milling a radius on a rotary table price

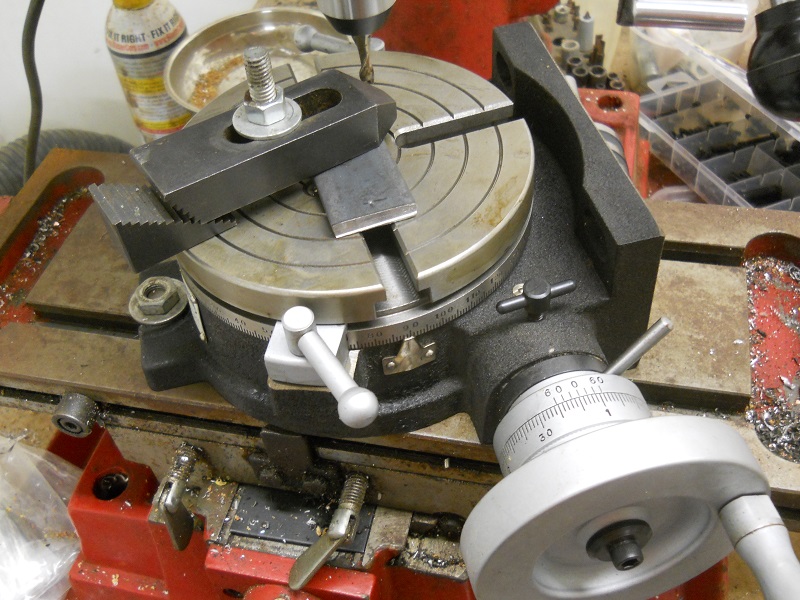

1. Build a fixture that will locate the aluminum on the rotary table so I can repeatedly use the same setup without indicating for each of the 4 corners on each piece and each of the pieces in the lot. The fixture will also hold the work piece about 1/4" above the table surface to keep it from being damaged during machining.

3. Bolt that fixture to the rotary table such that each piece to be cut will be located with the center-line of the corner radius right on top of the rotational center of the table.

7. Advance the table further left some to avoid taking too big of cut and drop the quill down so the end mill will cut the entire thickness of the 1/4" aluminum on each pass.

Anyway...I"m a beginner at all of this and this is just what I came up with in my head. Hoping someone has a better way! (i.e. an easier way). These aluminum pieces are decorative...and they need to look right but really tolerances aren"t all that critical.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

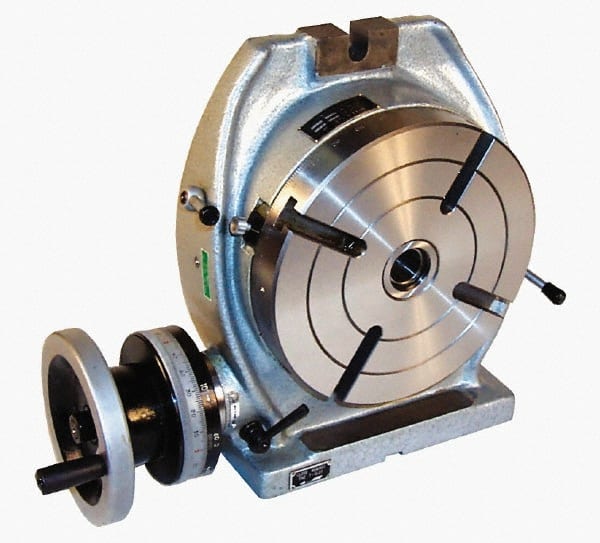

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

Three dividing plate set(Plate "A" - 15, 16, 17, 18, 19, 20 Plate "B" - 21, 23, 27, 29, 31, 33 Plate "C" - 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, VEVOR has occupied markets of more than 200 countries with 10 million plus global members.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part.

The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost.

As will become more obvious as you read this post, I"m new to the vertical mill - have had mine for a whole three weeks now, and just finished installing a Newall 3-axis DRO (Z-axis on the quill) a couple of days ago. Which brings up a question - one of the guys here posted a photo of a nice saddle block he machined to fit atop the ram of his B"port. It"s sitting right over the hole the machine lift eye threaded into, and is the base he used to mount the arm that holds the DRO control head/console. He did a very nice job of finishing it, even machined a radius or bevel (couldn"t tell which in the photo) around the top edge of the block. My question is how you would set up to machine the radius into the bottom of such a block to match the radius of the top of the ram? I"d like to make a copy of his saddle block out of 6061, and am also looking at machining a one piece scope base (also of 6061) to fit rifle actions that have different radii on the front & rear receiver rings.

I"ve seen a vidio clip of cutting an outside radius by turning the workpiece by hand online, but don"t think that"s going to cut it with either of these projects. I guess I could try to figure out how to keller the radius with multiple passes with a ball end mill, but would sure prefer a quicker, less complicated method, even if it required the construction of a jig or fixture - if it worked well enough, I"d like to make scope bases for sale. I"m starting to wonder if you"d need a CNC machining center to do what I have in mind.

·Typical use cases include machining the flutes of a milling cutter, cutting the teeth of a gear, milling curved slots, or drilling a bolt hole circle around the circumference of a part.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

As for tightness of everything that is debatable as many of the Chinese imports don"t mate up part correctly. You need to make sure everything is well fitted on the mill and rotary table. This means properly fitted gibs on linear slides and a rotary table mechanism that properly mates up.

I might ask how does the mill work cutting the same material with the same tool without the rotary table. If the machine does better without the rotary then you have a couple of possibilities. The rotary table needs work. Or the hight of the rotary table gives the cutter enough leverage to hi light issues with the linear slides on the mill.

A rotary table used in conjunction with a mill allows a machinist to produce virtually any part they can design. Sherline’s rotary table is a precision piece of equipment that has been designed to work with their vertical milling machines. However, it can be used on any mill whenever the small 4-inch size would be an advantage. The only limits are size, not complexity.

The table is 2″ high and 4″ (100mm) in diameter. The main components have been machined from solid bar stock steel, and the complete unit weighs seven pounds. The table has been engraved with a laser, giving sharp and precise lines every 5°, numbered every 15°. These lines are calibrated with the 72-tooth worm gear that is driven by the handwheel. The handwheel is divided into 50 parts, making each line on the handwheel 1/10°. This allows a circle to be divided into 3600 increments without interpolation. Seventy-two revolutions of the handwheel rotate the table one revolution.

The rotary tables can hold more weight when they are not under a continuous load. Click on the Video tab above to see examples of different weights and uses for our rotary tables.

The table T-slots are identical to those used on the Sherline mill and lathe, making the vast line of Sherline tooling available for use with this product. Two hold-down clamps and T-nuts are provided with the table. Also included is an adapter that allows Sherline’s 3- and 4-jaw chucks to be screwed directly to the rotary table. An optional right-angle attachment is available (P/N 3701) to mount the table in the vertical position to increase its versatility further. With the table mounted vertically, an optional adjustable right-angle tailstock (P/N 3702) can be mounted to the mill table. It is used to support and stabilize the other end of long work held in a chuck or otherwise attached to the rotary table.

we parag machine tools ar the leading suppliers in this industry we provide material of best quality and best price possible our goal is to provide customer satisfaction

Our company is a prominent in the industry as a manufactures and supplies Rotary Table. We offer our product in diverse specifications to fulfill the differentread more...

Waluj, Aurangabad D1 C 270, Udyog Bharati Estate C/o,Udyog Bharti Estate,Mahaveer Chowk, Near Hotel Dream Line Phase No-3, Plot No.-X340,Waluj,, Waluj, Aurangabad - 431136, Dist. Aurangabad, Maharashtra

Shivaji Udyam Nagar, Kolhapur A-249, Kagal Hatkanangale, Five Star MIDC Kagal, Village Halsawade, Shivaji Udyam Nagar, Kolhapur - 416203, Dist. Kolhapur, Maharashtra

George Town, Chennai 1ST FLOOR OLD NO.68, NEW NO.100/F ARMENIAN STREET, GEORGE TOWN Chenna, George Town, Chennai - 600001, Dist. Chennai, Tamil Nadu

Compact precision CNC rotary table, suitable for single part or small batch production in precision engineering. A horizontal or vertical assembly is possible. You can not buy a better quality!

It is suitable as 4th axis on engraving and milling machines for engraving, lasering, drilling, grooving, milling or for use on a tool or surface grinding machine. Square, hexagonal, gear milling of any pitch or 3D machining is possible.

Technical data: - center distance 1500 mm- center height 400 mm- max. machining diameter FI 400 mm- motor power 4,0 kW- voltage 400 V / 50 Hz- spindle speed 3000 rpm- number of controlled axes 3- guide linear guides and ball screw- control MACH3 + software- pneumatic workpiece clamping- V-shape steel- milling spindle for flat engraving- compressed air supply 6 bar- dimensions L=2700, W=1400, H=1750 mm- net weight 1800 kg

The "File it, it"s faster and easier" Well, I have a car, driving to get a bacon buttie is fast and easy, flying there is a pain in the butt, slow, unreliable, fraught with wasted effort, but good fun ! (99 times out of 100, I"ll take the easy option, but when it"s new . . I"ll go with the wasted effort just for the experience)

I went with the "Pin through a hole and rotate in the vice" method, Sadly, a long (ish) piece of work and a low vice meant I managed very little of the curve that way, but enough to get a "feel" for the shape, 5 minutes on the belt sander and, from a distance, with yer glasses off, in low light, it kind of, looks ok.

I"m discovering that "machining" is probably best done by fairly accurate sawing, finished off by machining the bits the saw can"t do and providing a surface texture.

An hour spent cleaning (that"s new to me too, I"m sure I"ll get faster) and the garage has a shiny, uncompleted "bit" in it, a clean shiny mill, and a happy bunny who is now waiting for more "essential tools" to arrive.

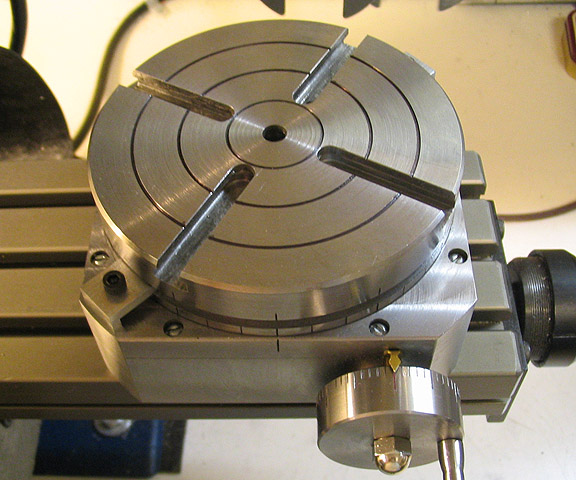

A rotary table is a really nice accessory to have for your mill, but one that you can delay purchasing for a while until you master the basic milling operations. The rotary table is driven by a worm-gear and is accurately calibrated in degrees and fractions of a degree.

It is used to mill or drill accurately positioned holes around a bolt circle, for milling arc-shaped grooves or slots and many other operations. Most, but not all, can be mounted in a vertical as well as a horizontal orientation; a very desirable feature.

Finding a rotary table of the right size for the mini-mill has been a lille problematic. 8-inch tables are really much too big. Even a 6-inch is pushing the limits. I have one from Grizzly. It is well made and works well, but mounting it to the table was a little bit of a challenge.

Sherline offers a very nice 4-inch model, and more recently LittleMachineShop.com has listed a 4-inch model as well. These are very nice, but a little smaller than I would like. In my view, a 5-inch model would be ideal, but I don’t know of one in that size.

The first rotary table I purchased was made in India and was of really poor quality. I returned it to the vendor for a refund. Unfortunately, the return shipping on a heavy object like this is not cheap, so be careful what you buy!

Sherline makes a beautifully finished 4″ rotary table which I got to see first hand at Cabin Fever 2001. I was very impressed by the high quality of this item, but It was a little small for my needs.

The table I currently use is a Grizzly G1049 6-inch model. As of 03/02 it sells for $199 plus shipping. It is well-made, and I have been very satisfied with it, although it is a little large for the mini-lathe as you will see in the photos below.

After cleaning off the packing grease with kerosene, a painbrush and a rag, I mounted it on the mini-mill table using 3/8″ carriage bolts that I also use for my 3 1/2″ Grizzly milling vise. The center hole is a #2 Morse taper.

The RT is really a little oversize for the mini-mill, but still provides enough clearance to be practical. I did not feel that the weight was beyond the capabilities of the mini-mill table.

Here’s a picture showing the table with a 12″ rule and a 1/2″ mill in an end mill adaptor. Mounting the mill in a collet would provide another 2″ or so of working room. The head is at the top of the column. Also shown is the 3″ chuck from the 7×10 mini lathe. As you can see, there is adequate clearance for most operations.

The casting has mounting lugs for both horizontal or vertical mounting. This makes it potentially much more flexlible, but the table of the mini mill is small compared to the RT which makes mounting the rotary table in the vertical orientation a little tricky.

One problem is that the lower edge of the handwheel for the RT is lower than the base of the RT, so it must be positioned off the edge of the table. If the RT is positioned perpendicular to the X-axis, the mounting holes in the RT are outside the limits of the T-slots in the mill table.

These problems can presumably easily be overcome by using custom-made riser blocks and clamps, though. I have not yet attempted to make these items, but would not expect them to be very difficult to make.

For the price, I was pretty impressed by the quality of the table. I would rate it somewhat lower in quality than the Sherline 4″, but much better than the Victor 6″.

The base is painted with wrinkle-finish black paint. Fortuitously, the T-slots in the RT are about the same width as those on the mini-mill, so the same T-nuts can be used on both.

The handwheel is satin-finish steel with cleanly etched divisions. Each full rotation of the handwheel rotates the table by 4 degrees. A brochure included with the RT illustrates an indexing plate accessory which can apparently be attached to the RT, but I’m not sure whether or not Grizzly sells this accessory.

An eccentric cam between the handwheel and the table permits you adjust the meshing of the worm-screw to minimize backlash. A screw with a T-handle locks the cam in place once it is set.

Here’s a nice little 4″ imported rotary table offered by LMS for $134.95. They offer several other models, including the Sherline 4″. I don’t have any first-hand experience with this one, so I can’t really comment on quality or capabilities.

8613371530291

8613371530291