seizing wire rope ends for sale

Interested in becoming a distributor for Miami Cordage/Florida Wire & Rigging Works? Whether you have a brick-and-mortar store or are an on-line retailer, we offer substantial discounts to our loyal distributors. Click here to find out more information.

Whatever cutting methods your applied, certain precaution - seizing both rope ends must be employed to protect the steel wire ropes from loosening. But carelessly or inadequately seized ends may cause distortion and flattening of the rope. If these loose ropes are applied to works, uneven distribution of loads to the strands may shorten the life of ropes badly. So it is important to seize the wire ropes in the optimal way.

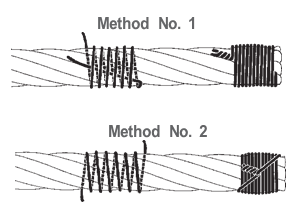

Normally, two methods are widely accepted by our customer. The method one is suitable for wire ropes with diameter over one inch, while the method two is for those with diameter one inch and under.

The diameter and length of seizing wires may different as the diameter of the wire rope. Make sure that the seizing length is no less than the diameter of the steel wire rope.

Generally, one seizing on each side of the cut is sufficient for preformed ropes. But for rotation resistant or non-preformed ropes, no less than two seizing parts are needed with the distance about six rope diameters.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Method No. 1: Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The Seizing Wire. The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table below ("Suggested Seizing Wire Diameters") for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

After cutting the rope (see below) it is good practice to braze PYTHON®, 19×7, and 34×7 rope ends to ensure that they don’t unravel. Leave the seizings on the rope for added holding strength. Be careful not to damage the seizing while brazing.

We found that blade cutting a rope gives the best results. Be sure to use a cutting blade suitable for the job (We use cutting blades made by ‘PFERD-HORSE’ type ELASTIC # 80 EHT 230-2 A 24 SG INOX.) Follow the safety precautions for free hand cutting.

applies on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there

The two widely accepted methods of applying seizing are illustrated in Figures 25A and 25B. The seizing itself should be soft, or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. But the length of the seizing should never be less than the diameter of the rope being seized. Normally, for preformed ropes, one seizing on each side of the cut is sufficient. But for ropes that are not preformed or rotation resistant ropes, a minimum of two seizings on each side is recommended; and these should be spaced six rope diameters apart (Fig. 26).

(a) The seizing shall be done with annealed iron wire, provided that other methods of seizing that give the same protection from loss of rope lay are permitted. Where iron wire is used for seizing, the length of each seizing shall be not less than the diameter of the rope.

(b) For nonpreformed rope, three seizings shall be made at each side of the cut in the rope. The first seizing shall be close to the cut end of the rope, and the second seizing shall be spaced back from the first the length of the end of the rope to be turned in. The third seizing shall be at a distance from the second equal to the length of the tapered portion of the socket.

(c) For preformed rope, one seizing shall be made at each side of the cut in the rope. The seizing shall be at a distance from the end of the rope equal to the length of the tapered portion of the socket plus the length of the portion of the rope to be turned in.

Rope diameter is specified by the user and is generally given in the equipment manufacturer’s instruction manual accompanying the machine on which the rope is to be used.

Rope diameters are determined by measuring the circle that just touches the extreme outer limits of the strands - that is, the greatest dimension that can be measured with a pair of parallel-jawed calipers or machinist’s caliper square. A mistake could be made by measuring the smaller dimension.

The Right Way To Unreel. To unreel wire rope from a heavy reel, place a shaft through the center and jack up the reel far enough to clear the floor and revolve easily. One person holds the end of the rope and walks a straight line away from the reel, taking the wire rope off the top of the reel. A second person regulates the speed of the turning reel by holding a wood block against the flange as a brake, taking care to keep slack from developing on the reel, as this can easily cause a kink in the rope. Lightweight reels can be properly unreeled using a vertical shaft; the same care should be taken to keep the rope taut.

The Wrong Way To Unreel. If a reel of wire rope is laid on its flange with its axis vertical to the floor and the rope unreeled by throwing off the turns, spirals will occur and kinks are likely to form in the rope. Wire rope always should be handled in a way that neither twists nor unlays it. If handled in a careless manner, reverse bends and kinks can easily occur.

The Right Way To Uncoil. There is only one correct way to uncoil wire rope. One person must hold the end of the rope while a second person rolls the coil along the floor, backing away. The rope is allowed to uncoil naturally with the lay, without spiraling or twisting. Always uncoil wire rope as shown.

The Wrong Way To Uncoil. If a coil of wire rope is laid flat on the floor and uncoiled by pulling it straight off, spirals will occur and kinking is likely. Torsions are put into the rope by every loop that is pulled off, and the rope becomes twisted and unmanageable. Also, wire rope cannot be uncoiled like hemp rope. Pulling one end through the middle of the coil will only result in kinking.

Kinks. Great stress has been placed on the care that should be taken to avoid kinks in wire rope. Kinks are places where the rope has been unintentionally bent to a permanent set. This happens where loops are pulled through by tension on the rope until the diameter of the loop is only a few inches. They are also caused by bending a rope around a sheave having too severe a radius. Wires in the strands at the kink are permanently damaged and will not give normal service, even after apparent "restraightening."

When wire rope is wound onto a sheave or drum, it should bend in the manner in which it was originally wound. This will avoid causing a reverse bend in the rope. Always wind wire rope from the top of the one reel onto the top of the other. Also acceptable, but less so, is re-reeling from the bottom of one reel to the bottom of another. Re-reeling may also be done with reels having their shafts vertical, but extreme care must be taken to ensure that the rope always remains taut. It should never be allowed to drop below the lower flange of the reel. A reel resting on the floor with its axis horizontal may also be rolled along the floor to unreel the rope.

Wire rope should be attached at the correct location on a flat or smooth-faced drum, so that the rope will spool evenly, with the turns lying snugly against each other in even layers. If wire rope is wound on a smooth-face drum in the wrong direction, the turns in the first layer of rope will tend to spread apart on the drum. This results in the second layer of rope wedging between the open coils, crushing and flattening the rope as successive layers are spooled.

A simple method of determining how a wire rope should be started on a drum is shown above. The observer stands behind the drum, with the rope coming towards him. Using the right hand for right-lay wire rope, and the left hand for left lay wire rope, the clenched fist denotes the drum, the extended index finger the oncoming rope.

Clips are usually spaced about six wire rope diameters apart to give adequate holding power. They should be tightened before the rope is placed under tension. After the load is placed on the rope, tighten the clips again to take care of any lessening in rope diameter caused by tension of the load. A wire rope thimble should be used in the eye of the loop to prevent kinking.

U-bolt Clips. There is only one correct method for attaching U-bolt clips to wire rope ends, as shown in the "Correct Way". The base of the clip bears on the live end of the rope; the "U" of the bolt bears on the dead end.

Compare this with the incorrect methods. Five of the six clips shown are incorrectly attached - only the center clip in the top view is correct. When the "U" of the clip bears on the live end of the rope, there is a possibility of the rope’s being cut or kinked, with subsequent failure.

Proper seizing and cutting operations are not difficult to perform, and they ensure that the wire rope will meet the user’s performance expectations. Proper seizings must be applied on both sides of the place where the cut is to be made. In a wire rope, carelessly or inadequately seized ends may become distorted and flattened, and the strands may loosen. Subsequently, when the rope is operated, there may be an uneven distribution of loads to the strands; a condition that will significantly shorten the life of the rope.

Either of the following seizing methods is acceptable. Method No. 1 is usually used on wire ropes over one inch in diameter. Method No. 2 applies to ropes one inch and under.

Place one end of the seizing wire in the valley between two strands. Then turn its long end at right angles to the rope and closely and tightly wind the wire back over itself and the rope until the proper length of seizing has been applied. Twist the two ends of the wire together, and by alternately pulling and twisting, draw the seizing tight.

The seizing wire should be soft or annealed wire or strand. Seizing wire diameter and the length of the seize will depend on the diameter of the wire rope. The length of the seizing should never be less than the diameter of the rope being seized.

Proper end seizing while cutting and installing, particularly on rotation-resistant ropes, is critical. Failure to adhere to simple precautionary measures may cause core slippage and loose strands, resulting in serious rope damage. Refer to the table for established guidelines. If core protrusion occurs beyond the outer strands, or core retraction within the outer strands, cut the rope flush to allow for proper seizing of both the core and outer strands.

Usually, if you have to field cut a high performance rope type (e.g. Python®, DoPar®, etc.), you do not need to re-cut a wire rope. However, you may encounter situations where it becomes necessary to shorten the rope. (But remember the old rule: 3 times cut and still too short.)

After cutting the rope it is good practice to braze or weld the rope ends to ensure that they don’t unravel. Leave the seizing on the rope for added holding strength. Be careful not to damage the seizing while brazing.

Attach 3 hose clamps on either side of the rope and clamp it securely in a vise. The distance between the first and second clamp should be about 3 rope diameters. Attach a 3rd clamp about 2 rope lays (12-14 rope diameters) away from the 2nd. Wear protective gloves and eye glasses.

Do not use a grinding wheel but a steel cutting blade; e.g. Elastic #80EHT230-2. Cut swiftly through the rope and have another person hold and secure it.

In the spirit of reconciliation Arcus Wire Group acknowledges the Traditional Custodians of country throughout Australia and their connections to land, sea and community. We pay our respect to their Elders past and present and extend that respect to all Aboriginal and Torres Strait Islander peoples today.

Using rigging equipment is necessary to lift heavy loads on a job site. However, as you use your slings and ropes, they can become worn. As a result, maintaining them is vital for ensuring safety on the job. The integrity of the equipment is essential; without it, you could get into dangerous situations with serious consequences. Learn how to properly take care of your wire rope for a safer work environment.

If you can’t store the rope correctly, the overall lifespan and condition of the equipment will decline before you can even use it. Place the wire rope in a covered area that’s both dry and well-ventilated. Leaving this equipment outside without a cover will allow moisture to penetrate the wire, which can cause corrosion.

When this rope is in long-term storage, you must regularly examine the reel it’s on and lubricate the wire from time to time to ensure it remains in working condition. Don’t allow the rope or reel to touch the ground where contaminants like dust, salt, and water could damage the equipment. Without proper storage, you could be shortening the lifespan of the wire rope.

Seizing the ends of your rope protects it from unraveling on itself or becoming loose. This process involves wrapping seizing wire around the edges of your wire rope to help evenly distribute the weight of your load better. Skipping this or being careless when applying it will lead to a shorter lifespan for your equipment. To properly take care of your wire rope, you should make sure you tightly bind the wire around the rope for proper seizing.

Regularly inspecting your rigging equipment should be a priority on the job site. Doing this will ensure the safety of the load you’re lifting, the workers performing the job, and the environment around the equipment. A professional will dismantle the wire rope and put it through various tests to look for broken strands and wear and tear. Employees must inspect this rope before each shift to be confident that the wire is in working condition.

When installing a wire rope with other rigging equipment, you must make sure the setup is perfect. Using the wrong size wire rope will lead to failure or a shorter lifespan. A certified professional will install the rope without issues. They can also train workers to look at the nominal diameter of the rope compared to the rest of the equipment to determine the correct rope size for your job.

Safety is critical when working with heavy equipment. The same goes for this industry. The integrity of your equipment and wire rope is vital for avoiding dangerous scenarios. Take care of your wire rope to ensure you get the most out of the equipment.

8613371530291

8613371530291