4th axis rotary table for vmc supplier

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

We are Professional Designer, Manufacturer, Supplier, Exporter of CNC 4th Axis Rotary Cradles (Cradles, Rotary Cradles, CNC Rotary Cradles, 4th Axis Cradles, CNC Cradles) from Aurangabad, Maharashtra, India.

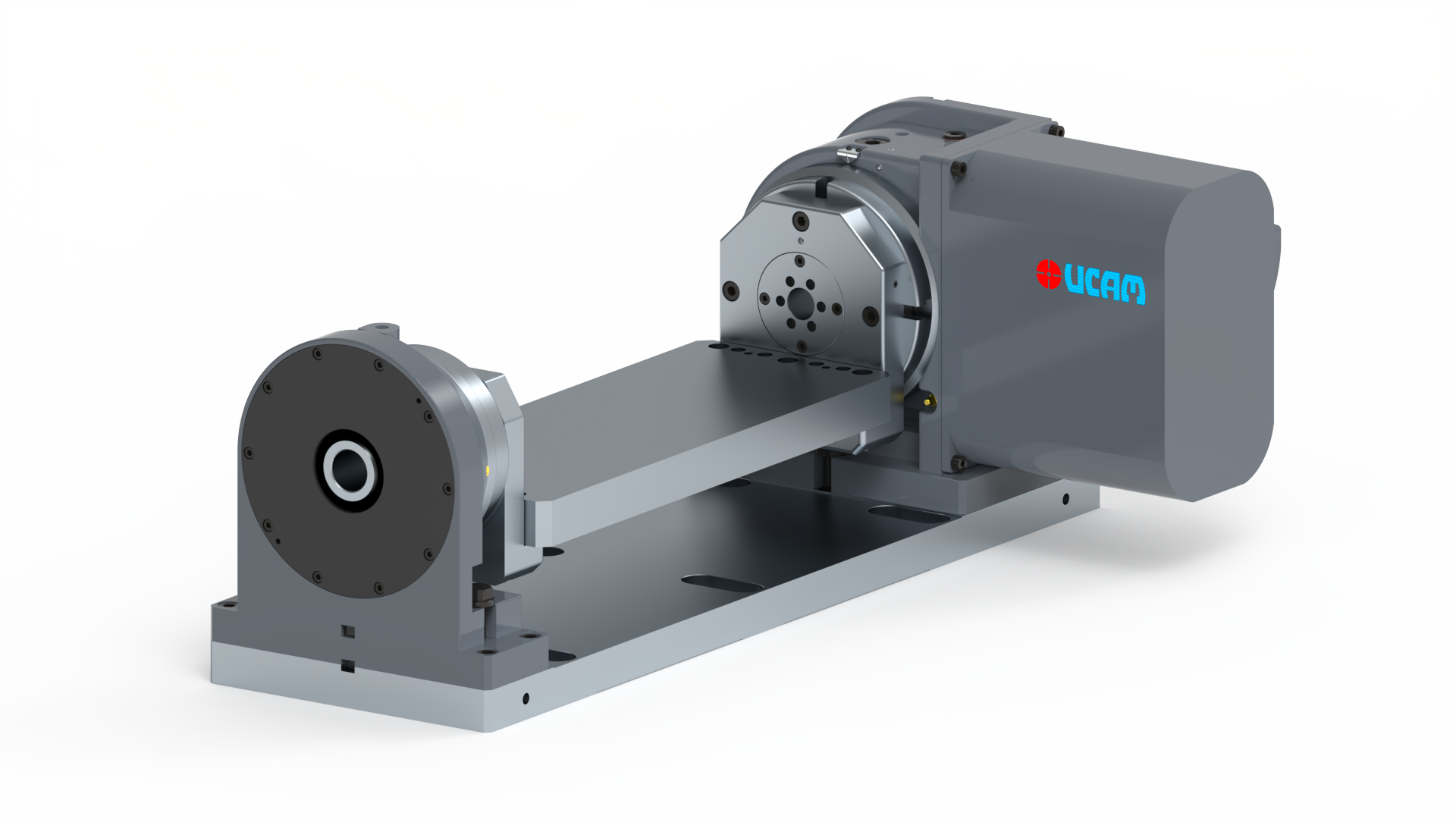

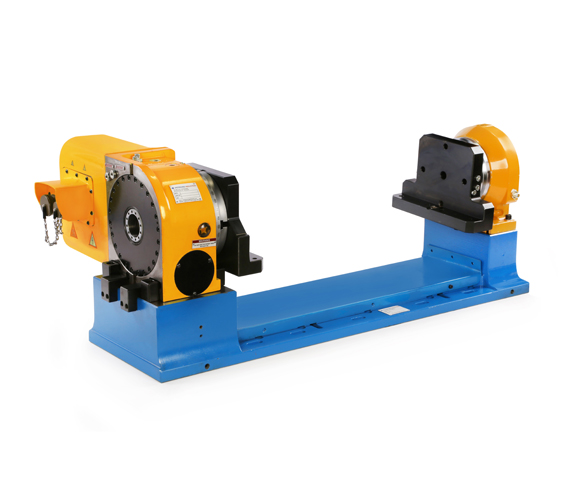

☆ Rotary Cradle is used to rotate the rotary VMC fixture. It consists of rotary drive at one side & tailstock at another side. Through rotary drive we can rotate the fixture in 360 degree. Various type Rotary Drives used in cradle, such as UCAM, T- SUDAKOMA, HASS, ETC.

☆ All Jyotirling CNC Rotary 4th Axis are reliable, offers high performance with unmatched accuracy and reduces noise due to its unique design and durable material quality.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

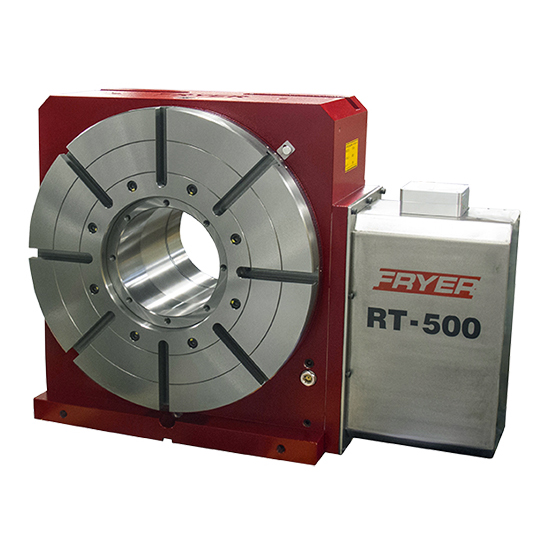

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Direct Drive (DD) motor or torque motor, will be the trend in mechanical transmission for the future. It has the advantage of high speed, high-accuracy, no backlash, etc. For this reason, in 2008, we have been actively involved in developing the rotary table with a direct drive motor for 4-axis or 5-axis CNC machines. This research and development we could achieve with the able cooperation and support from PMC and could able to showcase the dual-axis NC rotary table at the Taipei International Machine Tool Show 2009 (TIMTOS 2009). This NC rotary table adopted a direct drive motor and encoder procured from Europe and integrated with the Heidenhain controller. By incorporating an appropriate cooling circuit it was possible to extract the max. Torque output from the DD motor torque characteristics.

Recently in the market, NC rotary tables with DD motors are incorporated with existing controllers available for the 4th-axis or 5th-axis on the machine. However, DD servomotors required high precision control system, so it becomes essential to get incorporate higher-level controllers such as HEIDENHAIN, Siemens, Fanuc 31iM, and Mitsubishi M70 for the machine which in turn will increase the overall costs. Due to this reason, SPINTOP developed a model of an external CNC controller that could be interfaced with the original controller or low-level CNC controller to meet the requirement of the DD motor as well as keep the cost reasonably low.

Due to this, the DD motor has characteristics of high speed, zero backlash and the ability to adapt to a normal encoder we can offer an NC Rotary Table of stable performance with reduced fault or error. It is easy to interface and integrate DD motor NC Rotary table within the existing machine with the help of the spare Mcode available.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

Best 4 Axis VMC Machine for Sale Are you looking for it? In this article, I will take you through a lot of knowledge about a 4-axis VMC machine. From the most basic definition, working principle, main components and its approximate price. If you’re looking for a qualified 4-axis VMC

What is a 4 axis CNC mill? Milling is the machining process of using rotary cutters to remove material from a workpiece by advancing (or feeding) the cutter into the workpiece at a certain direction, CNC mill is a CNC machine tool also called CNC machining center What is a 4

What is a 4-axis CNC machining center? 4-axis machining is an interesting and important subpart of the CNC milling world. This is an article series to help beginners understand how And why a 4th Axis is used on CNC machining center. In the first instalment, we’ll look at what a 4-axis

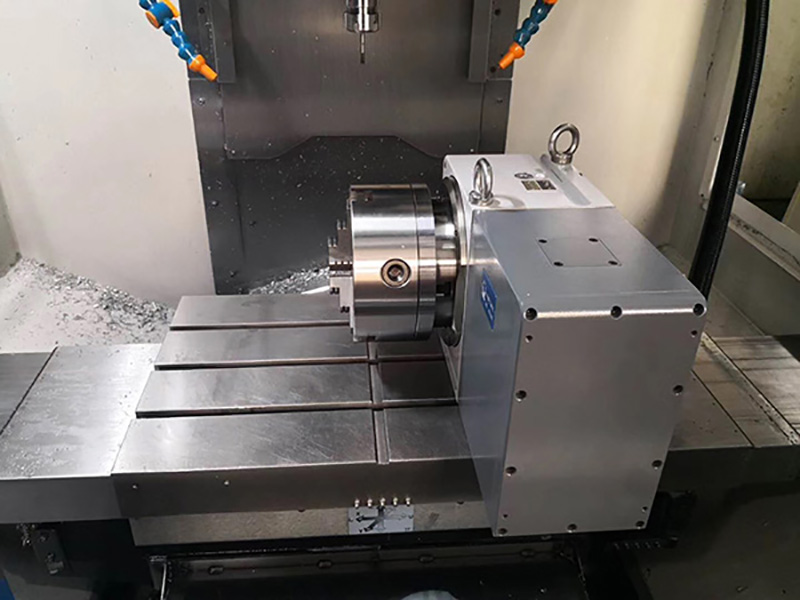

vertical machining center with 4th axis, also known as the 4-axis machining center, it is equipped with a four-axis indexing head based on the 3-axis machining center. What is a 4th machining center? Generally, when the workpiece is not positioned in space, there are six degrees of freedom, X\Y\Z three

The function of the 4th axes rotary table is to perform continuous rotation, feed motion or adjustment of the rotary index according to the signal transmitted by the control system or the transmitted command, and then enable the CNC machine to complete the program to be processed as required. The fourth axis is usually matched with a vertical machining center and a CNC milling machine. It can be used for machining with T-axis and sleeve items. The 4th axes rotary table can be controlled by a separate control program or device, and of course, can be controlled by the host’s number system or device depending on the relevant interface.

After the installation of the 4th axes rotary table, the production efficiency and processing quality and quality of the processed articles can be quickly improved.

8613371530291

8613371530291