drill string safety valve supplier

Sub-drill exclusively represents Global Manufacturing Inc, an industry leading and world renowned US based manufacturer of Drill Stem Valves and Associated Products.

Global Manufacturingspecialise in the design and manufacture of a complete range of Drill Stem Valves, developed and engineered using FEA to be the highest quality and most reliable valve on the market.

Precision machined from the highest quality materials, Global Valves are competitively priced and reliable - designed to last the pace offshore in all types of well and operating conditions, including 20k designs for the next generation of drilling.

Sub-drill are the approved service facility for Global Manufacturing USA; we inspect, repair and test all types of Top Drive, IBOP’s, Full Open Safety, Kelly, Gray Type and Drop-In Check Valves to OEM standards. Sub-drill provides in-house inspection, repair, refurbishment and pressure testing facilities to the latest industry standards at its Aberdeen Westhill facility.

In addition to our in-house inspection, repair and test facilities, Sub-drill provide the means to test valves offshore using our compact portable Sub-drill DSV™.

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

The IBOP, also called Gray Valve or BVR, is a back pressure valve used in the drill string to prevent the well from flowing uncontrollably up the drill string. It is generally used in 2 ways:

Below the rig floor without a plug when connected in the drill-string. It can be left in the drill string as long as necessary to re-establish control of the well-pressure balance.

The RDCV, also called Dart Valve or a Back-Pressure Valve, controls backflow through the drill pipe during a kick or when tripping pipe into the hole against pressure. Check-valve compatibility should be checked with Kelly Cock free passage.

Kelly valves are used as a safety valve in drilling rigs. The use of the kelly valve enables an interruption of the flow inside the drill string. Depending on the conditions, we supply our kelly valves with different overall lengths, external and internal diameters as well as thread types. Manufacturing is done according to API specifications 7-1 and in compliance with IS0 9001:2015. Certification (Type Approval) by ABS and DNV is possible.

Searching for tools to control the flow of your piping system? Explore one of the largest featured collections of products and discover a range of wholesale drill pipe safety valve on Alibaba.com. When you search for drill pipe safety valve and related items, you will be able to find many types of drill pipe safety valve varying in size, shape, use, and quality, all at prices in which are highly reasonable!

There are many uses of valves - mainly controlling the flow of fluids and pressure. Some examples include regulating water for irrigation, industrial uses for controlling processes, and residential piping systems. Magnetic valves like those using the solenoid, are often used in a range of industrial processes. Whereas backflow preventers are often used in residential and commercial buildings to ensure the safety and hygiene of the water supplies. Whether you are designing a regulation system for irrigation or merely looking for a new replacement, you will be able to find whatever type of drill pipe safety valve that you need. Our products vary from check valves to pressure reducing valves, ball valves, butterfly valves, thermostatic mixing valves, and a lot more.

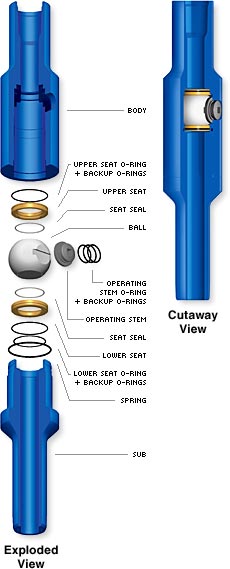

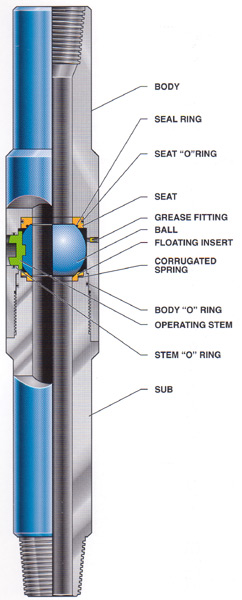

Kelly Valve/Drill Pipe Safety Valve is a full opening valve that provides positive pressure control of the fluids in the drill string. These valves can be used as a drill pipe safety valve or upper kelly valve to control blowout pressures, or as a lower kelly valve to prevent loss of drilling fluid when the kelly is disconnected.

The valve seals in both directions with metal to metal seals. Available in 10,000 psi working pressure as standard, 15,000 psi working pressure is available in certain sizes upon request. The valve uses a hexagon socket on the operating stem and has positive stops in the open and closed positions.

In 2006, Forum purchased the Baker SPD product line. Forum continues to manufacture the products formerly known as Baker SPD under the SPD name and offers a complete line of float valves, repair kits, and puller assemblies for a wide range of drilling situations and operating conditions. We are the premier provider of “Certified” drill pipe float valves that includes high- and low-pressure testing, serialization, and full material traceability, providing improved reliability and failure prevention.

High-performance drill pipe float valves are essential for consistent fluid control throughout drilling. Also known as non-return valves, this type of downhole safety valve prevents undesirable fluids from backing up into the drill string any time your crew is modifying connections.

M&M’s Top Drive Safety Valve Bottom Load™ lower valves have an extended pin nose profile that matches the mating ID profile of M&M’s Top Drive Safety Valve Bottom Load™ upper valves. These valve systems have the all-important, rig downtime saving, Bottom Load™ feature. When the time comes for scheduled routine maintenance, the lower valve only needs to be removed to allow quick and easy access to the upper valve’s internal components.

Along with its innovative design features and our CANISTER GUARD® technology, the Top Drive Safety Valve Bottom Load™ system allows for the quickest possible inspection and/or redress procedure. Since its inception over 20 years ago, M&M’s Top Drive Safety Valve Bottom Load™ system has saved countless hours of rig downtime.

We encourage you to discuss your needs with our team. We can walk you through our extensive selection of float, gate and relief valves, in addition to the many other products we provide.

Producers Supply Company ensures that a dedicated employee will be able to answer the phone 24-hours a day, seven days a week. This is not only to provide a level of customer service that allows us to separate ourselves from other distributors but also to answer any question that you may have. Whether you are looking for valves, chemicals, or hoses, we are ready to be your on-call supplier. We are partnering with the best manufacturers like Keystone Energy Tools, to offer you the best products to ensure your employees’ safety and assist in making your next project go as smoothly as possible. Call or visit us today and see how quickly we will become your trusted partner and preferred supplier.

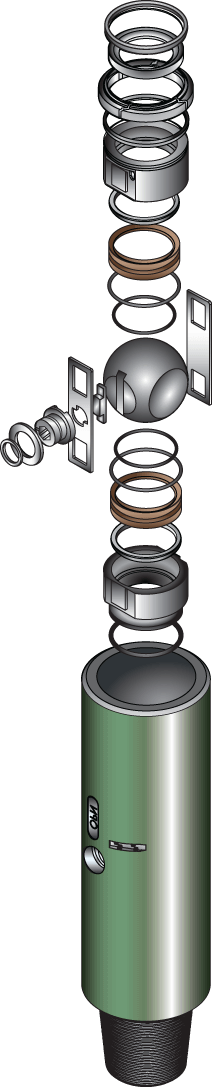

Packard safety valves are designed to either stab into the drill pipe or tubing at the rig floor or are used as part of the drill string to shut off a well kick. Use of these valves in the drill string enhances rig safety.

The Packard two-piece safety valve offers the convenience of a two-piece body for easy maintenance. Its full bore also allows the unrestricted flow of drilling fluid � reducing wear on critical parts while providing unrestricted access for downhole tools.

Packard International�s safety valves are built with enough length on each end to allow fully recutting the connections in the event of damage to the threads or shoulders where sealing takes place.

High and low pressure sealing is assured by the Teflon and metal sealing system of the ball and seats. The ball and lower seat float while the upper seat is fixed in the body. This floating/fixed design aids in low pressure sealing and enables the operator to pressure balance the valve under full rated working pressure.

Packard International�s safetyvalves are designed for even the harshest drilling conditions; however, it is suggested that parts most subject to wear and tear be replaced regularly.

For complete maintenance instructions and valve specifications, please phone 281-399-8771, e-mail support@packardint.com, or click the link below to download a PDF.

Product&Reapir: Crown block(TC225 TC250 TC315 TC450 TC585), Travelling block(YC225 YC250 YC315 YC350 YC450 YC450S YC585), Hook(DG225 DG250 DG315 DG350 DG450 DG585 DG675), Rotary table(ZP175 ZP205 ZP275 ZP375 ZP975AS ZP495), Swivel(SL225 SL250 SL450 SL585), Drawworks(JC20 JC30 JC40 JC50 JC70B JC90DB), Mud pump (F-500 F-800 F-1000 F-1300 F-1600 F-1600HL F-2200 F-2200HL 3NB500C,3NB1000C 3NB1300C 3NB1600 SL3NB-1000 SL3NB-1300A SL3NB-1600A),BOP(FH,FZ,Cameron,Shaffer), Control System for Surface Mounted BOP Stacks(FKQ,FKDQ),Disc brake (PS,PSZ, DBS), Bladder accumulator (NXQ), Drilling rig(ZJ40/2250DZ ZJ50/3150DZ ZJ70/4500DZ ZJ90/6750DZ), Workover rig (XJ40,XJ60, XJ80,XJ100,XJ12,ZJ15,ZJ20,ZJ3,XJ350, XJ450, XJ550,XJ650,XJ750), BPM Top drive((DQ120BSC, DQ90BSD, DQ90BSC, DQ80BSC, DQ70BSD, DQ70BSE, DQ70BSC, DQ50BC, DQ40BC, DQ40BSG, DQ40BCQ, DQ40YR, DQ30Y) Make: Bomco, Lanzhou LS,LSPE, SJ Petro, RG Petro, Sichuan Honghua, CPTDC, Beijing BPM, Shanghai Shenkai, Kingdream, CCDC, SJS Serva, DFXK, LS-NOV, Beijing PSK, Gold basin, Renqiu Boke,Guangdong Dongsu.(Guangshi), XBSY.,Tiehu, Rongsheng (HBRS), TSC. Replacements:Mission magnum/Halco centrifugal pump, Cameron FC gate valve,Cameron R check valve, Demco mud valveE( 3K&5K ), Demco butterfly valve,BJ varco handling tools (SDXL, SDML, SDS,DCS,SSC,SSD,YT, HYC, LYT, MP,MYT, MG, RGG, HGG, MGG, TA, SJ), MI SWACO / Mongoose / Derrick / /Brandt / King cobra shale shaker screen (FLC2000,FLC503,Derrick 626), M/D & OTECO Gauge(Type F,Type D,Model 6,Model 7,Model 8), Twin disc,WPT, Eaton clutch & friction disc, National (10-P-130,12-P-160 ,14-P-220 ,8-P-80 ,9-P-100), Gardner denver (PZ-7,PZ-8,PZ-9,PZ-10,PZ-11), EMSCO FB1600.International Brand: Moog, CCS, ATOS, Rexroth, Eaton, Flowrox, Italvibras, Martin, Norgren, Parker, Siemens, Vickers, 3M.Standard:API Spec 4F, API Spec 6A,API Spec 6D,API Spec 600, API Spec 7K, API Spec 8A, API Spec 8C,API Spec 16A, API Spec 16C, API Spec 16D

The global Drill Pipe Safety Valve market size is projected to reach multi million by 2028, in comparision to 2021, at unexpected CAGR during 2022-2028 (Ask for Sample Report).

This report on Drill Pipe Safety Valve market helps to Quickly diagnose its exposure to external risks and identify problems on the horizon - critical tasks whether to sell into that industry, invest in it, or provide a business valuation or consulting services. The market is further classified based on the applications like Petroleum Industry,Natural Gas Industry,Others which is further segmented into various types like Kelly Valves,Inside BOP Valve,Retrievable Drop-In Check Valves. It classifies the market and its trends based on various regions like North America: United States, Canada, Europe: GermanyFrance, U.K., Italy, Russia,Asia-Pacific: China, Japan, South, India, Australia, China, Indonesia, Thailand, Malaysia, Latin America:Mexico, Brazil, Argentina, Colombia, Middle East & Africa:Turkey, Saudi, Arabia, UAE, Korea. The research report has an analysis of the key market players like M&M International,TIW,Vallourec,Hi-Kalibre,Sub-drill,D�?"Valves,Unionlever International Group,BOTTA-Equipment,Taylor Valve Technology,Jiangsu Zhaoyou Petrochemical Machinery Co., Ltd..

Key Benefits For Industry Participants And Stakeholders:The Drill Pipe Safety Valve research study examines and forecasts countries throughout the world, as well as current trends and opportunities in various regions.

Sections In Drill Pipe Safety Valve Market Research ReportSection 1 focuses on providing an overview of the Drill Pipe Safety Valve market with a spotlight on the key trends and market definitions.

Section 2 offers an extended aspect of the market strategies, sales management, and various development factors followed by the Drill Pipe Safety Valve market.

Section 5 largely analyzes the impact of the Drill Pipe Safety Valve industry towards growth in accordance with the competitive and ambitious circumstances.

Section 8 postulates the details regarding the Drill Pipe Safety Valve company’s marketing schemes which is an efficient way to promote and market a product.

The Drill Pipe Safety Valve Market Industry Research Report contains:This Drill Pipe Safety Valve market report has updated information on market opportunities and investments, key shifts and trends, regulations and industry-specific challenges, and other factors that will shape this market demand over the coming years.

The Drill Pipe Safety Valve market report gives the structure of the Drill Pipe Safety Valve market, forecasts for the following years, market drivers, restraints, opportunities, and current trends along with historical data, estimations for the forecast period., developments, and trends in the Drill Pipe Safety Valve market.

The Drill Pipe Safety Valve market research report shares vital information like shareholding pattern, revenue mix, plant location, and financial summary of the key companies.

Lockdown induced by governments across the globe due to Covid-19 has disrupted the supply chain and manufacturing operations worldwide. The Drill Pipe Safety Valve market had a mixed impact due to the changes in demand from various end-user industries. The outbreak of the Covid-19 pandemic resulted in a reduction in travel worldwide. This harmed the transportation and logistics industry, thus restricting the usage of outdoor products of the Drill Pipe Safety Valve company. However, end users, such as healthcare, witnessed increased demand to make products related to COVID-19 precautions.

The Drill Pipe Safety Valve market is definitely enduring many challenging tests due to the emergence of new competitors in the market. The report offers a glimpse of various approaches and schemes levied by the government for the industry. The Drill Pipe Safety Valve report also focuses on providing numerous forecasts and pointers which help boost the industry performance and make better decisions. This report focuses on the well-recognized suppliers of the industry, market components, competition, and macro environment.

Reasons to Purchase the Drill Pipe Safety Valve Market Research Report:The Drill Pipe Safety Valve market research includes historical and forecasts market data, demand, application details, pricing history, and company shares of the Drill Pipe Safety Valve market by geography.

The Drill Pipe Safety Valve research report gives a characterization of the Drill Pipe Safety Valve company, along with its marketing strategies, corporate growth, and full-fledged structure and organization of the company.

The Drill Pipe Safety Valve market report analyzes important operational and performance data so one may compare them to their own business, the businesses of their clients, or the companies of their rivals.

Additionally, the Drill Pipe Safety Valve company helps its readers to understand how the market is being affected by the Covid-19 Pandemic and how it is likely to grow as the impact of the virus abates.

The Top Drive Valve Bottom Load™ lower valves have a mating OD profile that matches the ID profile of M&M’s Top Drive Valve Bottom Load™ upper valves. These valves have the all-important rig downtime saving Bottom Load™ feature and also include all of the other CANISTER GUARD® features such as LITE-TORC™,SURE-STOP™ and CHECK-SEAL™.

Since its inception, M&M’s Top Drive Valve Bottom Load™ system has saved countless hours of rig downtime. When the time comes for scheduled routine maintenance, the lower valve only needs to be removed to allow quick and easy access to the upper valves internal components. M&M’s modular Canister Guard® system allows for the quickest possible inspection or redress thanks to its innovative design features.

8613371530291

8613371530291