safe working load of wire rope sling free sample

Wire ropes are essential for safety purposes on construction sites and industrial workplaces. They are used to secure and transport extremely heavy pieces of equipment – so they must be strong enough to withstand substantial loads. This is why the wire rope safety factor is crucial.

You may have heard that it is always recommended to use wire ropes or slings with a higher breaking strength than the actual load. For instance, say that you need to move 50,000 lbs. with an overhead crane. You should generally use equipment with a working load limit that is rated for weight at least five times higher – or 250,000 lbs. in this case.

This recommendation is all thanks to the wire rope safety factor. This calculation is designed to help you determine important numbers, such as the minimum breaking strength and the working load limit of a wire rope.

The safety factor is a measurement of how strong of a force a wire rope can withstand before it breaks. It is commonly stated as a ratio, such as 5:1. This means that the wire rope can hold five times their Safe Work Load (SWL) before it will break.

So, if a 5:1 wire rope’s SWL is 10,000 lbs., the safety factor is 50,000 lbs. However, you would never want to place a load near 50,000 lbs. for wire rope safety reasons.

The safety factor rating of a wire rope is the calculation of the Minimum Break Strength (MBS) or the Minimum Breaking Load (MBL) compared to the highest absolute maximum load limit. It is crucial to use a wire rope with a high ratio to account for factors that could influence the weight of the load.

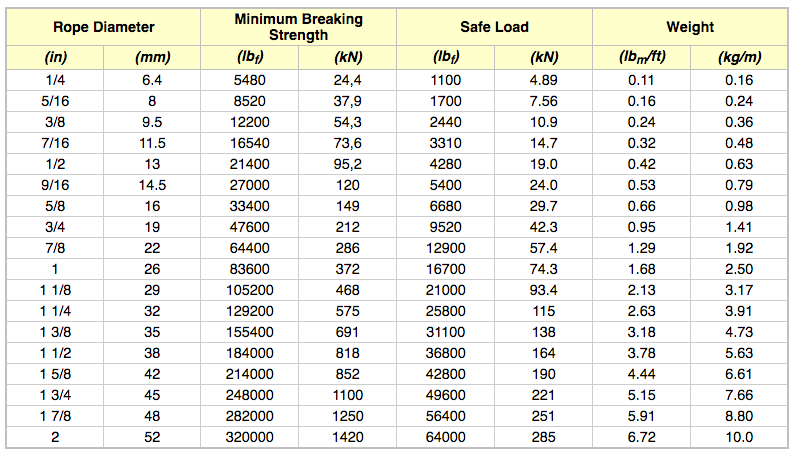

The Safe Working Load (SWL) is a measurement that is required by law to be clearly marked on all lifting devices – including hoists, lifting machines, and tackles. However, this is not visibly listed on wire ropes, so it is important to understand what this term means and how to calculate it.

The safe working load will change depending on the diameter of the wire rope and its weight per foot. Of course, the smaller the wire rope is, the lower its SWL will be. The SWL also changes depending on the safety factor ratio.

The margin of safety for wire ropes accounts for any unexpected extra loads to ensure the utmost safety for everyone involved. Every year there aredue to overhead crane accidents. Many of these deaths occur when a heavy load is dropped because the weight load limit was not properly calculated and the wire rope broke or slipped.

The margin of safety is a hazard control calculation that essentially accounts for worst-case scenarios. For instance, what if a strong gust of wind were to blow while a crane was lifting a load? Or what if the brakes slipped and the load dropped several feet unexpectedly? This is certainly a wire rope safety factor that must be considered.

Themargin of safety(also referred to as the factor of safety) measures the ultimate load or stress divided by theallowablestress. This helps to account for the applied tensile forces and stress thatcouldbe applied to the rope, causing it to inch closer to the breaking strength limit.

A proof test must be conducted on a wire rope or any other piece of rigging equipment before it is used for the first time.that a sample of a wire rope must be tested to ensure that it can safely hold one-fifth of the breaking load limit. The proof test ensures that the wire rope is not defective and can withstand the minimum weight load limit.

First, the wire rope and other lifting accessories (such as hooks or slings) are set up as needed for the particular task. Then weight or force is slowly added until it reaches the maximum allowable working load limit.

Some wire rope distributors will conduct proof loading tests before you purchase them. Be sure to investigate the criteria of these tests before purchasing, as some testing factors may need to be changed depending on your requirements.

When purchasing wire ropes for overhead lifting or other heavy-duty applications, understanding the safety dynamics and limits is critical. These terms can get confusing, but all of thesefactors serve an important purpose.

Our company has served as a wire rope distributor and industrial hardware supplier for many years. We know all there is to know about safety factors. We will help you find the exact wire ropes that will meet your requirements, no matter what project you have in mind.

Some of our calculators and applications let you save application data to your local computer. These applications will - due to browser restrictions - send data between your browser and our server. We don"t save this data.

The purpose of this safety policy and procedure is to establish the methods and guidelines for the safe use of slings throughout [COMPANY]. Slings, a component of hoisting and rigging systems, are used to lift and move loads. In [COMPANY], alloy steel chain, wire rope, natural and synthetic fiber rope, and synthetic web slings are typically used. Slings are capable of lifting tremendous loads.

This safety policy and procedure provides guidelines for implementing an effective safe sling use program. It includes provisions for training, recognizing the types of slings used in [COMPANY], understanding the attachments used with slings, and inspecting slings. Additionally, it presents information on sling repair requirements and subsequent removal from service.

It is the policy of [COMPANY] is to provide a place of employment free from recognized hazards that cause or are likely to cause death or serious physical harm to employees or the public. Therefore, to minimize and eliminate material lifting hazards, properly rated slings that are not damaged or defective will be used in [COMPANY]. When hazards exist that cannot be eliminated, then engineering practices, administrative practices, safe work practices, Personal Protective Equipment (PPE), and proper training regarding Slings will be implemented. These measures will be implemented to minimize those hazards to ensure the safety of employees and the public.

It is the responsibility of each manager/unit head, supervisor and employee to ensure implementation of [COMPANY]’s safety policy and procedure on Slings. It is also the responsibility of each [COMPANY] employee to report immediately any unsafe act or condition of equipment to his or her supervisor.

Managers/Unit Heads are responsible for ensuring adequate funds are available for the purchase of chains and slings for their areas. They will also be responsible for identifying the employees affected by this safety policy and procedure. Managers/Unit Heads will obtain and coordinate the required training for the affected employees. Managers/Unit Heads will also audit their safe sling use program to ensure effective implementation with this safety policy and procedure.

Supervisors. Every six months, supervisors or a designated employee will inspect all slings in their work area for wear and for defects in composition and welds. Supervisors will ensure that defective or damaged slings are removed from service. Supervisors will also ensure that employees are provided with the appropriate Personal Protective Equipment (PPE) as necessary for their job (e.g., foot, hand, or eye protection as necessary).

Employees shall comply with all applicable training. Additionally, employees shall report all damaged slings and/or unsafe conditions to their supervisors.

Safety and Loss Control. Safety and Loss Control will provide prompt assistance to managers/unit heads, supervisors, or others as necessary on any matter concerning this safety policy and procedure. Additionally, Safety and Loss Control will assist in developing or securing the required training. Safety and Loss Control will work with Purchasing to ensure that all newly purchased slings comply with this safety policy and procedure. Additionally, Safety will provide consultative and audit assistance to ensure the safe use of slings.

Central Equipment unit shall maintain an adequate supply of appropriate slings. Central Equipment Unit will ensure that all components are delivered with the appropriate manufacturer’s certification.

The user should determine that the sling is being used in accordance with rated capacity as listed in the manufacturer’s catalog. The alloy steel chain, wire rope and fiber rope slings are typically used where sling damage to the load is not critical. Synthetic web slings are ideal where sling damage to a load is not acceptable.

Alloy chain slingswill have permanent identification affixed to the sling indicating the size, grade, rated capacity, and reach of the sling. Untagged slings will be removed from service. Alloy steel chains and chain slings should not be heated above 600 degrees after being received from the manufacturer.

Wire rope slings must be proof-tested by the manufacturer to ensure quality. A certificate verifying rated capacity will accompany each wire rope sling. This certificate must be available for review.

Synthetic web slings must be marked or coded to show the rated capacities for each type of hitch, type of web material, and manufacturer. Additionally, synthetic web slings must not be exposed to fumes, vapors, sprays, mists, liquid acids, liquid phenolics, or liquid caustics.

Equipment Inspections are conducted to ensure specific safety equipment is in good working order and will function when needed. Examples and frequencies are:

All attachments including hooks, rings, oblong links, pear shaped links, and welded link components will be rated at least at the capacity of the sling itself. Makeshift links or other shop fabricated attachments will not be used. Slings twisted more than 10 degrees from the plane of the unbent hook will not be used.

Slings will be inspected each day prior to use. Any visual defect will be reported. Damaged slings will not be used. In severe conditions (e.g., temperature, corrosion, etc.), slings will be inspected throughout the day. Alloy chain slings will be inspected every six months by a supervisor or designated employee for wear and defects in composition and welds. This inspection will consider not only the physical aspects, but also the total service life of the slings. This inspection will be recorded and maintained on file with the date of the inspection and name and signature of the employee performing the inspection.

Slings must be in good condition and not damaged or defective to ensure safe and reliable use. If slings are worn, damaged or defective they shall not be used. If the slings are believed to be repairable, then those slings will be returned to the sling manufacturer for repairs. The manufacturer must proof-test all repaired slings before they are accepted for reuse. Under no circumstances will employees attempt to repair slings for reuse. Broken links or attachments on steel alloy chain slings will not be repaired using mechanical coupling links. Additionally, any sling with temporary repairs will not be used.

If slings are damaged or defective, they shall not be used. Until repairs are made on defective or damaged slings, they will be removed from service. If these slings are not repairable, they will be permanently removed from service. Appendix G lists the conditions that must be present to remove any sling from service.

• In manila rope, eye splices will consist of at least three full tucks, and short splices will consist of at least six full tucks, three on each side of the splice center line.

• In synthetic rope, eye splices will consist of at least four full tucks, and short splices will consist of at least eight full tucks, four on each side of the center line.

• Strand end tails will not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail will project at least six inches beyond the last full tuck.

• For all eye splices, the eye will be large enough to provide an angle of not greater than 60% at the splice when the eye is placed over the load or support.

The following information is to be used as a guide for inspecting wire rope and wire rope slings. Inspection frequency should be based on safety factors, property damage, and the cost of replacing destroyed or damaged goods and material dropped due to the use or misuse of improper or damaged wire rope and slings. Additionally, slings should be inspected at regular intervals. This interval should be determined by the user and is dependent upon the particular use of the sling and [COMPANY] safety requirements. A sling should be inspected after any unusual situation that may have damaged it, such as overload, accident, or fire. It should not be returned in service until continued safe operation has been verified.Each sling should have a serial number. If no number is available, a tag should be attached at the time of inspection. This number should be listed on the inspection report. Inspection should be performed only by persons with sufficient experience and knowledge to properly apply the criteria for rejection. The following should be considered criteria for rejection:

• Abrasion: There should be no wearing, scrubbing, or preening of any outside wire causing the reduction of the diameter of a single wire by more than 1/3.

• Reduced Diameter: There should not be any reduction of the diameter of the rope along the main length or of any section (overloading or contact with sharp edges of load without permission).

• End Attachments: There should be no evidence of cracks, deformity, excessive corrosion, or excessive wear of the fittings forming the splice or socket.

A good chain and chain sling inspection program should provide more than a physical check of the chain’s condition. It should be a complete recorded history of each unit. If conditions and/or time make it impossible to write such a history,

(1) Cable laid and 6 x 19 and 6 x 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

(c) Safe Operating Temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200o F. When nonfiber core wire rope slings of any grade are used at temperatures above 400o F, or below minus 60o F, the sling manufacturer"s recommendations shall be followed.

(2) A prototype of each welded end attachment shall be proof tested by the manufacturer or equivalent entity to check the design and welding method at twice the rated capacity before production is started. Subsequent tests of random samples shall be made. The manufacturer or equivalent entity shall provide a certificate of such tests which the employer shall retain and make available for examination by the Division upon request.

(3) Where rope clip attachments are used, they shall be made with U-bolts on the dead or short end of the rope and the saddle on the live end. The minimum number of clips for end attachments shall be not less than indicated in manufacturer"s tables, but in no case shall be less than three for any permanent installation. Clips shall be drop-forged steel. The clips shall be spaced at a distance equal to at least six times the diameter of the rope. All clip or clamp bolts shall be kept tight after tightening while rope is under tension.

(6) Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

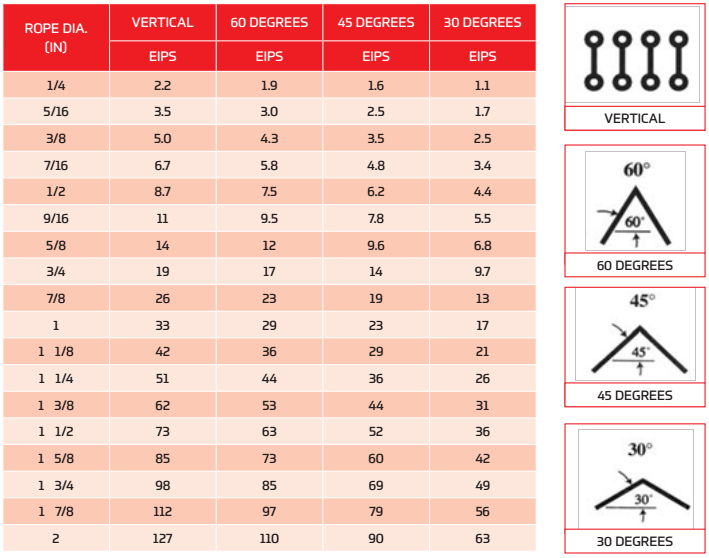

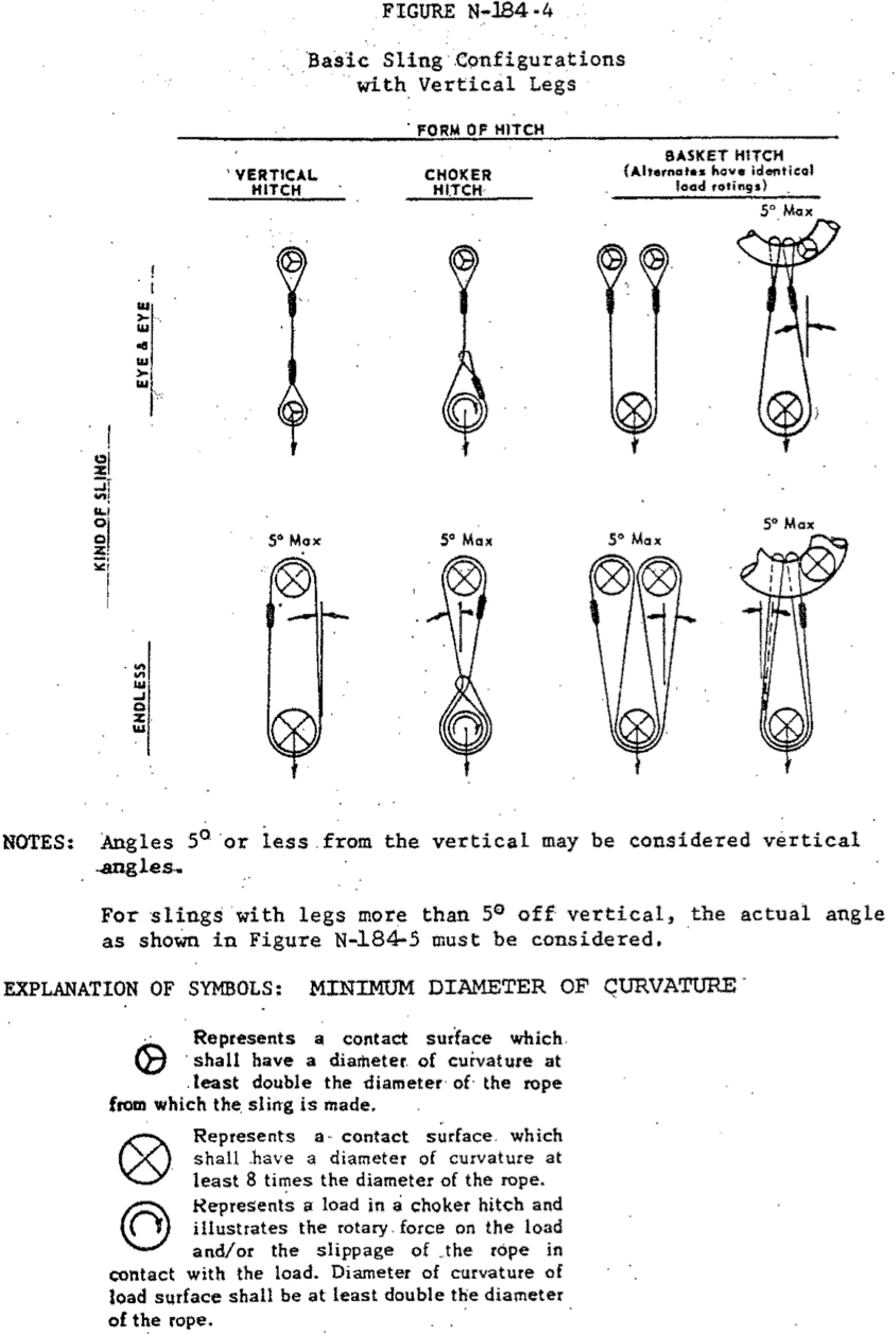

(1) Have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one; and

Safe Working Load (SWL) is the limiting safety factor to lift and carry any load safely. It must be clearly marked on any lifting device (hoist, lifts, lifting machines, and lifting tackles).

“No lifting machine and no chain, rope or lifting tackle shall, except for the purpose of the test, be loaded beyond the safe working load which shall be plainly marked and duly entered in the prescribed register, and where this is not practicable, a table showing the safe working loads of every kind and size of lifting machine or chain, rope or lifting tackle in use shall be displayed in prominent positions on the premises”

Where the safe working load may be varied by the raising or lowering of the jib, a table indicating the SWL at the corresponding indication of the jib or corresponding radii of the load shall be attached with the jib-crane.

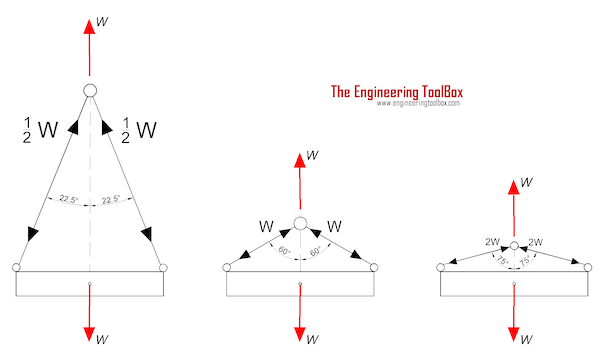

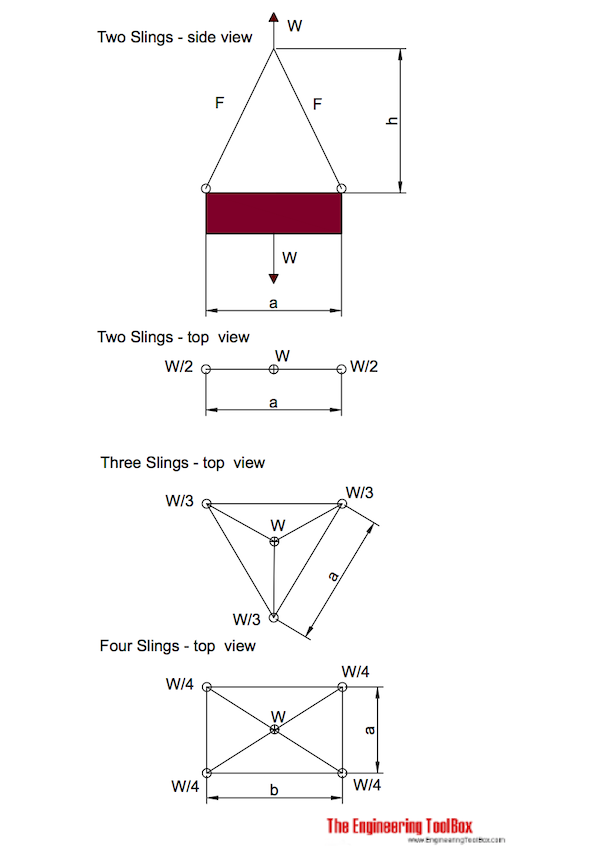

A table showing the SWL (Safe Working Load) of every kind and size of chain, rope, or lifting tackle in use, and in case of multiple slings, the SWLat different angles of the legs, shall be posted in the storeroom.

Lifting equipment should have a tally plate indicating the Safe Working Load. The tally plate also indicates the identification number which can be mentioned in the test certificate held by the user. It should also indicate the date of the last inspection.

Safe Working Load (SWL) of any mobile crane depends on the operator’s skill, condition of the ground, boom length, the radius of rotation while lifting the load, the inclination of the boom to the vertical and outrigger blocked or free.

Safe Working Load is generally tabulated in the load chart of the crane. Sometimes, it is de-rated(decreased) due to defect in welding, bend in angle, bracing, etc., and condition of clutch, brake, etc. Modern cranes give a digital display of SWL, angle indicator, boom limit switch, and alarm for exceeding load.

The factor of the safety (Safety Factor) of fiber ropes varies from 6 to 12 mm depending on the conditions of use. fiber rope less than 12 mm dia should not be used for a sling or apart of a lifting appliance. Their factor of safety (FS) varies with diameter. The factor of Safety for the hook, wire rope sling, chain, fiber rope, and belt are given in the table below:

Proof testing is the application of a load greater than the SWL (Safe Working Load) to detect defective workmanship, faulty weld or other inherent weaknesses. It is not a means to assess the SWLwhich should only be done by calculations and checked where necessary by suitable tests on samples.

The proof test is required as a part of ‘thorough examination’ u/r 60(1) of GFRand no lifting machine or tackle should be used for the first time without this proof test.

In general, the proof load applied to chains, rings, hooks, shackles, and similar gear is twice the SWL. It should be just under the yield stress for the material.

Chain, ring, hook, shackles, swivel, sling, individual components of the hoist, wire rope, chain, pulleys, hooks, eye bolts, pins, axles, bearings, turnbuckles & ringing screws.2 SWL

After the above proof test, the parts are to be examined thoroughly by a competent person for signs of cracks, fatigue, deformation, permanent stretch, etc.

Easy-to-read, question-and-answer fact sheets covering a wide range of workplace health and safety topics, from hazards to diseases to ergonomics to workplace promotion. MORE ABOUT >

Maintain a record for each rope that includes the date of inspection, type of inspection, the name of the person who performed the inspection, and inspection results.

Use the "rag-and-visual" method to check for external damage. Grab the rope lightly and with a rag or cotton cloth, move the rag slowly along the wire. Broken wires will often "porcupine" (stick out) and these broken wires will snag on the rag. If the cloth catches, stop and visually assess the rope. It is also important to visually inspect the wire (without a rag). Some wire breaks will not porcupine.

Measure the rope diameter. Compare the rope diameter measurements with the original diameter. If the measurements are different, this change indicates external and/or internal rope damage.

Visually check for abrasions, corrosion, pitting, and lubrication inside the rope. Insert a marlin spike beneath two strands and rotate to lift strands and open rope.

Assess the condition of the rope at the section showing the most wear. Discard a wire rope if you find any of the following conditions:In running ropes (wound on drums or passed over sheaves), 6 or more broken wires in one rope lay length; 3 or more broken wires in one strand in one rope lay. (One rope lay is the distance necessary to complete one turn of the strand around the diameter of the rope.)

Corrosion from lack of lubrication and exposure to heat or moisture (e.g., wire rope shows signs of pitting). A fibre core rope will dry out and break at temperatures above 120°C (250°F).

Kinks from the improper installation of new rope, the sudden release of a load or knots made to shorten a rope. A kink cannot be removed without creating a weak section. Discarding kinked rope is best.

Although every effort is made to ensure the accuracy, currency and completeness of the information, CCOHS does not guarantee, warrant, represent or undertake that the information provided is correct, accurate or current. CCOHS is not liable for any loss, claim, or demand arising directly or indirectly from any use or reliance upon the information.

Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Hooks that have been opened more than 15 percent of the normal throat opening measured at the narrowest point or twisted more than 10 degrees from the plane of the unbent hook.

8613371530291

8613371530291