sheave design for wire rope supplier

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

Above all else, we are an engineering firm that can take your technical requirements for sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application. For over fifteen years now, Sheaves Inc. has been the number one source for the wire-rope industry, designing and providing QSheaves™, alongside othercustom engineered wire rope sheavesthat meet your specific needs and rigors of your application. We also supply a large inventory of stock sheaves from thebest known brands in the industry. Contact ustoday or send a request for quotation, and our engineering team will work alongside you to find your custom pulley solution.

Want a sheave system to solve your design problem? Our expertise is based on decades of engineering and supplying leading manufacturers, from the simplest applications to the most demanding. We’ve supplied sheaves for both recreational and large commercial boat lifts, to military applications. No problem is too big for us, and no solution is too small for a consultation.

Esheaves.com offers custom solutions engineered to meet the exact requirements of your application. From the strength and durability of a nylon sheave, to the rapid shipping and stock availability of QSheaves™, we will help you meet any challenge. If our customizable options don’t measure up, we’ll engineer a complete, original solution just for you!

Need an individualized application solution?EShevaes.com is the trusted team of sheave engineers you can turn to. Find additional information about our customization options below. Ready to start a Custom Pulley Project? Visit our Custom Sheave Project page by clicking the link below

Contact us with your sheave requirements before freezing your equipment designs. We can offer a better sheave at a lower cost in many cases if we are consulting early in the design stage. Many times a modification of our QSheaves™ is the economical choice when certain design parameters preclude use of an off-the-shelf sheave. Even fully custom pulleys can be quite economical when the right decisions are made on materials and designs. Put our experience to use for your business.

Many applications, particularly in wire rope sheaves and in wire & cable processing, have design constraints that can’t be met by stock sheaves from us or other suppliers. In recent years, Process Sheaves LLC has developed over 300 custom engineered sheaves to meet critical customer parameters. We welcome the opportunity to work with you to achieve the most economical solution for your particular situation.

We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs; achieved, for example, in our patented line of steel sheaves that allow us to provide an extensive range of 6” to 12” sheaves to be shipped the same day.

Engineering sheave solutions is what we do best and what we do all day, every day. We respond to our customers immediately with technical answers and practical solutions. If we, on the rare occasion cannot provide you with the solution you are looking for we will point you to who can. Why? Because our customers are OUR number one priority!

Custom sheaves expressly designed to meet you exact requirements can usually be shipped within 2 to 4 weeks after receipt of your order. Quotations are usually delivered within 24 to 48 hours after receipt of your inquiry.

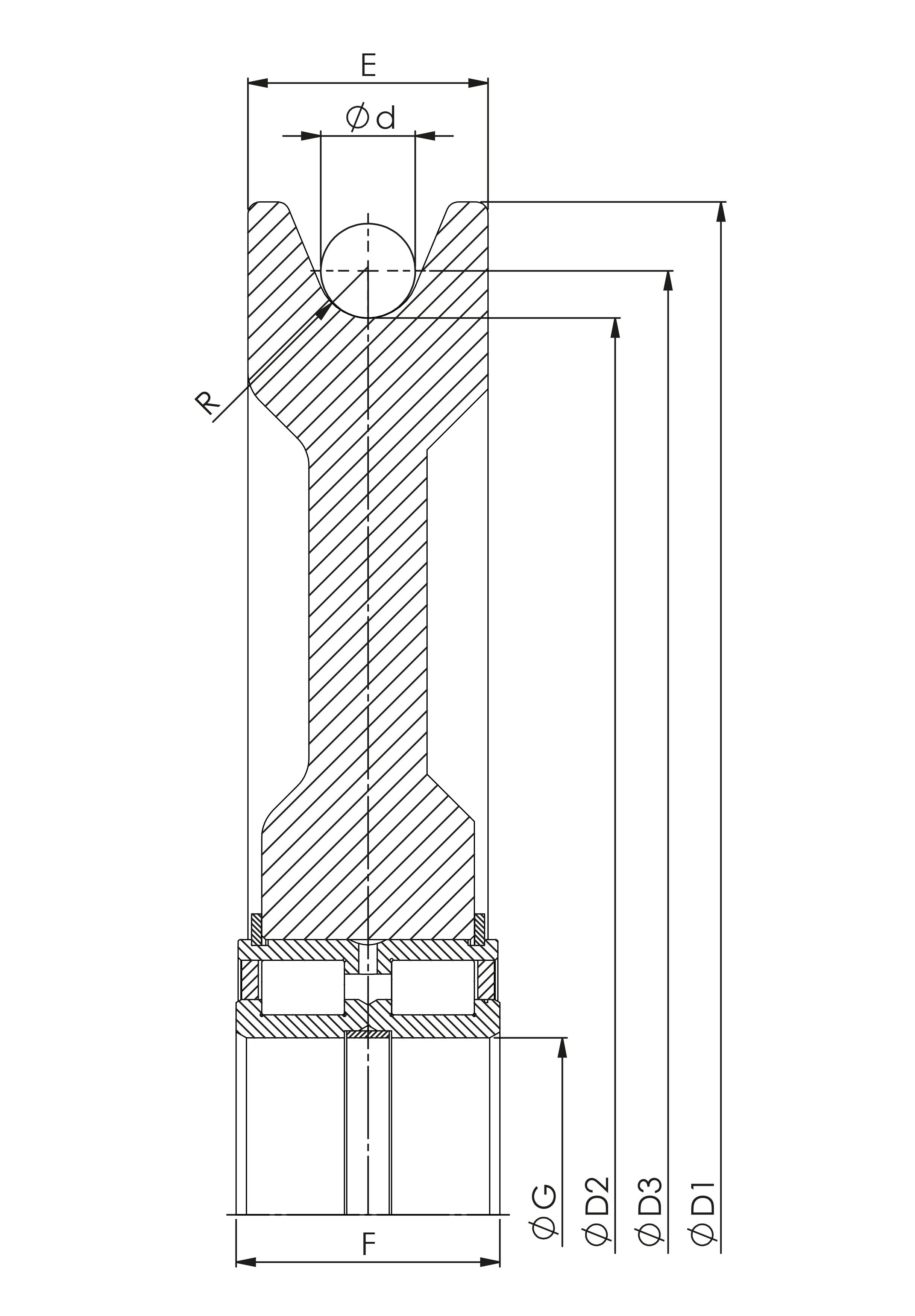

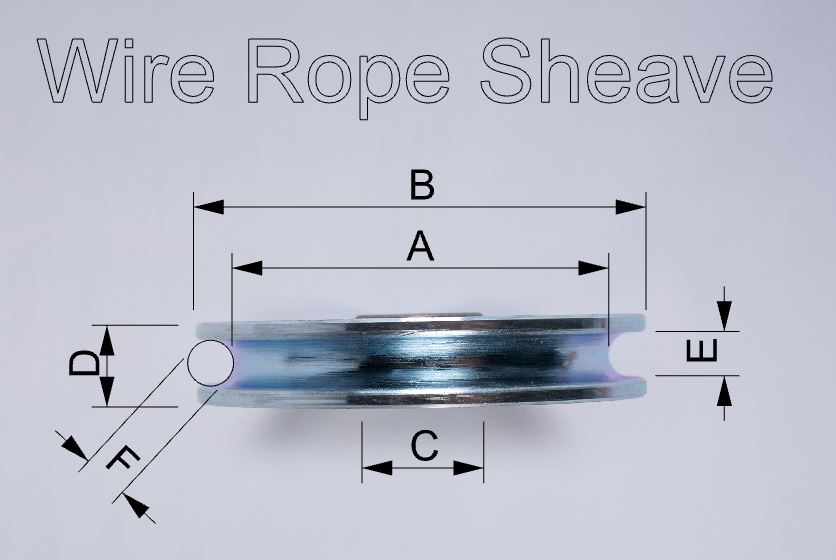

The custom sheave design process is relatively simple. You tell us which are the constraining parameters – OD, bending radius, weight, temperature, shaft diameter, etc – and we will propose solutions. Refer to our order form under the ‘Request Quotation’ link. We must have maximum product size and minimum bending radius (Root Diameter).

It is generally uneconomical to purchase fewer than ten identical sheaves due to engineering and setup costs. The simplest sheaves (and most sheaves) require three distinct CNC operations and each step requires programming and setup time.

Materials are purchased to requirements. Very small orders for one or two pieces are relatively expensive. For less than ten sheaves, it may be more economical to modify a stock sheave. Prices for thirty or more identical sheaves will often be comparable to stock sheaves of a similar size.

For custom processing sheaves of 22” OD or less, we prefer Gar-Dur, the densest and most abrasion-resistant UHMW-PE available commercially. It is available in a variety of sizes and shape from stock, generally yellow in color. We have been using it for 15 years and have experienced excellent results. Other materials we use are:

Composites such as carbon fiber are our newest development in sheave manufacturing. We have a technical collaboration with a leading aerospace manufacturer that promises to yield lightweight, strong, sheaves with excellent wear characteristics. We have seen weight savings of 50% with no compromise in expected performance.

Due to tooling costs, these sheaves are economical only if the ultimate requirements will be 100 or more. However, sheaves of 30″ OD and larger may be very cost competitive even in smaller quantities. As our experience grows, we will post some case studies on our web site to give you concrete examples or weight and cost advantages.

Our products can be statically or dynamically balanced to suit your requirements. Normally balancing is not required because precision machining of homogeneous materials produces inherently balanced finished sheaves, requiring no dynamic balancing for 1500 RPM and above.

Unique upset roll forging process provides a thicker groove section for extra strength.Stepped Hubs are precisely centered and mechanically locked in place.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This information is needed in order for usto be able to manufacture a sheave for you. If Bushings or Bearings are needed, please contact your distributor or the Renfroe factory and provide specific information. If you want us to quote and/or provide bearings, you must give us the bearing manufacturer name, and part numbers.

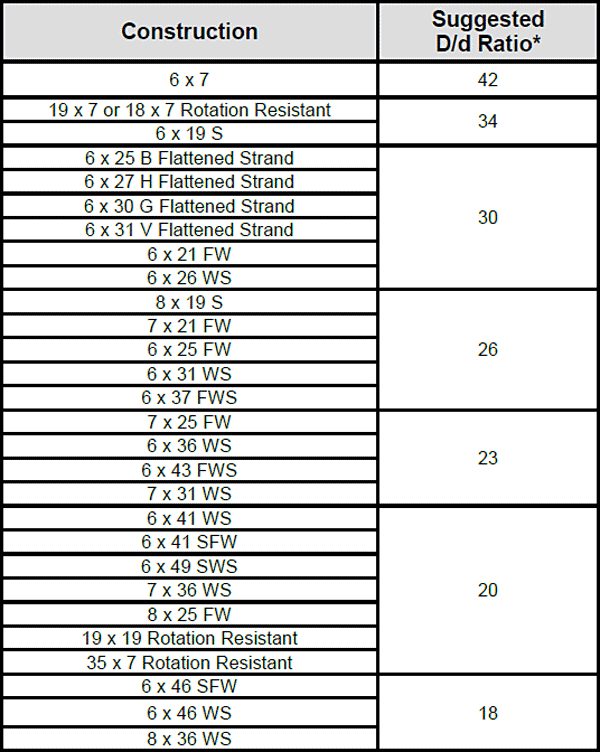

Multi-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next.

Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Python Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten rather quickly.

Selecting the right size for sheaves will help prevent frequent wire rope damage which in some instances occurs after just one run. Many common operational issues including the wireline getting dislodged or losing its strength are caused by improper sheave sizing and alignment problems. Our experts offer 3 valuable tips to eliminate stress failure, improve equipment safety and efficiency, as well as increase the lifespan of your sheaves and wire rope.

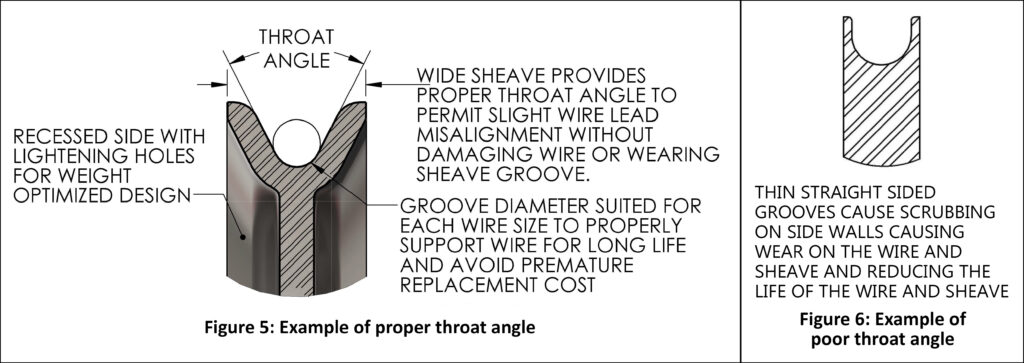

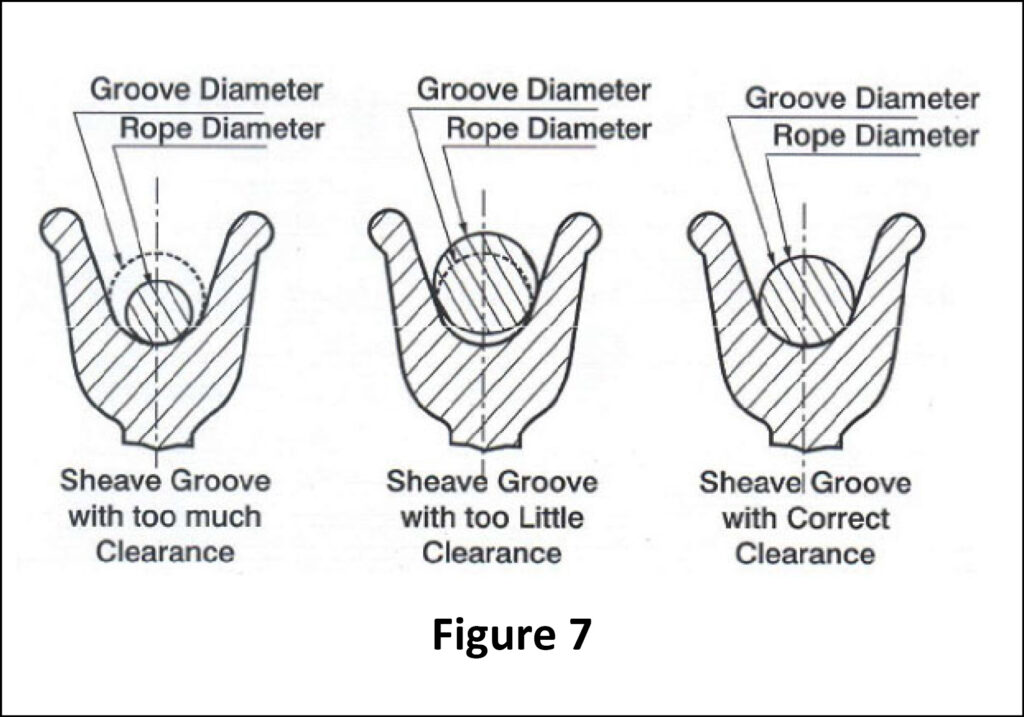

Pay attention to sheave groove size and diameter: When sheaves for your wire rope are too large or too small, there is greater stress on both resulting in spooling trouble and premature wear. For instance, grooves that are too large have proven to cause the wire rope to flatten and unbalance leading to the wire breaking. When properly sized, the groove provides maximum support to the rope lowering the sheave bearing pressure and increasing sheave and rope lifespan. Typically the groove diameter should exceed that of the wire rope by 5% while groove depth should be one-and-a-half times the rope diameter. A groove angle between 30° and 45° offers the best support for the wire rope. Specific dimensions and angles may vary depending on your application.

Ensure sheave groove hardness: The hardness of sheaves is a factor that is often overlooked. Since the wire rope is hard, the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To avoid this, ensure your steel cable sheaves are flame hardened. (A simple way to determine if your grooves are worn out is by using a sheave gauge.) At Rockett Inc., we can provide flame hardening for wear resistance along the contact area.

Correct sheave groove alignment: Poor alignment of your sheaves wears out the wire rope and sheave flange. This is because the rope comes into constant contact with the flange creating stress on the rope, abrasion damage and fatigue breaks. Any alignment issues should be corrected immediately.

To avoid operational problems, opt for custom made steel sheaves. This way the sheaves for your wire ropes are tailored to your specific requirements instead of the other way around. As an experienced sheave manufacturer with a state-of-the-art facility in Mississippi, Rockett Inc. offers comprehensive custom solutions for diverse industrial and commercial needs.

Should you have a specific requirement, our experienced engineers can work closely with you to design and manufacture the product your application requires. Precision engineering and state-of-the-art metal fabrication equipment result in a closer tolerance fit to the wire rope to reduce fatigue and wear. Inspection at every stage of our manufacturing process ensures that the final output meets your specifications.

Need assistance with designing sheaves for wire rope? We are always happy to help. Our team can work directly from your drawings and specifications, or offer 3D CAD design and engineering support optimized for practical, cost-effective results. Over the years, we have produced the most diverse range of custom steel cable sheaves for our clients across the globe. Having the ISO 9001:2008 Certification means we take pride in quality and customer satisfaction.

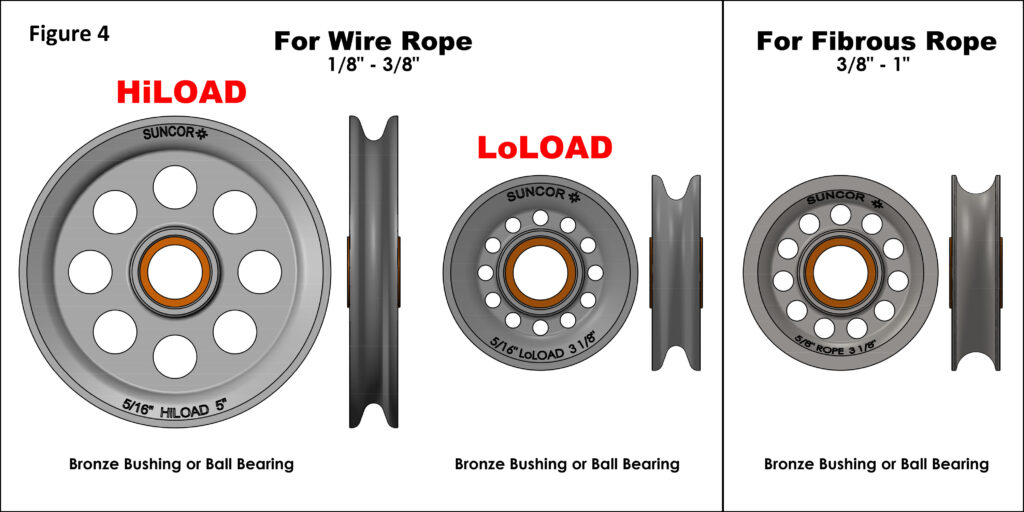

Sheaves are widely used throughout the industry for a variety of pulling and lifting functions. Sheaves are available in a variety of materials including steel, plastic, or stainless steel. There are many configurations available including HiLoad sheaves, LoLoad sheaves, fibrous rope sheaves, and wire rope sheaves. You can source sheaves with bearings or bushings and some sheaves come very specialized.

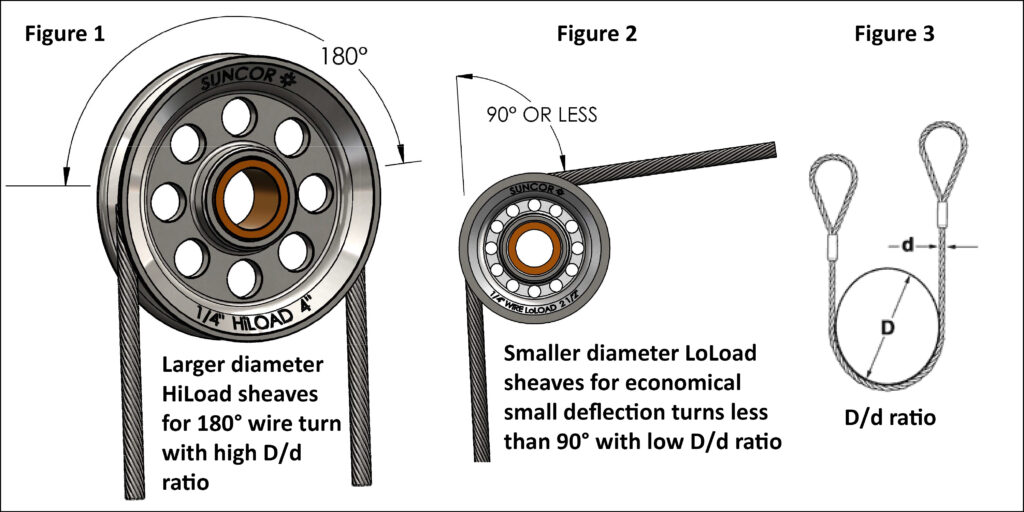

HiLOAD indicates a premium, larger diameter sheave suitable for 180° degree rope turns (see Figure 1) with a high D/d ratio, which is the ratio of the diameter around which the rope is bent, divided by the body diameter of the rope (see Figure 3). LoLOAD indicates a smaller diameter sheave designed for economical small deflection turns less than 90 degrees with a lower D/d ratio (see Figure 2).

Work load is important for both wire rope and fibrous rope sheaves, but work load limit (WLL) is critical with wire rope sheaves due to the comparative increased capacity of wire rope.

Quality sheaves should meet ASME B30.26-2610 and exceed the minimum 4:1 design factor. In most instances, the WLL for Suncor sheaves is significantly higher than comparable products and proof loads (or max WLL) are twice the WLL. Generally, twice the WLL of the wire represents the wire maximum load with a 180° wire wrap around the sheave.

A critical, and often overlooked area, is the wear exerted on the sheave during use. Throat angle, groove diameter, and sheave size are three significant factors of wear for sheaves. Sheaves are often designed with thin straight sided grooves which can cause scrubbing on the side walls and unnecessary wear on the rope and the sheave (see Figure 6). Suncor’s sheaves were designed with wide sheave grooves that provide a proper throat angle to permit slight rope lead misalignment without damaging the rope or wearing the sheave groove (see Figure 5).

The groove diameter is critical for proper wire rope support under load and has a significant effect on the overall safety and lifespan of the sheave and rope. If the sheave groove diameter has too much clearance, it will not support the rope properly leading to distortion, increased fatigue, failure, and costly repair. Conversely, if the sheave groove diameter has too little clearance the rope will not fit properly causing excessive wear and accelerated abrasion, which results in lost performance (see Figure 7).

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

We are renowned in the market as a dependable Rope Sheave Pulley Manufacturer. As we are a trusted Rope Sheave Pulley Manufacturer and Supplier, we have been offering the range in varied standard sizes. Wire Rope Sheave Wheels, offered by us, are designed as per the requisites of the clients in terms of size, configuration and surface finish condition. Manufactured from optimum quality cast iron, cast steel, carbon steel and alloy steel, our range assures long lasting life with high performance. They are perfect for lifting apparatus for heavy-duty overhead cranes. They are available with rope potation hardness including standard heat treatments.

Our team understands that choosing the right cable assembly manufacturer, and pulleys for your cable assemblies requires thoughtful consideration, from bearing life, to minimum pulley diameter. Let Sava"s engineering expertise guide you toward the best selection of wire rope pulley wheels.

When cable is used over pulleys, the cable life can be significantly prolonged by proper pulley groove design. Laboratory tests on wire rope pulleys prove that improper groove design reduces cable bending life up to 90%. These same tests show that doubling a pulley diameter can increase cable bending life up to thirteen times what is otherwise typical. Also, pulley diameters less than sixteen rope diameters fall into a range in which cable life is relatively low.

The life of steel cable pulleys is reduced as the groove radius changes from the contour of the cable to a flat surface. For maximum cable life, the groove should make contact with the cable on at least 1/3 of the cable circumference.

Sava has been manufacturing the pulleys the world depends upon for almost a half-century. Talk to Sava"s pulleys experts now and build it right the first time.

Stainless steel wire rope and sheave gauges for measuring worn sheave grooves on the end, together with a rope gauge on the shank. The gauges are produced in thick 18 gauge (0.05") Stainless Steel.Click here to Order

8613371530291

8613371530291