sheave design for wire rope in stock

Esheaves offers the Wire Rope sheave solution to tackle any challenge you face. From strength, to availability, to like -for- like replacement, there is no heavy duty sheave application we can’t assist you with. If you need assistance selecting the best solution for your project, contact us directly to speak to a member of our knowledgeable engineering staff.

Strongman Sheaves are fully customizable steel wire rope sheaves, shipped to you in a matter of weeks from design completion. There is no need to modify existing equipment to make replacement sheaves fit, or to compromise new designs to fit a ‘catalog’ sheave. With Strongman Sheaves, you get experienced sheave engineers answering your inquiry and processing your request. Withdecades of manufacturing experience, wire rope and sheave industry experts, and a wide variety of styles andmaterialsto choose from, you can feel secure choosing Strongman Sheaves for your next project.

Manufacturing sheaves for wire rope is our primary business. We have the capability to manufacture your sheaves to your design and specifications or you can choose your wire rope sheave from our large inventory.

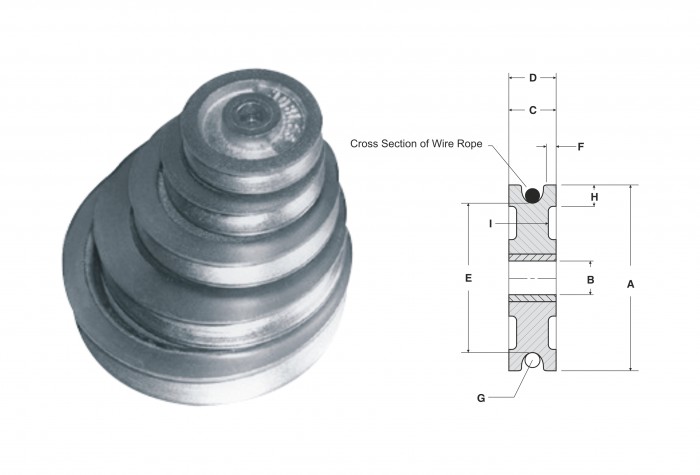

Our wire rope sheaves are made from quality materials and machined to precise dimensions and tolerances in order to meet our high standards. In addition, we offer many other options to satisfy your sheave requirements, including choice of material, heat treating of the groove, case hardening, grease fittings, keyways and set screws, plating and many more. We also carry bearings and bronze bushings.

Choose from our stock sheave sizes or we can manufacture your wire rope sheaves to your design and specifications. SELECTING FROM OUR STOCK SIZES OFFERS YOU QUICKER DELIVERY AND ECONOMY, or we can stock for your ongoing requirements. Please complete this form and we will gladly quote.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Precision CNC machining, turning and milling services. Capabilities include bending, waterjet cutting, routing, forming, drilling, casting, urethane molding, additive manufacturing (3D printing) and welding. Works with rubber, polyurethane, nylon, acetal, polycarbonate, acrylic, fiberglass reinforced plastics (FRP), laminates, PVC and other plastic materials. Manufacturer of custom and standard truck parts, bumpers, gaskets, seals, bushings, trays, anti-vibration or manifold grommets, caps and vibration mounts. Bearings, sheaves, pulleys, channels, nozzles, profiles, sprockets, outrigger pads, strip doors, elbows, rollers, matting, barriers, ceramic and truck liners are provided. Prototypes, short and high runs production volumes are offered. Materials are available in the form of sheets, tubes and rods. Serves agricultural, aggregate, biomass, construction, marine, port, material handling, mining, oil, gas, retail, transportation, automotive, food and beverage industries.

Sheaves, drums and rollers must be of a correct design if optimum service is to be obtained from both the equipment and the wire rope. Because there are many different types of equipment and many different operating conditions, it is difficult to identify the one specific size of sheave or drum most appropriate for every application.

The guideline to follow is this: the most practical design is the one that most closely accommodates the limiting factors imposed by the equipment, the operating conditions and the wire rope.

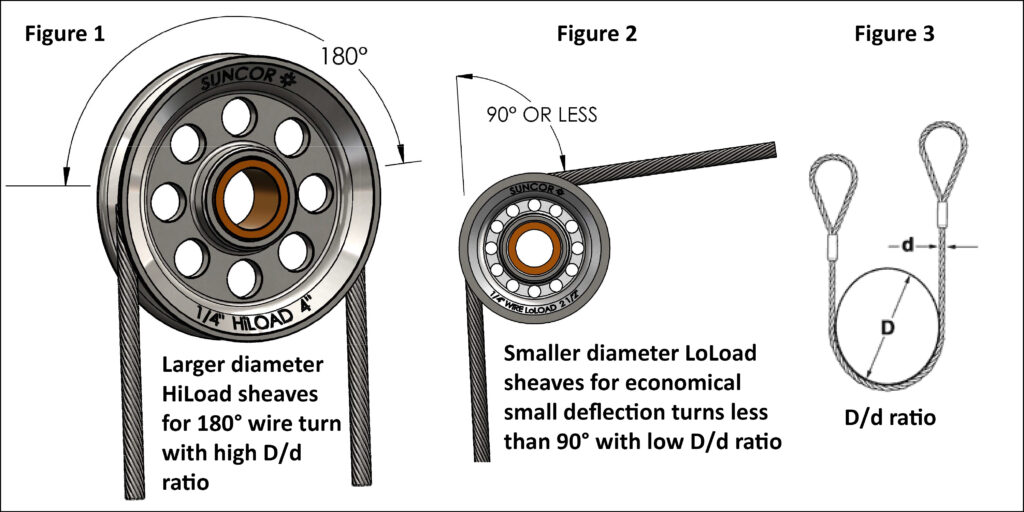

All wire ropes operating over sheaves and drums are subjected to cyclic bending stresses, thus the rope wires will eventually fatigue. The magnitude of these stresses depends—all other factors being constant—upon the ratio of the diameter of the sheave or drum to the diameter of the rope.

Frequently, fatigue from cyclic, high-magnitude bending stress is a principal reason for shortened rope service. In order for a rope to bend around a sheave, the rope’s strands and wires must move relative to one another. This movement compensates for the difference in diameter between the underside and the top side of the rope, the distance being greater along the top side than it is on the underside next to the groove.

Proper rope movement (and service) is adversely affected if the wires cannot adjust to compensate for this length differential. Also, there can be additional limitations to wire movement because of excessive pressure caused by a sheave groove diameter which is too small, or by lack of rope lubrication. Avoid changing the bending direction from one sheave to another as this reverse bending further accelerates wire fatigue.

The relationship between sheave diameter and rope diameter is a critical factor that is used to estimate the rope’s fatigue resistance or relative service life. It is expressed in the D/d ratio mentioned earlier in which D is the pitch diameter of the sheave and d is the diameter of the rope. Table 1 lists suggested minimum D/d values for various rope constructions. Smaller values can affect rope life. Table 2 (on next page) shows the effect of rope construction and D/d on service life.

These D/d ratios are based on sheave and drum diameters being approximately 400 times the outer wire diameter of the rope. For rope constructions not listed, consult your Lifting Specialist.

A new wire rope requires careful installation and following all the appropriate guidelines previously noted. After the rope is installed and the ends secured in the correct manner, the equipment should be started carefully and then permitted to run through a cycle of operation at very slow speed.

During this trial operation, closely watch all working parts—sheaves, drums, rollers—to make certain that the rope runs freely, and without any possible obstructions as it makes its way through the system. If no problems appear in running the rope, the next step should include several repetitions of the normal operational cycle under increasing loads and speeds.

This procedure allows the component parts of the new rope to make a gradual adjustment to the actual operating conditions. Taking the time and effort to perform these breaking-in procedures should result in obtaining the optimum service life from the wire rope.

This service life curve only takes into account bending and tensile stresses. This curve can be utilized to predict comparative service life of a specific wire rope with varying D/d ratios.

That resultant comparison is illustrated by the following example: A rope working with a D/d ratio of 26 has a relative service life of 17. If the same rope works over a sheave that increases its D/d ratio to 35, the relative service life increases to 32.

The Crosby Group has a long history of delivering quality products and innovative processes through the years. In 1978, Crosby, with the partnership of McKissick, invented the roll forged sheave. When it comes to sheave design and manufacturing processes, Crosby is still the leader in the industry, with sheave centers across the world that focus on providing products for each local market. Locations include Putte, Belgium; Singapore; Hangzhou China; and Tulsa, Oklahoma (USA).

Not only does Crosby stock key materials, it has the manufacturing capacity to provide short deliveries, as well as operational and technical support. This enables every team to learn more about the product and material they will be handling. Crosby offers roll forged sheaves that provide an upset meta flow without creating a stress zone at the splitting point. The dome-reinforced sheave design provides for a continuous weld in a circular pattern.

Sheaves produced come in: 30, 35, and 45-degree profiles. The McKissick roll-forged sheave is available in the following: plain bore, bronze bushed, roller bearing, tapered roller bearing, lubrication thru hub, key ways, set screws, full complement bearing.

All products have been tested for underwater and hard environment uses, giving the client confidence in using sheaves for all applications. In addition, Crosby has achieved API Q and TS29001 statues and are licensed to manufacture sheaves to API 8C and provide to API, DNVA, and ABS requirements.

Crosby Roll-Forged Sheaves have a reputation of reliability you can depend on. First, teams must know which type of sheave needs to be used on the job. The type of project, duration, and environment all determine the type of sheaves that is required, as well as the maintenance schedule for the product.

Canbear Equipment Inc. offers various sheave types/styles that are stocked and manufactured from several material choices such as nylon, aluminum, and stainless steel.

We will gladly stock your item for your ongoing needs. We have many years of experience in supplying of stock and custom made wire rope sheaves. We have seen it all.

Would you like to keep abreast of what Ropeblock is up to regarding product development, new additions to the product range, interesting projects, international trade fairs − or Smart Engineering in general? Just subscribe to our newsletter, so you won’t miss a thing.

Manufacturers can make heavy-duty cable pulleysfor mechanical cables with a variety of materials, such as steel and industrial plastics. Steel pulleys can be made of plated, carbon steel and stainless steel, while the plastic materials used to make customized solid pulleys, include Delrin, nylon, PEEK and Teflon. In addition to the material comprising the pulley, cable manufacturing designers must also consider its diameter when selecting a pulley for a particular application. If you need an aircraft cable pulley, the specifications required will be much different than if your operations needed a medical cable pulley. Below are three important factors to consider.

A smaller mechanical cable pulley requires the cable to make a sharper bend, thus increasing the bending stress with which the cable is subjected. Larger stainless steel cables, and cables of other material will experience greater stresses when passing over the same round belt pulley as a smaller cable, all other factors being equal. Each application, therefore, has a wire rope pulley specification based on the size and construction of the mechanical cable.

Cables are constructed of a number of strands wrapped around each other, which are themselves composed of a number of individual wires. Cable construction is, therefore, a function of the number of strands per cable and the number of wires per strand. Its design is typically expressed as a x b, where a is the number of strands per cable and b is the number of wires per strand.

Both the cable diameter and its construction determine the size of the pulley appropriate for the application. Industry testing over the years has created recommended minimum groove diameters to be used with various cable constructions. For example, the groove diameter of a pulley for a 7x19 cable should be at least 25 times the diameter of the cable. Similarly, a 7x7 cable should use a pulley with a groove diameter at least 40 times that of the cable, while a 7x49 would be recommended at 15 times the diameter of the cable. In general the more flexible the cable, the smaller the recommended groove diameter would be to maximize the cable life.

The primary tradeoff in pulley size is that a smaller pulley will wear out the cable faster, while a larger pulley may be too big for that application. Since the remaining disadvantage of using a pulley greater than the recommended size deal largely in costs, designers should use the largest size pulley that will fit that particular application. In practice, this means that most pulleys are still too small. Too often designers allow insufficient space for properly sized pulley selection, which will limit the cable’s lifespan.

When possible, selection of pulleys and cables should involve avoiding metal-to-metal contact, because such combinations will lead to premature cable failure due to abrasion. Extruded, or coated, cable should be used in applications with metal pulleys, while plastic pulleys may be used with bare cable. Of course, these guidelines are established to maximize cable life. If a given application does not require high cycle counts, such applications are afforded more deviations from conventional rules.

Browse Sava’s wire rope and pulley catalog, which contains small cables as well as fittings, pulleys and tools. Sava also provides engineering and sales expertise to meet all your mechanical cable needs. Contact us today!

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Miller Lifting Products offers high quality lifting and rigging components for the energy, construction, communications, manufacturing, maritime, military and other industrial sectors.

8613371530291

8613371530291