drill string safety valve factory

Sub-drill exclusively represents Global Manufacturing Inc, an industry leading and world renowned US based manufacturer of Drill Stem Valves and Associated Products.

Global Manufacturingspecialise in the design and manufacture of a complete range of Drill Stem Valves, developed and engineered using FEA to be the highest quality and most reliable valve on the market.

Precision machined from the highest quality materials, Global Valves are competitively priced and reliable - designed to last the pace offshore in all types of well and operating conditions, including 20k designs for the next generation of drilling.

Sub-drill are the approved service facility for Global Manufacturing USA; we inspect, repair and test all types of Top Drive, IBOP’s, Full Open Safety, Kelly, Gray Type and Drop-In Check Valves to OEM standards. Sub-drill provides in-house inspection, repair, refurbishment and pressure testing facilities to the latest industry standards at its Aberdeen Westhill facility.

In addition to our in-house inspection, repair and test facilities, Sub-drill provide the means to test valves offshore using our compact portable Sub-drill DSV™.

TIW is the original designer and manufacturer of ball type Safety and Kelly valves. Our strict adherence to API specifications as well as our own quality requirements ensures TIW valves are the highest quality valves in the market.

TIW Class I & Class II Kelly Valves may be utilized as a Drill Stem Safety Valve or as an Upper or Lower Kelly Cock and is designed to hold pressure from both directions.

TIW Kelly Valve Design and Quality System are certified by API.TIW Safety and Kelly Valves are also offered for H2S service, meeting all NACE standards. Standard Pressure rating is 10,000 PSI Test with higher pressure ratings available.

Kelly valves are used as a safety valve in drilling rigs. The use of the kelly valve enables an interruption of the flow inside the drill string. Depending on the conditions, we supply our kelly valves with different overall lengths, external and internal diameters as well as thread types. Manufacturing is done according to API specifications 7-1 and in compliance with IS0 9001:2015. Certification (Type Approval) by ABS and DNV is possible.

Kelly Valve/Drill Pipe Safety Valve is a full opening valve that provides positive pressure control of the fluids in the drill string. These valves can be used as a drill pipe safety valve or upper kelly valve to control blowout pressures, or as a lower kelly valve to prevent loss of drilling fluid when the kelly is disconnected.

The valve seals in both directions with metal to metal seals. Available in 10,000 psi working pressure as standard, 15,000 psi working pressure is available in certain sizes upon request. The valve uses a hexagon socket on the operating stem and has positive stops in the open and closed positions.

We encourage you to discuss your needs with our team. We can walk you through our extensive selection of float, gate and relief valves, in addition to the many other products we provide.

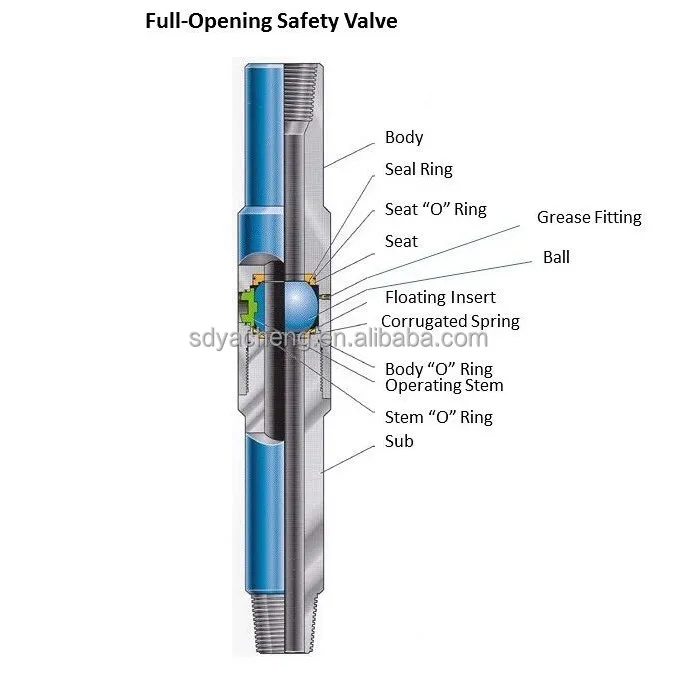

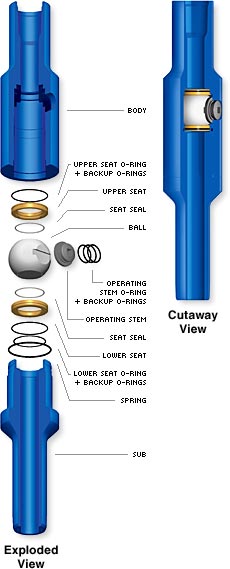

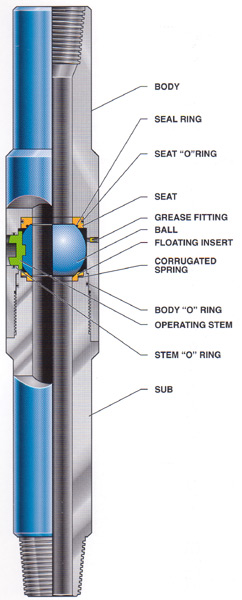

Full Opening Safety Valve (short for FOSV) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

TIANHE FOSV is dual body full-opening safety valve, so it does not interfere with the running of tools such as core barrels or survey instruments. It is designed to be stabbed into the top joint of drill pipe or tubing string at the rig floor and closed quickly in case a well kicks.

The ball-type design permits the valve to be compact, easy to handle, and yet have great strength. Standard test pressure is 10,000PSI, but higher pressure ratings are available.

As a rental company we inspect, clean and test the valves every time they are returned to us from a rig. Before the next job, we need to make sure that the valve is in optimal condition. Just a few words about the valve before we start ...

The valve is placed in the top of drill string, right below the top drive. When abnormal situations occur and the pressure limit is exceeded, the driller can close the valve to stabilize the pressure and avert a potential kick.

The device is named after the kelly drive, which was turning the drill string. As a side note, the "Dictionary of Petroleum Exploration, Drilling and Production" states that the kelly was named after Michael J. Kelly, a Chicago baseball player from the 1880s. He was known for his base running and long slides.

They even made a song about the baseball player called "Slide Kelly, Slide!". As you probably know, "sliding" is what you do when you pass the kelly through the kelly bushing when you drill.

When we receive the valve in the yard we first high pressure clean it. Then we start disassembling it, while inspecting and cleaning each part by hand. We typically look for things like:

All the internal parts are visually inspected and measured. We also replace all seals with a complete new seal-kit before re-assembling. If, for instance, the valve is going to be used in a Sour Gas Well, we insert gaskets that are resistant to H2S (Hydrogen Sulphide).

After that, we perform functional test and leak tests (a kind of pressure test) according to its class. The class is specified in the data book that comes with the valve:

These valves are only tested upstream. That means you test it in the closed position from below (the pin-end) to verify that it holds pressure. The valve is tested at a low pressure (250 PSI) and at the maximum working pressure.

Class 2 valves are tested with the same procedures as class 1 valves, but both upstream and downstream. First by testing low pressure and working pressure upstream, and then testing downstream in the same manner.

*In some HPHT (High Pressure, High Temperature) wells valves are also placed in the part of the string that is down hole. The challenge here is that you can"t access the valve while down hole. This is usually solved by placing a valve in each stand, so the driller can operate the valve while tripping out.

After the leak test, the valve is dried with air and preserved (with light oil) to avoid corrosion while lying on stock in the yard or on the rig. That"s it! Now you know how a kelly-valve is maintained and serviced.

In 2006, Forum purchased the Baker SPD product line. Forum continues to manufacture the products formerly known as Baker SPD under the SPD name and offers a complete line of float valves, repair kits, and puller assemblies for a wide range of drilling situations and operating conditions. We are the premier provider of “Certified” drill pipe float valves that includes high- and low-pressure testing, serialization, and full material traceability, providing improved reliability and failure prevention.

High-performance drill pipe float valves are essential for consistent fluid control throughout drilling. Also known as non-return valves, this type of downhole safety valve prevents undesirable fluids from backing up into the drill string any time your crew is modifying connections.

Drillstring valves and IBOPS are one of the most critical well control equipment on the rig. This VDO training will teach you about drillstring valves and iBOPs. After watching this, you will fully understand several of the valves and their applications. Additionally, we also have full VDO transcript to help anyone who are unable to fully understand the English speaking in the VDO. We wish you would enjoy watching it.

Drill string valves stop fluid from flowing up the drill string often if the drill kicks with the bit off bottom. Formation fluids flow from the annulus and up the drill string. Crewmembers close of the drill string valves. The flow is in the string, If the Kelly is made up the can close the upper or lower Kelly cock. If the Kelly is not made up then they can install the full opening safety valve in the top of the drill string.

An inside blowout preventer or IBOP is a one-way valve, a check valve that they can install in the drill string. One type of IBOP is a float valve that is sometimes made up in the drill string near the bit. It prevents backflow up the drill string.

Another type of IBOP is the drop in valve or D.I.V. It is dropped into the drill string and falls to a special landing sub that is usually located near to the top drill collar in the drill string. It allows the driller to pump mud down the string but the check valve will not allow influx fluid to flow up the string.

Another type of inside BOP is the heavy-duty check valve or a gray type valve named after the company that makes it. It is a plunger check that crew stab into the drill pipe at the surface. It is usually used during stripping operations.

Here is a full opening safety valve. If the Kelly is not made up in the drill string and flow occurs, crewmembers can insert this safety valve into the drill string. This procedure is called stabbing.

A full opening valves has as large an inside opening as possible. When fully open flow from the drill pipe passes through the valve with no additional restriction. This relatively large opening allows the crew to stab the valve against pressure coming out of the drill string. The cruel picks up this safety valve by its lifting handles. They make sure it is fully opened and stab it into the drill pipe then they screw it into the pipe. Finally, the you was a special operating wrench to close the valve and shut off flow. Driller’s should make sure that valves have the right to cross over subs handy on the rig floor. Crewmembers should be able to make up the safety valve in any drill string member coming out of the Rotary. For example if a drill collar is in the Rotary, these safety valves threads may not match the drill collars threads. They will need the right cross over sub to make it work.

Float valves also prevent flow of the drill string. Crewmembers place a float valve in a string, a special drill string fitting just above the bit. One type allows mud to be pumped down but shuts against upward flow. Under normal conditions pump pressure moves drilling mud through the open one-way valve. An influx of formation fluids from below causes of the float valve to close. This prevents further flow of the drill string.

Two types of stabbing valves that must be prepared for well control are Full Opening Safety Valve (TIW valve) and Inside BOP valve (Gray Valve). We would like to describe what the differences between two valves are.

Full Opening Safety Valve or TIWvalve is a ball valve designed for high pressure condition and it can hold pressure from both directions. It is called “Full Opening” because when the ball valve is opened; the flow path through the valve has a smooth inside diameter. One thing that you need to remember is that the term “Full Opening” does not mean that the ID of the valve is the same of drill pipe ID. ID of the valve is typically smaller than the pipe in the hole.

The valve should be always located on the rig floor and left in the open position. Additionally, you need to ensure that personnel on the rig have a right wrench to close the valve. The valve left in the open position is critical because the valve can stabbed quickly into drill string if the well flows through drill pipe.

For good drilling practices, you must have all size full opening safety valves which can be screwed into each size of drill pipe, drill collar, tubing, etc on the rig. When there is any string in the hole, the correct connection of the valve must be ready on the rig floor to stab in. Furthermore, it is a good practice to perform well control drill during tripping operation in order to ensure that the crew are familiar with the stabbing procedure.

This valve is a non-return valve (check valve) allowing pumping through the valve into the drillstring but it prevents upward flow and the more widely used type is “dart-type”. The dart is used to hold the tool open therefore it is possible to stab the valve while the fluid is flowing through the drillpipe. With the IBOP valve installed in the drill string, it allows you to strip in hole without mud flowing through the drillsting. The IBOP valve should not be used for shut the well in while tripping.

Drill String Safety Valves (DSSV"s) are considered as part of the essential well control equipment on every rig but they are currently only addressed in a very limited fashion in industry specifications. Performance problems with DSSV"s in stripping operations motivated Mobil to lead an industry effort to develop appropriate functional specifications for consideration by API and to conduct performance testing to establish that new generation valves could be built to meet the proposed new specifications. Results from testing three new generation valves indicate that common DSSV performance problems can be addressed and the proposed new specifications are workable.

Producers Supply Company ensures that a dedicated employee will be able to answer the phone 24-hours a day, seven days a week. This is not only to provide a level of customer service that allows us to separate ourselves from other distributors but also to answer any question that you may have. Whether you are looking for valves, chemicals, or hoses, we are ready to be your on-call supplier. We are partnering with the best manufacturers like Keystone Energy Tools, to offer you the best products to ensure your employees’ safety and assist in making your next project go as smoothly as possible. Call or visit us today and see how quickly we will become your trusted partner and preferred supplier.

8613371530291

8613371530291