rotary table feeder supplier

Global provider of vibratory feeders and other custom part feeding solutions, specializing in automated equipment that orients bulk parts by means of vibration and centrifugal feed systems, built to customers specifications. Products include custom tooled vibratory bowls, inlines, escapements, bulk hoppers, gravity tracks, sound enclosures, tables, base plates, PLC packages, IV sensors and cameras. Also offer custom centrifugal feeders, conveyors and bulk prefeeders. These feed systems use both mechanical tooling as well as vision or profile sensor integration. Systems are managed by either simple bowl and track level sensor monitoring to full PLC Logic with or without Ethernet capabilities. Engineering services from proof of principle to Solid Works modeling. Documentation/FAT approval via live streaming available. Serving the following industries: medical, medical devices, pharmaceutical, injection molding, packaging, labeling, aerospace, defense/munitions, electronics, cosmetics, fasteners, irrigation, automotive, and hardware.

Components of a Rotary FeederThe rotor shaft is a component found at the center of the electric motor. It produces a torque force, or motion, that causes movement of the material through the rotary feeder.Housing is the metal shell that contains and protects the electrical components of the rotary feeder. It forms the shape of the rotary feeder.

A rotary feeder works by separating pressure differences while allowing the passage of material into the processing system. To best illustrate how a rotary feeder works, it is best to imagine how a revolving door works. It permits the passage of material through while maintaining the difference of pressure in the building against the outside pressure.

Commonly known as ARFs, these feeders have varied speeds. They usually follow the direction of material flow and make use of a rotating member and the articulable gate to control the flow volume of material. There is also what is called drum rotation. This regulates and prevents the backflow of material and reduces overloading, product distraction, formation of fine dust, and ensures a uniform flow of material.

These feeders are usually set to feed material in a pneumatic conveying line. Rotation of the valve, coupled with the leakages between the rotor and the stator, cause gas from the conveying line to go upstream and be emitted.

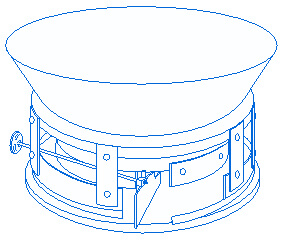

Rotary Table Feeder will consist of a power driven circulated plate rotating directly below a hopper / bunker. A feed collar located immediately above rotating table used in conjunction with an adjustable plough, determines the volume of material discharged.

The lower edge of the feed collar will be parallel to the table with a predetermined gap from table top. This arrangement permits equal quality of material to flow under the collar and spread over the table as it resolves. The material is then ploughed off into the discharge chute.

Let us be your one-stop supplier for all your rotary table, bar feeder, bar loader and high pressure coolant needs. Check out CNC Indexing & Feeding Technologies and you’ll see – no other supplier of CNC machine tool accessories can compare!

Established in the year1995,"M. V. Industries"is one of the foremost organization that is engaged in manufacturing, supplying and exporting quality approved range of Industrial Processing Machines and Equipment. Technically advanced, our range encompasses Pulverizer, Flaker, Impact Pulverizer, Pin Mill, Ball Mill (Batch Type), Ribbon Blender, Vertical Continuous Blender and Reaction Blender. In addition, we specialize in offering a wide array of Nauta Mixer, Continuous Mixer, Double Cone Mixer, Centrifugal Sieve, Vibro Screen, Rotary Sieve and many more equipment. We also take turnkey projects for Guar Gum, CMC and TKP Projects.

Rotary feeders, also referred to as centrifugal feeders, utilize rotary force in order to orient and sort parts before feeding them to the next stage in automated processes. As a component of bulk and specialty material handling processes, rotary feeders are often utilized in industries such as agriculture, industrial, automotive, cosmetics, mining, food and chemical processing.

Ideal for air pollution control applications, rotary feeders provide quiet, subtle processes to separate materials in order to feed a wide variety of parts without the use of tracks or vibration. Typically constructed from cast iron, carbon steel or stainless steel, rotary feeders are often used for dry free-flowing powders. Offering high feed rates, rotary feeders are ideal for thick parts that are not inclined to tangle when pulled to the outside of the bowl at high speed. Offering efficient separation of both large and small parts, rotary feeders tend to mar parts less than any other feeder type and offer an ergonomic solution to monotonous and physically strenuous sorting tasks.

Primarily used to discharge production materials from hoppers and bins, cyclones and receivers, rotary feeders are constructed from components including a rotor shaft, housing, head plates, and packing seals and bearings. The rotors typically have large vanes that are cast or welded on and are often driven by either small internal combustion engines or electric motors. The parts are simultaneously stabilized as they accumulate on the outer edge in order to start orientation. After orientation, the parts exit the bowl and are conveyed to the next stage in the process. However, parts that are damaged or misaligned in any way will not be conveyed forward, but will be returned back to the feeder bowl to either be recirculated or discharged. Specialized custom tooling is often available in order to better suit certain types of parts and well as to achieve a desired rate of speed. For example, one special type of rotary feeder, referred to as a rotary airlock feeder, is best suited for pneumatic conveying systems and dust control equipment.

Are you looking to achieve the highest performance and the highest quality in the least amount of time? AccuBrass’ wide range of vibratory feeders can help increase your company’s production output and improve the quality of your products. Our small and bench-top feeders range from 0.25 Cubic Foot to .5 Cubic Foot, while our medium and large feeders range from 1.0 to 10.6 cubic feet. To make sure you have the feeder you need, customization options are also available. Contact us today!

AFM Engineering is a manufacturer of vibratory feeder bowls, conveyors, hoppers and parts feeding systems. Our products show not only quality but durability, dependability and conform to OSHA and ISO standards. We offer integration, installation and service on our products.

At Air Way Automation, we are committed to providing high-quality parts feeding and assembly equipment, as well as unparalleled customer service. Our team will evaluate the requirements of your application, and use cutting edge waterjet and EDM technology to design and manufacture the feeder. Additional services include installation and facility integration to ensure that your company starts production on schedule.

Our vibratory feeders are known around the world for their quality and simplicity. We believe in only using the most simple and efficient manufacturing methods in our products- making them easy to install, use, and fix. We have over 40 years of experience in our industry, and we know just how to make things easier for you. Find out more by contacting us today!

Over 50 years California Vibratory Feeders has been manufacturing vibratory parts feeders along with centrifugal feeders. We are known all over the world for our quality, service and reliability. We custom build vibratory feeder bowls, centrifugal feeders, gravity tracks, inline’s, tables, hoppers, pre-feeders and elevators. We look forward to fulfilling your automation needs. Check out our website today!

CDS Manufacturing is a manufacturer of vibratory feeders, parts feeders, bowl feeders, and linear feeders. CDS Manufacturing designs high-quality feeding equipment to be used in a wide variety of applications including light bulb filaments, balloons, ball bearings, molded plastics and more.

For decades we have been committed to providing our customers with bowl feeders that will stand up against the wear and tear of everyday application in order to provide a lifetime of product service. Our technicians will work closely with you in order to come up with a product that will fit your exact specifications. For more information on how we may be able to assist you in keeping your business moving forward, visit us on the web today!

DEPRAG is an automatic assembly equipment manufacturer with a 70-year plus experience. We manufacture air and electric power tools, screwdrivers, drills, grinders, polishers, hammers, pliers, saws, shears, industrial tools, air motors, power tool accessories, fastener feeders and complete assembly machines.

Dial-X has been building vibratory feeder bowls for over 35 years. We also specialize in vibratory hoppers and elevating parts storage hoppers. We build bowls for the medical, automotive, food and consumer products industries.

Dynamic Air engineers and manufactures vibratory feeders for a wide variety of applications. Our line of equipment includes bin activating feeders, bin dischargers, shakeouts, and more. Over the years, we have gained comprehensive expertise in serving industries ranging from agricultural to mining to pharmaceutical. Contact Dynamic Air today and our team will help find the solution that works for you.

Feed Rite Automation specializes in the design and manufacture of superior parts feeders and automated equipment. Centrifugal rotary feeders, vibratory bowl feeders, conveyors and more, we have built a reputation for solving difficult parts feeding challenges. Our mission is to provide you with top quality equipment and service from engineering to machining, fabrication, electrical and assembly.

Gough Econ is a conveyor system manufacturer providing bucket conveyors and elevators, belt conveyors, overhead conveyors, storage conveyors and vibratory feeders/sieves. We design and manufacture a variety of material handling conveyors and conveyor systems for a wide variety of industries.

JR Automation can designing and building vibratory feeders that can be fully integrated into your overall strategy. Our material handling solutions can greatly increase the productivity of your application"s material handling processes. JR Automation strives to remain at the forefront of automation technologies by developing innovative solutions to the needs of our clients. Contact us today to learn more!

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines unsurpassed in quality and performance. For more information, visit us online at www.jvivibratoryequipment.com

Kinergy is a leading manufacturer of high-quality vibratory feeders with induced vertical flow and conveying for bulk solid materials. With gravity being a major assistant in moving the materials, our equipment only needs two drive components—the vibratory motor and the isolator.

Since 1973, Leonard Engineered Products has been serving process equipment users with the finest manufacturers" product lines. Let us be your first choice for vibratory feeders. We represent LIGHTHNIN Mixers, and ERIEZ Vibratory Feeders & Screeners and Recycling Equipment.

M&S Automated Feeding Systems creates parts feeders built and tested to each customer’s specific application. Fully equipped to design, fabricate and service a complete range of quality feeding equipment and specialized parts handling systems, including vibratory controls, conveyors, custom mechanisms, centrifugal feeder bowls, hoppers, vibratory inline feeders, sealing and vision systems.

Martin is the leader in industrial vibrators and vibration systems and solutions. We provide the quietest and most energy efficient vibratory feeders, hoppers and compaction tables available and a host of other products to make material flow easy. Martin serves a wide range of manufacturing industries which use our equipment to improve productivity and safety all while increasing the bottom line.

MGS Machine Corp. is a manufacturer of vibratory feeders, centrifugal feeders and bowl feeders. We serve a variety of industries including pharmaceutical, medical, paper goods and more with quality vibratory parts feeders.

Our rotary feeders cannot be beat! Since our inception our company has become known for the high attention that we pay to detail. Our quality control team will ensure that each and every product that we output is the very best! We us, you get nothing but quality! For more information on what we may be able to do for you; get in touch with us by telephone or email today!

Parts Feeders provides industries with quality parts feeders, feeder bowls and other vibratory feeder equipment. We provide a wide range of products and services to ensure that you, the customer, receive the best in quality and reliability. A leader in the industry since 1957.

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

QSI Automation, Inc. offers decades of experience in designing and building vibratory feeder equipment. Among the products QSI provides are vibratory feeder bowls, vibratory inline tracks and storage hoppers for automatic feeding, orientation, and sorting. QSI also supplies floor bin hoppers with attached elevating conveyors and sound enclosures.

Highly efficient, precision vibratory feeders serving hardware, electronic, automotive, pharmaceutical, packaging & other industries--rates from 1 to 1000+ per minute with ZERO failure, and up to 10 different parts handled in one feeder! Check out all our manufacturing options today: sound enclosures, elevators, storage hoppers, inlines, gravity tracks, pick & place units and replacement bowls.

Triple/S Dynamics is a manufacturer of vibratory feeders, vibrating screens, conveyors. This equipment is selected from a wide range of design types to best fit the requirements of each application. Your source for specialized dry-bulk-material separation and conveying equipment since 1888!

UTI specializes in the engineering of vibratory and rotary parts handling equipment. UTI leads the industry in innovative parts handling solutions. We provide simple and efficient solutions to complex problems. We are an engineered based provider of parts feeders, simple mechanisms, systems, solutions, and service.

With USVibra’s cutting edge vibratory feeder technology, you have options for complete flexibility in all work-cell, robotic handler & Pick-N-Place applications. Our renowned feeder & conveyor systems customized to OEM machine requirements include Multi & Single Lane, Linear, Belt, Stick, and Tube Feeders.

Ward Industrial is an experienced manufacturer of vibratory equipment like vibratory screens and vibratory feeders. We also specialize in bulk material handling equipment systems and conveyors.

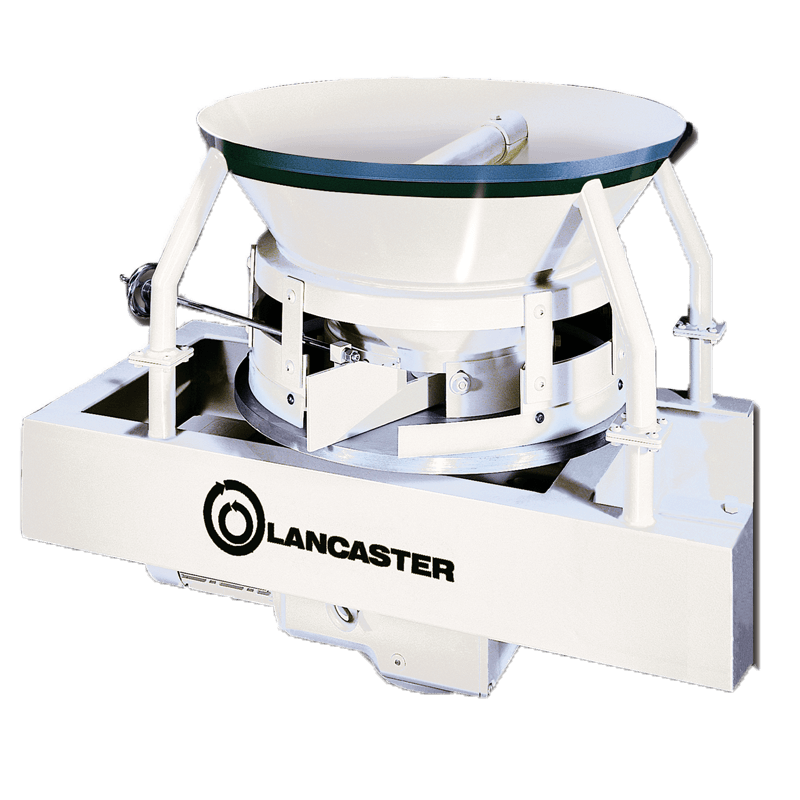

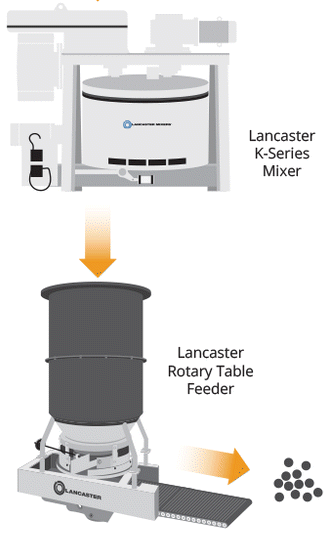

GENERAL DESCRIPTION AND SPECIFICATION ROTARY TABLE FEEDER Rotary Table Feeder will consist of a power driven circulated plate rotating directly below a hopper / bunker. A feed collar located immediately above rotating table used in conjunction with an adjustable plough, determines the volume of material discharged. The lower edge of the feed collar will be parallel to the table with a predetermined gap from table top. This arrangement permits equal quality of material to flow under the collar and spread over the table as it resolves. The material is then ploughed off into the discharge chute. The plough inside the feed collar. The major components of the Rotary Table Feeder will be :- The table will be fabricated from 12 mm thick m.s. plates and will be mounted on the output shaft of the gearbox. The table will be driven from the output shaft of the reduction gear. Adjustable plough assembly. Guard ring assembly. Drive equipment will consist of TEFC sq. cage induction motor coupled through V-belt equipment to the input shaft of a totally enclosed oil imersed worm reduction gearbox. The drive unit will be mounted on a fabricated m.s. base frame. The Rotary Table feeder will ranges from 5 tons/hr to 30 tons/hr.

It is suitable for feeding can/jar/tin/bottle one by one to the following process,such as filling system.It is also can be used as collecting the can /jar/tin/bottle,which have been filled.

First ,our machine is stable and easy to operate, what you need to do is just learn some basic skills like how to operate PLC. We will send you manual and video, we suggest you to come to visit our factory to learn more thing by yourself, and if there is something goes wrong, you can call us ,video-chat or email us .We will fix problems within 24 hrs .Our engineer also can be dispatched to overseas as you required.

Rotary Table Feederis supremely versatile in handling materials which are sluggish and get arched over restricted openings. The ultra-advanced feeder is mounted over the hoppers or bin. It has been specifically prepared to prevent arching or bridging of materials. The conveying medium of the modern feeder is a horizontal table which is rotated under an adjustable collar. It features a fixed plow which is excellent in removing material flows from under the table. With premium raw materials, robust construction, standard design, the rotary feeder is unequaled both in terms of quality and performance.

Advanced technologyRotary Table Feeder are used in industries, which require the moving or feeding of powder or granular substances. Table feeders are particularly helpful in moving sticky or hard to feed materials. They are also very useful in converting an intermittent batch process into a continuous material feeding process.

The TJR AR-5C pneumatic collet rotary table is designed to provide an affordable alternative to three- or four-jaw chucks for workpieces requiring 5C collets.

PMTS 2017: CNC Indexing & Feeding Technologies’ Tracer Minibar hydrodynamic magazine bar feeder is able to feed bar diameters from 0.8 mm to 12 mm and up to 10 ft. in length.

The Tracer Vs-105XL bar feeder from CNC Indexing & Feeding Technologies is designed for heavy bars ranging to 41/8" (105 mm) in diameter and measuring as long as 72".

The Ganro HR-3030 rotary table available from CNC Indexing offers a table-top dimension of 3,000 mm (118.11"), a table-swing diameter of 3,905 mm (153.75") and a maximum workload capacity of 50,000 kg (110,230 lbs).

Distributed by CNC Indexing & Feeding Technologies, Ganro Industrial Corporation’s GCT series manual horizontal index table adds indexing capability to a horizontal boring mill.

CNC Indexing & Feeding Technologies says its GSI CNC-201R rotary indexing table is designed for companies that want to add fourth-axis productivity at minimal cost. According to the company, the table provides high clamping torque and indexing accuracy.

The GSI CNCT-321 tilt/rotary table is designed to add four- and five-axis productivity at a minimal cost. The table allows manufacturers to machine as many as five sides of a part while minimizing second and third operations and setups. The table also provides excellent clamping torque and indexing accuracy, the company says.

CNC Indexing Technologies says its GSI CNCT-321 tilt/rotary table is designed for adding fourth- and fifth-axis productivity at minimal cost. The table allows users to machine as many as to five sides of a part while minimizing second and third operations and setups. The table has a 12.

The GSI DNC-400 direct-drive rotary indexing table is suited for high-volume and aerospace manufacturers performing high speed, high-accuracy contouring operations. Compared to tables using a servomotor and worm gear, this direct-drive table offers higher accuracy, faster rotational speeds and higher torque, the co

8613371530291

8613371530291