cdtp safety valve factory

As we had discussed the backpressure that relief valve faces in a closed system would not be present during testing in the shop and this needs to be compensated for conventional relief valves.

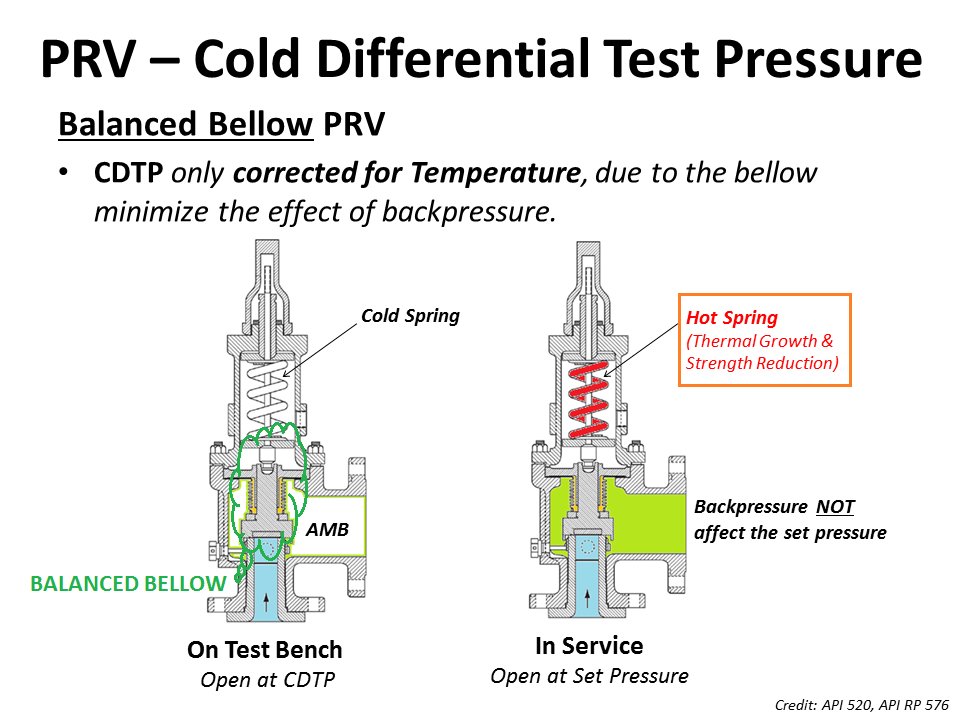

However as discussed above the parameter of Temperature correction factor would still be applicable to Bellows and pilot-operated relief valve if the PRV temperature is significantly different from that of ambient temperature.

Project Scenario : A Relief valve of Dresser 1900 Series (Conventional relief valve) valve is required to open at 800 Psig where the service temperature is 400°F and backpressure is 100 Psig.

Did you know, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

Have you come across a conventional pressure relief valve relieving to a flare header? Did you know that, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

API 520 Part I, Ninth Edition, Section 5.3.2.1 says, "Superimposed backpressure at the outlet of a conventional spring-loaded PRV acts to hold the valve disc closed with a force additive to the spring force. The actual spring setting can be reduced by an amount equal to the superimposed backpressure to compensate for this."

It further goes on to say in Sections 5.3.2.2 & 5.3.2.3, "Balanced spring-loaded or pilot-operated PRVs should be considered if the superimposed backpressure is variable. However, if the amount of variable superimposed backpressure is small, a conventional valve could be used provided:

For example, conventional valves are often used when the outlet is piped into a relief header without compensating the set pressures for the superimposed backpressure caused by other relieving devices. This approach can be used provided the allowable accumulation is not exceeded during the release.

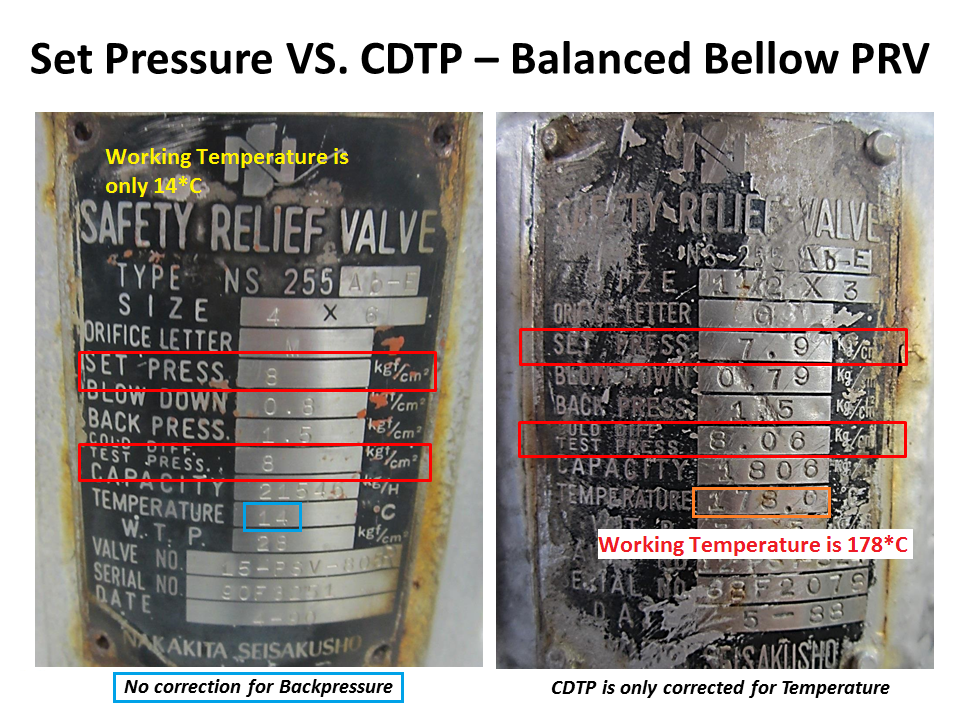

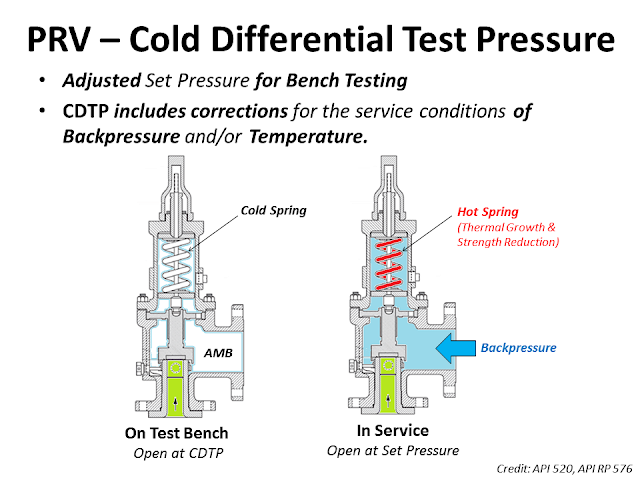

The Cold Differential Test Pressure (CDTP)of thePressure Relief Valve (PRV) is a set pressure that is adjusted to be used for the PRV (Bench Testing). Because in actual use conditions, the PRV may be affected by the Backpressure. And the operating temperature. Therefore, when testing at room temperature and without backpressure, it is necessary to adjust the set pressure to compensate for these factors. In other words, the shop test pressure = CDTP.

An example of aCold Differential Test Pressure (CDTP)with abackpressure (superimposed)effect. In this case, CDTP is equal to Set Pressure minus Backpressure.

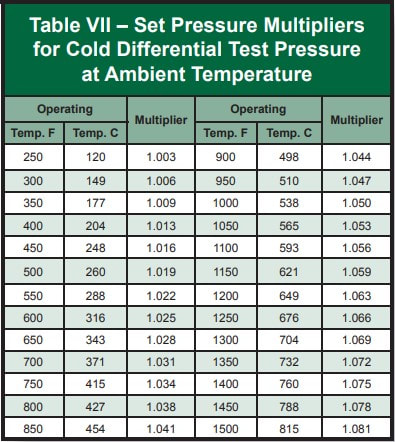

An example of aCold Differential Test Pressure (CDTP)with different temperature compensations for use and testing. And an example ofCDTP that has been adjusted to compensate for both Backpressure (Superimposed) and temperatureeffects.

Test Stand or Test Bench is a set of equipment used for Pressure Relief Valve (PRV) in Pop Test (Set Pressure Test), Blowdown and Seat Tightness Test (Leakage Test)

As for theBalanced Bellow Pressure Relief Valve, which has a bellowfor reducing the impact of theBackpressure, the Cold Differential Test Pressure (CDTP) of the Balanced Bellow Type PRV will compensate only for the impact of different temperatures between the Shop Test and In-service.

I think that CDTP has been used for set pressure. The data sheet should state both. Set pressure would be 25.5 but this value is stated as the operating pressure.

Note also. The subject Fulflo valves are Hydraulic Bypass Relief Valves and not of the API-520/-526 Pressure Relief Valve variety. A PRV data sheet has been used.

Yes, it is a conventional piston type pressure limiting valve. Set pressure is mentioned as differential pressure. i.e, 7.03 Kg/cm2D. Constant back pressure is 18.47 Kg/cm2g. Presently the valve set in the RV shop test stand is 7.03 kg/cm2g. Our concern is, we would like to know, whether the CDTP value is correct or not? As mentioned by " The Obturator" , I think, set pressure should be mentioned as 25.5 Kg/cm2g instead of 7.03 kg/cm2g. RE: CDTP for Fulflo valve

API 520 part 1 says that the CDTP temperature correction is required when the relieving temperature exceeds 250 F however, my practice with Crosby has showed that when the OPERATING NOT RELIEVING temperature is > 150 F, the correction factor is required, u may find it in Installation manual of the relevant manufacturer i think

3) If the valve is balanced, u have to only consider the temperature correction factors in the case of CROSBY. Not sure about the manufacturer u mentioned

for Anderson greenwood 400 series, piston type modulating valve, i couldn"t find any correction factory in the datasheet also checked with the software by increasing the both relieving and operating temperature to 250 F seems no correction is required , however, api says that u have to consult with the manufacturer RE: CDTP for Fulflo valve

“The Fulflo valves operate on differential pressures but temperature normally doesn’t affect the set pressure at which the valve will open as the valve set pressure and then relieves.”

My concern is how to calculate the CDTP. We have more than 7500 PSVs in our plant. But only these two PSVs having concern, how to calculate the CDTP. In all other PSVs data sheet, set pressure is mentioned in kg/cm2g engineering unit, but in these two pzvs, set pressure is kg/cm2D (Differential pressure).

At present, we have mentioned the CDTP as 7.03 kg/cm2g. As we considered as Set pressure is 25.5 kg/cm2g & constant back pressure is 18.47 kg/cm2g. As mentioned above by " The Obturator" , set pressure should be mentioned as 25.5 Kg/cm2g instead of 7.03 kg/cm2g.

Regarding also your attached manufacturers chart. It is incomplete. For example, for Crosby, that is the chart for J series (JOS-E/JBS-E). For steam and other valve types the compensation chart is different. The chart also fails to advise that the compensation factor applies to operating temperatured (too many users have taken relief temperature - note Tai incorrectly state this - see API-520).

The temperature compensation factor should be outlined in the manufacturers IOM, The Obturator correctly points out that this should be based on operating not relieving temperature as the impact of the thermal effect will not be observed unless the spring is normally exposed to the high temperature. RE: CDTP for Fulflo valve

“4.2.3.3 The temperature used for the correction factor should be based on the temperature at the inlet to the relief valve at its normal service (nonrelieving) conditions

and also used in sizing software programs (ie: PRV2SIZE, etc.) are based on operating temperature at the valve normal service (nonrelieving) conditions.

As per previous Saudi Aramco pzv procedure, for Crosby PZVs, relieving temperature will be considered as operating temperature, while calculating the temperature compensation. May be you have noticed the highlighted portion from the procedure screen shot. Based on API update, it was updated. Now for any manufacturer pzvs, operating temperature will be considered for CDTP.

Further for Convetional Valve API-521 paragraph 4.2.3.3 A convetional PRV Operating with a constant superimposed back pressure normally required a correction factor to compensate for the back pressure. In this case the required set pressure minus superimposed back pressure is equal to CDTP. This change account for the addtional closing force exerted on the valve disk by back pressure.

Now, we have to add this pressure for back pressure consideration or valve is tested based on CDTP, But if we tested based on CDTP than this is less that the set pressure as CDTP is Set Pressure - Superimposed back pressure.

NATIONAL BOARD tells how to calculate the CDTP for a PRD taking into account a temperature differential and a back pressure, CDTP is not more than the difference of the SET PRESSURE minus the superpositions exerted by the effect of the temperature and the back pressure of a valve of conventional design (without bellows). By the way, the temperature correction is given by a multiplying factor that will depend on the quality of the internals of each valve and this is supplied by the manufacturer"s brand. For example DRESSER has its own tables of multiplying factors

A question we commonly receive is why a valve appears to open, or actuate, earlier than expected. Often, we find that the valve is not, in fact, opening early. Rather, the perception that it is actuating early is due to a misunderstanding of set pressure.

The set pressure, also called the opening pressure, of a safety or relief valve is the inlet pressure at which the valve begins to open as required by code.

A valve should be set to open at the maximum allowable working pressure (MAWP) of the vessel the valve is intended to protect. There is some tolerance to actual set pressure, which means that a valve set at 100 psig may open slightly above or slightly below this level.

The first step is to determine if your valve really is opening early. Sometimes safety and safety relief valves appear to open before they reach the set pressure — there may be an audible or visible release of fluid between the seat and the disc. This is known as “simmer” or “warn,” and it is not the same as a full open.

Simmer, or warn, occurs when a valve opens slightly, discharging only a small percentage of its rated capacity. For example, direct spring-operated safety valves may simmer or warn at 90% of the nameplate set pressure. A valve that is simmering is not considered open.

The next step is to check your gauge to ensure that it is reporting the set pressure correctly. The gauge should be calibrated properly and located upstream of the valve, close to the valve inlet. Rapid increases in system pressure can make it appear that a valve is opening early because the gauge can’t accurately report the pressure.

If you still believe your valve is opening early, assess the operating factors that might be contributing to the situation. Valves are factory set using standard conditions, and factors like high temperature, vibration, and back pressure can cause them to open early. These conditions can be compensated for using cold set pressure, aka cold differential test pressure (CDTP). Learn more about CDTP from the National Board.

Proper repair of a Pressure Relief Valve starts with knowing the PRV Manufacturer and Model Number. All Pressure Relief Valves are similar, but being aware of the differences is the first step to being a qualified PRV Technician. Identification and interpretation of Nameplate Data is the basis for a proper repair.

CDTP(Cold Differential Test Pressure) may be stamped on PRVs certified to ASME Section VIII service. CDTP compensates for Elevated Temperature and/or Back Pressure. CDTP is an item of Nameplate Data that is much misunderstood. Simply put, the use of a CDTP means that the PRV Technician does not have to recreate "In-Service" conditions at the Test Bench. Elevated system temperature and/or Back Pressure can be accounted for during testing by application of the CDTP.

Built-up back pressure is the backpressure generated due to pressure losses at the outlet of an open relief valve when it is discharging. This pressure depends on the pressure of the vent header downstream to the relief valve and the relieving flowrate which is being discharged. The built-up backpressure is the pressure in the vent header plus pressure drop in the line from relief valve to vent header, when the valve is discharging at full capacity.

For certain relief valve designs, the backpressure on the valve acts as a closing force and can affect the opening pressure for the valve. ‘Conventional’ valves are highly susceptible to this effect and hence not used in applications where high backpressure is expected. ‘Balanced Bellows’ and ‘Pilot Operated’ relief valves relatively shielded from effects of high backpressure.

For some relief valves (especially conventional type relief valves), the opening of the valve is affected by backpressure seen by the valve. If the backpressure seen by such relief valves is higher than atmospheric, then it has to be designed to open at a lower differential pressure value than the relief valve set pressure minus atmospheric pressure. However when the relief valve is tested before installation, it only sees atmospheric pressure as backpressure. Hence to open this relief valve at same differential pressure value, the set point pressure for opening the valve has to be lower than original design set point pressure. This set point value is known as cold differential test pressure (CDTP).

For pilot operated and balanced bellows type relief valves, effect of backpressure on valve opening characteristics is very low and hence CDTP is the same as the original design set point pressure value.

The valve backseat test is performed in the valve with a backseat feature. This is a feature that allows possible replacement of the valve packing while in service. In this test, the valve shall be fully opened and packing gland shall be loose or not installed. No leakage is permissible in the backseat test. Keep in mind that the test pressure for the backseat is same as the other seat test of the valve.

The pressure safety valve (PSV) is a direct, spring-loaded pressure-relief valve that is opened by the static pressure upstream of the valve and is characterized by a rapid opening or pop action.

Adjust (raise) the nozzle ring to -2 notch position (gas trim valve). The operator applies the pressure (as per valve specification and data sheet) at the inlet of the valve.

A safety relief valve pops or releases pressure when it reaches the desired set pressure. A POP-test needs to be repeated a minimum of three times to identify consistency. A reseating pressure shall be noted and recorded. In the industry, for this type of test, the standard which is widely followed is ASME Sec VIII Div.I.

In the seat test, the operator raises the pressure up to 90 per cent of the CDTP and observes the leakage at the outlet of the valve for a particular period of time. Acceptance criteria in bpm or meter cubic feet are described in API-527 standard based on size and testing medium.

This test is performed for Safety Relief valves which contain a bellow feature. Main function of this feature is to deal with back-pressure effects caused by different outlet situations. For such valves, it is mandatory to perform verify bellow integrity. To check the bellow, approximately 1 to 2 bar pressure at the outlet of the valve needs to be applied and one needs to observe leakage from the vent which is situated in the bonnet. No leakage is allowed.

In the shell test for a conventional safety valve, one has to apply 100 PSIG / 7 Bar at the outlet of the valve and then observe leakage at different connecting points such as body/bonnet joint, nozzle/body, nozzle ring adjustment lock and the stem opening on top. But for the body test of a balanced-type valve, the same pressure is to be applied at both outlet and bonnet vent. Leakage observing points are the same which are mentioned above

8613371530291

8613371530291