torque motor rotary table brands

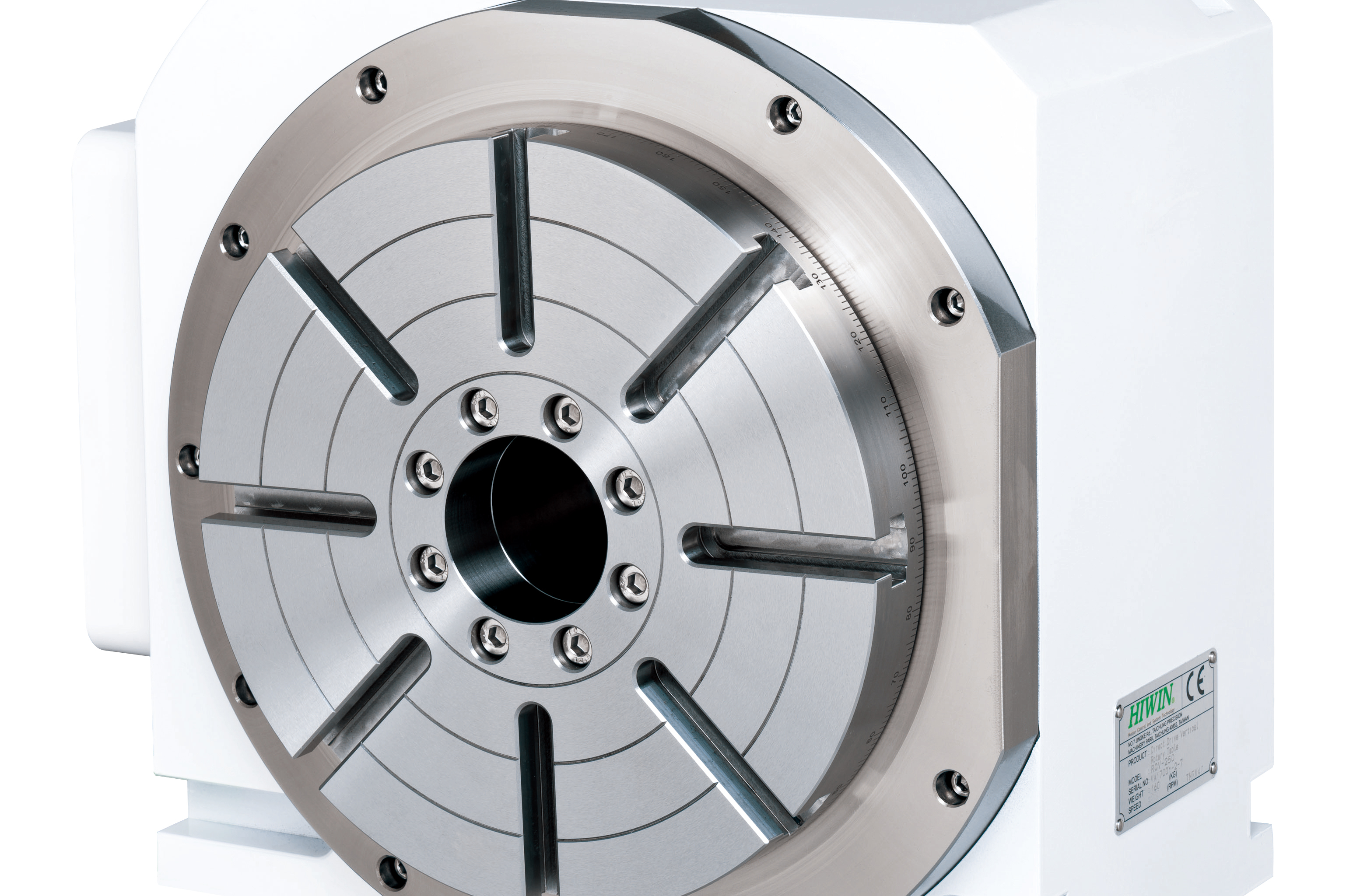

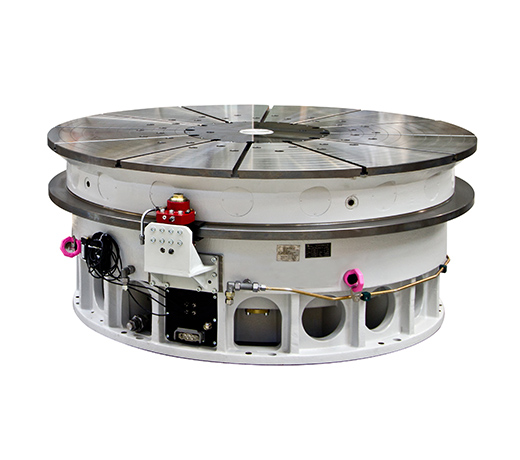

HIWIN Corp. will feature families of precision motion control components this year at IMTS, with their torque motor rotary tables as a highlight of their booth.

Designed for machine tool original equipment manufacturers (OEM) and retrofitters, the TMRT series enables 3-axis machine tools to be upgraded to 3+1, 3+2, 4+1 or even 5-axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders, and a brake system ensure acceleration capabilities and high precision when machining complex part geometries.

The TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates gear reducers, resulting in dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

The series is compatible with most major CNC brands and uses HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hiwin Corp., a manufacturer in motion control and system technology, highlights its families of precision motion control components with a focus on its Torque Motor Rotary Tables (TMRT).

Designed for machine tool OEM’s and retrofitters, the TMRT series enables three-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even five-axis capability. High speed, high-torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system promote acceleration capabilities and high-precision when machining complex part geometries.

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy, Hiwin says. Directly coupled encoders and zero backlash intend to enable tighter part tolerance. Direct drives are designed provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, promoting thermal stability even during high-duty cycle, high-load conditions, which yields consistent part quality, Hiwin says.

Hiwin Torque Motor Rotary Tables utilize Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hexram CNC machines feature FANUC controls, moving gantry, moving portal, moving table, as well as moving and fixed rotary table options. According to the company, a selection of durable cutting heads enable manufacturers to take on applications from nearly any industry.

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

... variety of markets including rotary indexing tables, printing, material handling, packaging and laser cutting.The largest motor in the 485 series can reach an ultimate torque ...

... flexibility in the application. It therefore suits a wide variety of markets including rotary indexing tables, printing machinery and materials handling.

The QTL 385 is one of the high-torque Tecnotion motor series. With a big inner diameter, it is very suitable to integrate into an (existing) application in a wide variety of markets like rotary ...

... suitable to integrate into an (existing) application like rotary indexing tables, and materials handling. It will deliver 659-907 Nm continuous torque and 1651-2202 Nm ultimate torque, ...

Torque motors are characterized by a very compact design in combination with a very high torque at low speed. A high force density in relation to the installation space and ...

Kitagawa"s new GT200 rotary table is a through hole unit capable of withstanding high cutting loads. It features a 200mm diameter table and provides ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages ...

... , photonic component alignment, high-accuracy laser machining and precision wafer inspection. These rotary stages can also be configured as multi-axis gimbals.

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

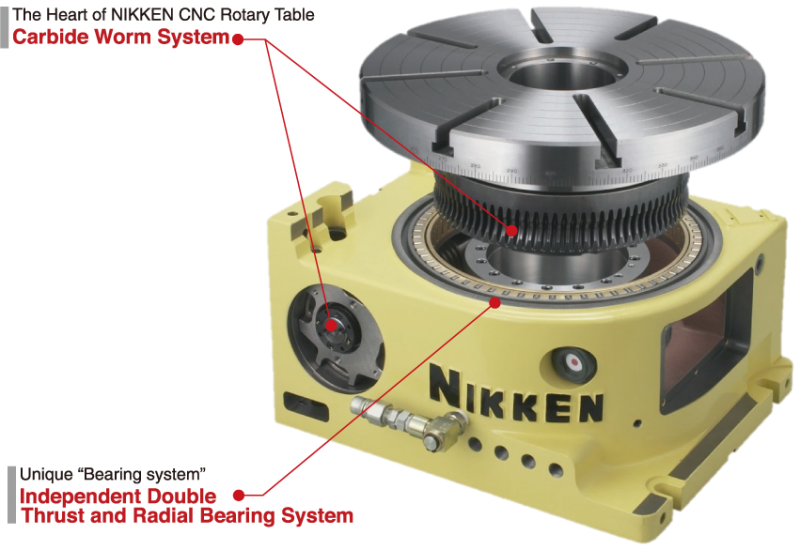

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

... secured. High positioning accuracy ensures precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

HIWIN Corporation, a provider in motion control and system technology, will feature families of precision motion control components this year at IMTS, with their Torque Motor Rotary Tables, (TMRT), as a highlight of their booth. IMTS will be held September 12-17, 2022, in Chicago.

Designed for machine tool OEMs and retrofitters, the TMRT series enables 3-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1, or even 5-axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders, and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlashes enable tighter part tolerance. Direct drives provide smooth motion, resulting in an improved part surface finish.

HIWIN Torque Motor Rotary Tables utilize HIWIN’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Hiwin Corporation, a leader in motion control and system technology, will feature families of precision motion control components this year, with its torque motor rotary tables (TMRT) as a highlight of its booth.

Designed for machine tool OEMs and retrofitters, the TMRT series enables three axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even five axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders, and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

Hiwin’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

Hiwin torque motor rotary tables use Hiwin’s torque motor components, which are also available for engineers who prefer to design and build a unique table.

Our direct drive rotary tables provide high torque and are easy to integrate. They contain high-energy magnets in a simplified mechanical design and drive loads directly without the need for a transmission mechanism or gearbox. It allows customers to build them right into a drive system for flexible placement and integration with cooling pipes and cables, for example.

We supply a wide range of frameless motors, and our adjustable motors include an optical encoder, scale, bearing and housing. Given our selection, it can be challenging to choose the best direct drive motor for your project. Our engineers prefer to help you find the right rotary table for your requirements.

Our most popular rotary motor, the AXD series is characterized by a slim, compact "pancake" design with high peak and continuous torque despite the motor"s quite small form factor.Direct drive and brushless motor

The ACD series is a set of ironless rotary tables. This motor is cogging-free and features high-resolution optical encoder feedback and low speed variability. This permanent magnet motor is equally suited for either low or high speed applications.Zero cogging coreless motor

The ACW series features a cogless construction and lean design, with high-precision coding and ultra-precision bearings. Together, this results in our highest performing motor in terms of repeatability and smooth motion.Direct drive brushless motor

The ADR-A series is available with both low and high speed windings and is fully equipped with an encoder and bearing. This series has a high slot fill factor and generates very high torque.Direct drive brushless permanent magnet motor

The ADR-B range performs at a similar slot fill factor and torque density to the ADR-A range, but has a larger center hole compared to its equivalent.Direct drive brushless permanent magnet motor

Similar to the ACD series, the AXM series also features an ironless design and zero noise characteristics. This motor has a compact design, making it ideal for applications with specialized size requirements.Direct drive brushless permanent magnet motor

Hiwin (Booth 134514) will feature families of precision motion control components this year at IMTS, with the company"s Torque Motor Rotary Tables (TMRTs) as a highlight.

Designed for machine tool OEMs and retrofitters, the TMRT series enables 3-axis machine tools to be readily upgraded to 3+1, 3+2, 4+1 or even 5 axis capability. High speed, high torque, built-in high-rigidity high-precision bearings, absolute encoders and a powerful brake system ensure excellent acceleration capabilities and high precision when machining complex part geometries.

HIWIN’s TMRT series rotary tables incorporate direct-drive torque motors. This innovative design eliminates any gear reducers, resulting in the highest dynamic performance and multi-axis path accuracy. Directly coupled encoders and zero backlash enables tighter part tolerance. Direct drives provide smooth motion, resulting in improved part surface finish.

The TMRT series incorporates integral liquid cooling in the table, ensuring thermal stability even during high duty cycle, high load conditions, yielding consistent part quality.

Benefiting from TJR’s proven knowledge and experience, TJR provides diverse transmission mechanisms such as 1. Driven by Worm & Worm Gear, 2. Driven by Roller Gear Cam, 3. Driven by Direct Drive Motor to meet various needs. If you are looking for the 4th axis rotary tables cooperation partner, please feel free to check out 4 axis rotary table here and get in touch with TJR.

We are identified as one of a prominent manufacturer and supplier of high quality Torque Motor Rotary Table. A turbo among rotary tables – the direct driven rotary tables with torque motor are optimally suited for all handling and assembly applications that require the shortest indexing times and flexible positioning. Thanks to its measuring system directly in the rotary table axis, any position can be moved to with the highest precision. The slim design with its very space-saving, compact construction and its fitted boreholes makes it very easy to integrate the rotary tale into your system

8613371530291

8613371530291