air rotary table free sample

Allenair carries Index Table. We have descriptions and specifications, principle of operation, standard index table, size and capacity and model 725 counterclockwise rotation.

ALLENAIR ROTARY INDEX TABLES are precision indexing mechanisms . . . unsurpassed in accuracy, performance and dollar value. We know of no other Tables of equal accuracy and quality available at comparable prices. Every detail of construction is designed to increase durability and efficiency, and provide for long, trouble-free life. All parts susceptible to wear are carefully hardened. Bronze and roller bearings are incorporated. Working parts are completely enclosed to protect against dust, dirt, and chips.

The Tables affect substantial savings in time and money in a wide variety of applications. For example, the Tables permit fast, automatic feeding of parts to tools in machine and assembly operations. Parts can be loaded and unloaded while machining operations continue. Other applications include cleaning and positioning operations, as well as use in conjunction with conveyor drive units.

ALLENAIR ROTARY INDEX TABLES are available in a COMPLETE PRODUCT RANGE of four basic models, and each model can be supplied with any one of the following operating options.

As a basic Table with a Single Solenoid Pressure Pilot 4-way Valve (VSSAP-AAS-1/4), a 3-way valve (V23), and piped with flexible air hose ready for use.

PILine® stages are particularly suitable for applications that require fast precision positioning. When switched off, the self-locking drive holds the position of the stage mechanically stable. Energy consumption and heat generation are therefore considerably reduced. Applications with a low duty cycle that are battery-powered or heat-sensitive benefit from these characteristics. The position of the axis is measured by an encoder and an optical reference switch allows reliable repeatable motion. The piezomotor drive principle and its electrical operation are inexpensive and can be customized.

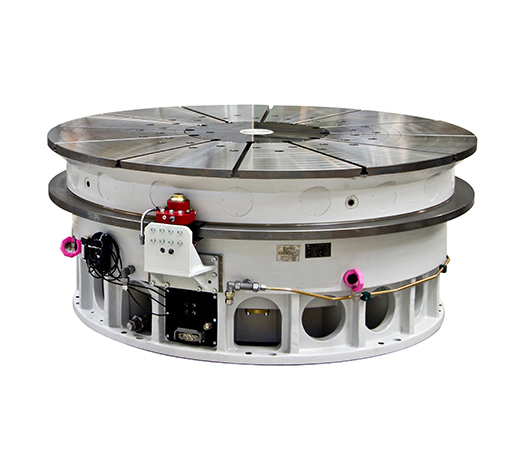

Among the many indexer manufacturers, what sets Pascal’s indexing table apart is undoubtedly its brakeless design, compact size, and durability. It has an ample amount of ports lending itself well to automation.

Pascal’s MDF index table operates with a 90° index 0.5 sec. Its unique rolling gear transmission is maintenance free and can operate with high index speed and accuracy for a long time unlike traditional worm gear. Traditional worm gear undergoes abrasive wear that can lead to backlash causing machining failure and degrading index accuracy.

Pascal’s high-performance rotary unions are integrated to enable clamp sensing and actuation but also provides a footprint 20% smaller than its competitors. Ideal for indexing large workpieces in compact machining centers, you will also achieve increased production capacity. As one example, our rotary indexing table can allow a machining center to increase their production capacity from 16 robodrill units to 24 units in the same amount of space.

The MDF index table has a total of 20 ports, lending itself well to automation. 18 of those ports can be used for hydraulic and air, while 2 are for coolant. A double acting cylinder with sensing can be used instead of a single cylinder, and its rotary joint accommodates a 7MPa pressure circuit.

Pascal is confident in the quality and reliability of our rotary indexers so much so that we use them in our own factories. That is also why these indexers are utilized in the factories of major automakers around the world.

Air Bearing Rotary Tables, Table Top and Work Load are Supported on Air Bearings whose Freedom from Friction Contributes to Extremely High Positional Accuracy

An Interlocking Switch is used when Motors are Incorporated to Prevent the Table Top from Moving when the Air Supply is Turned Off. When the Air Supply is Turned Off, the Table Top Sits Firmly on our Cast Base with an Extremely High Accuracy of Parallelism Between the Base and Table Top

Rotary tables specifically developed for use in Metrology applications. CMM tables, inspection tables, assembly tables. Range of sizes 100mm thru 5,000mm. Larger on request.

Air bearing rotary tables, when rotating, the table top and work load are supported on air bearings whose freedom from friction contributes to the extremely high positional accuracy. High precision needle roller bearing maintains radial accuracy.

Supplied with each table. On/off Switch controls the compressed air supply to the table. Interlocking ensures that the motor drive can only operate if the air supply is on. When air supply is off, table sits firmly on the base casting with extremely high accuracy of parallelism between the top surface and the underside of the base.

Rotary tables are positioning devices that are oftentimes used in precision manufacturing applications. More specifically, they are tools that hold parts on rotating axes, which increases productivity, accuracy, and repeatability. It seems simple enough, but there are various types of rotary tables. So how do you choose which one is best for you? Let’s go through three common kinds of rotary tables – air-bearing, oil hydrostatic, and mechanical-bearing – to assist you in answering that question.

In many cases, air-bearing rotary tables will be the answer. This is due to the fact that they have the capacity to run longer than other kinds. These are exactly what they sound like; with air-bearing rotary tables, parts float on air above the table. With this, there are no contacting parts to wear the machine down, resulting in decades of maintenance-free motion. That is a significant benefit to any piece of air-bearing equipment, but these rotary tables are specifically beneficial for certain applications.

Maximizing metrology productivity can be challenging, but utilizing air-bearings can assist in boosting turnover. Additional industries such as optics, assembly lines, and light machining and grinding, can use them to increase accuracy and productivity as well.

Similar to air-bearings, oil hydrostatic rotary tables do not have any contacting mechanical parts, as they float parts on oil. These rotary tables are most commonly used for grinding and machining when smooth and repeatable motion is a necessity. They provide high load capacity and can be useful when extreme stiffness is necessary.

Mechanical-bearing rotary tables are a bit different from the other two. Just as the name suggests, this type of rotary table does have moving, touching mechanical parts. And while this does sometimes result in a shorter life than the air-bearing or oil hydrostatic tables, many organizations will still pick these out of the others. Why? They still offer high performance.

These rotary tables can be used in most applications and provide superior performance in radial, axial, and angular error motions. In all, mechanical-bearing rotary tables do the job; however, it is possible that they will not last as long as other types.

The answer to the question, “Which one is best?” is the ever-hated, “It depends!” In general, air-bearing rotary tables will provide the highest accuracy for the longest amount of time. The lack of touching mechanical parts allows this type of rotary table to last decades. However, if you need a stiffer hold, oil hydrostatic could be the better choice. And in other cases, mechanical-bearing rotary tables could be best. All in all: It depends.

But if you want to know more about rotary tables and which would be the right choice for your application, contact the experts at ABTech. We will ensure you get exactly what you need.

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an AlphaStep closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

8613371530291

8613371530291