torque motor rotary table price

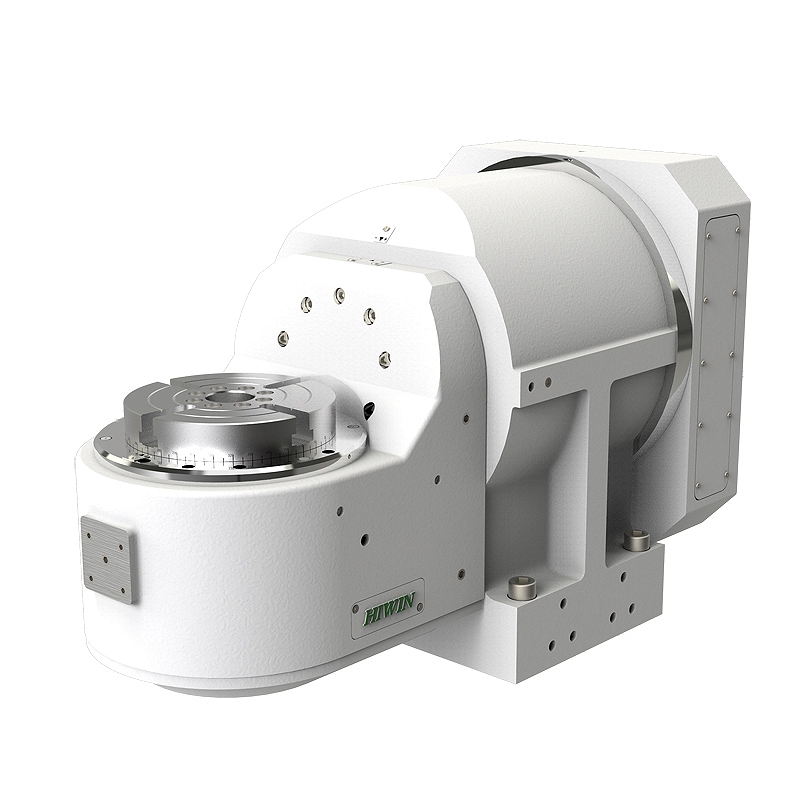

HIWIN Corporation Torque Motor Rotary Tables (TMRT) use a direct-drive torque motor, built-in high-rigidity and high-precision bearings, absolute encoders and powerful brake system to ensure excellent acceleration capabilities and high precision uniform movements. HIWIN TMRTs are backlash-free, optimized for high torques, have robust dynamics and are highly adaptive to the most demanding of automation processes. Compared with the mechanical indexing table, TMRT has high speed and high torque characteristics, suitable for the needs of various machining equipment.

A rotary table is the revolving plate on the rig"s drill floor that turns the drill string in a clockwise path. The rotary desk surrounds the 4 or six-sided kelly bushing and kelly drive to which the drill string is attached, transferring the power from the rig"s drive machine to the drill string and bit.

The rotary table hyperlinks the rig"s electricity supply to the drill string, it may be defined as a seize. maximum rigs have a rotary table because the top mover for the drill string, however, pinnacle power systems that permit continuous rotation of the drill string have changed the rotary table, the kelly bushing and the kelly pressure in some rigs, because of adjustments in trenchless construction requirements.

The rotary drive desk is prevalent in pinnacle-force rigs, that is, those that have their drive motor on the pinnacle of the rig. Drill string sections are first connected to the lowest hollow assembly. As drill string sections pass into the bore, extra sections of drill string are attached to the top pressure motor and to sections inside the bore, building the drill string from the pinnacle. those sections of drill string screw together using a clockwise movement. The rotary table -- which turns clockwise -- is used to tighten the segments of the drill string.

Widely used in machining center main axis and working table SKU: HIWIN-TRT-RCVCategory: Torque Motor Rotary TableTags: hiwin RCV Series Torque Motor Rotary Table, Hiwin Torque Motor Rotary Table, Rotary Table, Torque Motor Rotary Table

... variety of markets including rotary indexing tables, printing, material handling, packaging and laser cutting.The largest motor in the 485 series can reach an ultimate torque ...

... flexibility in the application. It therefore suits a wide variety of markets including rotary indexing tables, printing machinery and materials handling.

The QTL 385 is one of the high-torque Tecnotion motor series. With a big inner diameter, it is very suitable to integrate into an (existing) application in a wide variety of markets like rotary ...

... suitable to integrate into an (existing) application like rotary indexing tables, and materials handling. It will deliver 659-907 Nm continuous torque and 1651-2202 Nm ultimate torque, ...

Torque motors are characterized by a very compact design in combination with a very high torque at low speed. A high force density in relation to the installation space and ...

Kitagawa"s new GT200 rotary table is a through hole unit capable of withstanding high cutting loads. It features a 200mm diameter table and provides ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis ...

The TR500SS is a high-speed, dual-axis trunnion rotary table that offers maximum rigidity and accurate performance for 3+2 and full 5-axis machining of large parts.

... X-RSW-E Series products are motorized rotary stages with built-in controllers. Rated for 2.25 N-m of torque, speed up to 75 rpm, and a load capacity of up to 20 kg, these stages ...

... , photonic component alignment, high-accuracy laser machining and precision wafer inspection. These rotary stages can also be configured as multi-axis gimbals.

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

This is the smallest CNC Rotary Table manufactured by Nikken Kosaksuho in Osaka, Japan. With pneumatic clamping this rotary table is used by many on their small vertical ...

... secured. High positioning accuracy ensures precise results for 5-axis machining. KESSLER`s very latest torque motor generation, the ultra-flexible rotary and rotary tilt tables ...

... Drive Rotary Table is a kind of rotary table used to the continuous operation which is several times more agile and accurate than conventional face gear or rack and pinion ...

PI’s direct-drive rotary tables with frictionless, brushless, closed-loop torque motors provide the best combination of high accuracy, high velocity, and maximum service life. PI provides closed-loop direct drive rotary tables with both mechanical bearings and air bearings. Stage models with large apertures and low profile are available. The stage design is optimized for high speed, stiffness, and high load capacity. If completely friction-free and maintenance free motion with virtually unlimited lifetime is required, air bearing rotation tables are recommended. These ultra-precision, high-speed rotary tables provide vibration-free motion with extremely high accuracy and negligible runout, wobble and eccentricity errors. The lack of lubricants makes these also clean room compatible and ideal for any high-performance metrology application in optics, photonics, and semiconductor manufacturing, test and metrology related projects.

In contrast to worm gear driven rotary stages or belt-drive rotation stages, torque-motor direct drive stages eliminate play in gears, couplings or flex in drive belts, providing motion with zero backlash and excellent constancy of velocity, while achieving higher speed than worm-gear drives.

PI’s precision direct-drive, positioning tables can be used in high performance factory automation, research, semiconductor, and laser processing applications. Due to the use of brushless high-torque, motors with direct metrology position feedback, backlash is completely eliminated, and reliability is greatly improved.

With modern direct-metrology rotary encoders, sensor resolution down to 1/100th of a microrad is available on select models with large rotary table platforms, using the high interpolation factors

Based on the high encoder resolution and powerful servo controllers, the direct-drive rotary tables also provide excellent velocity control, which is required in automation applications including high-speed laser processing, indexing, and semiconductor wafer inspection.

Most Direct Drive Rotation stages can be mounted horizontally and vertically, and with combinations all 3 rotary degrees of freedom (3DOF, pitch, yaw, and roll) can be addressed.

A new report released by Market Research Update is Torque Motor Rotary Tables Market 2023. This report provides up-to-date information on the market and also pinpoint all the opportunities for Torque Motor Rotary Tables market growth. The report begins with a market outlook and offers market basic introduction and definition of the worldwide Torque Motor Rotary Tables industry. The overview part of the report contains Torque Motor Rotary Tables market dynamics which includes market growth drivers, restraining factors, opportunities and Torque Motor Rotary Tables current trends along with the value chain analysis and pricing structure study.

Torque Motor Rotary Tables market is segmented by region, players, by Type, and by Application. Players, stakeholders, and other participants in the global Torque Motor Rotary Tables market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region, by Type and by Application in terms of revenue and forecast to 2029.

The report also includes the effects of the ongoing global crisis. COVID-19, on the Torque Motor Rotary Tables Market and what the future holds for it. It provides an analysis of the impact of the pandemic on the global economy. The epidemic has directly disrupted demand and the supply chain. The report also analyzes the financial impact on businesses and financial markets. This Torque Motor Rotary Tables report have gathered information from several industry delegates and have been involved in primary and secondary research to provide customers with data and strategies to address market challenges during and after the COVID-19 pandemic.

Top Key Players of the Torque Motor Rotary Tables Market:Hiwin Corporation, Motor Power Company, Velmex, Tecnotion BV, PARKER, SMC Corporation of America, Kitagawa, FIBRO INC, Techsystem, Magtrol, Sherlineipd, Newmark Systems Incorporated, Sankyo Automation, ZOLLERN GmbH & Co. KG

The global, regional, and other market statistics including CAGR, financial statements, volume, and market share mentioned in this report can be easily relied upon in light of their high precision and authenticity. The report also provides a study on the current and future demand of the Global Torque Motor Rotary Tables Market.

With the present market standards revealed, the Torque Motor Rotary Tables market research report has also illustrated the latest strategic developments and patterns of the market players in an unbiased manner. The report serves as a presumptive business document that can help the purchasers in the global market plan their next courses towards the position of the market"s future.

Torque Motor Rotary Tables market competitive landscape provides details and data information by players. The report offers comprehensive analysis and accurate statistics on revenue by the player. It also offers detailed analysis supported by reliable statistics on revenue (global and regional level) by players. Details included are company description, major business, company total revenue and the sales, revenue generated in Torque Motor Rotary Tables business, the date to enter into the Torque Motor Rotary Tables market, Torque Motor Rotary Tables product introduction, recent developments, etc.

In the end, the Torque Motor Rotary Tables Market report includes investment come analysis and development trend analysis. The present and future opportunities of the fastest growing international industry segments are coated throughout this report. This report additionally presents product specification, manufacturing method, and product cost structure, and price structure.

Ensure that your servo drive can handle the Nominal- and Peakcurrent of the Motor. An adjustment of the Speed and DC Bus Voltage can be done after consultation. The nominal data in this datasheet are based on an ambient/coolant temperature of 20°C.

Because the exact duty type depends also on the thermal connection of the motor, the embedded thermal monitoring system has to be analysed and attented. However, attention has to be payed that the temperature sensors do not show the exact temperature of the winding and this could be up to 20 K higher due to thermal capacities. Despite an electrical insulation towards the winding, you are only allowed to connect the sensors to your controller by using a galvanic separation in between.

AD series DDM NC rotary table features unrivaled high precision, high rigidity, and durability. The built-in DD motor makes the AD series DDM rotary table more compact. Thus, this rotary table series is used by many small vertical machining centers to deliver 4th axis capabilities at an affordable price. It can work with a brakeless support table to further optimize the space arrangement.

The FANUC direct drive motor is an option for the AD series CNC rotary tables. It can achieve optimal performance when FANUC direct drive motor is driven by FANCU control. Moreover, the torque motor will not be burned due to any accident operation error. Besides, it is equipped with an over-temperature protector and temperature detector. FANUC can also support the warranties via their global networking whenever necessary.

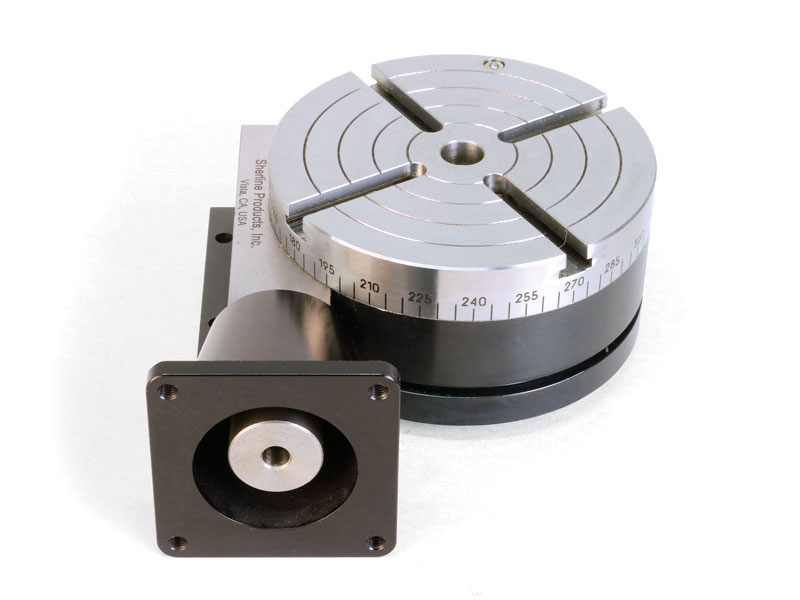

Sherline offers one of the finest small rotary tables on the market. It is available in manual or stepper motor drive modes. It can even be purchased with its one controller to be used as a programmable indexer.

can mount our chucks. This modification came about after requests from our laser engraving customers. The larger through hole allows for larger stock to be held. It also has a Nickel-Teflon plating on it because it was designed to be used in an every-day production environment. This gives the table a rust resistant surface that is hard and has added lubrication qualities.

Sherline�s rotary table offers an accurate, stable platform for rotary laser marking applications. Its compact size makes it a good fit in small enclosures. Visit our Video page to watch a Sherline CNC-ready rotary table in use in a laser marking application on round parts, illustrating the difference between trying to mark on a round part without rotating it vs. rotating it. Some of the videos are from Jimani Inc. Laser Marking Systems who use a high-speed motor to drive the table.

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuringI/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor"s own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

Rotary tables are used for precision metal work. They are usually made of a solid base that can be attached to another bracket. The table is a disk that rotates freely or with the help of a spiral (hand crank).

The rotary table is a disk-shaped metalworking device that enables precise positioning of the workpiece. It allows the metalworker to cut or drill the workpiece at precise intervals vertically or horizontally around a fixed axis. The turntable can be controlled both manually and digitally by computer. Some types of rotary tables are designed to be used with indexers or separators for special operations. A rotary table used with one of these positioning plates is often called a dividing or indexing head.

The Rotary tables is usually a sturdy base that can be attached to a separate stand or table. This device is basically a rotating disc that holds the workpiece in place while cutting or drilling. The disk portion of the rotary table can be freely rotated or rotated for indexing operations by means of an attached control lever known as a worm wheel. Tables used in precision operations are usually turned with a duplex type helical wheel to compensate for clearance. Rotary tables used in automated metalworking processes are connected to a digitally controlled computer.

Rotary tables are mostly used in a flat position with the table axis vertical. Sometimes they are installed with the shaft pointing horizontally so that the suppository can be used to support the free end of the workpiece. When this device is attached to the secondary table, the workpiece can be centered on the axis of the rotary table, which is then centered on the axis of the cutter. In this configuration, the axes of the rotary table, secondary table and cutter are coaxial to facilitate concentric cutting operations. This configuration also allows the secondary table to be moved to drill evenly spaced holes in the workpiece.

Rotary Table offers an unparalleled combination of good accuracy and high load capacity. These rotary stages utilize a precision worm gear with the worm “flexed” against the gear to ensure a proper mesh. This feature provides high repeatability with very smooth operation. Additionally, the rotary stages incorporate an oversized pre loaded cross roller bearing, offering exceptional stiffness and load capacity.

8613371530291

8613371530291