seizing wire rope ends quotation

Whatever cutting methods your applied, certain precaution - seizing both rope ends must be employed to protect the steel wire ropes from loosening. But carelessly or inadequately seized ends may cause distortion and flattening of the rope. If these loose ropes are applied to works, uneven distribution of loads to the strands may shorten the life of ropes badly. So it is important to seize the wire ropes in the optimal way.

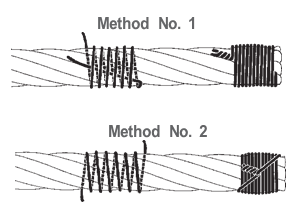

Normally, two methods are widely accepted by our customer. The method one is suitable for wire ropes with diameter over one inch, while the method two is for those with diameter one inch and under.

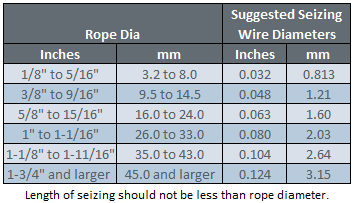

The diameter and length of seizing wires may different as the diameter of the wire rope. Make sure that the seizing length is no less than the diameter of the steel wire rope.

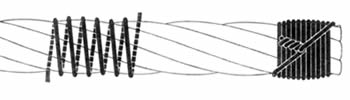

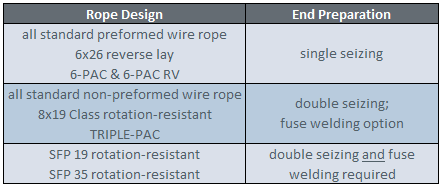

Generally, one seizing on each side of the cut is sufficient for preformed ropes. But for rotation resistant or non-preformed ropes, no less than two seizing parts are needed with the distance about six rope diameters.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

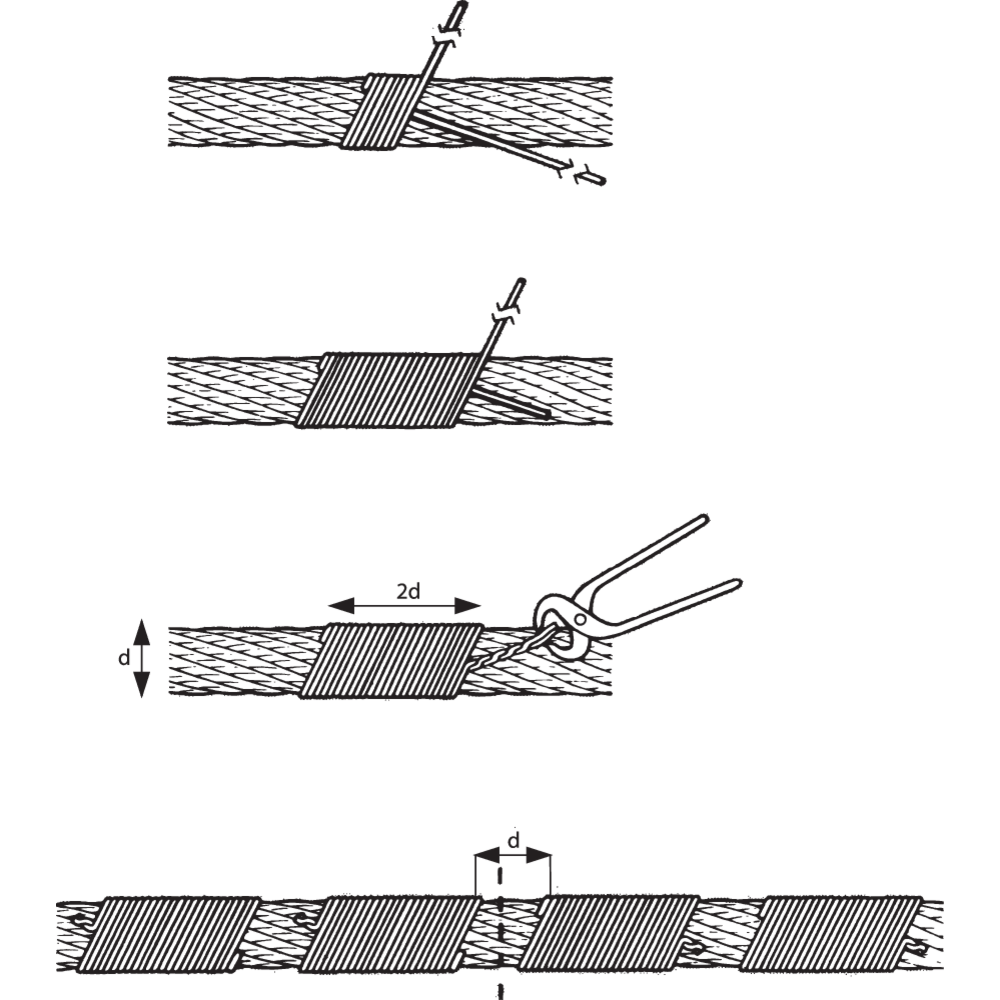

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

Interested in becoming a distributor for Miami Cordage/Florida Wire & Rigging Works? Whether you have a brick-and-mortar store or are an on-line retailer, we offer substantial discounts to our loyal distributors. Click here to find out more information.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

CONSTRUCTION: Expressed in numbers of strands x number of wires. 6 x 25 indicates that the wire rope consists of 6 strands, which in turn have 25 individual wires.

How to measure (or caliper) a wire rope correctly. Since the "true" diameter (A) lies within the circumscribed circle, always measure the larger dimension (B). Actual diameter can be 5% larger than nominal wire rope diameter.

There are numerous ways to cut wire rope - use only appropriate tools specifically designed to cut wire rope. Safety goggles and work gloves must always be worn. Observe other precautions peculiar to the tools used. Wire rope should be properly seized on both sides of the cut with wire or strand. Seizing wire diameter and the number and length of the seizings will depend on the diameter of the wire rope, and whether or not it is preformed.

Since wire rope is a machine with many moving parts, it requires careful installation and breaking in procedures for maximum safety and long service life. After proper installation, allow the wire rope to run through a cycle of operation at a very low speed. Keep a close watch on the wire rope, its attachments and any working parts such as sheaves, drums, rollers, etc. to make certain that the wire rope runs freely. If no problems appear at this stage, run the wire rope through several cycles of operation under light load at reduced speed. This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions.

Wire rope will develop 100% efficiency, that is, break at or above minimum acceptance strength (not less than 2 1/2% below nominal breaking strength) under controlled laboratory conditions. Once fittings such as sleeves, clips, sockets, etc. are attached and/or the wire rope passes over a curved surface such as sheaves, pins, etc. its strength is decreased. In the case of wire rope passing over a curved surface this decrease in strength depends on the severity of the bend. In the case of wire rope fittings, the decrease in wire rope strength will depend on the type of fittings used. The wire rope efficiency usually ranges from 70% - 100%. For more detailed information consult the strength efficiency of wire rope table on page 86. Note, that hand spliced wire rope, while not using any fittings, has less efficiency than properly flemished and swaged wire rope. There are other factors, depending on the application of wire rope, that can cause a decrease in nominal wire rope strength. They must be considered when choosing a design factor. Refer to the Wire Rope Users Manual and/or other qualified sources for details.

Wire rope is an elastic member; it stretches or elongates under load. This elongation can be permanent or recoverable. The extent of elongation will depend on the wire rope used and the design factor chosen. While it may be acceptable for many wire rope uses to neglect its elastic properties, they are of critical importance for some uses. When in doubt about the importance of wire rope elongation consult professional help. Pre-stretching wire rope will only remove some of the constructional stretch and will not totally eliminate elongation under load.

Installation of wire rope on a plain or grooved drum requires a great deal of care. Make certain the wire rope is properly attached to the drum. Keep adequate tension on the wire rope as it is wound onto the drum. Guide each wrap as close to the preceding wrap as possible, or follow the groove in case of a grooved drum. No blanket recommendations can be given concerning direction of winding, desirable drum diameter, fleet angle, etc. Consult the Wire Rope Users Manual for this and other important technical information.

The majority of Loos & Co manufacturing is dedicated to the manufacturing of Military Specification wire rope fittings, connectors, and terminations. These products are on the QPD (Qualified Producers Database) for the US Government. There are several hundred product numbers that are produced and warehoused in our Naples plant. Additionally, they manufacture the swaging machines and tools necessary to connect the manufactured hardware to the numerous types of wire rope.

Interesting that Stevenson used the wrong word. Although he came from a family of lighthouse engineers and went with his father to visit some of his father"s projects he was not a sailor. A seizing has never meant a wrapping to prevent a rope"s end from fraying. As the OED definition quoted makes clear, a seizing always involves binding two parts together. As Hans in Texas points out, the normal usage is to "whip" the end of a rope. However, although that is current usage, it is not modern. It"s recorded as far back as the 15th century.

Interesting that Stevenson used the wrong word. Although he came from a family of lighthouse engineers and went with his father to visit some of his father"s projects he was not a sailor. A seizing has never meant a wrapping to prevent a rope"s end from fraying. As the OED definition quoted makes clear, a seizing always involves binding two parts together. As Hans in Texas points out, the normal usage is to "whip" the end of a rope. However, although that is current usage, it is not modern. It"s recorded as far back as the 15th century.

If the steel wire rope is to be used in hazardous conditions a risk evaluation is to be done. The WLL of the steel wire rope should be decided or adjusted according to this. Example of such conditions are offshore, lifting people or dangerous load.

Broadly speaking, there are two significantly different kinds of wire rope – ‘normal’ and non-rotating. The difference is explained elsewhere however the difference greatly affects how the wire rope should be cut.

When cutting any kind of wire rope, care should be taken to protect the ends of the material from impact or damage. To protect the immediate ends of the cable as it is cut, wrapping it tightly with several layers of stretchy vinyl electrical tape. Cut at the middle of the tape and both ends stay un-damaged. You then remove the tape or seizing wire to thread the cut end through crimp-sleeves (oval or hourglass) or end-stops.

For wire rope cutting tools, using a manual or ratchet cutter – ensure that the length of arms are matched to the diameter of wire rope you are cutting as well as your upper body strength. This is necessary to get adequate leverage. Ratchet cutters act to further multiply your mechanical advantage.

Our tools are a good example as each is ‘rated’ to the maximum wire diameter and type of wire that it can effectively cut. Please note that cutting different structures (1×19 vs 7×7) of wire will also put different loads on the cutters – stiffer wire is much harder to cut.

One other point is that up to 3.2mm (1/8th inch) wire, a good 1 handed set of cutters is both fast and accurate. For wire in the 4.0mm to 10.0mm range, a good 2 handed cutter is accurate and capable. Above 10.0mm wire, you will need a specialised approach – and if you are reading this and you don’t already know this, please go find someone who can help before you hurt something vital.

When cutting non-rotating wire rope it is important to seize the cable with multiple wraps of safety wire (typically 0.032″ wire for 1/4″ cable). Do this on both sides of the cut point so the cable deformation is minimized. This will also keep the cable from fraying/un-ravelling after it is cut.

We need to take proper care of our tools and equipment to ensure their longevity and endurance. Their safe and prolonged use is dependent upon the upkeep that they receive. I’m sure you would agree that looking after them isn’t easy.

A wire rope is one of the most essential equipment in several industries. Since it is a consumable item, it comes with a shelf life. It is, typically, used in heavy industries and due to the nature of the work it serves its properties are bound to change when in use. In the beginning, each wire and strand settles in place and the rope’s strength increases. On reaching its maximum potential, however, the strength starts to deteriorate rapidly.

This difference in the strength of the rope is brought about by factors such as changes in the structure of the rope, wire breaks, corrosions and abrasions. Some would argue about replacing a wire rope with a chain. But this isn’t feasible as a chain is a series of connections of load bearing elements. If even one link in the chain breaks, it will take only a split second for the entire lifting device to fail.

A wire rope, on the other hand, compiles various wire strands together which makes it sturdy and resilient. It can therefore be operated safely even after a couple of breaks.

Since wire ropes are mainly used in heavy lifting, it is advisable to carry out timely inspections and examinations. It is important to ensure the removal of defective ones, before they break down completely and lead to injury or accident.

There is a minor difference between an ‘inspection’ and an ‘examination’ of wire ropes though. In an inspection, a careful and intensive analysis of the condition of the rope and the fittings is carried out without dismantling it. In an examination, however, a careful and intensive analysis of the state of the rope and the fittings is carried out by a qualified authority through visual assessment and non-destructive testing. This may also require dismantling the wire.

A wire rope should ideally be inspected by trained and experienced workers at the start of every shift or when resuming stalled work. Usually, machine operators are trained to visually assess the entire wire rope, with special emphasis on the points of attachment to the equipment.

A thorough inspection also needs to be carried out after reattaching or refitting the rope on the same or different equipment. Should a change in the condition of the rope be detected at any time during the inspection, it should immediately be reported and the wire should be taken out of service until further examination by an expert.

Proper care is required for the maintenance and upkeep of wire ropes. This is directly related to unloading, storing, handling, seizing and installing it.

The rope in a reel or a coil is largely unprotected and a fall can lead to serious destruction. Hence, when handling a wire rope, ample care needs to be taken not to drop the reel. Its collapse can break the reel and damage the wire rope, thereby making its removal very difficult.

The ideal procedure for lifting a reel with ropes is by using a spreader bar (of an adequate length) to keep the sling legs from coming in contact with the reel. This will deter the flanges of the reel from bending, distortion, or damage in any way by the slings.

Wire ropes should be stored in well-ventilated, dry and covered areas or sheds and should not be allowed to come in contact with the floor. Make sure that they are protected from dust, water, steam, brine, chemical fumes and adverse climatic conditions. Moisture can play spoil sport and induce corrosion in them. So if they are required to be stored in the open, ensure that you cover them properly.

It is important to store the reel in a dry, cemented place to prevent termite infestation. Occasionally turning it will help prevent the wearing off of the rope lubricant. If ropes are stored for long time, it is advisable to get them examined periodically and apply a coat of lubricant to them.

At times, wire ropes tend to kink while uncoiling or unreeling. A kink can permanently cause a weak spot in the rope, which will wear out quicker than the rest of the rope. Care must be taken when unreeling/uncoiling the rope by ensuring that the reel rotates as the rope unwinds to avoid kinks.

Always make sure that before a rope is cut at a particular spot, it is properly seized from both sides, i.e. it is wound by soft iron wires to prevent an occurrence of flyaway strands. Usually, two or more seizings are required to be made on each side.

It is important to take into account the design factor of the equipment before installing a wire rope. This should preferably be done by a knowledgeable and experienced person as the rope is at a great risk of being damaged at this stage. It is important to check the rope’s diameter prior to installing it as wrongly measured diameters will result in a failed rope. Carrying out a risk assessment before installing the rope to nullify chances of damage to it may also help.

It is important to adhere to safety guidelines and manuals when working with heavy and sensitive equipment. I hope the above mentioned points offered you some perspective on the various aspects of dealing with wire ropes.

Abstract:646,485. Splicing ropes. AMERICAN CHAIN & CABLE CO., Inc. June 3, 1948, No. 15010. Convention date, Feb. 10, 1948. [Class 109] A splice for two rope ends A, B is made by passing the strands of the splayed portion of each rope end between the strands of the splayed portion of the other rope end, helically disposing the strands in the valleys of the laid portion of the other rope end and then securing the strands of the splayed portion of each rope end in the valleys of the underlying laid portion of the other rope end. The securing means preferably comprise ferrules 10. The rope ends are preliminarily prepared, as shown in Fig. 1, by applying a ferrule 10 to each rope end, seizing each rope end at 11 at a suitable distance, unlaying the strands from the core 12 back to the seizing 11, and finally cutting the core 12 of each rope near the seizing. The rope ends are then "married," as shown in Fig. 2, by passing the strands 1a-6a of the rope A between the strands 1b-6b of the rope B. The seizing 11 is then removed and each strand of one rope is wrapped around the laid-up portion of the other rope so as to lie in the helical valleys between the strands of that rope. In the resulting splice, any strand is preferably laid in the valley between the pair of strands it was placed between in the " marrying "" step. The above process is then performed on the other end of the splice. Finally, the ferrules 10 are compressed around the free ends of the outer strands, with or without an additional ferrule at the centre of the splice. The ropes A and B may be two separate ropes to be joined or may be the ends of the same rope, particularly when making grommets intended for slings. The splice is intended particularly for wire ropes and the individual strands thereof may be single wires.

Birdcaging is caused by sudden release of tension and the resulting rebound of rope. These strands and wires will not be returned to their original positions.

Localized Wear? over an equalized sheave. The danger is that it’s invisible during the rope’s operation. Localized wear The rope should be pulled off the sheave during inspection and bent to check for broken wires.

High Strand is a condition in which one or more strands are worn before adjoining strands. This is caused by improper socketing or seizing, kinks, or dog-legs.

Curled is a condition in Curled which one or more strands are worn before adjoining strands. This is caused by improper socketing or seizing, kinks, or dog-legs.

Valley Wire Breaks where the wire fractures between strands or a broken wire protrudes between strands, replace when there is Drum Crushing more than one valley break.

Mobile cranes for six and eight strand constructions, replace when you see six randomly distributed broken wires within one lay length, or three broken wires in one strand within one lay length.

Overhead and Gantry Cranes for six and eight strand constructions, replace when you see twelve randomly distributed broken wires within one lay length, or four broken wires in one strand within one lay length.

For rotation ? resistant constructions, replace when you see two randomly distributed broken wires in six rope diameters, or four randomly distributed broken wires in 30 rope diameters.

Wire ropes used as standing ropes such as guy lines, escape lines and pendant lines should be removed from service when any of the following conditions exists:

Some whippings are finished cleanly, as by drawing the bitter end of the cordage beneath the whipping itself. Others are tied off or have the end(s) of the twine sewn through the rope. According to whipping is to prevent the end of a rope from fraying ... A whipping should be, in width, about equal to the diameter of the rope on which it is put ... [Two sailmaker"s whippings], a short distance apart, are put in the ends of every reef point, where the constant "whipping" against the sail makes the wear excessive; this is said to be the source of the name whipping."seizing knot.

Whipping is suitable for synthetic and natural stranded and braided lines, including 3-strand rope, 4-strand cable and 8-strand multiplait, as well as concentric and braided constructions.

Multiple turns of twine (sometimes called small stuff for smaller lines) or heavier whipcord (for large diameter cables and ropes) are tightly wrapped around a rope"s cut end to prevent its fibers from unlaying.

Usually one end of the whipping cord is looped along the rope to be whipped, and the remaining cord wound tightly over the loop. Finally the loose end of the wound whipping is passed through the loop so that both ends may be drawn securely inside the winding.

Whippings may also be applied by hand or using a palm and needle, and either simply tied off or made neat and permanent by reeving the twine"s cut ends into or behind the whipping, sewing them to adjacent strands, or through the rope itself.

French whipping is merely a series of half hitches. Start with a running eye and finish up with the end tucked back under the last few hitches. The ridge of the hitches should follow the lay of the rope.

French whipping is a whipping knot that consists of a series of half hitches. It is used to stop unraveling of rope ends as well as to provide a grip over railings.

Portuguese whipping is the quickest of all to apply; the ends are merely reef knotted together. It is given by Esparteiro in his Dicionario de Marinharia (Lisboa, 1936).

The Portuguese whipping is a type of whipping knot. To make it you take the small diameter string and lay one end against the rope. Wrap backwards up the rope until you have both ends side by side, finish by tying a reef knot. This is the quickest of the seizings, but is not as secure as some.

The ends of some man-made fibers such as Dacron, Nylon, polyethylene, polyester, and polypropylene (but not aramid fibers) may be melted to fuse their fibers to prevent fraying. However, the rope and knotting expert Geoffrey Budworth warns against this practice for boat operators thus:

Sealing rope ends this way is lazy and dangerous. A tugboat operator once sliced the palm of his hand open down to the sinews after the hardened (and obviously sharp) end of a rope that had been heat-sealed pulled through his grasp. There is no substitute for a properly made whipping.

Among the methods of fusing are using an electrically heated rope cutter, heating the blade of a knife, or melting cut ends in a flame. The cool (transparent) part of a butane lighter flame works best.

Back splicing uses a stranded rope"s own fibres to prevent fraying. A back splice adds extra thickness to the rope end, preventing it from running through blocks and sheaves. It can also be of benefit when a user needs to feel the end of the rope, as on a bucket lanyard.

Liquid whipping is a semi-permanent rubbery coating applied by dipping the cut end of a line into a container of the product. When the coating sets it is flexible but solid enough to keep the rope together. Liquid whipping can be used on both natural and synthetic fibers.

An aglet is a permanent ending applied mechanically to bind the end of the rope. A typical example is the plastic aglet at the end of a shoelace. Metal aglets may be crimped onto ropes or cables. Aglets may also be made by melting a softer metal to cap the end of the cable.

8613371530291

8613371530291