skf wire rope lubricator price pricelist

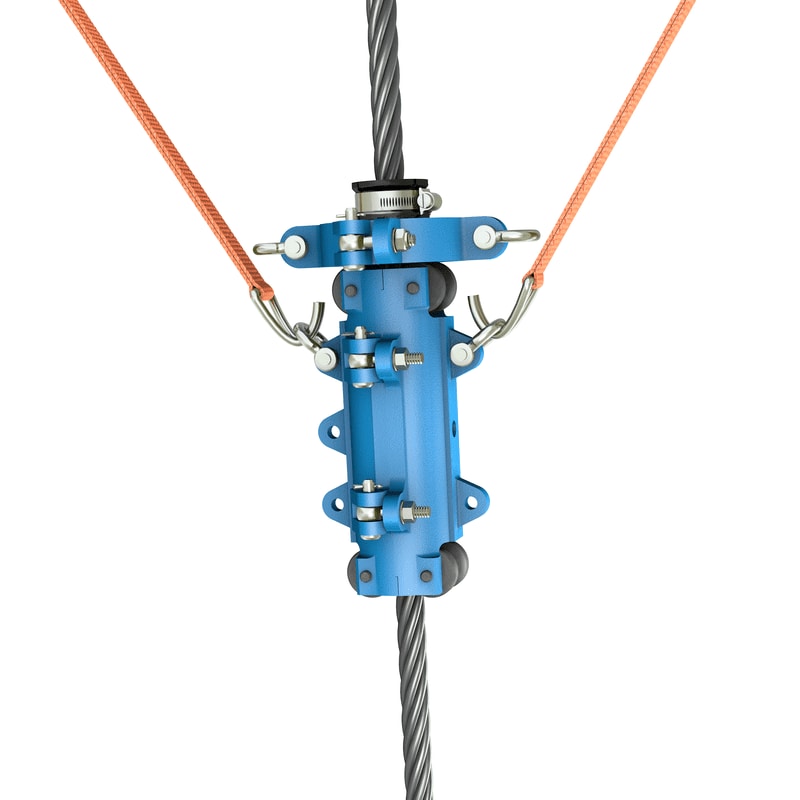

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Beneits of wire rope lubrication Groove cleaner advantages The use of lubricant on a steel wire rope considerably reduces friction and, as a result, it minimizes the following two related factors: Regular lubrication helps to increase the lifetime of a steel wire rope signiicantly compared to a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general. The...

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste. Advantages: • Fast and eficient – reduces lubrication time by up to 90% vs. manual lubrication • Increases operator safety • Easy to use with any wire rope up to 2 in (52 mm) • Helps to prevent corrosion • Protects the wire ropes...

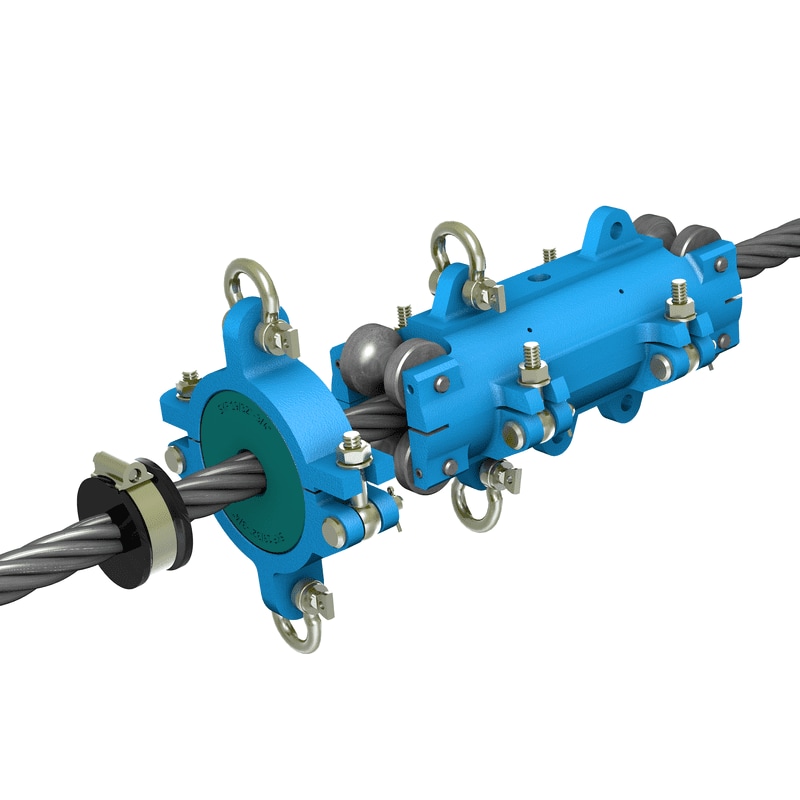

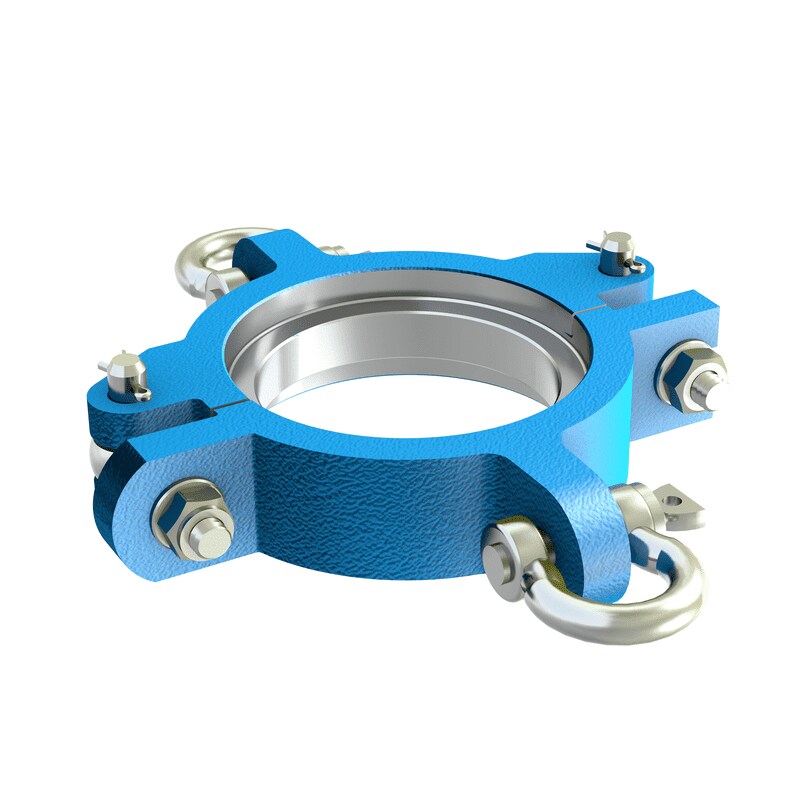

Typical wire rope lubrication system components Ordering wire rope lubrication (WRL) systems: 1 Select seal and roll kit to it the wire rope diameter. Interchangeable kits include seals and rolls to it wire rope diameters in their respective size ranges. Seal and roll kits Seal and roller kit model 3 Select pump and accessory package to it the required grease container size. Pump and accessory packages Nominal wire rope diameter 1) minimum maximum Pump and accessory package includes the Lincoln series 20 50:1 grease pump, air ilter, regulator, gauge, low control, WRL sling with ratchet,...

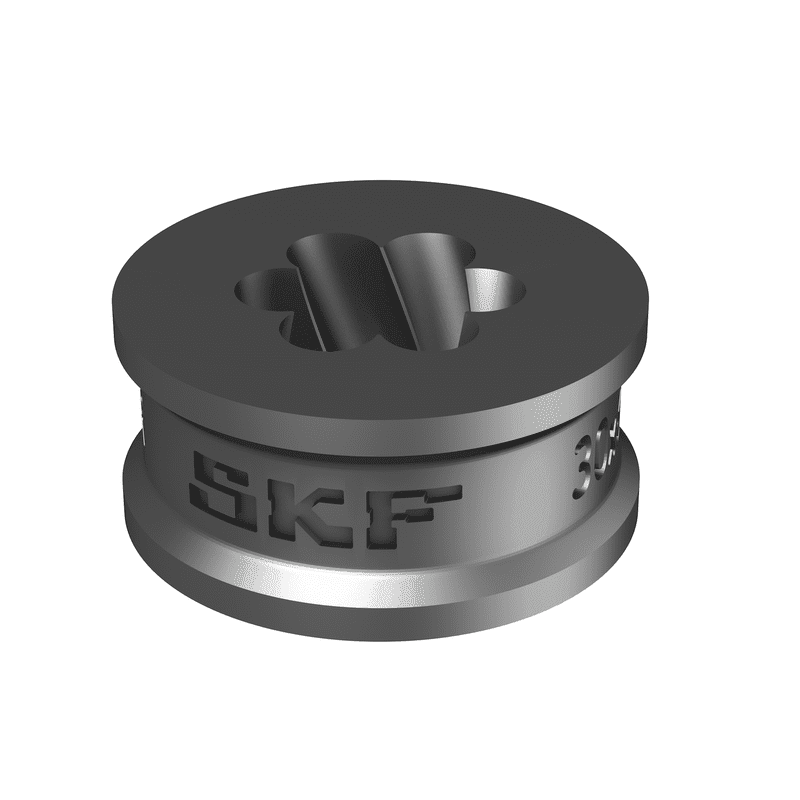

Groove cleaner helps extend wire rope service life Groove cleaner Separating bushing Designed to complement the Lincoln wire rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life. Each groove cleaner is produced individually based on rope speciications to make sure that the device proile matches accurately with the strands. The groove cleaner unit consists of a groove cleaner device, as well as...

Groove cleaner and separating bushing identiication codes For the correct selection of a groove cleaner and separating bushing, the user must determine the accurate dimensions and type of wire. We recommend the following steps: A Measure the real diameter (A) of the wire rope with a caliper. Identify the number of outer strands. Determine the lay (right or left) of the wire rope strands. 4 Choose the separating bushing that its with the nominal diameter of the wire rope. Separating bushing Order no. Nominal wire rope diameter minimum maximum in For wire rope diameters 19/32" - 3/4" For wire...

6 The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope speciication, or send a sample. To ensure an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included). Groove cleaner element with breeze T-bolt clamp For rope strands with right lay Groove cleaner element with breeze T-bolt clamp For rope strands with left lay Order no. Wire rope diameter in Wire rope diameter in

skf.com/WRL | skf.com/lubrication | lincolnindustrial.com ® SKF and Lincoln are registered trademarks of the SKF Group. © SKF Group 2019 The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB LS/P2 17901 EN · August 2019 Certain image(s)...

The service tool has been designed to deliver highly effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely operated vehicles and winding machines in mines. Used as part of the maintenance cycle, the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also dramatically reducing downtime.

Supporting all lubricants typically used with wire rope, the system ensures optimum lubrication by applying the exact amount of grease required and distributing it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it reduces lubrication time by up to 90 per cent compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

The easy to use wire rope lubrication system comes to the market following extensive field testing. It is ultra-reliable and features an extremely robust design, making it ideal for long-term use in even the most challenging environments and harsh conditions.

Commenting on the new Lincoln WRL, Tim Veal, Lubrication Systems Business Manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.

Do your wire ropes, cables and draglines become rusted, corroded or frayed? You can protect your wire rope and cable from high stress loading, shock loading, jerking and heavy loads with LE"s full line of penetrating and coating wire rope lubricants. Whether you want lubricant to penetrate to the core or to coat and seal, LE has a full range of protective lubricant solutions, including wire rope lubricant applicators to reduce labor costs and ensure safe, reliable operation.

New Extended Warranty: Documented use of LE452, LE453 Wirelife™ Almasol Wire Rope Lubricant or Earthwise™ EAL Wire Rope Lubricant will double the Viper warranty period to 24 months.

Herewith sharing an interesting story of a new Wire Rope Lubricator (WRL) body field trial test on a Container Terminal, one of the busiest & largest container ports in Europe;

We discussed our customers feedback with our factory & they worked in the design of a bigger WRL body of up to Ø3”. They manufactured a prototype WRL-3, that was send for a field test. Container Terminal has 2 different wire rope dimensions to lubricate in their cranes, Ø28mm & Ø30mm (both Right Lay & with 8 Strands).

From this 1st trial test, we had a lot of positive comments (Groove Cleaner worked perfectly with the new body, evenly distributed grease to the outside surface of the wire rope, higher speeds, etc.) coming from the experienced maintenance personnel of the terminal.

With the new WRL body we cover a wider range of wire ropes. So, the above problems are all solved, and our customers will lubricate more efficiently their wire ropes & with lower investment cost too!

FLO is pleased to announce it has once again received the SKF Lubrication Business Unit, “Lincoln Distinguished Distributor Award” for 2021. This award is presented annually for outstanding sales performance to one or two distributors in North America. This is FLO’s eigth time receiving this particular recognition, the previous years being 1999, 2002, 2005, 2007, 2010, 2017 and 2020.

The award was presented to FLO’s Vice-President, Mike Deckert and Operations Manager, Roger Freitas by SKF Lubrication Business Unit, Ontario District Manager, Bert Nyenhuis on Nov 1, 2022.

We thank everyone who participated in the contest as well as the Media that helped get the word out about the contest and our sponsor – SKF Lubrication Business Unit.

We thank everyone who participated in the contest as well as the Media that helped get the word out about the contest and our sponsor – SKF Lubrication Business Unit.

Be sure to visit FLO Components at TRUCK WORLD 2022 on April 21-23 in Booth #5638. We will be featuring FLOlink, FLO’s new Telematics Monitoring & Notification System for Autolubers, as well as SKF MonoFlex brand of Fluid Grease Automatic Lube Systems for trucks, Lincoln, Alemite and Graco Bulk Fluid Handling & manual greasing equipment for service garages and the QuickFitTM Onboard Oil Change System with several different working demos and system experts on hand to answer your questions.

Be sure to visit the FLO Components booth #2016 at the National Heavy Equipment Show 2022 on March 31 – April 1. We will be featuring FLOlink, FLO’s new Telematics Monitoring & Notification System for Autolubers, as well as Lincoln brand Automatic Greasing Systems for heavy equipment, SKF MonoFlex brand of Fluid Grease Automatic Lube Systems for trucks, Alemite Bulk Fluid Handling & Inventory Control Systems for service garages and the QuickFitTM Onboard Oil Change System with several different working demos and system experts on hand to answer your questions.

FLO is proud to announce that it has received the SKF Lubrication Management, “Lincoln Distinguished Distributor Award” for 2020. This award is presented annually for outstanding sales performance to one or two distributors in North America. FLO has been a leading distributor for Lincoln since 1977 and has been previously recognized with this award in 1999, 2002, 2005, 2007, 2010 and 2017.

The award was presented to FLO’s President, Chris Deckert and Vice-President, Mike Deckert by SKF Lubrication Management, Ontario District Manager, Bert Nyenhuis on June 24, 2020, who stated; “In my decades of working in this industry, I have never seen a more dedicated and skilled group of people working towards lubrication system excellence. It continues to be my pleasure to support them.”

FLOlink is the evolution of ALS, designed to give customers’ key personnel direct wireless data access to ALS on specific machines, and independent ALS specific data that isn’t buried in massive machine reports generated by the machine’s regular telematics. FLO customers now have remote, real-time, up-to-the-minute status monitoring of any number of systems with FLOlink installed. This enables customers at any time, to check where each machine is, its current ALS status, its status history and more.

Spilltration® Husky fibers are more complex, using more intricate properties between the two binding groups, making overall UV resistance much greater compared to polypropylene. Combined with a much thicker construction and polyethylene backing, the Spilltration® mats are more durable, more absorbant, safer for the environment and reduce remediation once the mat is finally replaced. The fibers are made from 100% post-consumer waste, making it the most sustainable track mat on the market.

We thank everyone who participated in the contest as well as the Media that helped get the word out about the contest and our sponsors – SKF Lubrication Business Unit.

Be sure to visit FLO Components at North America Mining Expo 2018 in Hanmer, Ontario, on September 12-13 in Booth #24. We will be featuring the QuickFitTM Onboard Oil Change and Engine PreLub Systems and the SKF MonoFlex and Lincoln brands of Automatic Greasing Systems, with several different working demos and system experts on hand to answer your questions.

FLO is pleased to announce it has received the SKF Lubrication Business Unit, “Lincoln Distinguished Distributor Award” for 2017. This award is presented annually for outstanding sales performance to one or two distributors in North America. This is FLO’s sixth time receiving this particular recognition, the previous years being 1999, 2002, 2005, 2007 and 2010.

The award was presented to FLO’s President, Chris Deckert and Vice-President, Mike Deckert by SKF Lubrication Business Unit, Ontario District Manager, Bert Nyenhuis on May 11, 2018.

We thank everyone who participated in the contest as well as the Media that helped get the word out about the contest and our sponsors – SKF Lubrication Business Unit.

The SKF Lubrication Product Division is running a special promotion on specific items purchased by end users between April 1, 2018 and June 30, 2018. There are eighteen different products to select from. Purchasing any one of the listed products qualifes the end user for a VISA gift card. End users can mail in proof of purchase to receive a VISA gift card ranging from $10 – $50 per item. Customers can purchase multiple items and get a VISA gift card worth up to a total of $250.

Once again we congratulate all the winners of the FLO 40th Anniversary Giveaway Contest. We also thank everyone who participated in the contest as well as the Media that helped get the word out about the contest and of course our sponsors – SKF Lubrication Business Unit.

On Friday, September 15, FLO Components Ltd. held a staff luncheon to celebrate its 40th Anniversary. In attendance was Mrs. Nora Deckert, founding partner of FLO Components. Also in attendance was Bert Nyenhuis, District Manager – Ontario for SKF Industrial Sales – Lubrication, to present Mrs. Deckert and FLO President, Chris Deckert with a special plaque recognizing FLO’s 40 years of successfully supporting the Lincoln/SKF product line.

• Portable Magnetic TrailerCamsTM. A revolutionary new product solution for blind spots, the TrailerCamTM is a magnetic, wireless, rechargeable battery operated back-up camera that requires NO invasive installation. The product literally can be placed (using strong, rugged magnets) on the side or rear of any trailer or equipment, up to 100 Feet in distance, and communicate to the monitor in the cab with zero latency or interference.

• SKF Hose Connection Control System (HCC) to monitor the grease lines in automatic greasing systems on trucks and heavy equipment (construction, road building, mining, etc.). The HCC is designed to check for breaks in the grease hose, and alerts the machine operator immediately if there is a fault in either the main line from the pump or in the feed lines to the bearing points.

• The SKF brand MonoFlex (formerly Vogel) fluid type Autogreaser for over-the-road trucks. The MonoFlex uses a totally electric pump, so there is no air required and therefore no impact on the truck air system, and will operate with any brand of fluid grease (NLGI #000 to 00) that meets the system specifications.

Introducing a revolutionary new product solution for blind spots – the Portable TrailerCamTM. The Portable TrailerCamTM is a magnetic, wireless, rechargeable battery operated camera that requires NO invasive installation. The product literally can be placed (using strong, rugged magnets) on the side or rear of any truck, trailer or equipment, up to 100 Feet in distance, and can communicate high quality video images and audio to the display monitor in the cab with zero latency or interference.

SKF has introduced the Lincoln 800030 Digital Grease Flow Detector for automatic lubrication systems. The Grease Flow Detector has been designed to generate a confirmation signal to verify lubrication events. Installed between the metering device and the bearing, the model 800030 is a positive- displacement flow detector consisting of oval gears. Signals are communicated to a control unit or PLC, detecting both small 0,016 cm³ (0.001 in³) and large 8,19 cm³ (0.5 in³) grease flow. Also, in the case of lubrication failure, the sensor signals the controller so that appropriate action can be taken. Usable with PLC control or with control units like LMC 301. The Grease Flow Detector is ideal for applications in steel mills, paper mills, glass plants and other heavy industries.

Looking to brush up your maintenance staff’s lubrication skills and knowledge? Sign them up for our March 1 Lube Basics Seminar in Grimsby, ON. Improper lubrication accounts for 53% of all bearing failures, a major cause of equipment downtime and significant unnecessary maintenance costs. FLO Lube Basics Seminars are designed to help you avoid these failures by turning your personnel into Lubrication Specialists. Each FLO Components 1-day Seminar maintains a balance of theory and practical – time allocation: 50% in class, 50% “hands on” training. Each is designed and presented as an unbiased, 3rd party lubrication training program – we don’t sell to you, we teach you what you need to know.

Developed as a service tool, the new Lincoln wire rope lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate steel wire ropes.

The Lincoln wire rope lubricator eliminates manual lubrication and, in turn, yields less downtime and longer service life. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation, which increases service life. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated.

The wire rope lubricator is easy to use and supports all types of grease lubricants typically utilized for this task. Fast and efficient, the lubricator helps to prevent corrosion and reduces waste and contamination.

Be sure to visit FLO Components at CWRE 2016 on November 9-10 in Booth #1305. We will be featuring the new QuickFitTM Onboard Oil Change System, SKF MonoFlex brand of Fluid Grease Auto Lube Systems and Lincoln Fluid Inventory Control Systems for garages or vehicle service facilities, with several different working demos and system experts on hand to answer your questions.

Be sure to visit FLO Components at TRUCK WORLD 2016 on April 14-16 in Booth #5638. We will be featuring the SKF MonoFlex brand of Fluid Grease Auto Lube Systems, with several different working demos and system experts on hand to answer your questions.

FLO has released the schedule for its 2015 Lube Basics Seminars. Improper lubrication accounts for 53% of all bearing failures, a major cause of equipment downtime and significant unnecessary maintenance costs. FLO Lube Basics Seminars are designed to help you avoid these failures by turning your personnel into Lubrication Specialists. Each FLO Components 1-day Seminar maintains a balance of theory and practical – time allocation: 50% in class, 50% “hands on” training. Each is designed and presented as an unbiased, 3rd party lubrication training program – we don’t sell to you, we teach you what you need to know.

Successful companies in the construction, road building, mining and other heavy equipment industries are constantly seeking new solutions and advanced technology to reduce costs, minimize downtime and maximize productivity. Can lubrication play a role in that? You bet! Automatic Lubrication Systems, also known as autogreasers, autolube or centralized grease systems, help eliminate unplanned and unnecessary expenses related to improper lubrication. This article outlines the basics you need to know about Automatic Greasing Systems on mobile equipment.

Successful companies in today’s ever-changing food and beverage industries are constantly seeking new solutions and advanced technology to maintain freshness, reduce spoilage, and maximize their productivity. In this perpetual move towards increased automation, proper lubrication of new high-speed advanced-technology machinery is essential. Unfortunately, food and beverage industries also have some of the toughest environmental conditions for maintaining machinery. Moisture, extreme heat, extreme cold, product spills and sanitary wash-down procedures all adversely affect lubrication processes and can severely reduce bearing life or cause failure.

FLO Components – “Meeting Customers’ Needs Better” as it continues to expand its resources to better serve manufacturing, construction, road building, aggregate, mining and trucking companies in the London and Sudbury regions. FLO’s dedicated installation and service vehicles, stationed in each area, will provide local service for both SKF and LINCOLN brand lube systems.

Watch this “2 Great Brands” video to learn more about FLO Components, Canada’s first LINCOLN and SKF dual brand System House, and our commitment to “Meeting Customers’ Needs Better” with qualified, well trained people who focus at making us the best at responding quickly, at installing professionally and at providing quality customized lubrication solutions for all our customers – done right the first time.

FLO Components is proud to announce that it has received a letter of intent from SKF Lubrication Business Unit (LBU) designating FLO Components as a SKF LBU System House for both LINCOLN and SKF brands. In November 2012, FLO reached an agreement with SKF LBU to become a key distributor in Ontario, of SKF Brand Lubrication Products and Solutions for industrial applications (manufacturing, processing & packaging). With this new announcement, FLO becomes the first official SKF LBU System House able to offer the entire spectrum of LINCOLN and SKF Lube Solutions, for all applications including on-road trucks and vehicles and off-road mobile and stationary equipment.

Effective May 1st 2013, SKF Lubrication Solutions restructured its frontline operations and appointed FLO Components Ltd. as their full service & support partner for Ontario. FLO is now stocking a full inventory of SKF lube product. Over the short-term, the current SKF Technical & Engineering support team will work alongside FLO to ensure the transition is as seamless as possible. In fact, FLO is pleased to announce it has hired an Installation Technician from SKF to join its current service and installation team.

FLO Components is now offering the SKF SYSTEM 24 Gas Driven Single Point Automatic Lubricators. These gas generating units are supplied ready-to-use straight from the box and filled with a wide range of high performance SKF lubricants. Tool-free activation and time-setting allow easy and accurate adjustment of lubrication flow.

This month’s video tip, “Single Point Automatic Lubricators: Part 2” is now live on YouTube. This eagerly awaited sequel to “Single Point Automatic Lubricators: Part 1” digs deeper into how these units operate and their set-up.

FLO Components Ltd. is proud to announce that it has reached an agreement with SKF Group – Lubrication Business Unit to become a key distributor of SKF Brand Lubrication Products and Solutions in Ontario.

Commenting on this announcement, Mr. Chris Deckert, President of FLO Components said; “We’ve been lube solutions experts and trusted lubrication advisors for our clients since 1977. Now we have even more solutions to offer. The “SKF branded” lube product compliments the “Lincoln branded” lube product, filling in gaps which existed in the Lincoln line for some unique special applications. With the addition of the SKF “branded” lube product line, our customers are now supported by an even more complete one-stop shop for all their lubrication needs. Combined with our thirty-five years focus on customer service, one phone call is all it takes.”

This month’s video tip, “Single Point Automatic Lubricators: Part 1” is now live on YouTube. Single point automatic lubricators are designed to lubricate a single point or few points, often in remote or hard to reach locations or when larger Automatic Lubrication Systems aren’t feasible. This video is an introduction to single point automatics.

Lube Tips by FLO Components is back with its second season. Check out this months video: “What a Properly Lubricated Bearing Looks Like“. Both under-lubrication and over-lubrication can be devastating to a bearing. This video shows how a properly lubricated bearing should look.

This month’s video tip, “Winter-Prepping Your Automatic Greasing System” is now live on YouTube. This video lists things you should do before winter to make sure your automatic lubrication system operates properly throughout the cold winter months.

This month’s video tip, “How to Properly Fill a Lube Reservoir on Automatic Greasers” is now live on YouTube. The incorrect method of refilling the lube reservoir through the lid will result in contamination of the system and ultimately leads to system breakdowns and unnecessary repairs or replacement costs. This how-to video shows you some of the alternatives available for properly filling the reservoir and some pitfalls to watch out for.

FLO Components is happy to announce that Glasvan Trailers Inc. has chosen to use FLO’s Automatic Lubrication Systems (ALS) as part of a limited-time special offer for new live bottom trailer purchases. Anyone who orders a new Etnyre Falcon Live Bottom 3, 4 or 5 axle trailer from Glasvan by December 15, 2010 will receive a FLO (Lincoln) ALS at half price.

Improper lubrication accounts for 53% of all bearing failures, a major cause of equipment downtime and significant unnecessary maintenance costs. The majority of failures are caused by: contamination of bushings by dust, dirt and moisture; inadequate amounts of lubricant applied to bearings; or over-lubrication of key pivot points. This article outlines 5 common lubrication mistakes and how to avoid them.

There are several leading factors that contribute to accelerated chain wear, including incorrect chain selection and installation, inadequate chain tension, environmental exposure and, of course, improper lubrication. In fact, according to chain manufacturers, 70 percent of all failures are a direct result of some form of improper lubrication. Here are a few key factors to consider for the various types of lubrication methods.

FLO Components is now offering the new P203 RemoteLinc™ pump as part of its automatic lubrication systems for fleets using telematics (telecommunication technology). Auto lube systems (ALS) dispense small measured amounts of grease at frequent intervals while your equipment is operating, maintaining a consistent lubricant seal to prevent dirt and contaminants from migrating into bearings. Designed to communicate with wireless systems, the new P203 RemoteLinc™ unit combines the proven Quicklub® 203 pump with two independent outputs to link the ALS to telematics systems. The unit easily interfaces with OEM and aftermarket telematics systems. Fleet managers can now be remotely notified when the lubricant reservoir in their ALS is low so that they know when to dispatch a lube truck. The RemoteLinc P203 can also immediately alarm managers when the ALS is in fault and a service technician must be contacted. Users can then more effectively manage and reduce refill service visits (the lube truck visits only when the pump is low on grease) and reduce cost by receiving immediate, real-time alerts when lubricant is low or the system is in fault.

FLO Components is now offering the new HTL429 Lubricator Pump for hydraulic tools. Designed to deliver precise lubrication each time a hammer or other hydraulically driven tool cycles, the pump is ideal for construction OEMs, hydraulic hammer retrofits, demolition attachments and medium to large breakers/hammers.

SKF Seals Knowledge Engineering Designed to optimize machinery performance From moulding high quantities to mach Sealing for power transmission The performance and service life of a power transmission

Machine tool optimization SKF solutions for super-precision, productivity and sustainability The Power of Knowledge Engineering Run faster, longer, Machine tools: whether you are designing them or using

Application Note Alarm Group in SKF @ptitude Observer 9.1 Introduction An alarm group can be created if a user wishes to collect data from other measurement points. When an alarm is raised, the measurement

Optimizing machine reliability and overall plant efficiency SKF capabilities for the food and beverage industry The Power of Knowledge Engineering Addressing the industry drivers The Power of Knowledge

SKF @ptitude Connect Simplify your condition monitoring programme with subscription-based software The Power of Knowledge Engineering Data collection Customers collect critical machine data using SKF condition

HMS lock nuts Contents The SKF brand now stands for more than ever before, and means more to you as a valued customer. While SKF maintains its leadership as the hallmark of quality bearings throughout

DR125 / DR150 Toll Free: 888-863-2252 PARTS AND PRICES ARE SUBJECT TO CHANGE 1 of 55 CYLINDER HEAD ASSY. 1 125-001 883099006937 CYLINDER HEAD COVER 1 1 2 125-002 883099006944 BOLT M6X28 2 3 3 125-003 883099006951

On the road to bring you SKF knowledge SKF Technical Training Trucks There are many ways for today s technicians to develop their skills, learn about new products and procedures, and determine best practices

Keep your trucks moving with SKF and Lincoln automatic lubrication systems for the mobile on-road market The Power of Knowledge Engineering Thousands of trucks, buses and commercial vehicles around the

- Easy -wire installation with no external spark box necessary, but can be used with one. - Precision CNC machining and hand assembled construction. This is a premium product. - Accurate super hot spark

Application Note Gating in SKF @ptitude Observer 9.1 Introduction In some applications, it is important to collect vibration data only at a specific operating condition of the machine. This way of collecting

Orion Pit Bike Sales Owners Manual (All information and content is the property of Orion Pit Bike Sales. Any attempt to copy or resell is a direct violation of our copyright. All violators will be prosecuted)

introduction to constant level lubrication Constant level oilers are designed to maintain a predetermined oil level in a sump, which is necessary for proper lubrication. If the oil level were to drop below

Metric roller bearing units SYNT and FYNT series (SKF ConCentra) Bearing types Spherical roller bearings Bearing dimension series 222 Shaft diameter range 35 to 100 mm SKF ConCentra roller bearing units

DR70 Toll Free: 888-863-2252 PART NUMBERS PRICES ARE SUBJECT TO CHANGE 1 of 43 CYLINDER & CYLINDER HEAD 1 DR70-001 883099044472 CYLINDER 1 1 2 DR70-002 883099044489 GASKET, CYLINDER 1 1 3 DR70-003 883099044496

FJ2 2 Ton Trolley Floor Jack Assembly & Operating Instructions READ ALL INSTRUCTIONS AND WARNINGS BEFORE USING THIS PRODUCT. This manual provides important information on proper operation & maintenance.

DR90 Toll Free: 888-863-2252 PART NUMBERS AND PRICES ARE SUBJECT TO CHANGE 1 of 51 CYLINDER & CYLINDER HEAD 1 DR90-001 842645048166 CYLINDER 1 1 2 DR90-002 842645048173 GASKET, CYLINDER 1 1 3 DR90-003

SKF spherical roller bearings are a common choice for a wide range of applications, from farming equipment to wind turbine shafts. In a radial bearing arrangement, one of the rings (usually the inner one) has a concave outer diameter to accommodate misalignment between the shaft and housing. This allows for free-moving movement within the bearings, which is particularly critical in situations where high rotational speeds or oscillating or slewing movement must be accommodated at relatively low sliding speeds. If you"re looking for a bearing to accommodate off-center loads and alignment movements, spherical roller bearings are a good option. SKF spherical roller bearings have a high load carrying capacity, which means they can accommodate high axial loads, large radial loads and high misalignment. This is particularly useful when your application requires accommodating large misalignment angles, such as wind turbine main shafts or continuous casters. Their ability to accommodate misalignment also helps to reduce maintenance costs because there is a lower risk of damage resulting from contact between bearing rings or rollers. SKF spherical roller bearings are designed for many different applications and have very low rolling resistance, meaning they provide high speeds and low power consumption.

Buy SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS online in India at wholesale rates. If you have been looking for SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS dealers, your search ends here as you can get the best SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS distributors in top cities such as Delhi NCR, Mumbai, Chennai, Bengaluru, Kolkata, Chennai, Pune, Jaipur, Hyderabad and Ahmedabad. You can purchase SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS of the finest quality and rest assured to get the best in terms of both durability and performance. If you are bothered about the SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS prices, you can be totally sure to get the best rates as Industrybuying brings you genuine SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS rates and quality assured products only from the best of brands with exclusive brand discounts you won’t find anywhere else. Procure SKF Imported Radial Spherical Plain Bearing 160 mmx 230 mm x 105 mm GE 160 ES-2RS today and avail the best offers on your purchase.

Developed as a service tool, the Lincoln wire rope lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments, in general.

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste.

Lubricating the traditional way is costly, requiring brushes, gloves and spillages, while the effectiveness is far less. Low-quality lubricants create a superficial layer on the outside, which is still afflicted with rusting at the very core of the core of the wire. This will keep the appearance of a metal wire rope in a healthy shape, while the corrosive moisture is eating away at its core.

Masto Wire Lubricators are the sole brand available to lubricate a wire thoroughly, both on the inside and outside. With the correct supervision and interval lubrication, the wires can last much longer, while avoiding a dangerous situation such as suspended load drop and wire failure. To gain this effect, the lubrication is performed under pressure, which passes through the most compact strand designs in the wire rope industry.

The systematic application of Masto Lubricators creates a minimum of 285 PSI; the lowest amount of pressure required in the lubrication chamber to gain a comprehensive lubricating result. Despite the material of the rope, the mechanical wear and moisture in an environment, the wires are prolonged significantly after Masto wire lubricators reduce friction, increase functionality and prolong the wires’ lifespan.

Masto Lubricators are designed for easy administration, which carry out the lubrication process by using Split Seals. These seals are installable chambers that create a high pressure environment for lubrication. The seals are engineered with two halves that come together and are further secured with two chains. A pump administers the lubricating content while the wire rope roller continues reeling the rope through the chamber.

A world-renowned cable lubrication tool,Masto pressure lubrication is an all-in-one solution. It can be used on land or for underwater lubrication to effectively lubricate wire ropes. It also helps cutting down the overall costs by reducing the intervals of lubrication, increasing the life of wire ropes by eliminating rust, corrosion as well as friction. If you are looking for a perfect wire rope lubrication solution, there is no better choice than Masto Lubricators out there in the market.

Do you still require more information? Unsure about the compatibility of your wire construction with this lubrication method? Or wanting to get a quotation on bulk orders? Contact Us today and we will be eager to answer all your questions.

8613371530291

8613371530291