sheave design for wire rope factory

Selecting the right size for sheaves will help prevent frequent wire rope damage which in some instances occurs after just one run. Many common operational issues including the wireline getting dislodged or losing its strength are caused by improper sheave sizing and alignment problems. Our experts offer 3 valuable tips to eliminate stress failure, improve equipment safety and efficiency, as well as increase the lifespan of your sheaves and wire rope.

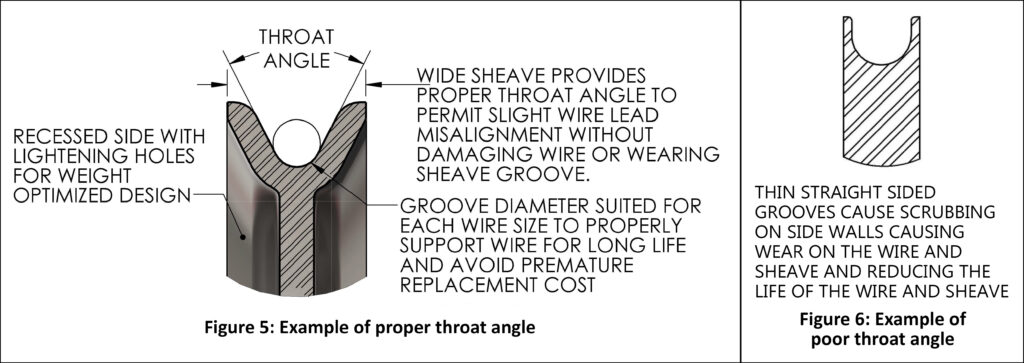

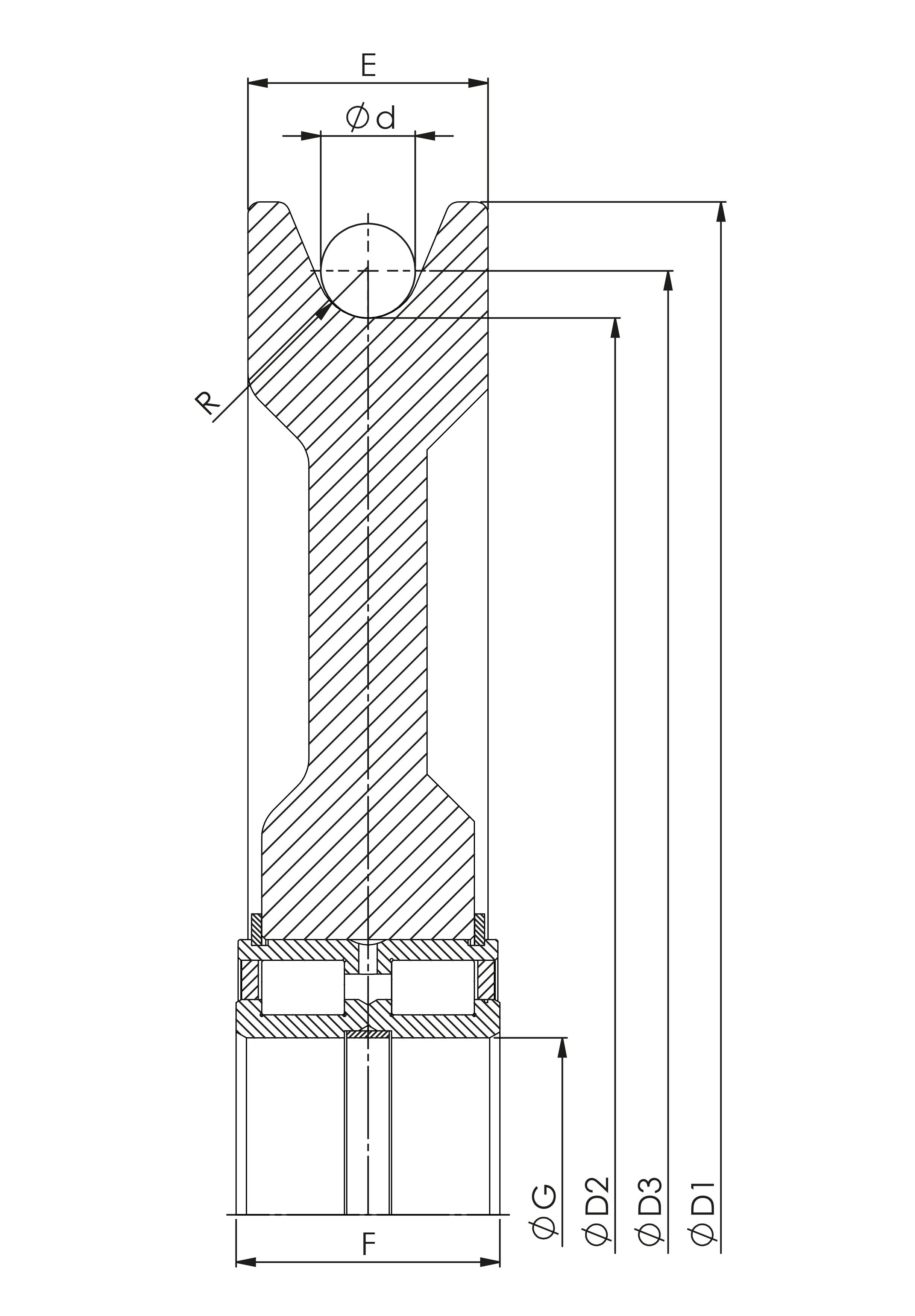

Pay attention to sheave groove size and diameter: When sheaves for your wire rope are too large or too small, there is greater stress on both resulting in spooling trouble and premature wear. For instance, grooves that are too large have proven to cause the wire rope to flatten and unbalance leading to the wire breaking. When properly sized, the groove provides maximum support to the rope lowering the sheave bearing pressure and increasing sheave and rope lifespan. Typically the groove diameter should exceed that of the wire rope by 5% while groove depth should be one-and-a-half times the rope diameter. A groove angle between 30° and 45° offers the best support for the wire rope. Specific dimensions and angles may vary depending on your application.

Ensure sheave groove hardness: The hardness of sheaves is a factor that is often overlooked. Since the wire rope is hard, the pressure it exerts on the groove can lead to corrugations if the sheave is not properly hardened. To avoid this, ensure your steel cable sheaves are flame hardened. (A simple way to determine if your grooves are worn out is by using a sheave gauge.) At Rockett Inc., we can provide flame hardening for wear resistance along the contact area.

Correct sheave groove alignment: Poor alignment of your sheaves wears out the wire rope and sheave flange. This is because the rope comes into constant contact with the flange creating stress on the rope, abrasion damage and fatigue breaks. Any alignment issues should be corrected immediately.

To avoid operational problems, opt for custom made steel sheaves. This way the sheaves for your wire ropes are tailored to your specific requirements instead of the other way around. As an experienced sheave manufacturer with a state-of-the-art facility in Mississippi, Rockett Inc. offers comprehensive custom solutions for diverse industrial and commercial needs.

Should you have a specific requirement, our experienced engineers can work closely with you to design and manufacture the product your application requires. Precision engineering and state-of-the-art metal fabrication equipment result in a closer tolerance fit to the wire rope to reduce fatigue and wear. Inspection at every stage of our manufacturing process ensures that the final output meets your specifications.

Need assistance with designing sheaves for wire rope? We are always happy to help. Our team can work directly from your drawings and specifications, or offer 3D CAD design and engineering support optimized for practical, cost-effective results. Over the years, we have produced the most diverse range of custom steel cable sheaves for our clients across the globe. Having the ISO 9001:2008 Certification means we take pride in quality and customer satisfaction.

Generally, we recommend grooved drums only. The rope is spooled properly and positively. Depending on the drum/rope diameter relationship helix-grooved drums can be used for up to 3 layers without excessive rope wear. For applications with more than 3 layers (e.g. Mobile cranes) we recommend ‘Lebus’ grooving.

It has to be remembered, however, that rope service life on multiple layer drum systems will always only be a fraction of that compared with single layer helix-grooved drums.

If these values are applied to single layer grooved drums the maximum permissible rope-deflection angle for regular wire rope constructions is 4°. For non rotating /rotation-resistant ropes the maximum permissible deflection angle is 1.5° only.

Multi-layer drum systems should use strand- or swage compacted Python® rope constructions having a steel core. The higher fill factor of such rope constructions will offer a greater resistance to crushing and flattening than conventional rope types. This is particularly important for boom hoist ropes on lattice boom cranes at the cross over point from one rope winding to the next.

Cranes equipped with multi-layer drum systems which require rotation-resistant or non-rotating rope are best served with Python Compac® 18 and Compac® 35. To further reduce drum crushing have the rope layers wound onto the drum with about 5-10% of the WLL and avoid that the first layer unspools and re-spools without tension. This would cause a ‘soft’ bottom layer which will flatten the rope.

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

Above all else, we are an engineering firm that can take your technical requirements for sheaves and translate them into cost effective solutions to meet or exceed the performance required of your application. For over fifteen years now, Sheaves Inc. has been the number one source for the wire-rope industry, designing and providing QSheaves™, alongside othercustom engineered wire rope sheavesthat meet your specific needs and rigors of your application. We also supply a large inventory of stock sheaves from thebest known brands in the industry. Contact ustoday or send a request for quotation, and our engineering team will work alongside you to find your custom pulley solution.

Want a sheave system to solve your design problem? Our expertise is based on decades of engineering and supplying leading manufacturers, from the simplest applications to the most demanding. We’ve supplied sheaves for both recreational and large commercial boat lifts, to military applications. No problem is too big for us, and no solution is too small for a consultation.

Esheaves.com offers custom solutions engineered to meet the exact requirements of your application. From the strength and durability of a nylon sheave, to the rapid shipping and stock availability of QSheaves™, we will help you meet any challenge. If our customizable options don’t measure up, we’ll engineer a complete, original solution just for you!

Need an individualized application solution?EShevaes.com is the trusted team of sheave engineers you can turn to. Find additional information about our customization options below. Ready to start a Custom Pulley Project? Visit our Custom Sheave Project page by clicking the link below

Contact us with your sheave requirements before freezing your equipment designs. We can offer a better sheave at a lower cost in many cases if we are consulting early in the design stage. Many times a modification of our QSheaves™ is the economical choice when certain design parameters preclude use of an off-the-shelf sheave. Even fully custom pulleys can be quite economical when the right decisions are made on materials and designs. Put our experience to use for your business.

Many applications, particularly in wire rope sheaves and in wire & cable processing, have design constraints that can’t be met by stock sheaves from us or other suppliers. In recent years, Process Sheaves LLC has developed over 300 custom engineered sheaves to meet critical customer parameters. We welcome the opportunity to work with you to achieve the most economical solution for your particular situation.

We pride ourselves on our quality products and excellent customer service, as well as our continual desire to look for innovative ways to meet your needs; achieved, for example, in our patented line of steel sheaves that allow us to provide an extensive range of 6” to 12” sheaves to be shipped the same day.

Engineering sheave solutions is what we do best and what we do all day, every day. We respond to our customers immediately with technical answers and practical solutions. If we, on the rare occasion cannot provide you with the solution you are looking for we will point you to who can. Why? Because our customers are OUR number one priority!

Custom sheaves expressly designed to meet you exact requirements can usually be shipped within 2 to 4 weeks after receipt of your order. Quotations are usually delivered within 24 to 48 hours after receipt of your inquiry.

The custom sheave design process is relatively simple. You tell us which are the constraining parameters – OD, bending radius, weight, temperature, shaft diameter, etc – and we will propose solutions. Refer to our order form under the ‘Request Quotation’ link. We must have maximum product size and minimum bending radius (Root Diameter).

It is generally uneconomical to purchase fewer than ten identical sheaves due to engineering and setup costs. The simplest sheaves (and most sheaves) require three distinct CNC operations and each step requires programming and setup time.

Materials are purchased to requirements. Very small orders for one or two pieces are relatively expensive. For less than ten sheaves, it may be more economical to modify a stock sheave. Prices for thirty or more identical sheaves will often be comparable to stock sheaves of a similar size.

For custom processing sheaves of 22” OD or less, we prefer Gar-Dur, the densest and most abrasion-resistant UHMW-PE available commercially. It is available in a variety of sizes and shape from stock, generally yellow in color. We have been using it for 15 years and have experienced excellent results. Other materials we use are:

Composites such as carbon fiber are our newest development in sheave manufacturing. We have a technical collaboration with a leading aerospace manufacturer that promises to yield lightweight, strong, sheaves with excellent wear characteristics. We have seen weight savings of 50% with no compromise in expected performance.

Due to tooling costs, these sheaves are economical only if the ultimate requirements will be 100 or more. However, sheaves of 30″ OD and larger may be very cost competitive even in smaller quantities. As our experience grows, we will post some case studies on our web site to give you concrete examples or weight and cost advantages.

Our products can be statically or dynamically balanced to suit your requirements. Normally balancing is not required because precision machining of homogeneous materials produces inherently balanced finished sheaves, requiring no dynamic balancing for 1500 RPM and above.

This information is needed in order for usto be able to manufacture a sheave for you. If Bushings or Bearings are needed, please contact your distributor or the Renfroe factory and provide specific information. If you want us to quote and/or provide bearings, you must give us the bearing manufacturer name, and part numbers.

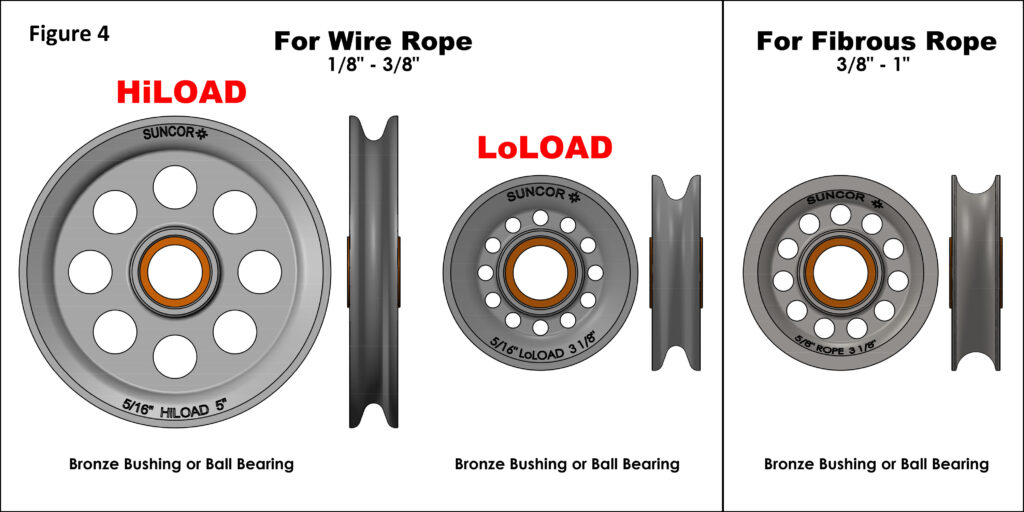

Sheaves are widely used throughout the industry for a variety of pulling and lifting functions. Sheaves are available in a variety of materials including steel, plastic, or stainless steel. There are many configurations available including HiLoad sheaves, LoLoad sheaves, fibrous rope sheaves, and wire rope sheaves. You can source sheaves with bearings or bushings and some sheaves come very specialized.

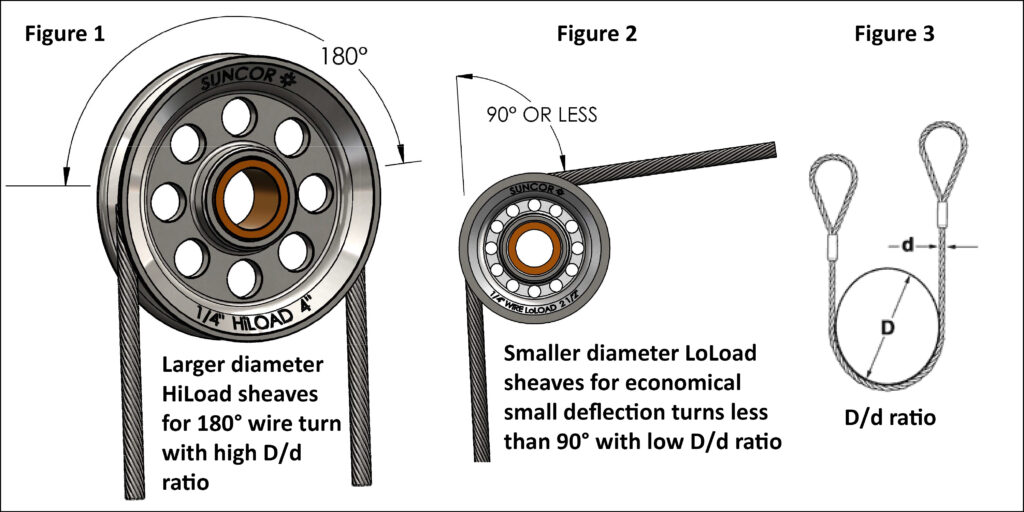

HiLOAD indicates a premium, larger diameter sheave suitable for 180° degree rope turns (see Figure 1) with a high D/d ratio, which is the ratio of the diameter around which the rope is bent, divided by the body diameter of the rope (see Figure 3). LoLOAD indicates a smaller diameter sheave designed for economical small deflection turns less than 90 degrees with a lower D/d ratio (see Figure 2).

Work load is important for both wire rope and fibrous rope sheaves, but work load limit (WLL) is critical with wire rope sheaves due to the comparative increased capacity of wire rope.

Quality sheaves should meet ASME B30.26-2610 and exceed the minimum 4:1 design factor. In most instances, the WLL for Suncor sheaves is significantly higher than comparable products and proof loads (or max WLL) are twice the WLL. Generally, twice the WLL of the wire represents the wire maximum load with a 180° wire wrap around the sheave.

A critical, and often overlooked area, is the wear exerted on the sheave during use. Throat angle, groove diameter, and sheave size are three significant factors of wear for sheaves. Sheaves are often designed with thin straight sided grooves which can cause scrubbing on the side walls and unnecessary wear on the rope and the sheave (see Figure 6). Suncor’s sheaves were designed with wide sheave grooves that provide a proper throat angle to permit slight rope lead misalignment without damaging the rope or wearing the sheave groove (see Figure 5).

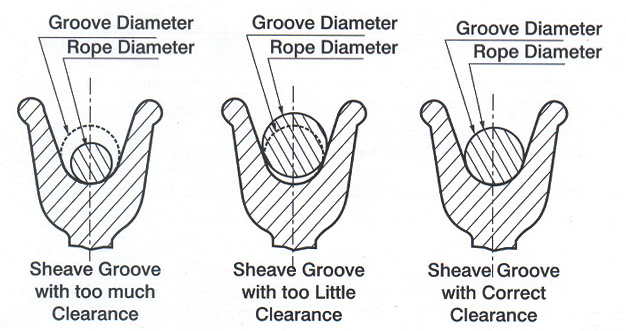

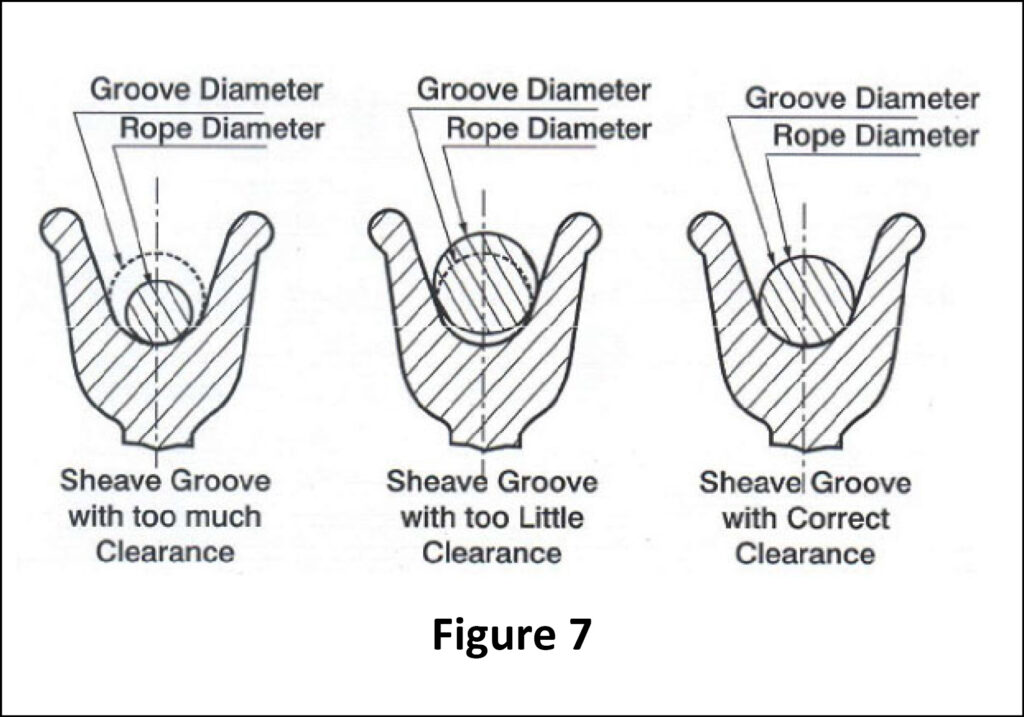

The groove diameter is critical for proper wire rope support under load and has a significant effect on the overall safety and lifespan of the sheave and rope. If the sheave groove diameter has too much clearance, it will not support the rope properly leading to distortion, increased fatigue, failure, and costly repair. Conversely, if the sheave groove diameter has too little clearance the rope will not fit properly causing excessive wear and accelerated abrasion, which results in lost performance (see Figure 7).

While sheaves may be a relatively small piece of hardware, they play a crucial part in mechanical engineering and lifting equipment. They are used in tandem with a rope, belt, or cable to lift items with a crane.

Essentially, a sheave is a wheel with an open groove that a rope or cable fits around so it can rotate around the exterior. One end of the cable is attached to an item that needs to be moved, while the other is attached to a fixed object, like the base of a crane. The cable smoothly moves over the wheel of the sheave as it is wound up on the fixed object, lifting the other object into the air.

Sheaves are also commonly known as pulleys, and when two or more pulleys are used together for extra strength, this is known as a sheave block. Rope pulleys were actually used as far back as the 1500s in order to hoist water out of wells, and they were likely used to lift and move heavy rocks that created Stonehenge in the UK.

Over the centuries, the overall design of sheave blocks has really not changed too much. These days, they are typically made with an alloy mix of iron and steel. Some models also add carbon and silicon for extra durability.

You certainly want to purchase a sheave block that is durable and strong enough for whatever task you will be using it on. You also want to look out for a sheave with a smooth radius to reduce friction between the pulley metal and the cable or rope. It is also best to buy a sheave with rounded outside diameters as any sharp corners could damage or wear down the rope as it slides over the pulley.

Finally, look for a sheave that has a thicker base and thinner side grooves. This provides better support while allowing the cable to move smoothly over the top.

Now, if you are in the market for lifting gear supplies, you may be a bit overwhelmed with the options available. There are lots of types and styles – and some are better for specific jobs than others.

A bearing is an axle inside of the pulley which helps to minimize friction as the cable or rope moves back and forth within the sheave block. There are several different types of bearings that are used for different applications.

There are also different shapes and styles of the grooves within the sheaves. These different styles are made to accommodate different types of ropes or cables, and it is best to choose a groove size that is 5% to 10% wider than the diameter of the rope used.

It is also very important to keep tabs on the groove’s wear and tear. Over time, it can wear down, especially if they are used with wire rope products – which cause additional abrasions. Excessive wear can break down ropes and cables much quicker.

There are also different shape styles of grooves. U-shared profiles are best for use with ropes since it prevents any pinching and allows the rounded shape to glide smoothly. V-shaped profiles are best for wire slings and cables.

As the name implies, normal duty sheaves are designed for moderate weight loads and “normal” duty applications. These sheaves are available in 76mm through 406mm (3” to 16”) wide sheaves and are often protected with sheave guards so the rope or wire being used stays in place.

There are five distinct types of bearing options on normal duty sheaves. Bearings are smaller circular pieces of metal that fit inside of the pulley to help it rotate.

Self-lubricating bronze bushings are best for pulleys that are difficult to reach for re-lubrication and are often best at low speed, intermittent operations.

Straight roller bearings are optimal for medium loads and high-speed operations. Regular lubrication is required, especially if it is in continuous operation.

Tapered roller bearings are designed for heavy loads and high-speed, uninterrupted operation. These do require regular lubrication, particularly if they are in continuous use.

Normal duty sheaves are made from machined ductile iron, which offers distinct advantages over other types of metals –, particularly steel. Ductile iron has a higher silicon content, which offers it more machinability and will often last longer than tools made of steel.

Heavy-duty sheave blocks are best for heavy-duty applications with thicker ropes and cables and heavier weight bearings. They are available in 102 mm through 305 mm (4” through 12”), and are often used in work environments where the sheave block will be operating continuously.

Heavy-duty sheaves use closed die forging, which means that the hot metal is poured on dies (or molds) and forged into particular shapes. This helps to strengthen the shape of the tool since it does not need to be welded together in multiple pieces.

Domed sheaves are reinforced for extreme duty applications. These sheave blocks are welded in a circular pattern, which reduces additional stresses made by welding ribs. Domed sheaves are also the largest and are available in 610 mm (24”) and larger sizes.

Domed sheave blocks have the greatest strength and rigidity of all sheave types and are made for applications with high working stress, heavy loads, and continuous operation.

Choosing the right equipment for the job at hand will always ensure that the task will be easier and most likely more successful. Sheave blocks play a crucial role in numerous types of applications, and they can make it possible to do anything from hoisting up a sail to moving large pieces of machinery from one point to the other.

If you have any further questions regarding sheave blocks, their applications, and which style or size you need to, please reach out to us at Hollow Houston Inc. Our team of experts can help you find the correct pieces of equipment for your specific applications.

The Crosby Group has a long history of delivering quality products and innovative processes through the years. In 1978, Crosby, with the partnership of McKissick, invented the roll forged sheave. When it comes to sheave design and manufacturing processes, Crosby is still the leader in the industry, with sheave centers across the world that focus on providing products for each local market. Locations include Putte, Belgium; Singapore; Hangzhou China; and Tulsa, Oklahoma (USA).

Not only does Crosby stock key materials, it has the manufacturing capacity to provide short deliveries, as well as operational and technical support. This enables every team to learn more about the product and material they will be handling. Crosby offers roll forged sheaves that provide an upset meta flow without creating a stress zone at the splitting point. The dome-reinforced sheave design provides for a continuous weld in a circular pattern.

Sheaves produced come in: 30, 35, and 45-degree profiles. The McKissick roll-forged sheave is available in the following: plain bore, bronze bushed, roller bearing, tapered roller bearing, lubrication thru hub, key ways, set screws, full complement bearing.

All products have been tested for underwater and hard environment uses, giving the client confidence in using sheaves for all applications. In addition, Crosby has achieved API Q and TS29001 statues and are licensed to manufacture sheaves to API 8C and provide to API, DNVA, and ABS requirements.

Crosby Roll-Forged Sheaves have a reputation of reliability you can depend on. First, teams must know which type of sheave needs to be used on the job. The type of project, duration, and environment all determine the type of sheaves that is required, as well as the maintenance schedule for the product.

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

The guideline to follow is this: the most practical design is the one that most closely accommodates the limiting factors imposed by the equipment, the operating conditions and the wire rope.

All wire ropes operating over sheaves and drums are subjected to cyclic bending stresses, thus the rope wires will eventually fatigue. The magnitude of these stresses depends—all other factors being constant—upon the ratio of the diameter of the sheave or drum to the diameter of the rope.

Frequently, fatigue from cyclic, high-magnitude bending stress is a principal reason for shortened rope service. In order for a rope to bend around a sheave, the rope’s strands and wires must move relative to one another. This movement compensates for the difference in diameter between the underside and the top side of the rope, the distance being greater along the top side than it is on the underside next to the groove.

Proper rope movement (and service) is adversely affected if the wires cannot adjust to compensate for this length differential. Also, there can be additional limitations to wire movement because of excessive pressure caused by a sheave groove diameter which is too small, or by lack of rope lubrication. Avoid changing the bending direction from one sheave to another as this reverse bending further accelerates wire fatigue.

The relationship between sheave diameter and rope diameter is a critical factor that is used to estimate the rope’s fatigue resistance or relative service life. It is expressed in the D/d ratio mentioned earlier in which D is the pitch diameter of the sheave and d is the diameter of the rope. Table 1 lists suggested minimum D/d values for various rope constructions. Smaller values can affect rope life. Table 2 (on next page) shows the effect of rope construction and D/d on service life.

These D/d ratios are based on sheave and drum diameters being approximately 400 times the outer wire diameter of the rope. For rope constructions not listed, consult your Lifting Specialist.

A new wire rope requires careful installation and following all the appropriate guidelines previously noted. After the rope is installed and the ends secured in the correct manner, the equipment should be started carefully and then permitted to run through a cycle of operation at very slow speed.

During this trial operation, closely watch all working parts—sheaves, drums, rollers—to make certain that the rope runs freely, and without any possible obstructions as it makes its way through the system. If no problems appear in running the rope, the next step should include several repetitions of the normal operational cycle under increasing loads and speeds.

This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions. Taking the time and effort to perform these breaking-in procedures should result in obtaining the optimum service life from the wire rope.

This service life curve only takes into account bending and tensile stresses. This curve can be utilized to predict comparative service life of a specific wire rope with varying D/d ratios.

That resultant comparison is illustrated by the following example: A rope working with a D/d ratio of 26 has a relative service life of 17. If the same rope works over a sheave that increases its D/d ratio to 35, the relative service life increases to 32.

The depth of groove should be selected so that the rope does not rub against the flange of the sheave or each other while entering running or leaving the groove. Angle of circular arc of the bottom of groove should not be less than 120 Degrees.

The grooves on the drum should be pitched so that there is clearance between neighboring turns of rope on that drum. The recommended clearances are 1.5 mm up to rope diameter of 28 mm and 3 mm for rope diameter above 28 mm.

The groove diameter of the pulley or sheave should always be larger then actual diameter of the rope. But if the groove diameter is too large the rope will tend to flatten and if it is too small pinching or rope will take place. The correct positioning is explained as under along with the tolerance and clearances on pully or sheave groove diameters.

8613371530291

8613371530291