4th axis rotary table for vmc factory

1MTA offers a large range of 4th axis rotary tables supplied by Kitagawa, specialists in high-quality machining equipment. 4 axis CNC rotary tables add an additional, rotary axis to your indexing table allowing for greater precision and versatility.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

With modular design concept and engineering, Rotary Production Systems have continued to support and succeed at applications which demand high volume productivity.

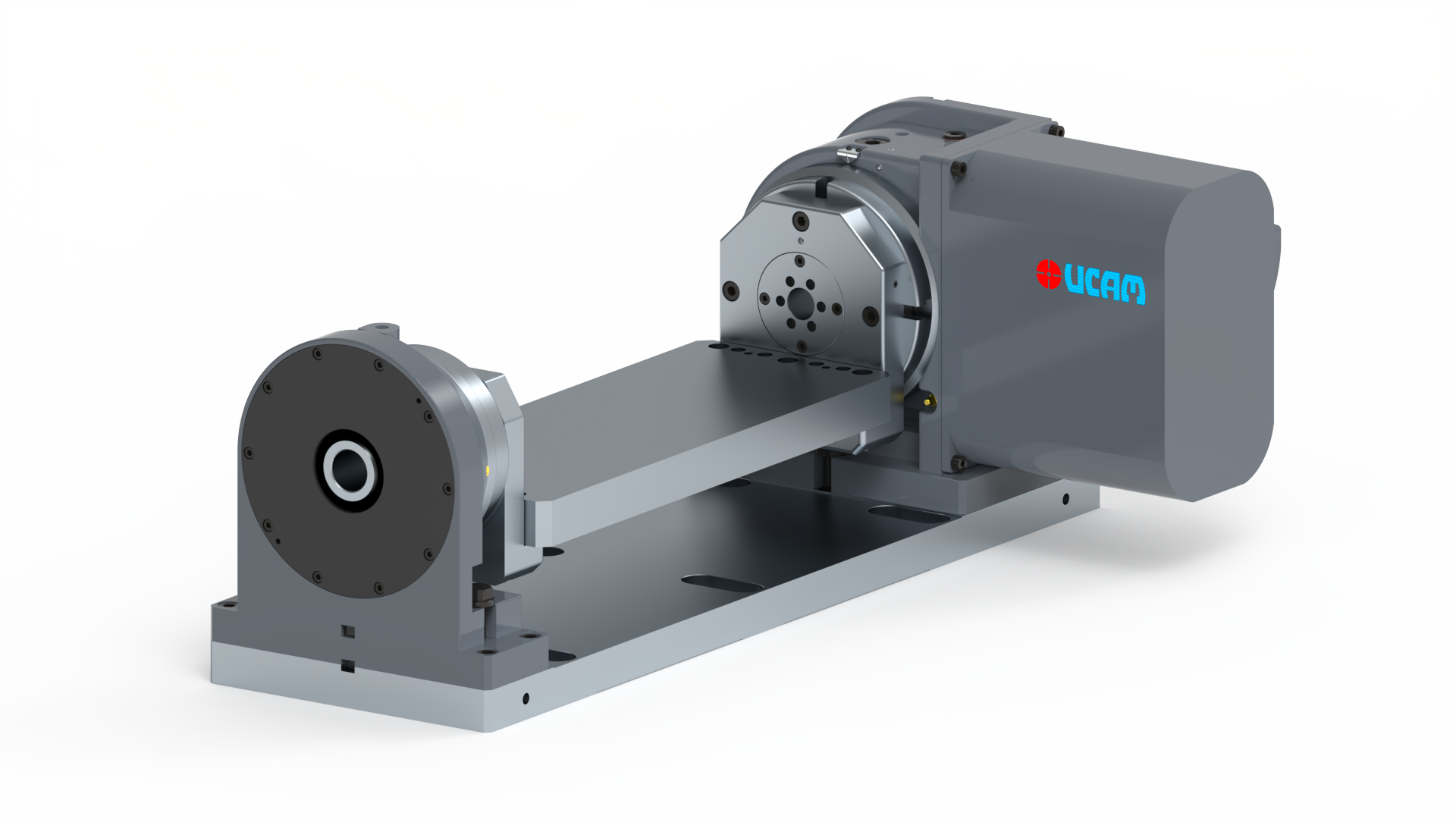

We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others

A rotary table is a workbench, designed to cut wood, metal, and other surfaces with a built-in tablebench, to make work easier. It is so compact and easy to use as a 4th axis tablebench, so that the work can be harder.

There are many types of rotary tables depending on your client"s needs. The rotary table is also called a rotary table, if it is a client"s design or a business, it can be compared to other rotary tables depending on the client"s needs. A rotary table is also called a rotary table, which allows users to cut many projects at once and have a different finish compared to the original rotary table.

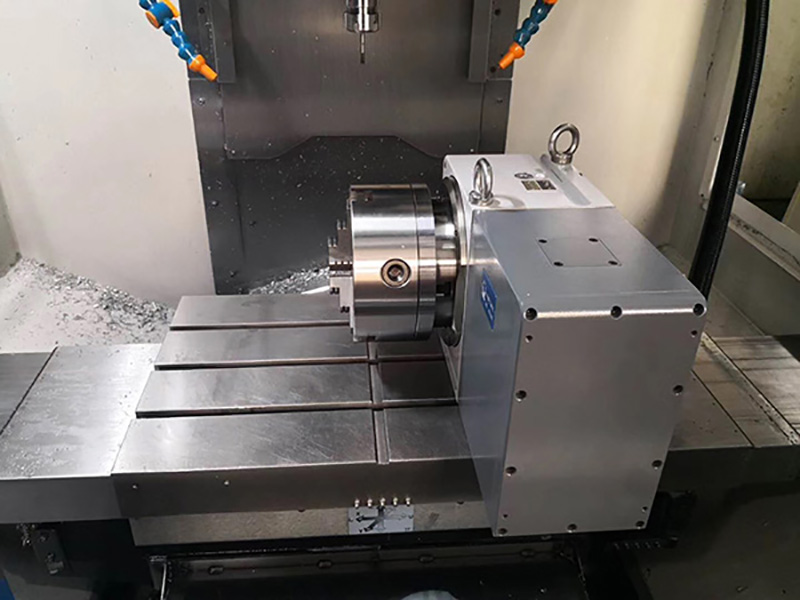

Adding a 4th axis rotary table to a milling machine provides several advantages to your job shop. Having another axis to work with gives milling machine users more precision and accuracy without having to change part positions.

Also, an additional axis would prove to make any milling machine more diverse in the work it is capable of doing. Lathe machines introduce the aspect of a rotating part, so a rotary table would add the same benefits provided. A 4th axis rotary table, in general, can provide more precision and ease to a complex design, reducing time and costs for the production of a certain piece.

A 4th axis rotary table serves to add a rotating axis to the desired piece being shaped. Similar to a lathe’s rotating head-stock, the rotary table holds the piece and moves it at exact intervals of revolutions.

Because it can move in precise degrees of motion, machinists can easily calculate correct positions, just as they do with the other three axes of motion on the machine. Once all 4 axes are used, making grooves or holes in the piece is much easier than without the rotary table. This saves time by discarding the task of removing and resetting the piece in another position. Having the ability to move the piece in determined intervals and precision in multiple axes is important for more complex machine work.

Just like with the other three axes of motion, the 4th axis can be adjusted for specific amounts of distances to accurately tell what position you are at in relation to the dimensions of the piece.

Also, the scales used to measure its motion can save time and resources by reducing the amount of mistakes that could result in major delays. A 4th axis rotary table can be integrated into a milling machine’s control in order to set the positions needed. This makes accurately machining multiple pieces faster and easier to accomplish.

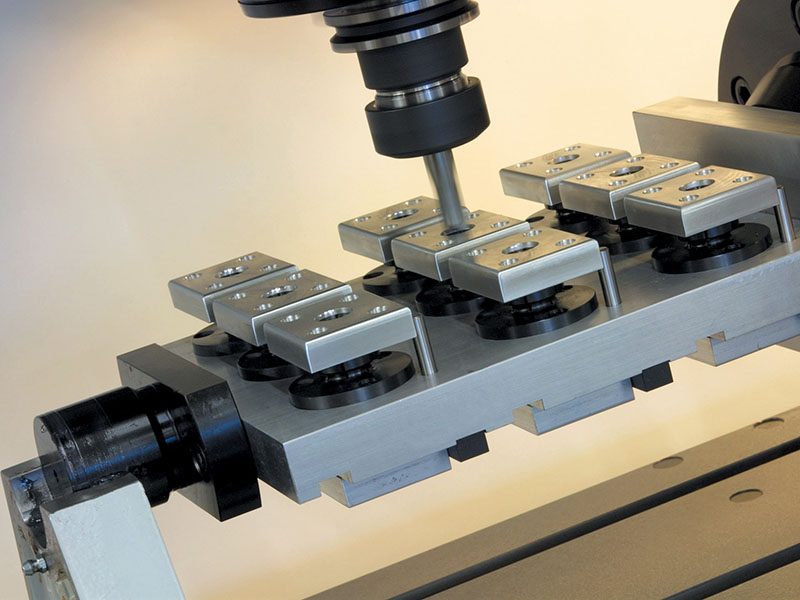

With a full 4th axis, your milling machine can handle a much more diverse set of jobs. For example, machining parts with holes in which mill must work with a circular pattern with equal distances is certainly possible with 360 degree movements. Arc cuts, grooves, and other complex curves are included with the benefits of a 4th axis rotary table. Cutting out the teeth of gear parts is another possible application.

A 4th axis rotary table extends the degree of motion necessary for complex work needed by any skilled machinist. With quality material, a machinist can create intricate parts and expand the types of orders your job shop can take on.

CNC Indexing & Feeding Technologies offers a wide selection of 4th axis TJR rotary tables. Contact us today to learn about our high quality CNC accessories.

Martin Trunnion Tables offers complete 4th axis packages for Samchully rotary tables. Ready to be mounted into your machine, your Stallion Trunnion Table will already be attached to your Samchully rotary table and assembled onto a baseplate. This allows for an easy transition from 3-axis machining to 4-axis CNC machining. Scroll down for examples and package options! Don"t hesitate to reach out to us to discuss your manufacturing needs. Our applications engineers are always happy to help!

The same Stallion Trunnion Table, up to eight times the productivity. Built for the highest production jobs. Available in 3 to 8 sided configurations. Complete solutions available to maximize your VMCs throughput. Also made for any rotary table and machine tool on the market.

MachineStation is keenly involved in the auction facilitation helping sellers capitalize on their surplus assets. Whether it be a Complete Plant or individual equipment. We work with nationally recognized auctioneers in finding the type of auction best suited for the seller’s unique situation.

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.See all condition definitionsopens in a new window or tab

Used: An item that has been used previously. The item may have some signs of cosmetic wear, but is fully operational and functions as intended. This item may be a floor model or store return that has been used. See the seller’s listing for full details and description of any imperfections.See all condition definitionsopens in a new window or tab

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

CNC rotary tables are a cost-effective alternative for the shops that cannot afford those high-end multi-axis machining centers. Though less versatile and efficient than a CNC machining center, a typical milling machine that incorporates a rotary table is able to carry out many more intricate tasks. In this article, we will walk you through the basic knowledge of the 4th and 5th axis CNC rotary tables, including how they work and what they can do for the shops.

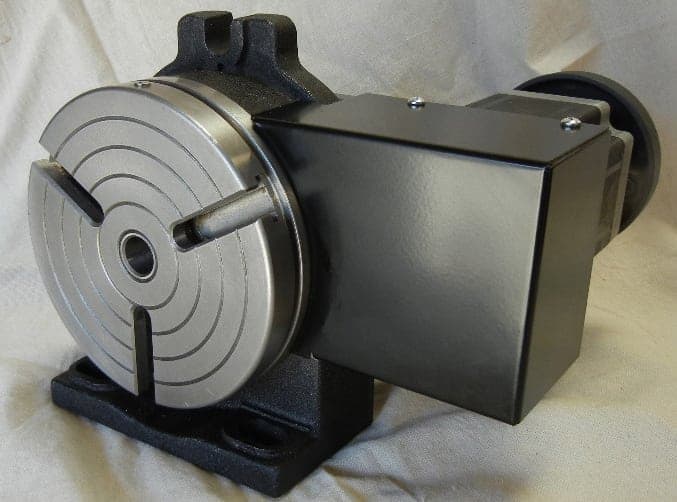

In essence, it is a mechanical device that offers an additional rotational axis to a machine tool. It is typically designed to work with a milling machine so that the machine has the ability to carry out more complex cuts. Provided with a rotational axis, in a sense it combines a milling machine with a lathe. Besides giving an extra axis, rotary tables are also used for indexing and positioning tasks.

Rotary tables were invented in the early 20th century. The construction has not changed much since the invention except the way they are driven. At first, chains were used. But from 1918 on the shaft-driven mechanisms replaced them. As the technology of powered machines and computer control advanced, NC and CNC models hit the market in the late 20th century. CNC controls facilitated precision positioning and indexing.

The primary benefit is the indexing accuracy. In the past, millimeter-scale accuracy was enough for general-purpose machining applications since the part tolerance requirements were not high. Today, medical equipment, military, and automotive components require higher precision. That is why CNC tables with micrometer precision prevail across industries.

The standard CNC rotary tables are also called the 4th axis or 4-axis rotary tables. The 4th axis refers to the rotational axis, their most important feature. It upgrades an existing machine tool with x, y, z dimensions by adding an additional axis.

As mentioned earlier, the working principle of a 4th axis CNC rotary table is similar to the headstock of a lathe. They are both electrically powered to clamp a workpiece and make turns. The CNC system enables precision positioning so that the milling machine can make cuts on the desired surfaces of a workpiece.

An additional fourth axis is beneficial because it can be adjusted for particular amounts of rotary motion. The degrees the table rotates are pre-programmed and accurately controlled by the computer. The other benefit is that it allows the milling machine to work on cylindrical parts. The milling machine can cut grooves, slots, and planes on the outer diameter of a bar.

The precision indexing ability of the rotary table enables the machine tool to cut equidistant holes in a workpiece around 360 degrees across its surface. Repositioning of the workpiece is not required during such an operation. Similar operations such as arc cuts and curved contours can be performed in a run as well.

A 5th axis CNC rotary table provides two additional machining axes to a machine tool. Besides the rotational axis, the 5-axis rotaries have another swinging axis. In other words, the table not only turns but also tips. With two more axes, the machine tool is able to perform multi-plane machining.

The working mechanism of a 5-axis CNC rotary table is simple. As you can see in the image above, the rotary is mounted onto a swivel base. In addition to the swivel, other designs such as a swing bed are also available to provide a tilting axis to the table. Here is a video showcasing the moving axes.

A 5th axis CNC rotary table not only features precision positioning but also eliminates multiple setups that are required for complex machining applications. Compared to the standard CNC rotaries, the 5-axis table covers more surfaces on the workpiece. The milling machine can machine a workpiece on any four of the five axes at the same time, which reduces the production lead time significantly.

One of the key applications of 5-axis machining is mold-making. The ability to achieve intricate surface designs on the workpiece allows for the machine to manufacture molds used in industries including aviation/aerospace, automotive, military/defense, and medical.

The 4th and 5th axis CNC rotary tables have their own pros and cons and are suitable for particular applications. The 4th axis rotaries are apt at precision indexing for simpler designs whereas the 5th axis tables excel at complex designs but the rigidity is compromised and chatter or deflection may take place accordingly. The shops should choose a model that meets their actual requirements.

Shenzhen, Guangdong Oct 12, 2022 (Issuewire.com) - Silver CNC has released a new 4th axis rotary table that is designed for use with VMC machines. The rotary table can be used to machine parts on all sides and features a built-in independent clamping system. This allows the user to quickly and easily clamp the part in place without having to worry about alignment. The table also includes an automatic lubrication system that keeps the bearings well-lubricated during operation. Lastly, the rotary table is equipped with a digital readout system that makes it easy to position the part accurately. Visit: www.silvercnc.com to learn more or call +86 180 9892 0890 to speak with a representative today!

The CNC roller cam rotary table is a 4th axis table designed specifically for use with CNC machines. This versatile tool allows for precision milling, drilling, grinding, and even engraving on circular components. The roller cam design ensures smooth and efficient rotation, allowing for precise control over the angle and speed of the table"s movements. Additionally, the rollers can be locked in place for added stability during operations.

By increasing the capabilities of your CNC machine, this 4th axis rotary table can greatly enhance your manufacturing productivity. Whether you are producing small electronic parts or large automotive components, the CNC roller cam rotary table is an invaluable addition to any factory floor.

The 4th axis rotary table is a valuable addition to any CNC operation. It allows for full circular cuts and greatly enhances the capabilities of the machine. The roller CAM driver stands out from other 4th axis options because it provides smooth, precise motion with minimal vibration. This not only improves the accuracy of the finished product but also extends the lifespan of both the 4th axis and the overall machine.

In addition, its compact design allows for easy installation in tight spaces and its durable construction ensures reliable performance for a long time to come. Overall, investing in a 4th axis rotary table with roller CAM driver technology is a smart choice for any CNC operation looking to expand their capabilities.

Looking for a rotary table that can handle the most demanding machining jobs? Look no further than the Silver CNC Roller CAM 4 Axis Rotary Table. This top-of-the-line rotary table is designed for use with vertical milling machines (VMMs), and can handle even the most challenging metal machining tasks.

The Silver CNC Roller CAM 4 Axis Rotary Table features a built-in roller cam structure that provides smooth, precise motion in all directions. With four axes of movement, this rotary table gives you the flexibility to machine complex parts with ease. And the heavy-duty construction ensures that this table will stand up to years of heavy use.

If you"re looking for a rotary table that can handle your most challenging machining jobs, the Silver CNC Roller CAM 4 Axis Rotary Table is a perfect choice. Order yours today and see what this outstanding table can do for your shop!

Silver CNC has just released a new 4th axis rotary table that is perfect for metal machining. This powerful tool has many features that will make your machining process easier and more efficient. If you are looking for a quality 4th axis rotary table, then contact us today and we would be happy to help you find the right one for your needs. We know that you won"t be disappointed with our products or customer service. Thanks for reading!

Tsudakoma had been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

8613371530291

8613371530291