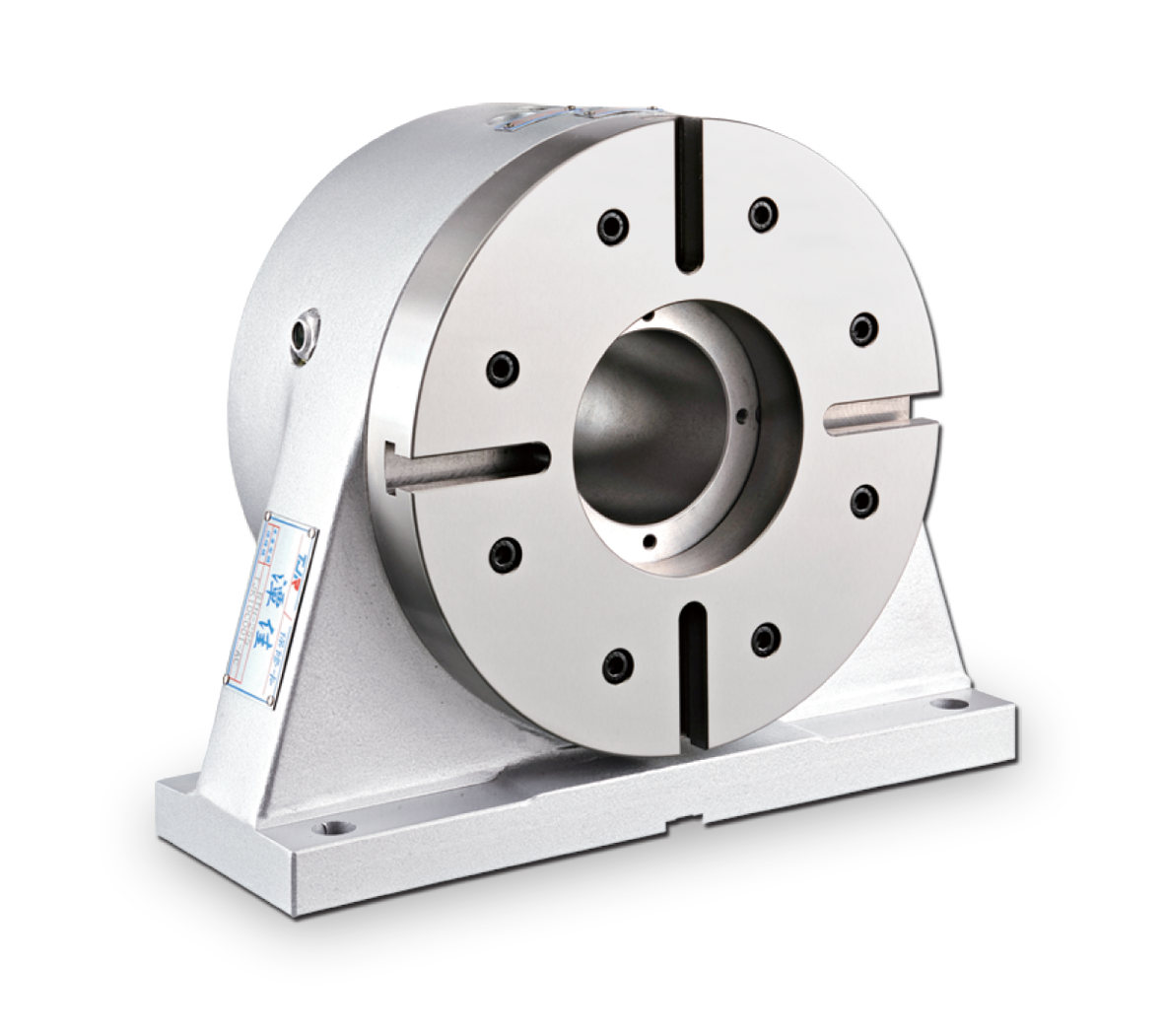

Components of a Rotary FeederThe rotor shaft is a component found at the center of the electric motor. It produces a torque force, or motion, that causes movement of the material through the rotary feeder.Housing is the metal shell that contains and protects the electrical components of the rotary feeder. It forms the shape of the rotary feeder.

A rotary feeder works by separating pressure differences while allowing the passage of material into the processing system. To best illustrate how a rotary feeder works, it is best to imagine how a revolving door works. It permits the passage of material through while maintaining the difference of pressure in the building against the outside pressure.

Commonly known as ARFs, these feeders have varied speeds. They usually follow the direction of material flow and make use of a rotating member and the articulable gate to control the flow volume of material. There is also what is called drum rotation. This regulates and prevents the backflow of material and reduces overloading, product distraction, formation of fine dust, and ensures a uniform flow of material.

These feeders are usually set to feed material in a pneumatic conveying line. Rotation of the valve, coupled with the leakages between the rotor and the stator, cause gas from the conveying line to go upstream and be emitted.

"twitter:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

"og:image": "https://520machinery.com/rails/active_storage/representations/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaHBBd2F4Q1E9PSIsImV4cCI6bnVsbCwicHVyIjoiYmxvYl9pZCJ9fQ==--13bb2bb710ce7130f241b7f572819ee8f5c04642/eyJfcmFpbHMiOnsibWVzc2FnZSI6IkJBaDdCam9VWTI5dFltbHVaVjl2Y0hScGIyNXpld2M2RUdGMWRHOWZiM0pwWlc1MFZEb0xjbVZ6YVhwbFNTSVFNek13TGpCNE1qSXdMakFHT2daRlJnPT0iLCJleHAiOm51bGwsInB1ciI6InZhcmlhdGlvbiJ9fQ==--6000fb9b97ff571a651106bd1dd411d1b44d6f5b/Rotary%20Table.png",

If you’ve been putting off the purchase of a new rotary table, it’s time to stop thinking and buy! All in stock rotary tables at CNC Indexing & Feeding Technologies are currently 50% off.

Ganro Industrial Corporation offers large rotary tables in their standard DR series configuration. The large rotary tables are available in a range of 1000mm (40”) to 2500mm (98”) in faceplate diameter. They can be utilized as a full rotating axis incorporated into a machine’s control or as indexers with Ganro’s M-Mate AC servo controller. These rotary tables and indexers are all capable of being mounted in both the vertical and horizontal positions to give manufacturers maximum flexibility. These large rotary tables and indexers utilize a hydraulic brake system to reach high clamping torques. All Ganro DR Series rotary tables and indexers use Ganro’s core technology of a double lead worm shaft and worm wheel system for high precision and reduced backlash. Ganro rotary tables are assembled using cross cylindrical roller bearings with high rotation accuracy capable of bearing heavy loads in every direction.

As the exclusive importer and dealer of Ganro products in the United States, CNC Indexing & Feeding Technologies stocks the most popular Ganro rotary table models, accessories and spare parts. We have certified service technicians for installation and repair of all Ganro and Golden Sun rotary table and indexer models. Please contact us today to learn how adding a Ganro rotary table or indexer can help improve your manufacturing process.

"description": "Clark Machinery Sales has a wide selection of quality used barfeeds, rotary tables and other accessories by companies like Haas, LNS, Edge Technologies, Tsudakoma and more.",

"twitter:description": "Clark Machinery Sales has a wide selection of quality used barfeeds, rotary tables and other accessories by companies like Haas, LNS, Edge Technologies, Tsudakoma and more.",

"og:description": "Clark Machinery Sales has a wide selection of quality used barfeeds, rotary tables and other accessories by companies like Haas, LNS, Edge Technologies, Tsudakoma and more.",

This Edge Technologies Patriot 551 barfeeder is designed to automatically feed round, square, and hexagonal barstock in fixed headstock and CNC Lathes. It features an 8" bar, channel for 1 5/8" bar...

This Edge Technologies Patriot 551 barfeeder is designed to automatically feed round, square, and hexagonal barstock in fixed headstock and CNC Lathes. It features an 8" bar, channel for 1 5/8" bar...

This Edge Technologies Patriot 551 barfeeder is designed to automatically feed round, square, and hexagonal barstock in fixed headstock and CNC Lathes. It features an 8" bar, channel for 1 5/8" bar...

This Edge Technologies Patriot 551 barfeeder is designed to automatically feed round, square, and hexagonal barstock in fixed headstock and CNC Lathes. It features an 8" bar, and channel for 1 3/4"...

This Edge Technologies Patriot 551 barfeeder is designed to automatically feed round, square, and hexagonal barstock in fixed headstock and CNC Lathes. It features an 8" bar, channel for 2" bar, an...

This Edge Technologies Rebel 102 Servo SE barfeeder is a compact bar loading system for use with CNC lathes. It has a 30" magazine capacity, 60" bar length, and a 4" bar diameter.

This Tsudakoma RBA-500R rotary table features a 19.6" diameter, 7" bore, and 12" height. It comes equipped with dual disc hydraulic clamping mechanism and built in air/hydraulic booster.

We generally have a selection of barfeeds and rotary tables available for sale from brands such as Haas, Edge and LNS. We carry many other brands and models as well. Looking to add a barfeed to an existing lathe or add a rotary or trunnion to your current machining center? We have a variety of accessories to meet all of your CNC needs. Call us today at 410-252-5494.

Rotary tables are an incredibly useful piece of equipment as they can perform many functions. Rotary tables may be used to sort product into single-file, orientate product in a specific direction and as a quality control mechanism to reject product which does not meet specification. These tables can be customised to handle a large range of product shapes and sizes.

This is a modification of our 4″ Manual Rotary Table. This modification came about after requests from our laser engraving customers. They wanted a rotary table that had a larger through-hole to which they could mount our chucks.

This version of the Sherline rotary table has a Nickel-Teflon plating on the tabletop because it was designed to be used in an everyday production environment. This gives the table a rust-resistant surface that is hard and has added lubrication qualities.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel or stepper motor. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

NOTE: You can have your manual rotary table upgraded to CNC-ready, but this is done as a factory-only replacement. You will need to ship your manual rotary table back to our factory for the conversion.

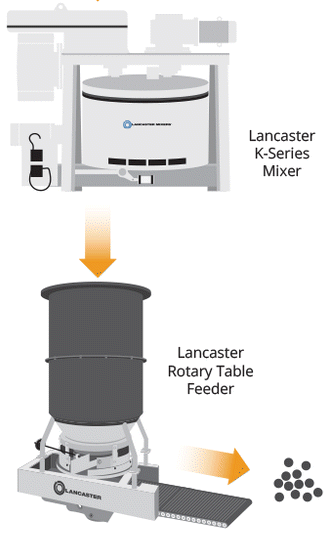

"Rotary Table Feeders are very useful in converting an intermittent batch process into a continuous material feeding process. They are also particularly helpful in moving sticky or hard to feed materials."

We have been widely appreciated in the market for providing supreme quality Table Feederto the customers. These products are highly demanded by the clients for their effective usage in large scale industries. The entire range is assembled using quality-tested components, under the expert guidance of our team of experienced professionals.

The Rotary Table feeder is used to feed sand from a bunker to a Conveyer or other downstream equipment where pre-set feed rate is required. The feed rate may be mechanically adjusted which would remain unaltered till it is re-set. These are available in three table sizes for various feed rates from 4 to 20 MT/hr.

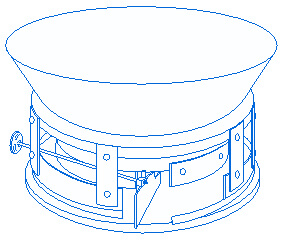

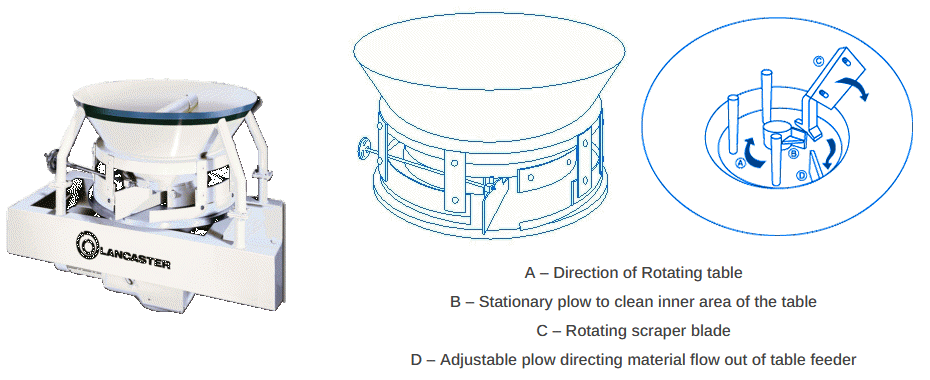

Whizz Rotary Table Feeder will consist of a power driven circulated plate rotating directly below a hopper / bunker. A feed collar located immediately above rotating table used in conjunction with an adjustable plough, determines the volume of material discharged.

The lower edge of the feed collar will be parallel to the table with a predetermined gap from table top. This arrangement permits equal quality of material to flow under the collar and spread over the table as it resolves. The material is then ploughed off into the discharge chute. The plough inside the feed collar.

· The table will be fabricated from 12 mm thick M.S. plates and will be mounted on the output shaft of the gearbox. The table will be driven from the output shaft of the reduction gear.

· Guard ring assembly.Drive equipment will consist of TEFC sq. cage induction motor coupled through V-belt equipment to the input shaft of a totally enclosed oil immersed worm reduction gearbox. The drive unit will be mounted on a fabricated M.S. base frame.The Rotary Table feeder will have following technical parameters:

The Globaltek rotary tables can be used to unscramble product and feed a conveyor, also as a buffer space to accumulate product until the downstream conveyor is ready for additional product or collect. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation. Accumulating rotary tables are designed to collect filled containers from a filling line to prevent slowdowns by quickly removing the finished product from the conveyors during operation. Can be set for clockwise and counterclockwise rotation.

8613371530291

8613371530291