natural gas safety valve factory

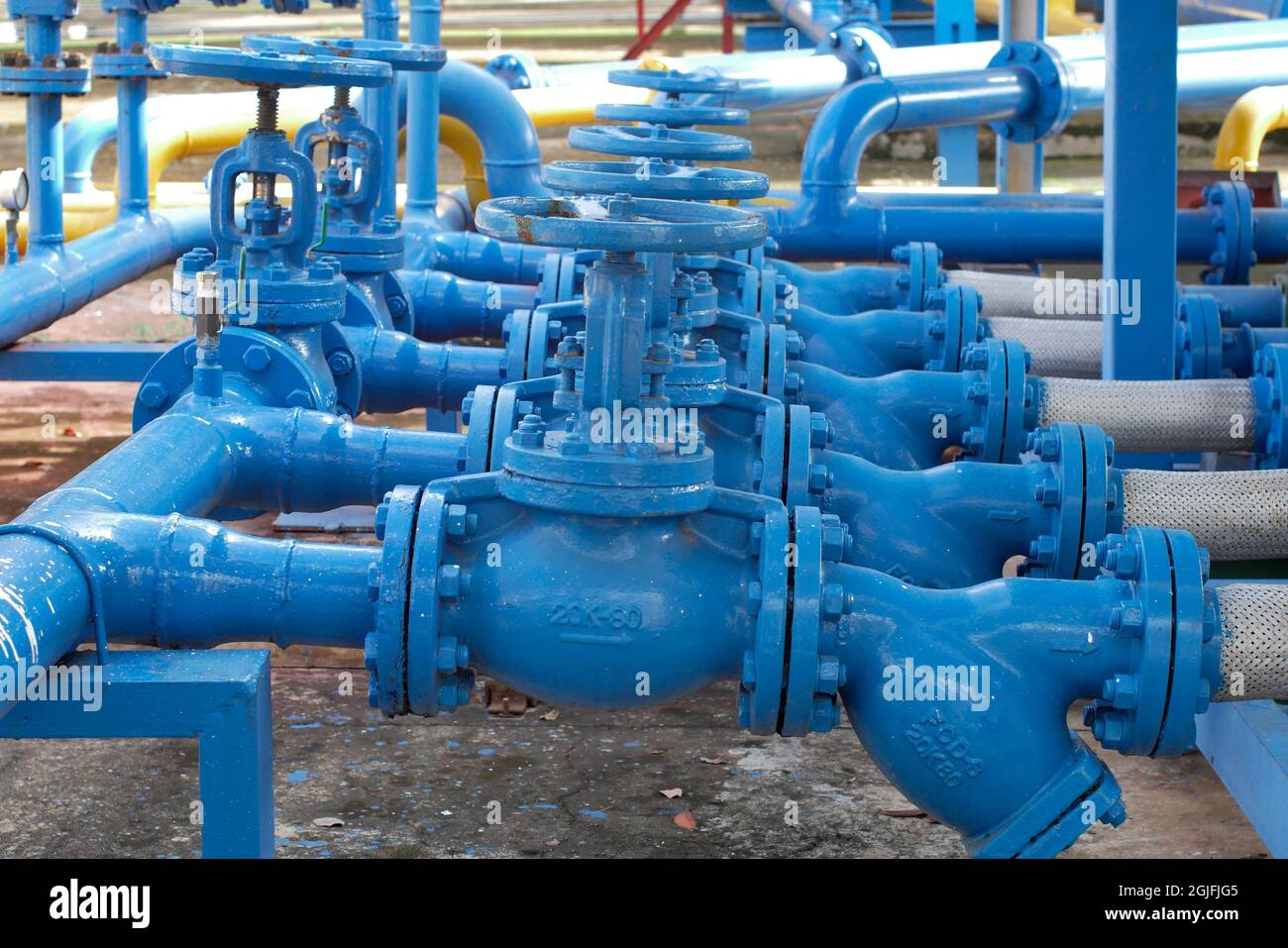

ISO 9001:2015 certified. Manufacturer of standard and custom natural ga valves. High pressure ball valves are available. Features include 316 stainless steel, alloy 400 and UNS N10276 body constructions, blow-out proof ball and bottom-loaded stem, trunnion-style ball design, low actuation-torque and 2-way and 3-way flow patterns. High pressure ball valves have working pressures up to 6,000 psi, temperature range from -40 degrees F to 450 degrees F and flow (Cv) up to 1.6. Made in the USA.

Manufacturer of compressed, shut-off, vent, control, high performance butterfly, cryogenic, internal, pressure regulator and cable natural gas valves. Made from stainless steel, carbon steel, aluminum and brass. Features vary depending upon model, including explosion proof enclosures, PEEK pistons, watertight coils, solenoid operators, closing springs, visual indications, pipe plugs, fabricated extension bonnets, PTFE wear pads and seat design. Suitable for commercial and industrial applications.

Manufacturer of cryogenic check valves for defense, storage and transportation applications. Made from stainless steel and bronze. Available in 725 psi operating pressure and -196 to +65 degrees C operating temperature. Suitable for various liquids and gases including oxygen, nitrogen, argon, carbon dioxide, neon, hydrogen, nitrous oxide, sulfur hexafluoride, natural gas, ethylene and trifluoromethane.

Manufacturer & custom manufacturer of emergency valves including fuel tank valves, natural gas valves, & gas valves. Pipe size ranges from 1/2 in. to 3 in. Pressure ranges from 150 psi to 300 psi . Maximum fluid temperature is 400 degrees F. Available in bronze & stainless steel. Suitable to control the flow of steam, corrosive fluids, deionized water, condensate, ammonia, vegetable oils, fuel oils, cryogenics, & flammable liquids.

Manufacturer of check valves suitable for horizontal and vertical installations in liquid, gas, and steam applications. Features include 2 to 42 in. line size, ASME class 150 to 2500, RF and RTJ flanged ends, stainless steel trim, as well as center and dual guided stem. Materials include carbon steel, alloys, and stainless steel. Industries served include building, chemical, gas, mining, petroleum, power, pulp and paper, textiles, municipal, and water treatment. Meets ANSI standards.

Manufacturer of standard and custom ball and transfer valves for natural gas pipeline transmission, power generation, midstream gas, refinery, compressor lube, seal oil system, duplex filters, shell and tube heat exchangers. Made from steel, 316/316L stainless steel and carbon steel materials. Available in 1 to 10 in. sizes and standard, split or straight-thru versions. Features include multi-ports, rugged, precision machined, spring-loaded pads and shaft designs with large cross-sections of O-ring seals. Serves the oil, gas, mining and marine industries.

ISO 9001:2015 certified. manufacturer and designer of spring loaded silent check valves for industrial and natural gases. Types of valves include flange, lined pipe, sanitary, union, straight sided and glass pipe insert, sanitary cartridge, low and high pressure, socket weld, connector, bushing, horizontal, vertical flanged, miniature and tubing valves. Materials include carbon and stainless steel, high and non-ferrous alloys and titanium and nickel alloys. Suitable for chemical, petrochemical, pharmaceutical, food and dairy and OEM applications. Meets NACE standards. CE certified. Made in the USA.

Distributor of natural gas valves. Check valves, solenoid valves, ball valves, cryogenic valves, relief valves, needle valves, plug valves, actuated valves, diaphragm valves, pressure regulators, cylinder regulators, back pressure regulators, control valves, & tube fittings. Markets served include industrial gas, chemical, medical, power, marine, oil & gas processing.

Distributor of combustion, refrigeration, and compressed natural gas (CNG) solenoid valves. Available in various model series. Suitable for controlling a range of liquids and gases. Same-day, FOB, and drop shipping are provided depending on orders.

ABCO, Anver, Atkomatic, Bee, Circle Seal, Coilhose, Conrader, DK-Lok, Dixon, Duravalve, Dwyer, Dyla-Trol, DynaQuip, Eaton, FMC, Flairline, Flowserve, Go, Goyen Mecair, HiP, Hoke, Jefferson, Kingston, Nachi, SMC, Smith-Cooper, WaterCop

Manufacturer of manual ball and check CNG valves made from stainless steel. Available in 19 mm orifice sizes, operating pressure up to 6,000 psi and operating temperature up to 375 degrees F. Features include low operating torque, end connectors, mounting panels, flow direction indicators, handles, stems, two way and three-way design. Serves the aerospace, oil/gas, CNG, marine, mining, chemical, power generation, biotechnology, geothermal, shipbuilding, pulp/paper and other industries. Stock items available.

Stocking distributor of natural gas ball valves. Available in bronze material and 1/4" to 3" sizes with adjustable packing gland feature. Butterfly, gate, globe, safety relief, and check valves are also supplied. Also suitable for LP gas, flammable liquid, and heated oil applications. Markets served include OEM, MRO, pipe-valve supply house, and process industries. UL listed.

ABZ, ASCO, Air-Mite, Apollo, Aquatrol, Bachman, Bonomi, Check-All, Davis, Delta, Fabrotech, Flomatic, Fulflo, Generant, Holyoke, Janatics, Keckley, Lube Devices, Magnatrol, Midwest Control, Ohio Valve, Spartan

Manufacturer of standard & custom control valves for natural gas applications. Types of control valves include pressure control valves, flow control valves, ultra high-resolution pressure control valves, precision back pressure control valves & precision vacuum control valves. Pressure control valves such as electronic air pressure control valves, electro-pneumatic pressure control valves, closed loop pressure control valves, high-flow electro-pneumatic pressure control valves, high-resolution pressure control valves, intrinsically-safe pressure control valves & OEM pressure control valves are available. Made in the USA.

Custom manufacturer of natural gas check valves. Specifications include 5,000 psi maximum pressure, 50 psi to 150 psi pilot pressure, 15 ft. lbs. torque, minus 45 degrees F to plus 200 degrees F fluid temperature, 0.85 specific gravity & 150 SUS viscosity at 100 degrees F temperature. Features include stainless steel springs, seats & push rods, Buna-N® O-rings, filter retainers, piston guide rings, aluminum bonnets & cartridge mounting threads.

ISO 9001:2015 certified custom manufacturer of manifold valves. Types of valves include ball, bellows and diaphragm sealed, manifold, purge, bleed, check, metering, needle, shut-off, gas, regulating, relief and quarter-turn plug valves. Materials for valves include brass, carbon and stainless steel and alloys. Serves the chemical, oil and gas, power, semiconductor and transportation industries. ASME approved and METI/KHK, UNSPSC, eClass and TUV certified.

Distributor of valves for industrial and commercial applications. Types include oil and gas shut-off, ball, modulator, control, solenoid and modulator valves. Equipment upgrade and repairs, burner tuning, preventative maintenance, installation, commissioning, troubleshooting, equipment start-up, calibration, NFPA safety audits and consulting services provided. 24/7 emergency services are available.

Stocking distributor of valves available in forged steel, cast steel, chrome molly, Monel®, Hastelloy® B & C, cast iron, ductile iron, bronze, brass & PVC. Electric, hydraulic & pneumatic actuations. Modifications include flange ups, conversions, coatings, hydro testing, packing changes & trim changes.

Custom manufacturer of ring damped, sealing compressor, concentric disc and plate valves. Various features include disc or milled seat design, spring pockets, interchangeable discs, heavy duty springs and threaded washers.

Custom manufacturer of wafer style butterfly valves for natural gas & oil burners. Valves are available in various models & configurations. Specifications of valves include 2 in. to 12 in. sizes, 60 psig to 80 psig minimum actuator air supply, minus 4 degrees F to plus 175 degrees F temperature range & 12.1 lbs. to 128.5 lbs. weight. Features of valves include ductile iron body, stainless steel discs & stems, mounting pads, visual position indicators & pneumatic actuators.

Master distributor of a wide variety of electronic, pneumatic & self-actuated valves, controls, controllers, regulators, gauges, meters, sensors for process, commercial and HVAC applications controlling temperature, flow, pressure and more.

Apollo, Aquatrol, Armstrong, Bonomi, CLA-VAL, Cash Acme, Cash Valve, Colonial, Conbraco, Consolidated, Dwyer, Gould, Granzow, Hammond, Homestead, Honeywell, Keckley, Kerotest, Kingston, Kunkle, Lance, Landis & Gyr, Leonard, Leslie, MCC Powers, Marsh Bellofram, Marsh Steam, Masoneilan, Milwaukee,...

Manufacturer of 1/8 in. NPT male outlet brass valves. Products include pilot, compression fit and burner valves. Burner valves with adjustable slip fit orifice or brass handles are also offered. Serves the OEMs (Original Equipment Manufacturers) and plumbing dealers, distributors, foodservice operators and metal fabrication industries.

Manufacturer of standard and custom valves for carbon dioxide and natural gas applications. Types of valves include check valves, shut-off valves, gas demand flow valves, header valves, residual pressure valves, line station valves and master shut-off valves. Made from different materials including steel, stainless steel, aluminum, brass, bronze and plastic materials. Available in different thread sizes and working pressures up to 6000 psi. Capabilities include design engineering, CNC machining, sawing, deburring, polishing, honing, grinding, welding and cleaning. Valves are REACH and RoHS compliant and meet CGA specifications.

Manufacturer of standard and custom natural gas valves. Various types include needle, gauge, ball, check, relief, hand, bleed, metering and toggle valves. RoHS and REACH compliant. Meets ASME and ASTM standards. CSA approved.

Stocking distributor of industrial valves for use in natural gas cylinders & compressors. Types include three-way, one, two & three-piece & miniature ball, swing & wafer check, butterfly & knife gate valves.

Distributor of replacement nuclear power, high pressure, cryogenic, cylinder and natural gas valves. Relief, diaphragm, low pressure, services, refrigeration, ball, emergency shut-off, excess flow control, isolation, in-line, gate, bonnet and seal valves are available. Back pressure, bypass, inlet, solenoid, swing check, angle, globe, flange, pilot, control, hose, toggle, needle, double, check, tank, filler, transfer, vapor and fuel valves are offered. ASME compliant valves are also available. Technical services, warehousing, shipping and installation are available.

Natural gas supply lines are exposed and vulnerable at the meter, and can easily be broken by impact from vehicles, landscape equipment, falling snow and ice, and more-often leading to a catastrophic incident.

When concrete or steel bollards are used to protect gas meter piping from damage, these often only provide nominal protection. In many cases, the bollards are actually the cause of the gas line rupture.

HaloValve is a patented breakaway valve installed to the riser where most breaks occur. Upon impact, HaloValve instantly seals the line, preventing the flow and accumulation of gas until the line can be repaired.

Because of their rigidity, gas risers and associated meter piping can easily break upon impact, causing dangerous leaks. HaloValve creates an intentional weak point in the meter set piping assembly, resulting in an engineered point that instantly self-seals.

HaloValve is a patented breakaway valve installed to the riser where most breaks occur. Upon impact, HaloValve instantly seals the line, preventing the flow and accumulation of gas until the line can be repaired.

If you have been searching for a safety release valve that you can use to reduce short-term pressure surges successfully and diminish the effects of gas leaks, this is the product for ...

... regulators have safety valves which will slam shut in the event of emergencies, such as the gas reaching too high a pressure level. The valve works to protect any fittings ...

This product has hydraulically actuated class A gas safety valves to EN 161 used for automatic shut-off. It shuts off when unstimulated for gas and air, ...

The S 104 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S50 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

The S100 Safety Shut Off valve is mainly used to avoid any damage to components as well as to avoid too high or too low pressure in the gas train. This could cause high financial losses ...

... Pressure Safety Valve + Rupture Disk is protected and may be utilized autonomously as essential security gadgets or in conjunction. There are 3 possible combinations. The first combinations ...

It"s a Safety valve in according with Directives ATEX 20K/34/EU. Technical Norm Fire Prevention 41/256 31/10/2019. d.P.R. 10/520 19/03/1955 and subsequent amendments.

130 Series Safety valves are also available as Relief valves. Relief valves, identified by the letter R after the type number, are devices with an operational function, ...

V651 Series safety relief valves are produced as safety and relief type. Safety valves are pressure relief elements used to evacuate excessive pressure ...

PVS type slam shut valves are pilot-operated relief valves in which the opening and the closing of the main plug is controlled by a pilot device which is very ...

This range of spring loaded conventional and balanced safety relief valves is specifically designed for overpressure protection of unfired pressure vessel (ASME Section VIII application). ...

The EMERSON BM7 SERIES is a disk slam-shut valve characterized as automatic isolating elements, which are suitable for installation as safety devices in regulating stations. This device has a high operation ...

... control and regulate the gas, air flow to burners and other combustion devices. HMV is a unique safety valve that can be supplied for the requiremen of handling higher ...

Type 50 is a safety valve for universal use. It can be used for nearly any industrial application, e.g. in shipping and pipeline construction, the chemical and petrochemical industries, ...

The RIEGER Safety valve Type SH prevents excessive pressure in steam and gaseous media in plant components and tanks. The set pressure is generally higher than the operating pressure of the system.

... sewage, gas, glycol, diathermic oil, industrial water, steam and other natural and aggressive media, depending on theresistance of materials usedfor the construction ofthe valve.

Safety shut-off valves (SSOVs) are the primary automatic means of turning gas flow ON and OFF for furnaces, ovens, and in some cases, individual burners (keep in mind that a "manual shut-off valve" is always required). SSOVs are required by national codes and standards with at least two SSOVs required between a burner and the fuel supply. Besides that, they are a good way of keeping you and your factory from joining the upper atmosphere.

WITT is a manufacturer of Pressure relief valvesor Safety relief valves for technical gases. They are designed to protect against overpressure by discharging pressurized gases and vapors from pipelines, pressure vessels and plant components. Safety relief valves (SRV) are often the last line of defense against explosion – and such an explosion could be fatal. Other common names for safety relief valves are pressure relief valve (PRV), safety valve, pressure safety valve, overpressure valve, relief valve or blow-off valve.

WITT safety valves are very precise. They are individually preset to open at a predetermined pressure within the range 0.07 to 652 Psi. Their small size and orientation-independent installation allow a wide range of connection options. WITT relief valves also stand out due to their high blow-off flow rates of up to 970m³/h. They can be used within a temperature range of -76° F to +518°F and even with very low pressures.

For maximum safety, WITT undertakes 100 % testing of each safety relief valve before it is delivered. In addition, WITT offers individual testing of eachsafety valveby the TÜV, with their certificate as proof of the correct set pressure.

WITTsafety relief valvesare direct-acting, spring-loaded valves. When the preset opening pressure is reached, a spring-loaded element in the valve gives way and opens, and the pressure is relieved. Once the pressures are equalized, the valve closes automatically and can be reactivated any time the pressure rises again. Depending on the application and the nature of the gas, the safety relief valvescan either discharge to atmosphere, or via a connected blow-off line. The opening pressure of the safety valves is preset by WITT at the factory according to the customer’s requirements.

Safety relief valvesare used in numerous industries and industrial applications where, for example, gases pass through pipelines or where special process vessels have to be filled with gas at a certain pressure.

For most industrial applications using technical gases, brass is usually the standard material of construction of thesafety relief valvebody/housing. For the use of pressure relief valves with aggressive and corrosive gases, the housings are made of high-quality stainless steel (1.4541/AISI 321, 1.4404/AISI 316L, 1.4305/AISI 303 or 1.4571/AISI 316Ti). The use of aluminium as a housing material is also possible.

Depending on the type of gas used and individual customer requirements, various sealing materials and elastomers are available to ensure the safety of your systems under even the most difficult conditions.

WITT pressure relief valves are available with different connections. In addition to the standard versions with the usual internal or external threads, special versions with KF or CF flanges, VCR or UNF threads can also be ordered. Special adapters for connecting the safety relief valve to a blow-off line are also available.

With more than 1,050 employees and 130,000 safety valves produced per year, LESER is the largest manufacturer of safety valves in Europe and one of the leading companies in its industry worldwide.

LESER offers spring loaded and pilot operated safety valves for all industrial applications according to the Pressure Equipment Directive and ASME XIII. Major companies in the chemical, oil and gas, petrochemical, energy, technical gases, LNG/LPG, pharmaceutical, food and beverage, shipbuilding and heating and air conditioning industries use LESER safety valves.

LESER safety valves are developed for the international market in Hamburg and manufactured in the modern plant in Hohenwestedt/Germany. In addition, LESER produces safety valves to the same standards in India and China for the local markets. Nine subsidiaries and offices in Europe, America, the Middle East and Asia as well as authorized contacts in over 80 countries guarantee competent customer advice and fast, reliable deliveries.

Industry leading pressure and safety relief valve designs with over 140 years of technical and application expertise providing custom engineered solutions for O&G, Refining, Chemical, Petrochemical, Process and Power applications. Our designs meet global and local codes and standards (API 526; ASME Section I, IV & VIII; EN ISO 4126; PED & more). Gain insight into the performance of your pressure relief valves with wireless monitoring.

The world is rapidly changing. As the industries we serve face increasing pressure to reduce their carbon footprint, digitally transform processes and optimize operations, the Valves team at Baker Hughes is ready to help our customers meet those challenges. Our culture of innovation and legacy of quality make us uniquely positioned to recognize and adapt to changing industry trends. From staying abreast of new manufacturing processes and materials sciences development, to converting our facilities and processes to reduce our own carbon footprint, we are creating solutions to help customers achieve their goals.

Flow Safe is a manufacturer of spring-operated and pilot-operated high-performance pressure relief devices. The Flow Safe product line is specifically designed for applications in Natural Gas Distribution, Pipeline, Aerospace, Marine, Industrial Gasses and other liquid and gas process applications.

We always stick to the principle "Quality First, Prestige Supreme". We are fully committed to providing our clients with competitively priced quality products, prompt delivery and professional service for Gas Safety Valve, Pipe Clamp Fittings, Oil Tanker Valve, 2 Pipe Clamp,Stainless Steel Boat Propeller. For more information, please send email to us. We are looking forwards the opportunity to service you. The product will supply to all over the world, such as Europe, America, Australia,Roman, Turkey,Japan, European.Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you"ll be served with good quality consultant service by our after-sale team. They"re about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Whether downhole or subsea, safety can be hard to achieve in the oil and gas industry. Sudden pressure spikes can ruin equipment, leading to production stoppages and worse. Protection starts at the component level, which is where Lee Pressure Relief Valvescome into play.

Our relief valves come in three main varieties. Safety relief valves are designed to be exercised for intermittent “pop-off” applications. Pressure-regulating valves are intended to operate more continuously with stable performance throughout the operating range. Thermal relief valves relieve a few droplets of fluid from a trapped volume expanding due to rising temperatures. Each type of valve plays an essential role in downhole oil tool applications, and each is manufactured to the exacting tolerances that this role requires.

Like all products from The Lee Company, pressure relief valves are small, lightweight, and incredibly durable– enough to serve out the entire lifespan of an oil tool. In addition, these products are available in a range of sizes and cracking pressures.

While it"s possible to manually shut off your natural gas, the following specialized valves are available that can automatically shut off your service in case of an emergency:

Earthquake natural gas shut-off valve (also known as a seismic natural gas shut-off valve) automatically shuts off your natural gas service when an earthquake of a sufficient magnitude occurs at your home.

An excess-flow valve (EFV) automatically closes and restricts the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter.

If you want to have an earthquake natural gas shut-off installed, or are required to have one by your insurance company or the local Department of Building and Safety, the valve must be installed on your house line.

If installation requires natural gas service closure, you"ll need to contact us to shut off the service and restore service when installation is completed. Natural gas service shut off and restoration of service orders can be scheduled by contacting us at 1-800-427-2200.

Under the regulations of the California Public Utilities Commission (CPUC), General Order 112-E, only SoCalGas® or its certified contractors are authorized to operate the natural gas service shut-off valve.

When you hire a qualified professional to install your earthquake valve, you"ll need to make sure that the valve is installed on your house line, not on SoCalGas" facilities. SoCalGas" facilities include all of the pipe fittings installed and maintained by SoCalGas, up to and including the last elbow or tee connecting to your house line. See the diagram below for to see where your house line starts.

All unauthorized valve installations found on SoCalGas" facilities will be removed. In addition, earthquake valves are not permitted in utility curb meter vaults.

If an earthquake or other significant event causes your earthquake shut-off or excess-flow valve to close, you can follow the manufacturer"s instructions for resetting the valve so that natural gas flows again. However, we recommend that you contact a qualified professional or SoCalGas to reset the valve, and to perform a safety check of your natural gas appliances before they are placed back in operation to verify that no natural gas leaks exist, and to re-light your pilot lights.

Remember that following a major emergency it may take many days or even weeks before someone can come to your location. (SoCalGas charges a fee to reset valves and re-light pilot lights when your earthquake shut-off valve has closed due to a non-earthquake occurrence.)

Price: The cost of the valve is going to vary based on the type and size of the valve, as well as the installation requirements and the company installing it.

Choosing a valve: In order to choose the right valve size and manufacturer, contact your local Department of Building and Safety to find out their earthquake valve requirements.

Where to buy a valve: You can purchase an earthquake valve at supply retailers, licensed plumbing contractors, or directly from the valve manufacturer.

Using a contractor: You can hire a qualified professional to install the earthquake or excess-flow valve on your house line. SoCalGas will not install a valve for you.

Effective February 10, 2002, California Public Utility Commission (CPUC) Decision 01-11-068 prohibits installation of an earthquake valve on SoCalGas" facilities. In addition, SoCalGas no longer installs earthquake shut-off valves for its customers, and does not allow any customer owned equipment, including excess-flow valves, be installed on SoCalGas" facilities.

If you have an earthquake valve that was installed by SoCalGas or one of its authorized contractors on or before the February 10, 2002 cutoff date, that is located on SoCalGas" facilities, with proper documentation your installation may be allowed to remain in place. Authorized contractors are those who participated in SoCalGas" earthquake program and were trained by SoCalGas to work on their facilities.

Additional information regarding earthquake valves and natural gas service restoration after a valve activates can be found in Tariff Book, Rule 10, Section G, "Earthquake Valve Service."

An Excess Flow Valve, or EFV, is a safety device installed on natural gas distribution pipelines to automatically close and restrict the flow of natural gas in the event an underground pipe is damaged or if there is a significant increase in the flow of natural gas to the meter. These conditions are typically caused by digging or construction but can also be caused by damage to your natural gas meter by a vehicle impact.

EFV can reduce the risk of explosions, fires, and personal injury because they close or restrict any unplanned or excessive natural gas flow. Installation of an EFV will not protect a customer from household appliance malfunctions, small punctures in underground pipelines, and pipeline damage from earthquakes or flooding. It is

important to understand that an EFV does not shut off the flow of natural gas completely. Some leakage may still occur resulting in a hazardous condition.

An EFV is installed on the service pipeline that runs underground between the natural gas main (usually located in or near the street, alley or easement) and the SoCalGas® meter on the customer’s property).

The best way to prevent damage to a natural gas pipeline due to digging is to call 811, the Underground Service Alert program, at least two working days before digging. Underground Service Alert will coordinate with SoCalGas to mark the locations of buried utility-owned lines - absolutely FREE.

If you are interested in having an EFV installed on the service pipeline serving you[1], please call SoCalGas at 1-800-427-2200. SoCalGas will first check to see if your service already has an EFV installed and, if not, an estimate to install the EFV will be provided. The cost to install an EFV can vary widely depending on site specific conditions and can range from $2,500 to $5,000 or more.

If you decide to have an EFV installed, we will coordinate with you to schedule the installation (note that it is possible that natural gas service will be interrupted to install the EFV). The construction crew will dig around the natural gas line in order to install the EFV and when the job is complete natural gas service will be restored (if it was shut off). If paving or concrete needs repair that work will be scheduled at a later date.

Please take a moment to understand the simplicity of our valves’ operation. It has been our experience, that the simpler the operation, the more accurate the function is when needed. Each valve is tested and certified before leaving our factory ensuring it meets Los Angeles Counties’ strict approvals.

8613371530291

8613371530291