safe working load of wire rope sling brands

Sling made with a triangle fitting on one end and a slotted triangle choker fitting on the other end. It can be used in a vertical, basket, or choker hitch.

Sling made with flat loop eye on each end with loop eye opening on same plane as sling body. This type of sling is sometimes called a flat eye-and-eye, eye-and-eye, or double-eye sling.

Sling made with both loop eyes formed as in Type III, except that the loop eyes are turned to form a loop eye which is at a right angle to the plane of the sling body. This type of sling is commonly referred to as a twisted-eye sling.

Return-eye (reversed-eye) sling is formed by using multiple widths of webbing held edge-to-edge. A wear pad is attached on one or both sides of the sling body and on one or both sides of the loop eyes to form a loop eye at each end which is at a right angle to the plane of the sling body.

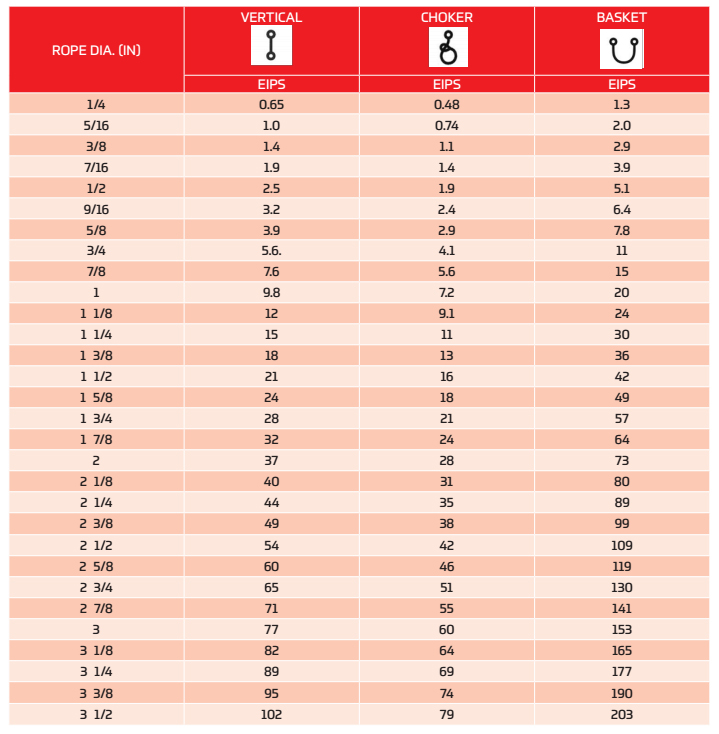

VERTICAL, or straight, attachment is simply using a sling to connect a lifting hook to a load. Full rated lifting capacity of the sling may be utilized, but must not be exceeded. A tagline should be used to prevent load rotation, which may damage a sling.

When two or more slings are attached to the same lifting hook, the total hitch becomes, in effect, a lifting bridle, and the load is distributed equally among the individual slings.

CHOKERhitches reduce lifting capability of a sling since this method of rigging affects ability of the wire rope components to adjust during the lift. A choker is used when the load will not be seriously damaged by the sling body — or the sling damaged by the load, and when the lift requires the sling to snug up against the load.

The diameter of the bend where the sling contacts the load should keep the point of choke against the sling BODY — never against a splice or the base of the eye. When a choke is used at an angle of less than 120 degrees (see next page), the sling-rated capacity must be adjusted downward.

A choker hitch should be pulled tight before a lift is made — NOT PULLED DOWN DURING THE LIFT. It is also dangerous to use only one choker hitch to lift a load which might shift or slide out of the choke.

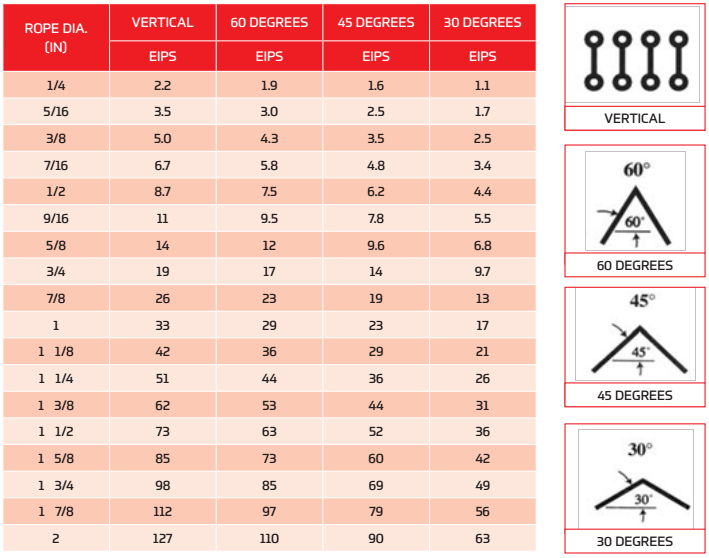

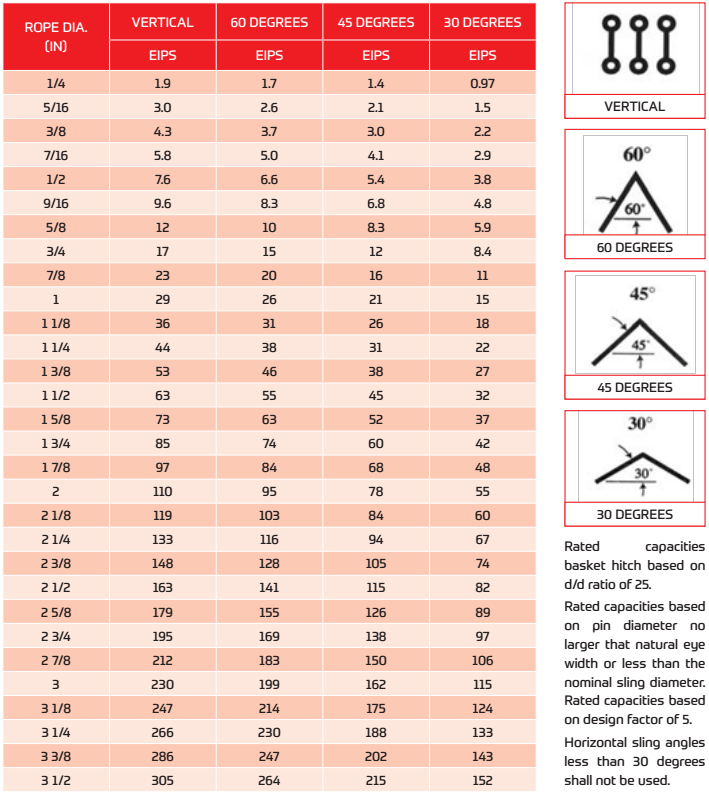

As the included angle between the legs of a sling decreases, the load on each leg increases. The effect is the same whether a single sling is used as a basket or two slings are used with each in a straight pull, as with a 2-legged bridle.

Anytime pull is exerted at an angle on a leg—or legs—of a sling, the load per leg can be determined by using the data in the table above. Proceed as follows to calculate this load—and determine the rated capacity required of the sling, or slings, needed for a lift.First, divide the total load to be lifted by the number of legs to be used. This provides the load per leg if the lift were being made with all legs being vertically.

Then MULTIPLY the load per leg (as computed above) by the Load Factor for the leg angle being used (from the table at the bottom) – to compute the ACTUAL LOAD on each leg for this lift and angle. THE ACTUAL LOAD MUST NOT EXCEED THE RATED SLING CAPACITY.

Thus, in the above drawing (sling angle at 60°): 1000 ÷ 2 = 500 (Load Per Leg if a vertical lift) 500 x 1.154 = 577 lbs. – ACTUAL LOAD on each leg at the 60° included angle being used.

In the above drawing (sling angle of 45°): 1000 ÷ 2 = 500 (Load Per Leg if a vertical lift) 500 x 1.414 = 707 lbs. = ACTUAL LOAD on each leg at the 45° horizontal angle being used.

The horizontal angle of bridles with 3 or more legs is measured the same as the horizontal sling angle of 2-legged hitches. In this case, where a bridle designed with different leg lengths results in horizontal angles, the leg with the smallest horizontal angle will carry the greatest load. Therefore, the smallest horizontal angle is used in calculating actual leg load and evaluating the rated capacity of the sling proposed.

Sling eyes are designed to provide what amount to “small inverted slings” at the ends of the sling body. Therefore, the width of the eye opening will be affected by the same general forces which apply to legs of a sling rigged as a basket.

On the other hand, the eye should always be used on a hook or pin with at least the nominal diameter of the rope—since applying the D/d Ratio shows an efficiency loss of approximately 50% when the relationship is less than 1/1.

When rigged as a basket, DIAMETER of the bend where a sling contacts the load can be a limiting factor on sling capacity. Standard D/d ratios— where “D” is the diameter of bend, and “d” the diameter of the rope—are applied to determine efficiency of various sling constructions, as indicated below:Mechanically Spliced, Single-Part Slings: 25 times rope diameter

Whether to use a single-part sling (one made of a single wire rope in the sling body) or a multi-part sling (several ropes in the body) is usually the first decision to make after determining the sling length and capacity for a lift.

The starting point for this decision involves the handling characteristics of the sling more than any other factor. Based on capacity alone, multi-part slings will be more flexible…more easily handled…than single-part slings. The larger the capacity of a sling, the more important this becomes…to the point, it becomes unrealistic to build big capacity slings from single, very large wire ropes.

Various approaches to building multi-part slings have been developed; the most common of these are Braided or Multi-Part. These are described in detail elsewhere in this catalog.

In the design of the sling, rope engineers must seek a balance between strength-handling characteristics and number of parts…since there is a tendency to lose strength as core parts are added to increase flexibility.

If a load is hanging free, the normal choke angle is approximately 135 degrees. When the angle is less than 135 degrees, an adjustment in the sling-rated capacity must be made. Choker hitches at angles greater than 135 degrees are not recommended since they are unstable.

Extreme care should be taken to determine the angle of choke as accurately as possible. In controlled tests, where the angle was less than 120 degrees, the sling body always failed at the point of choke when pulled to destruction. Allowance for this phenomenon must be made anytime a choker hitch is used to shift, turn or control a load, or when the pull is against the choke in a multi-leg lift.

This is the length of wire rope between splices, sleeves or fittings. Generally, the minimum body length is equal to ten (10) times the sling body diameter. This allows approximately one and one half (1-1/2) rope lays between splices. For Multi-part slings, the minimum body length between splices is equal to forty (40) times the component rope diameter.

In the case of the "U" shaped sling, lifting is accomplished by firmly attaching the eyes to a hook or hoist, though both ends are then simultaneously lifted in order to wrap around or cradle the supplies or finished goods to be lifted.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping, and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope.

Though the majority have predetermined dimensions, they may be adjustable to accommodate a change in the size of cargo while maintaining a secure fit.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively, the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is comprised of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper, and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion, and environmental conditions as well as the intended use for the sling.

Manufacture of material handling gripper slings made from 304 or 316 stainless steel, 4130 heat-treated alloy steel, exotic alloys and neoprene. Features include polyurethane plastic-covers, wire mesh construction, interwoven and tolerate abrasive loads. Suitable for handling all types of products such as coiled strips, thin-walled tubing, polished shafting, lumber, paper machine rolls, precast hollow core concrete beams, structural beams, cold drawn flats and irregularly shaped objects. Serves the marine, automotive, beverage, cement, energy, food and mining industries.

SWR specialise in the design, specification and manufacture of wire rope slings and assemblies for a large range of industries. Our UK facility can produce slings ranging from 1mm to 52mm in rope diameter which conform to BS EN 13414-1: 2003. We also have a large stock of wire rope and fittings to choose from. Need something more specific? No problem, we can even design bespoke fittings and create tailored solutions on request.

All wire rope slings are produced with their own ID numbers to ensure full traceability under our ISO9001 production system. In-house testing also means we can proof load and destruction test your slings and wire rope. Rest assured, everything that leaves our facility meets the highest possible standards.

... All lifting keys act as attachment points for lifting solid precast concrete elements. As well as the million-times proven rope eyes, the user can also choose from flared lifting loops, special lifting loops and swivel ...

Manufactured according to SR EN 13414-1 they are available from non-galvanized, lubricated non-galvanized or galvanized wire ropes, in 6x19, 6x36 or 6x37 constructions for diameters between 1.5 and 78 mm.

... CarlStahl® offers this wire rope sling that can accommodate loads with capacity of 700 kg up to 25,000 kg. The attachment point for 1 leg wire rope slings ...

• Used to create safe anchoring point for working at height• PVC coated stainless steel wire rope of dia 8 mm. • The PVC coating prevents exposure to dirt and chemicals, hence increases ...

Steel wire rope and components are all manufactured according to strict specifications for quality and reliability, in-house or with proven top quality partners.

... configuration only, the Cable Sling is approved for use by one person at a time with approved systems. Two strands of cable sling must be of equal length to ensure an ...

... Panzerband, the STAS wire mesh sling is made of riveted chain links. Produced in specialised steel, it offers a safety factor of 4. Unlike other products, the mesh ...

TGS manufactures Sling Connectors for various purposes, For example to handle tetrapods or other type of blocks for breakwater. The Sling Connectors are manufactured of high wear restant steel.

The CarlStahl® offers this wire rope sling that can accommodate loads with capacity of 700 kg up to 25,000 kg. The attachment point for 1 leg wire rope slings with loops should have at least 2x the diameter ...

Different construction rope with different working load, we can calculate the working load according with the steel wire rope constrution which the consumer required.

Steel wire rope and components are all manufactured according to strict specifications for quality and reliability, in-house or with proven top quality partners.

*Style* 6X7+FC Steel Wire Rope *Type* 6X7+FC Steel Wire Rope *Application* Lifting / Hoisting / Marine / Rigging / Various Cable Carriage / Rope and Belt Conveyer ...

When it comes to using wire rope slings in or on your jobsite, there are a few things to keep in mind in order to make sure that your wire rope sling is ready for use and that it will last for years to come. For starters, be sure to designate a qualified person to inspect all of your slings, fastenings, and attachment each day before use for damage or defects. A thorough inspection of your wire sling should check for:

By regularly performing these inspections that check the condition of your rope, you’ll not only be able to give your wire rope sling the care and maintenance that it needs to work at its best, you’ll be protecting your entire team and jobsite from the potential dangers that can occur if a wire rope sling snaps during use.

Have you wondered why rigging experts always suggest a sling that has a significantly higher breaking strength than the actual weight of the load you are lifting? The manufacturers know that the rigging used in overhead applications need to have room for error. This is known as the Safety Factor.

Northern Strands manufactures wire rope slings rated up to 36,000 lbs and sells round synthetic slings that are rated up to 140,000 lb capacity. This capacity is the Working Load Limit of the sling, which is the maximum amount of weight or force that the sling"s user is allowed to put on the sling. Note: These slings do not break at the working load limit. These slings are designed with a safety factor of 5:1. This means that 5 times as much force as the working load limit has to be applied to the sling before it potentially fails. This means the wire rope slings have a Breaking Strength of up to 180,000 lbs and the round synthetic slings can withhold up to 700,000 lbs.

Wear - Working load limits are based on slings in brand new condition and a safety factor can help account for normal wear and tear until it is deemed unfit for further use.

Uneven loading - Slings are made up of either wires or fibers that must all share the weight of the load evenly. If any situation arises where the sling is bent or wrapped around an object, there is potential that some of the wires or fibers will be taking on a greater share of the load than others.

Visit Northern Strands website to use the sling tension calculator. The Northern Strands Sling Calculator has been designed to assist you in selecting slings with enough load carrying capacity for your lifting applications. It is your responsibility to assure that the slings you use are appropriate for your application. http://www.northernstrands.com/sling-calculator.aspx

Wire rope slings are frequently used in hoisting operations across diverse sectors including oil and gas, automotive, construction, and manufacturing industries where people need to lift heavy loads frequently and that too in rugged environments. Wire rope slings are also commonly used in steel mills and forging operations and in the marine industry as well.

Steel Wire rope slings are used to connect the load, which is being lifted, to the lifting device and they come in a number of configurations that are supported by different types of attachments. Some of the commonly-used wire rope slings are single leg slings, grommets, single-part slings, multi-part slings, multiple leg bridles, and multiple leg slings. In the manufacturing sector, which is quite similar to industrial design and engineering, the objects that are being lifted appear in various shapes and sizes depending on the stage of production.

Steel rope slings are categorized on the basis of the number of wires that constitute a strand and the number of strands that are wound around the core of a wire rope sling. For example, a wire rope of 6x 19 dimension consists of 6 strands of 19 wires. Slings of a wide variety are used in the manufacturing industry and some of the most commonly-used wire rope slings are:

Nine-part Slings:Nine-part slings are meant to lift heavy and large objects. This is mainly due to the fact that the load can be distributed consistently over nine parts of the sling’s body. The nine-part design also facilitates inspection, which is very important if the sling is used multiple times to lift multiple loads.

Bridle Slings:Bridle slings, which are commonly available as 2, 3, or 4-legged bridle slings, are appropriate for lifting objects with fixed lifting points. These slings are directly connected to the weight by hooking it into the lifting eyes.

Eye & Eye Slings:These slings feature an oval “eye” at each end, which is what gives these slings their names. These slings are noted for their ruggedness, reliability, and versatility and are mostly used in basket, choker, and vertical hitches.

Multi-part wire rope sling:Multi-part wire rope slings can be used efficiently to carry single objects of moderate weight. They are recognized for their strength, durability, and flexibility and are made of braided wire rope that promotes equal distribution of weight throughout the entire body of the sling.

Wire rope slings are crucial rigging hardware, which should be chosen wisely. The deployment of unsuitable slings may jeopardize loading operations, eventually leading to the collapse of the rigging structure.

Wire rope slings are extremely strong and an excellent choice for heavy duty jobs involving not only lifting, but also hoisting, towing, or anchoring loads. The fabrication of wire slings also offers excellent abrasion-resistance and heat resistance so it can be used in extreme conditions and temperatures. Its pliable design can conform to the shape of a load for a more secure application.

Wire rope slings are manufactured in a variety of configurations, with 6x19 and 6x36, being two of the most common. The numbers represent the number of wires making up the strand and the number of strands wrapped around the core. For example, a 6x19 indicates that there are 19 wires making up a strand, and 6 strands are wrapped around the core.

Each steel wire rope configuration will offer different benefits and will be better suited to certain applications. In general, a smaller number of large outer wires offers better wear and corrosion resistance, while a larger number of small wires provides a better level of flexibility and fatigue resistance.

We offer steel wire rope slings in both 6x19 and 6x36 configurations, depending on the diameter of the wire rope. All are in a bright (unfinished) wire rope, but other configurations are available by request. Our cable laid slings are manufactured in a 7x7x7 galvanized wire rope (composed of 7 strands of 7x7 cables), which make them extremely flexible and useful for more specialized applications.

The eye loops on our sling cable are created with a Flemish splice, which is a mechanical splice where the rope cable is separated into two parts (one part has three strands, the other part has the remaining three strands plus the core), then re-laid back in the opposite direction to form the loop. The ends are then secured with a carbon steel sleeve around the entire area. Flemish splices offer the most efficient use of capacity.

The core of the wire rope used in cable slings can be made of several different materials, including steel or natural fibers. Our steel wire rope slings are made with Extra Improved Plowed Steel (EIPS) around an Independent Wire Rope Core (IWRC) for the ultimate in strength and durability.

Our categories of wire rope slings are broken down by number of legs, hardware, and the diameter of the wire rope. Each wire sling is made to order, so custom slings are also always an option if you don"t see what you"re looking for here.

We offer a wide selection of both domestic wire rope slings and import wire rope slings online, with additional options and customization available by calling our sales team.

Import slings are a more cost-effective choice yet offer the same wire rope strength and working load limits as our domestic slings. Our imported slings also feature sleeve components from Crosby. Wire rope slings we import are also available in custom configurations.

Sometimes called eye & eye slings because of an oval "eye" at each end, these 1 leg cable slings are rugged and reliable and a very popular choice among wire slings. The eyes are formed using a Flemish eye splice and secured with a carbon steel sleeve.

Single leg cable slings are available in a variety of styles: Eye & Thimble, Thimble & Thimble, Eye & Hook, Eye & Eye, Sliding Choker, and Cable Laid.

Also known as a 2 leg bridle sling, this sling offers increased versatility over a sling with just a single leg. Manufactured with a Flemish eye that"s spliced with a carbon steel sleeve; end options range from a latched eye hook to a simple eye design. Our 2 leg wire rope slings are available in seven different diameters of rope. Custom options are also an option.

Our 3 leg wire rope slings are also known in the industry as a 3 leg bridle sling. Each is manufactured with a Flemish eye that"s spliced with a carbon steel sleeve for the ultimate in safety and strength. End options include latched eye hooks, eyes equipped with thimbles, and more, as customized options are always available. Our 3 leg wire rope slings are available in seven different diameters of rope.

A 4 leg bridle sling offers the ultimate in versatility. Also known in the industry as wire rope 4 leg bridle slings, ours are manufactured with a Flemish eye that"s spliced with a carbon steel sleeve for an extra measure of security. And because legs can be fitted with hardware of your choosing, from simple eye formations to heavy duty hooks, it results in a sling customized to your exact application needs. Our 4 leg wire rope slings are available in six different diameters of rope.

Braided wire rope slings are formed when multiple wire ropes are braided continuously to form the body of the sling and the eye/eyes into a single fabricated sling. Braided wire slings are excellent for higher capacity lifts and can be either round or flat. One benefit of a braided sling is its ability to conform snugly to a load that"s in a choker hitch. Because of the braided design, they also are better resistant to kinking.

Our braided wire rope slings are made in the USA and available in a variety of configurations, including a 3-part braid, 6-part braid, 8-part braid, and 9-part braid. Several style options are also available, including standard eyes, thimble eyes, and more, to create a customized braided wire rope sling to your specifications.

Wire rope bridles are measured by the length of the sling leg plus the end hook. The length of the oblong master should not be included in the overall measurement.

Our slings are available in a variety of lengths, but can also be customized to any length you need. Give our sales team a call for more information or to place a custom order.

"Slings in contact with edges, corners, protrusions, or abrasive surfaces shall be protected with a material of sufficient strength, thickness, and construction to prevent damage."- ASME B30.9 (2021) 9-5.10.4(d)

All of our slings are inspected, certified and tagged with metal tags displaying rated capacities by hitch types and angles; diameter or size; and name/trademark of the manufacturer.

Proof testing certificates can be supplied with your order for a nominal fee and must be requested at the time of order. Proof tests are performed in the factory where the sling is pull tested to 2x the vertical rating and officially recorded as proof for governing bodies. During the standard manufacturing process, only random slings during a production run are tested for compliance; in order to provide proof testing certificates with your order, every sling must be pull tested at the time of manufacture.

If steel wire rope slings are not the best choice for your application, we also offer chain slings, nylon lifting slings, and polyester round slings in a wide range of styles and capacities. As with all of our lifting slings, customization is always an option.

If you need help selecting a sling, check out our How to Choose a Lifting Sling page or call our product specialists . They"ll be happy to any answer questions you may have and can even place a custom order if needed.

Wire rope slings are common components of wire rope assemblies that serve as a point of attachment for cranes, hooks and hoists in many heavy lifting or pulling applications.

Unlike synthetic or fiber slings, wire rope offers increased resistance to wear and abrasion and can be used for both hot and cold materials as well as in corrosive applications such as those in marine, construction, aerospace, manufacturing, assembly, transport, shipping and other industries where wire rope slings are commonly used. Wire ropes fitted with slings in these applications also serve to improve connectivity and prevent fraying of the rope. Though the majority have predetermined dimensions, they may be adjustable to accommodate for a change in the size of cargo while maintaining a secure fit.

Slings are most commonly constructed simply by looping or folding the end of a wire rope back onto itself and holding it in place with a firm fitting such as a clamp. Alternatively the folded segment of wire may be braided or twisted along the main body of rope and otherwise held in place through welding or similar processes.

The rope itself is composed of cold drawn filaments that are twisted or braided into strands which in turn are helically wrapped around a core. The multilayered formation of wire rope acts as a safety measure as individual strands are more likely to fail than the rope as a whole, allowing the other strands to act as a backup.

Additional considerations include the wire rope sling"s dimensions, fatigue strength, its ability to bend without distortion, to withstand abrasion and environmental conditions as well as the intended use for the sling. Wire rope slings are stress tested during manufacturing to determine breaking point and safe usage guidelines which should be carefully considered.

The term sling can refer to one of two configurations for lifting and hoisting apparatus. Slings as wire rope fittings involve the addition of a loop at the end of a length of wire through which hooks and other apparatus may be looped or fastened. The term may also apply to a length of cable that has this same “U” or teardrop shaped eye, but on either end of the cable.

In the case of the "U" shaped sling, lifting is accomplished by firmly attaching the eyes to a hook or hoist, though both ends are then simultaneously lifted in order to wrap around or cradle the supplies or finished goods to be lifted.

Popular materials for wire rope and sling construction include aluminum, nickel alloy, bronze, copper and titanium, although steel and stainless steel are the most common due to their increased strength and availability.

Like stranded wire ropes, the slings that they attach too are strictly regulated and must be inspected regularly as mechanical failure puts both machinery and employees at serious risk. To prevent such disruptions, it is important to select the proper sling for a given application.

8613371530291

8613371530291