cdtp safety valve supplier

As we had discussed the backpressure that relief valve faces in a closed system would not be present during testing in the shop and this needs to be compensated for conventional relief valves.

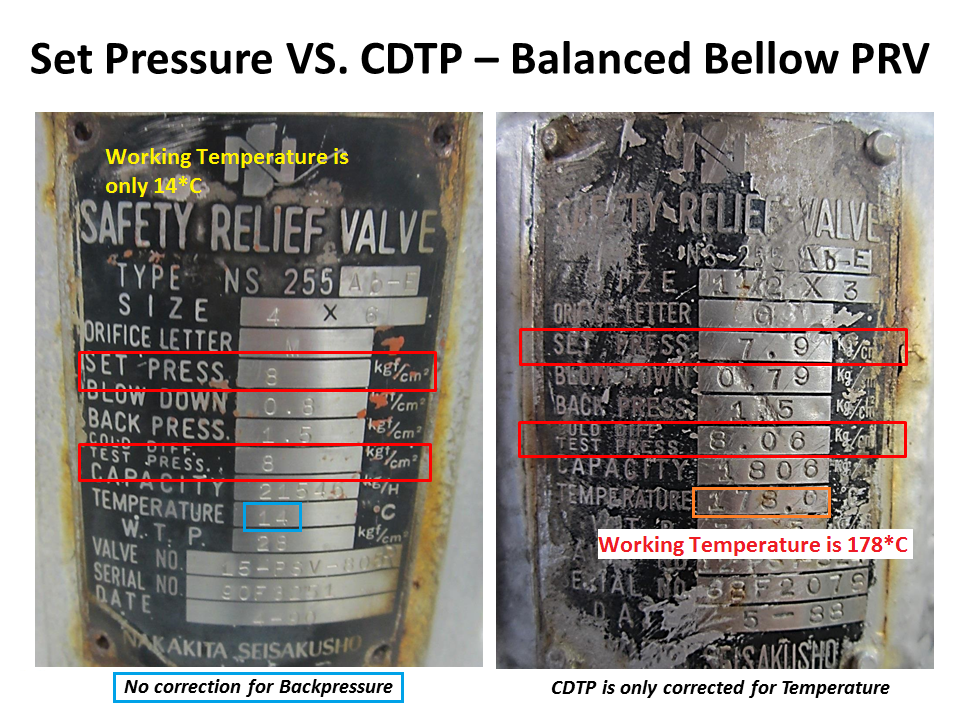

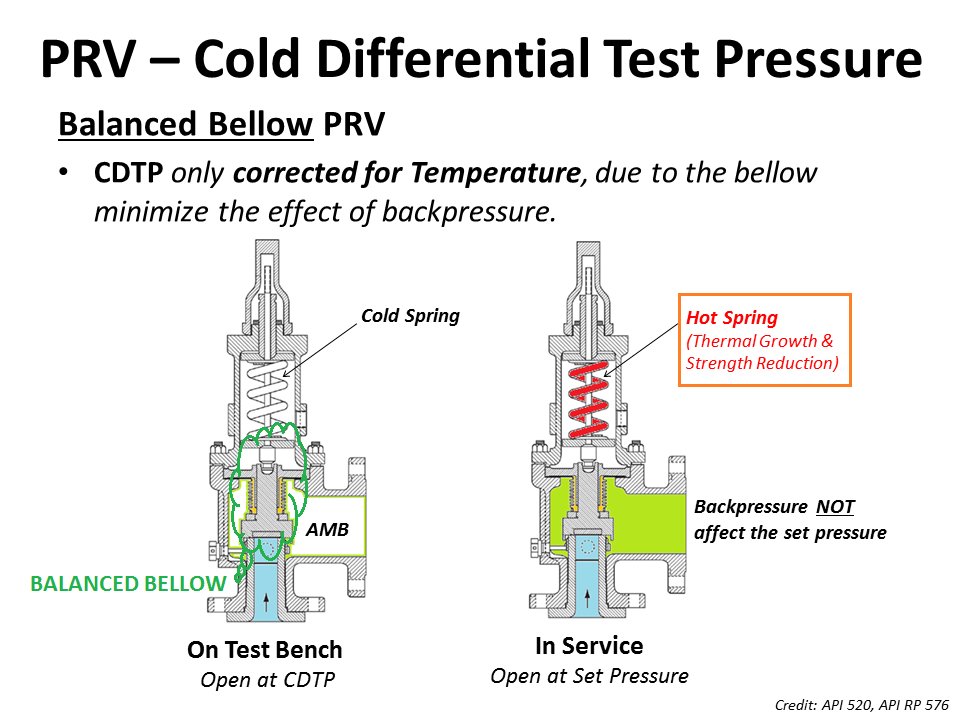

However as discussed above the parameter of Temperature correction factor would still be applicable to Bellows and pilot-operated relief valve if the PRV temperature is significantly different from that of ambient temperature.

Project Scenario : A Relief valve of Dresser 1900 Series (Conventional relief valve) valve is required to open at 800 Psig where the service temperature is 400°F and backpressure is 100 Psig.

Built-up back pressure is the backpressure generated due to pressure losses at the outlet of an open relief valve when it is discharging. This pressure depends on the pressure of the vent header downstream to the relief valve and the relieving flowrate which is being discharged. The built-up backpressure is the pressure in the vent header plus pressure drop in the line from relief valve to vent header, when the valve is discharging at full capacity.

For certain relief valve designs, the backpressure on the valve acts as a closing force and can affect the opening pressure for the valve. ‘Conventional’ valves are highly susceptible to this effect and hence not used in applications where high backpressure is expected. ‘Balanced Bellows’ and ‘Pilot Operated’ relief valves relatively shielded from effects of high backpressure.

For some relief valves (especially conventional type relief valves), the opening of the valve is affected by backpressure seen by the valve. If the backpressure seen by such relief valves is higher than atmospheric, then it has to be designed to open at a lower differential pressure value than the relief valve set pressure minus atmospheric pressure. However when the relief valve is tested before installation, it only sees atmospheric pressure as backpressure. Hence to open this relief valve at same differential pressure value, the set point pressure for opening the valve has to be lower than original design set point pressure. This set point value is known as cold differential test pressure (CDTP).

For pilot operated and balanced bellows type relief valves, effect of backpressure on valve opening characteristics is very low and hence CDTP is the same as the original design set point pressure value.

I think that CDTP has been used for set pressure. The data sheet should state both. Set pressure would be 25.5 but this value is stated as the operating pressure.

Note also. The subject Fulflo valves are Hydraulic Bypass Relief Valves and not of the API-520/-526 Pressure Relief Valve variety. A PRV data sheet has been used.

Yes, it is a conventional piston type pressure limiting valve. Set pressure is mentioned as differential pressure. i.e, 7.03 Kg/cm2D. Constant back pressure is 18.47 Kg/cm2g. Presently the valve set in the RV shop test stand is 7.03 kg/cm2g. Our concern is, we would like to know, whether the CDTP value is correct or not? As mentioned by " The Obturator" , I think, set pressure should be mentioned as 25.5 Kg/cm2g instead of 7.03 kg/cm2g. RE: CDTP for Fulflo valve

API 520 part 1 says that the CDTP temperature correction is required when the relieving temperature exceeds 250 F however, my practice with Crosby has showed that when the OPERATING NOT RELIEVING temperature is > 150 F, the correction factor is required, u may find it in Installation manual of the relevant manufacturer i think

3) If the valve is balanced, u have to only consider the temperature correction factors in the case of CROSBY. Not sure about the manufacturer u mentioned

for Anderson greenwood 400 series, piston type modulating valve, i couldn"t find any correction factory in the datasheet also checked with the software by increasing the both relieving and operating temperature to 250 F seems no correction is required , however, api says that u have to consult with the manufacturer RE: CDTP for Fulflo valve

“The Fulflo valves operate on differential pressures but temperature normally doesn’t affect the set pressure at which the valve will open as the valve set pressure and then relieves.”

My concern is how to calculate the CDTP. We have more than 7500 PSVs in our plant. But only these two PSVs having concern, how to calculate the CDTP. In all other PSVs data sheet, set pressure is mentioned in kg/cm2g engineering unit, but in these two pzvs, set pressure is kg/cm2D (Differential pressure).

At present, we have mentioned the CDTP as 7.03 kg/cm2g. As we considered as Set pressure is 25.5 kg/cm2g & constant back pressure is 18.47 kg/cm2g. As mentioned above by " The Obturator" , set pressure should be mentioned as 25.5 Kg/cm2g instead of 7.03 kg/cm2g.

Regarding also your attached manufacturers chart. It is incomplete. For example, for Crosby, that is the chart for J series (JOS-E/JBS-E). For steam and other valve types the compensation chart is different. The chart also fails to advise that the compensation factor applies to operating temperatured (too many users have taken relief temperature - note Tai incorrectly state this - see API-520).

The temperature compensation factor should be outlined in the manufacturers IOM, The Obturator correctly points out that this should be based on operating not relieving temperature as the impact of the thermal effect will not be observed unless the spring is normally exposed to the high temperature. RE: CDTP for Fulflo valve

“4.2.3.3 The temperature used for the correction factor should be based on the temperature at the inlet to the relief valve at its normal service (nonrelieving) conditions

and also used in sizing software programs (ie: PRV2SIZE, etc.) are based on operating temperature at the valve normal service (nonrelieving) conditions.

As per previous Saudi Aramco pzv procedure, for Crosby PZVs, relieving temperature will be considered as operating temperature, while calculating the temperature compensation. May be you have noticed the highlighted portion from the procedure screen shot. Based on API update, it was updated. Now for any manufacturer pzvs, operating temperature will be considered for CDTP.

NATIONAL BOARD tells how to calculate the CDTP for a PRD taking into account a temperature differential and a back pressure, CDTP is not more than the difference of the SET PRESSURE minus the superpositions exerted by the effect of the temperature and the back pressure of a valve of conventional design (without bellows). By the way, the temperature correction is given by a multiplying factor that will depend on the quality of the internals of each valve and this is supplied by the manufacturer"s brand. For example DRESSER has its own tables of multiplying factors

Further for Convetional Valve API-521 paragraph 4.2.3.3 A convetional PRV Operating with a constant superimposed back pressure normally required a correction factor to compensate for the back pressure. In this case the required set pressure minus superimposed back pressure is equal to CDTP. This change account for the addtional closing force exerted on the valve disk by back pressure.

Now, we have to add this pressure for back pressure consideration or valve is tested based on CDTP, But if we tested based on CDTP than this is less that the set pressure as CDTP is Set Pressure - Superimposed back pressure.

METRUS SV series safety valve test benches are designed for stationary use in maintenance Workshop as well as in production environment. Use the comprehensive choice of options to taylor your test bench according to your specific needs.

Did you know, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

Have you come across a conventional pressure relief valve relieving to a flare header? Did you know that, under certain circumstances, you need to verify if the Cold Differential Test Pressure (CDTP) is properly compensated for the superimposed backpressure from the flare header?

API 520 Part I, Ninth Edition, Section 5.3.2.1 says, "Superimposed backpressure at the outlet of a conventional spring-loaded PRV acts to hold the valve disc closed with a force additive to the spring force. The actual spring setting can be reduced by an amount equal to the superimposed backpressure to compensate for this."

It further goes on to say in Sections 5.3.2.2 & 5.3.2.3, "Balanced spring-loaded or pilot-operated PRVs should be considered if the superimposed backpressure is variable. However, if the amount of variable superimposed backpressure is small, a conventional valve could be used provided:

For example, conventional valves are often used when the outlet is piped into a relief header without compensating the set pressures for the superimposed backpressure caused by other relieving devices. This approach can be used provided the allowable accumulation is not exceeded during the release.

Another example is a nonfire case where two valves are installed with one PRV set at MAWP and one set at 1.05 times MAWP; the built-up backpressure should not exceed 16% and 10% of the respective set pressures. When the superimposed backpressure is constant, the spring load may be reduced to compensate for the superimposed backpressure. When the downstream piping is designed within the above backpressure criteria, no backpressure capacity correction (Kb = 1.0) is required in the valve sizing equations, for gases at critical flow or for liquids. When the backpressure is expected to exceed these specified limits, a balanced or pilot-operated PRV should be specified. Note that the built-up backpressure limitations discussed above do not necessarily apply to valves with open bonnet design due to the nature of their design. Consult the manufacturer for guidance."

Depending on the system, there are specific situations, other than external fire or multiple valves (such as adjusted CDTP or when the MAWP is higher than the set pressure), that allow for a total backpressure larger than the commonly specified limits.

If the pressure differential across the valve is larger enough to ensure that the valve is stable, the allowable backpressure can be as large as needed as long as your allowable accumulation (MAWP + specified limit) and any practical limitations (such as mechanical backpressure limits) are not exceeded.

Taylor Valve Technology® is a manufacturer leader in high-quality industrial valves. We deliver safety relief, high-pressure relief, and back pressure relief valves. Our wide array of choke and control valves and pilot-operated valve products are second to none. Products are designed for demanding industrial needs, meeting quality API and ASME Code requirements. High-demand oil & gas industry, chemical plants, power generators, and the processing industry depend on our valves for consistency and durability. Get effective flow control of liquid, steam, and gas. Valves ship from the Taylor Valve Technology, Inc. United States facility. Delivering worldwide, you can depend on quick turnaround times.

8613371530291

8613371530291