4th axis rotary table for vmc manufacturer

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

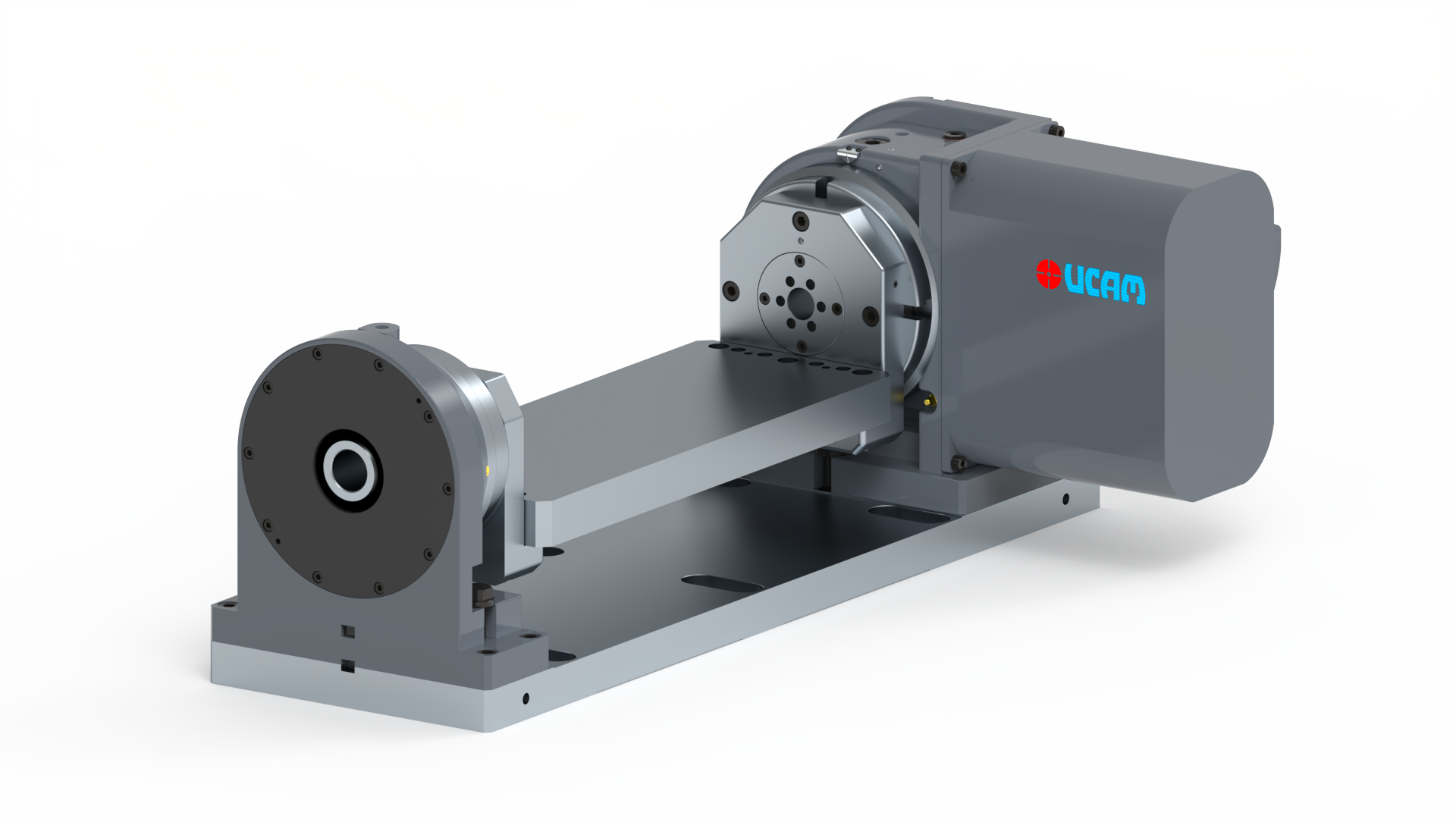

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

We are Professional Designer, Manufacturer, Supplier, Exporter of CNC 4th Axis Rotary Cradles (Cradles, Rotary Cradles, CNC Rotary Cradles, 4th Axis Cradles, CNC Cradles) from Aurangabad, Maharashtra, India.

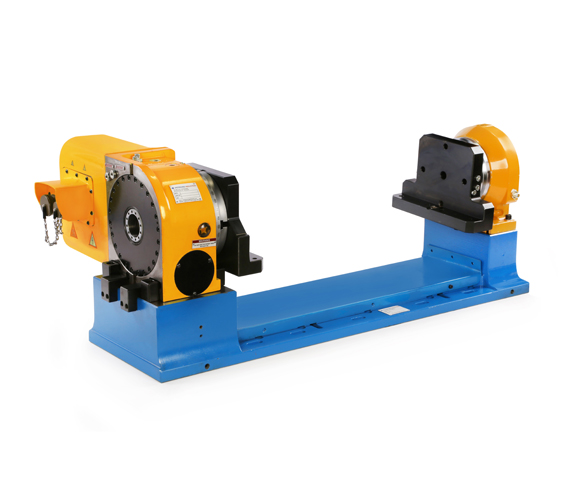

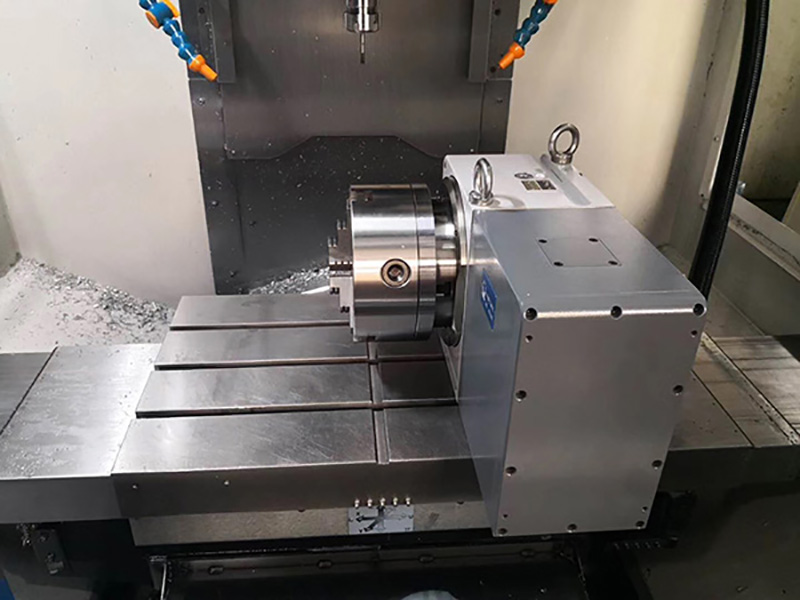

☆ Rotary Cradle is used to rotate the rotary VMC fixture. It consists of rotary drive at one side & tailstock at another side. Through rotary drive we can rotate the fixture in 360 degree. Various type Rotary Drives used in cradle, such as UCAM, T- SUDAKOMA, HASS, ETC.

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

New Trunnion model TR 100RF has all of the features of the standard wired models while being the perfect application for palletizing VMC An easy to use system with no messy cables

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

Index Designs is an all-American company. Our founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. We entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Our products are completely manufactured in our Chatsworth, California facility. We use state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines. You are always welcome to visit our plant and see for yourself.

Index Designs provides engineering and manufacturing professionals with top quality products and services for the manufacturing industry. From the small job shop to the large OEM’s our customer base serves any and all types of industries including automotive, aerospace, defense, medical and energy just to name a few.

Our rotary tables are constructed of heavy-duty materials and are designed to provide long lasting, dependable service. Compare the components and design of our rotary tables with others in the industry. We take special care at our Chatsworth, California facility to manufacture and assemble products to the highest level of performance, yet offer a very cost competitive price for our customers.

For machining components from small, 5C collet sized parts, up to 15 inch diameter or larger work pieces, Index Designs offers a rotary product to fit your needs – including 5 axis rotary tables.

Whether your CNC control has AC or DC drives, or uses Fanuc (Alpha or Beta), Mitsubishi, Yaskawa, Glentek, Siemens, Baldor, etc. we can build a rotary table with a compatible motor for just about any 4th axis-ready machine on the market! If you need help getting a machine 4th axis ready, we can also supply the parts you need; such as amplifiers, drives, cables and connectors.

If your application does not require true, continuous 4th axis simultaneous cutting, we offer an easy-to-program, single-axis control box that can be interfaced using a spare M-function from your CNC machine. The control box can either be programmed directly or fed data via RS-232 for fast, accurate indexing to any angle.

8613371530291

8613371530291