air rotary table quotation

... is a single-axis rotary table based on the HRT210 model. It has an A1-6 spindle nose instead of the T-slot platter. This allows chucks, faceplates, and collet chucks to bolt directly to the rotary ...

The “HOMGE” PRECISION INDEXING TABLES are constructed with an AIR CYLINDER between the mating surfaces. This system ensures reduces friction when heavy loads ...

CNC Tilting Rotary Tables are two axes (4th & 5th Axes) units and can rotate the component in two axes making a machine capable of accessing the areas which can not be reached with only 3 axes. Tilting ...

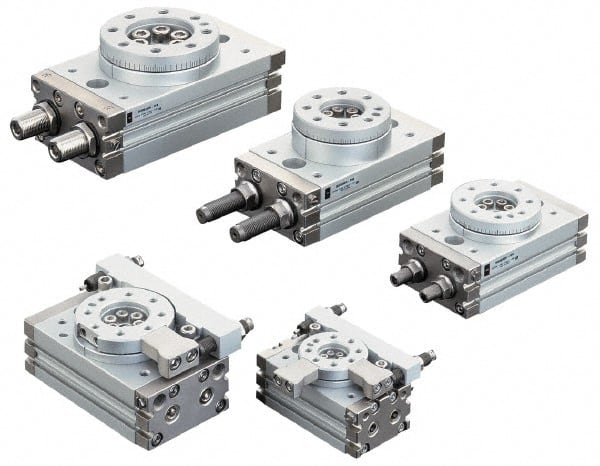

Pneumatic indexing tables use pneumatic power to rotate objects in a wide variety of applications. They can start and stop the object at precise angular intervals.

Choice will depend on the maximum weight of the parts to be handled. Other specifications to take into consideration are the table"s diameter, its concentricity and the indexing accuracy.

Rotation tables with air bearings are used when rotary motion with the highest accuracy, smoothness, and geometric performance is required. Due to the lack of friction, these high precision rotation bearings and direct-drive motorized rotary tables can achieve angular resolution in the sub-microradian range. PI’s air bearing design and manufacturing group provides hundreds of man years of design experience along with the manufacturing and test equipment to produce high quality rotary tables with the tightest tolerances.

Rotary air bearings (air bearing spindles) are friction free, and all of PI’s motorized air bearing rotation stages employ closed-loop, non-contact 3-phase direct-drive torque motors, and optical high-resolution rotary encoders for ultra-reliable maintenance-free operation with basically unlimited service life.

Absolute angle-measuring feedback sensors are available to provide closed-loop control with single digit microradian bi-directional repeatability. Direct-drive rotary air bearing tables also provide better eccentricity, flatness, and minimized wobble compared to rotary stages based on mechanical bearings. The friction-free design allows for high angular velocity without vibrations and noise.

Applications of rotary air bearing spindles / motorized direct-drive rotary tables include indexing, metrology, optical lens testing, bio-medical engineering, runout measurements of machined parts, and fiber optics.

PI’s high-performance closed loop servo motor controllers are available to precisely control position, acceleration and velocity, with advanced algorithms. Fully integrated multi-axis motion systems with linear air bearing stages and combinations with gantry systems are also available from PI’s air bearing division.

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

The A. G. Davis Air Float Rotary Table consists of hardened steel face plate which is floated on air in the thrust plane and centered by preload ball bearings radially during rotation. After an index move is completed the Air float is shut off allowing the faceplate to rest on the base of the rotary table producing excellent wobble characteristics. This action also friction locks the Air Float Rotary Table. A high grade meehanite base casting is used to support the faceplate. Standard face plate mounting pattern is by threaded hole patterns with other configurations available. The Air Float Type Precision Rotary Table can only be used with the face plate in the horizontal plane.

The P5RS compact rotary table is ideal for material transfer applications. It incorporates load bearings and a mounting face with twin racks and pinion movement and an adjustable rotation angle of 0 to 190° offering precise control even under heavy loads.

The P5RS is a pneumatic double acting rotary table unit available in bore sizes Ø16, Ø20, Ø25 and Ø32mm. End stroke positioning using an adjusting bolt offers dependable linear cushioning enabling objects to be carried and positioned safely and securely. Optional hydraulic shock absorbers for bores 20 and 25mm allow for heavier loads and increased cycle times. Magnetic piston as standard with optional sensors mounted in the integrated protected sensor grooves allows positional detection. Flexible, easy mounting of workpiece. A hollow axis through the table center can accommodate piping and wiring for the safe mounting of additional equipment. The precision table allows for accurate, flexible and easy work piece location. -5°C to +60°C temperature range. Resistant to corrosion.

• Operating Medium : For best possible service life and trouble-free operation dry, filtered compressed air to ISO 8573-1:2010 quality class 3.4.3 should be used. This specifies a dew point of +3°C for indoor operation (a lower dew point should be selected for minus temperature operation and we recommend the use of an inline dryer) and is in line with the air quality from most standard compressors with a standard filter.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

8613371530291

8613371530291