skf wire rope lubricator price factory

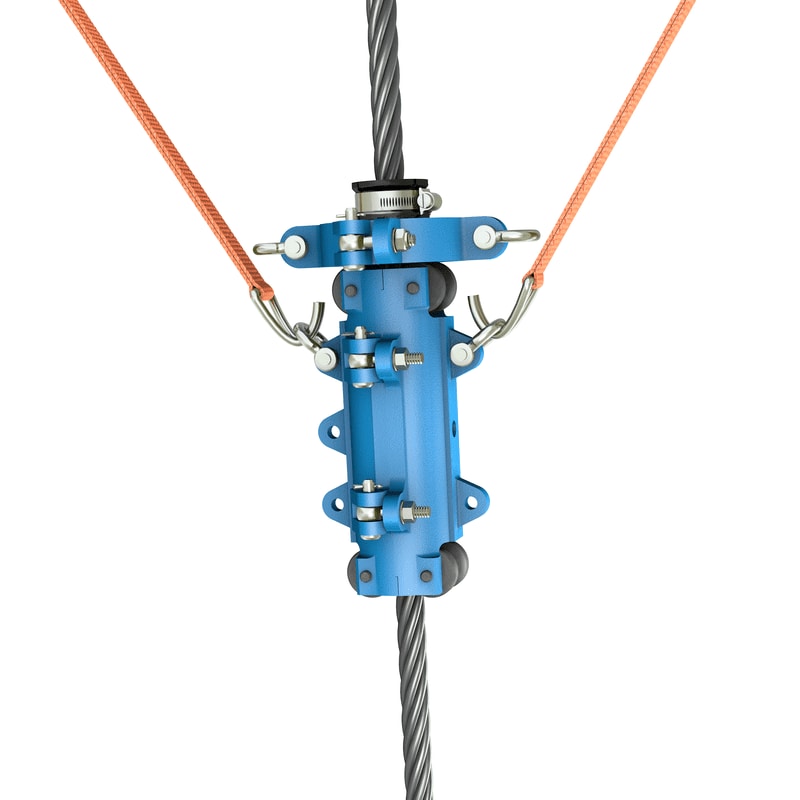

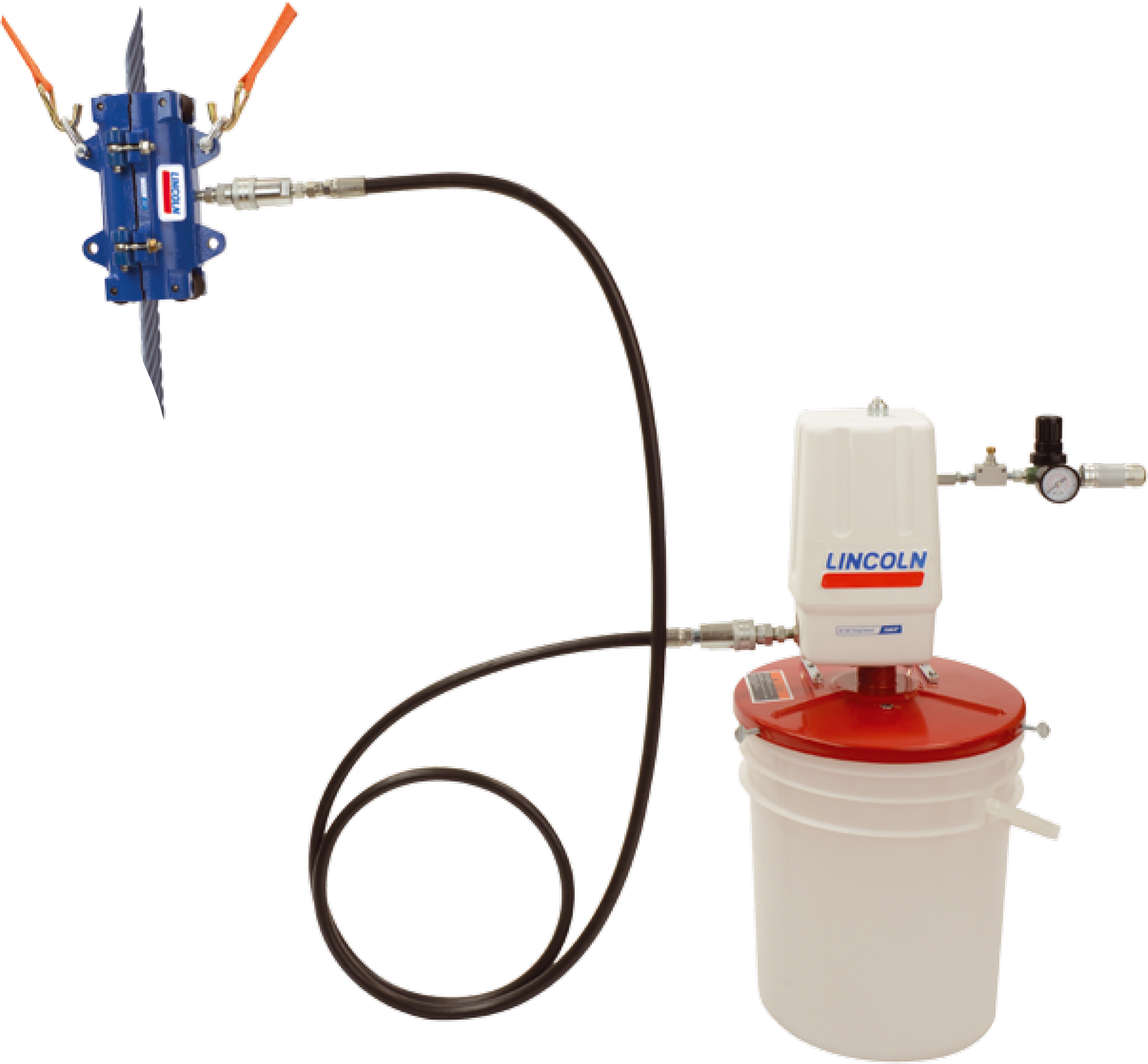

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Herewith sharing an interesting story of a new Wire Rope Lubricator (WRL) body field trial test on a Container Terminal, one of the busiest & largest container ports in Europe;

We discussed our customers feedback with our factory & they worked in the design of a bigger WRL body of up to Ø3”. They manufactured a prototype WRL-3, that was send for a field test. Container Terminal has 2 different wire rope dimensions to lubricate in their cranes, Ø28mm & Ø30mm (both Right Lay & with 8 Strands).

From this 1st trial test, we had a lot of positive comments (Groove Cleaner worked perfectly with the new body, evenly distributed grease to the outside surface of the wire rope, higher speeds, etc.) coming from the experienced maintenance personnel of the terminal.

With the new WRL body we cover a wider range of wire ropes. So, the above problems are all solved, and our customers will lubricate more efficiently their wire ropes & with lower investment cost too!

Developed as a service tool, the Lincoln Wire Rope Lubricator is attached periodically to equipment on a monthly, quarterly or other cycle to lubricate wire ropes. Lubrication intervals should be determined according to rope manufacturer specifications. The life cycle of a steel wire rope that has been periodically lubricated is approximately six to eight times longer than a wire rope that has not been lubricated. Specifically for Wire Rope Lubricator applications a biodegradable grease LGTE 2 is available. The grease is environmentally acceptable and certified with Ecolabel.

Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general.

Are you looking to squeeze more life out of your wire rope? Literally speaking, you now have the ability to squeeze more life into your wire rope using the Lincoln Wire Rope Lubricator (WRL). As a matter of fact, up to six to eight times more life can be achieved by the proper application and frequency of lubrication.

The WRL was developed by Lincoln with those individuals in mind who have the desire to protect the significant investment they have made in wire rope. Even when used in modest lengths, gauges, and conventional materials, the cost of wire rope can quickly add up. As wire rope is typically used in applications involving lifting, hoisting, dragging, pulling, arresting, etc., and often subject to harsh conditions, the life span of wire rope is usually extremely short lived. Wire rope that is not periodically lubricated is likely to fail prematurely from the effects of excessive heat generation and abrasion caused by friction.

For those individuals looking to extend the life of their wire rope, investment in a Lincoln Wire Rope Lubricator (WRL) will be the surest means to achieve this result. It’s not uncommon to discover wire rope failure caused by a rotted and fatigued core. Although there are other products and systems on the market designed to apply a protective coating of lubricant to wire rope, only the Lincoln Wire Rope Lubricator (WRL) is designed to inject protective lubricant into the rope’s core while simultaneously applying a protective coating of lubricant to the outside diameter of the wire rope.

The design of the Lincoln Wire Rope Lubricator (WRL) prevents excessive application of lubricant common to other applicators on the market. The efficient application of lubrication reduces expense due to lubricant waste and associated cleanup activities. The WRL is designed to dispense and apply the lubricant automatically thus avoiding manual application altogether, allowing valuable manpower to be deployed elsewhere. The potential risk of harm to an employee is alleviated when the Lincoln WRL replaces the manual application of lubricant, thereby contributing to a reduction in costs due to accident and injuries.

We will carry out lubrication on our 103 mm wire in the coming days. This will be the third time this has been conducted, and I am extremely satisfied with the results. No wastage due to drop off during application and very good penetration.

Bridon Ropes has used Masto machines in its factories for over 10 years, in cases where a special lubricant coating is required on particular wire ropes. Over the years the machines have given dependable service over a wide range of rope sizes and constructions, and have given satisfactory seal lives.

After having used the Masto unit for approximately 2 ½ years, we are more than satisfied with the unit. It is a clean and efficient way of greasing wires. Before we got the unit, greasing wires was a hard task, but now the unit is doing the work for us and the wires are greased properly and evenly.

The undersigned surveyor to Det norske Veritas was present when the “MASTO” wire lubricator was demonstrated on two wire dimentions. After being greased, the wires were split apart, and we can confirm that the grease had penetrated through the whole cross-section of the wires.

We have tested different types of wire rope lubricators and can ensure you that we are very satisfied with your product. We would definitely go for Masto lubricators should the need for such a product arise again.

I can confirm that the ‘Maesto’ wire rope lubricator has been in use on the vessels under my control for several years, during which time it has proved to be a highly effective tool to assist particularly in maintaining the wire ropes of the deck cranes in good order, despite the most ardous operating conditions.

After having used the MASTO unit for approximately one year, we are very satisfied with the unit. It is a safe and clean way of greasing wires. It has proved to be a timesaving tool, compared to brush, cloth etc.

Today we have used the Lubricator for the first time. One word: Amazing! 2 hours instead of two days, no backache, 60 Kg grease instead of 250 Kg, clean dungarees, no mess everywhere around. It’s a great advisable product. I will recommend the wire lubricator to my collegues.

The Lincoln wire rope lubricator (WRL) has been developed to eliminate manual lubrication and is available in a range of models for use with any wire rope up to 52mm in size.

The service tool has been designed to deliver effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely-operated vehicles and winding machines in mines. When used as part of the maintenance cycle, SKF says the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also reducing downtime.

Supporting all lubricants typically used with wire rope, the system applies the exact amount of grease required and distributes it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it is said to reduce lubrication time by up to 90% compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

Tim Veal, lubrication systems business manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.”

Beneits of wire rope lubrication Groove cleaner advantages The use of lubricant on a steel wire rope considerably reduces friction and, as a result, it minimizes the following two related factors: Regular lubrication helps to increase the lifetime of a steel wire rope signiicantly compared to a wire rope that has not been lubricated. Also, lubricating a wire rope while in service helps to prevent corrosion of the wires. Corrosion can be internal and external, and it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive and industrial environments in general. The...

The Lincoln wire rope lubrication system eliminates manual lubrication and, in turn, yields improved results. This reliable tool forces lubricant into the wire rope core to reduce friction and heat generation for longer service life. The wire rope lubrication system applies the right amount of lubricant, distributes it evenly and eliminates over-lubrication waste. Advantages: • Fast and eficient – reduces lubrication time by up to 90% vs. manual lubrication • Increases operator safety • Easy to use with any wire rope up to 2 in (52 mm) • Helps to prevent corrosion • Protects the wire ropes...

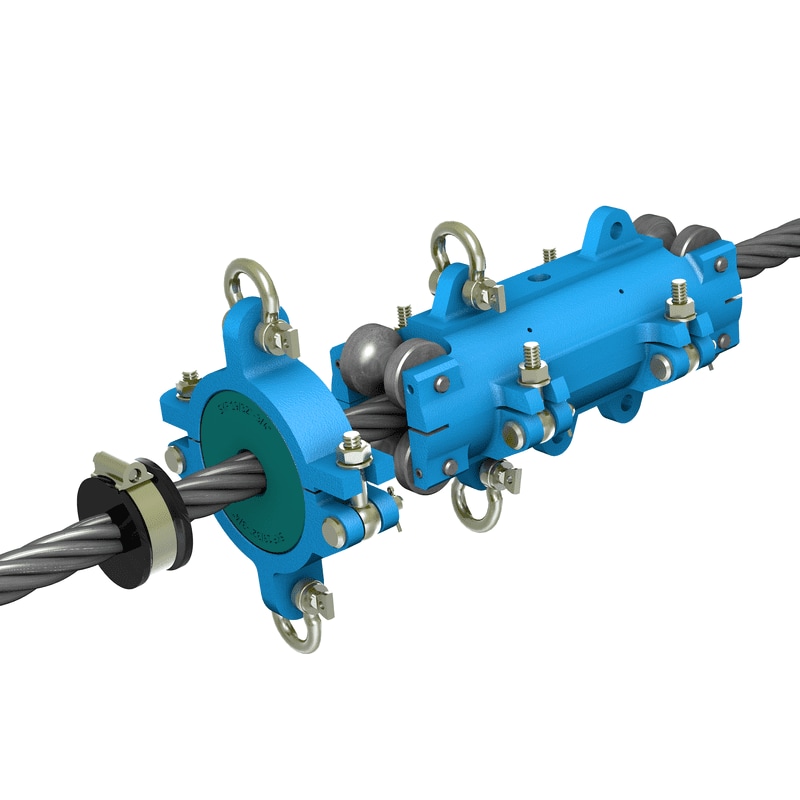

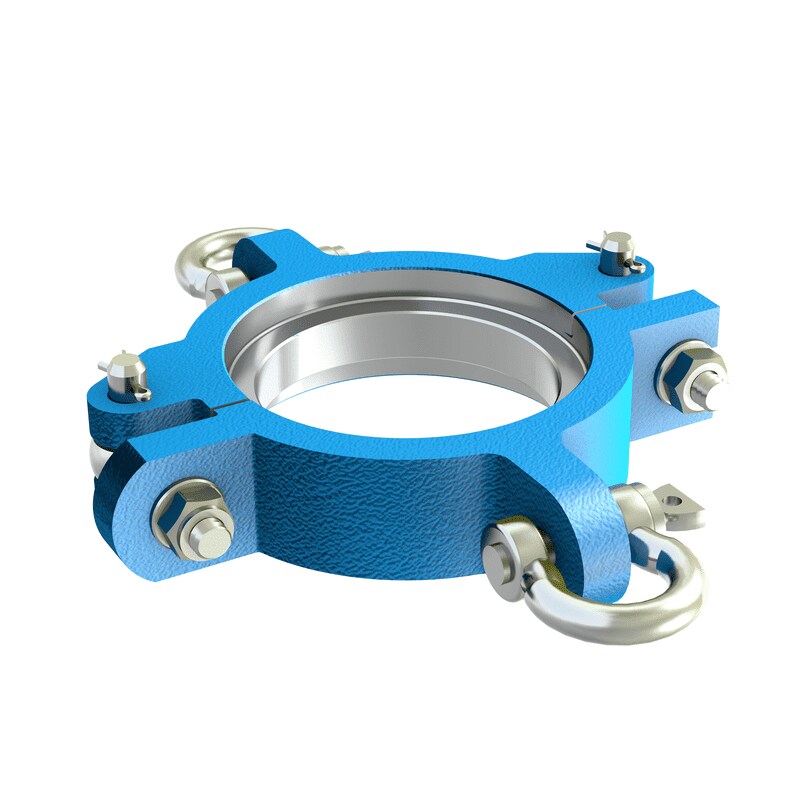

Typical wire rope lubrication system components Ordering wire rope lubrication (WRL) systems: 1 Select seal and roll kit to it the wire rope diameter. Interchangeable kits include seals and rolls to it wire rope diameters in their respective size ranges. Seal and roll kits Seal and roller kit model 3 Select pump and accessory package to it the required grease container size. Pump and accessory packages Nominal wire rope diameter 1) minimum maximum Pump and accessory package includes the Lincoln series 20 50:1 grease pump, air ilter, regulator, gauge, low control, WRL sling with ratchet,...

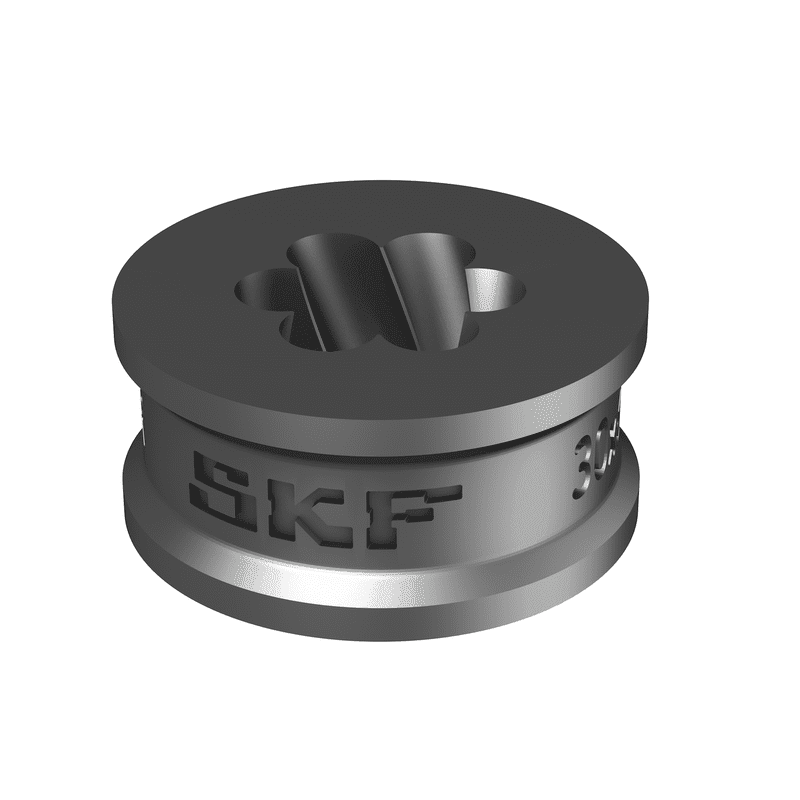

Groove cleaner helps extend wire rope service life Groove cleaner Separating bushing Designed to complement the Lincoln wire rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life. Each groove cleaner is produced individually based on rope speciications to make sure that the device proile matches accurately with the strands. The groove cleaner unit consists of a groove cleaner device, as well as...

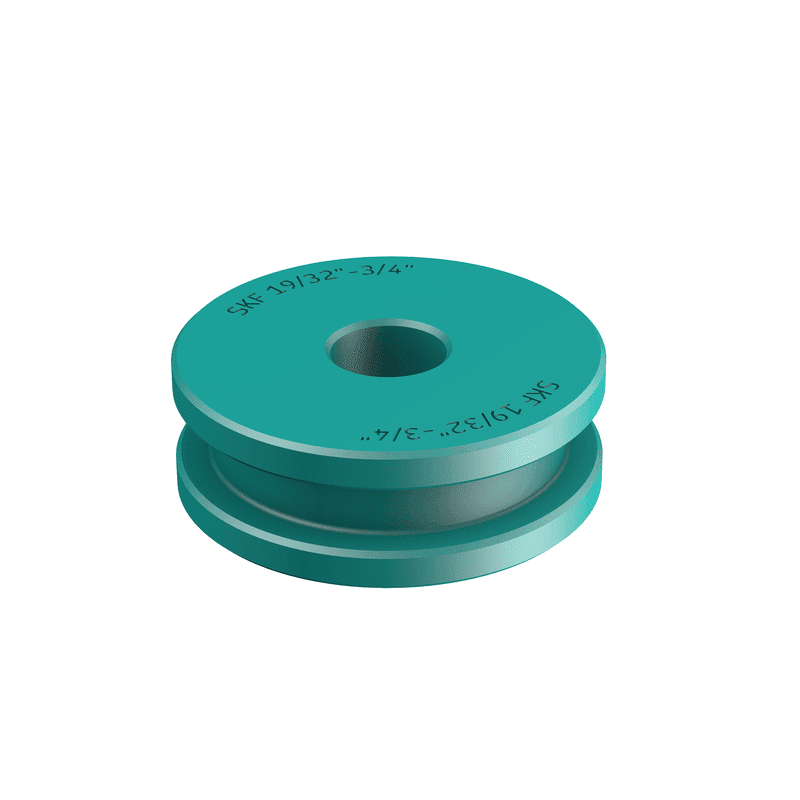

Groove cleaner and separating bushing identiication codes For the correct selection of a groove cleaner and separating bushing, the user must determine the accurate dimensions and type of wire. We recommend the following steps: A Measure the real diameter (A) of the wire rope with a caliper. Identify the number of outer strands. Determine the lay (right or left) of the wire rope strands. 4 Choose the separating bushing that its with the nominal diameter of the wire rope. Separating bushing Order no. Nominal wire rope diameter minimum maximum in For wire rope diameters 19/32" - 3/4" For wire...

6 The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope speciication, or send a sample. To ensure an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included). Groove cleaner element with breeze T-bolt clamp For rope strands with right lay Groove cleaner element with breeze T-bolt clamp For rope strands with left lay Order no. Wire rope diameter in Wire rope diameter in

skf.com/WRL | skf.com/lubrication | lincolnindustrial.com ® SKF and Lincoln are registered trademarks of the SKF Group. © SKF Group 2019 The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted. Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damage whether direct, indirect or consequential arising out of the use of the information contained herein. PUB LS/P2 17901 EN · August 2019 Certain image(s)...

The QY Research released a latest market research report on the global and United States Wire Rope Lubricator market, which is segmented by region (country), players, by Type and by Application. Players, stakeholders, and other participants in the global Wire Rope Lubricator market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region (country), by Type and by Application for the period 2017-2028.For United States market, this report focuses on the Wire Rope Lubricator market size by players, by Type and by Application, for the period 2017-2028. The key players include the global and local players, which play important roles in United States.

For More Information About This Report, Please Enter:https://us.qyresearch.com/reports/349083/wire-rope-lubricatorSegment by Type Wire Ropes Under 50mm In Diameter Wire Ropes From 50 to 100 mm In Diameter Wire Rope Greater Than 100mm In DiameterSegment by Application Crane Elevator Suspension Bridge OtherBy Region North America United States Canada Europe Germany France U.K. Italy Russia Asia-Pacific China Japan South Korea India Australia China Taiwan Indonesia Thailand Malaysia Latin America Mexico Brazil Argentina Colombia Middle East & Africa Turkey Saudi Arabia UAEBy Company SKF Viper WRL Masto Ferryl Poseidon Marine Supplies Kirkpatrick Corelube Equipment TST MEP Karmsund LKS Top Slings Lubretec The Goal of the ReportTo study and analyze the global Wire Rope Lubricatorconsumption (value & volume) by key regions/countries, type and application, history data from 2017 to 2022, and forecast to 2028.

Focuses on the key global Wire Rope Lubricatormanufacturers, to define, describe and analyze the sales volume, value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To strategically profile the key players and comprehensively analyze their growth strategies.Target Audience> Wire Rope Lubricator companies> Research organizations> Government Organizations> Research/Consultancy firmsTable of Contents 1 Study Coverage

3.3.3 United States Wire Rope Lubricator Average Selling Price (ASP) by Application (2017, 2022 & 2028) 4 Global Wire Rope Lubricator Competitor Landscape by Company

10.3 DisclaimerAccess full Report Description, Table of Figure, Chart, FREE sample, etc. please click https://us.qyresearch.com/reports/349083/wire-rope-lubricatorAny doubts and questions will be welcome.Customization of the Report:This report can be customized to meet the client"s requirements. Please contact with us (global@qyresearch.com), who will ensure that you get a report that suits your needs.About Us:QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company With over 15 years" experience and professional research team in various cities over the world,QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 59,000 clients across five continents. Let"s work closely with you and build a bold and better future.Contact UsQY ResearchE-mail: global@qyresearch.comTel: +1-626-842-1666(US) +852-5808-0956 (HK)Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United StatesWebsite: https://us.qyresearch.comThe QY Research released a latest market research report on the global and United States Wire Rope Lubricator market, which is segmented by region (country), players, by Type and by Application. Players, stakeholders, and other participants in the global Wire Rope Lubricator market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region (country), by Type and by Application for the period 2017-2028.QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company With over 15 years" experience and professional research team in various cities over the world,QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 59,000 clients across five continents. Let"s work closely with you and build a bold and better future.

Increases wire rope life and reduces lubrication time, lubricant waste and environmental contaminationImportance of Beneits of wire rope Groove cleanerlubrication lubrication advantagesThe use of lubricant on a steel wire rope The life cycle of a steel wire rope that has The groove cleaner was designed to removeconsiderably reduces friction and, as a been periodically lubricated is approximately dirt and used grease from wire rope beforeresult, it minimizes the following two six to eight times longer than a wire rope it passes through the wire rope lubricator.related factors: that has not been lubricated. This process improves the penetration of Also, lubricating a wire rope while in ser- new grease and enhances corrosion protec-• Abrasion on the wire rope vice helps to prevent corrosion of the wires. tion to maximize the service life of wire rope.• Heat generation Corrosion can be internal and external, and• Corrosion it often is caused by acids, alkaline waters, salt air, humidity, fumes, and abrasive andDeveloped as a service tool, the Lincoln wire industrial environments in general.rope lubricator is attached periodically toequipment on a monthly, quarterly or other Lubrication of wire rope:cycle to lubricate wire ropes. Lubrication • Reduces frictionintervals should be determined according to • Protects against corrosionrope manufacturer speciications. • Enables lubricant to adhere to each wire and penetrate to the core for long-lasting protection

2The Lincoln wire rope lubrication system Wire rope lubrication system with wire rope lubricator (WRL) and pump and accessoryeliminates manual lubrication and, in turn, packageyields improved results. This reliable toolforces lubricant into the wire rope core toreduce friction and heat generation forlonger service life. The wire rope lubrication system appliesthe right amount of lubricant, distributes itevenly and eliminates over-lubrication Pneumatic pumpwaste. 35 lb (16 kg) version shown Wire rope Lubricant lubricator hoseAdvantages:• Fast and eficient – reduces lubrication time by up to 90% vs. manual lubrication• Increases operator safety Wire rope Quick coupling• Easy to use with any wire rope up to Air low regulator 2 in (52 mm)• Helps to prevent corrosion• Protects the wire ropes• Penetrates the wire rope core• Reduces waste and contamination• Robust design for harsh environments

Applications:• Traveling cranes• Wharf cranes Wire rope lubricator• Ship cranes• Deck winches• Ship hoists• Wire ropes for ROVs (remote-operated vehicles)• Winding machines in open pit mining• Mobile cranes• Oil and gas rigs• Chains and ropes• Chair and ski lifts• Elevators• Drag ropes

Newly installed wire rope lubricator on wire rope previously lubricated manually. Note: Even, clean penetrating distribution vs. uneven, messy cover- age from previous method.

Ordering wire rope lubrication (WRL) systems:1 Select seal and roll kit to it the wire rope diameter. Interchangeable kits include seals 3 Select pump and accessory package and rolls to it wire rope diameters in their respective size ranges. to it the required grease container size.

Seal and roller Nominal wire rope diameter 1) Seal Model Size kit model minimum maximum model 2) nominal size lb kg in mm in mm in mm

802238 35 16 For use with small lubricator 802175 802239 120 54 802185 0.437 11,1 0.496 12,6 802270 7⁄16 11,1 802240 400 180 802188 0.500 12,7 0.559 14,2 802271 1⁄2 12,7 802191 0.562 14,3 0.621 15,8 802272 9⁄16 14,3 European bucket size 802194 0.624 15,9 0.683 17,4 802273 5⁄8 15,8 802330 1) 55 25 802197 0.687 17,5 0.785 19,4 802274 11⁄16 17,5 802330-E 2) 55 25

802200 0.749 19 0.796 20,2 802275 3⁄4 19 802203 0.812 20,6 0.871 22,1 802276 13⁄16 20,6 802206 0.874 22,2 0.933 23,7 802277 7⁄8 22,2 802249 0.937 23,8 0.996 25,3 802278 15⁄16 23,8 802209 1 25,4 1.059 26,9 802279 1 25,4 Pump and accessory package includes the Lincoln series 20 50:1 grease pump, air ilter, regulator, gauge, low control, For use with large lubricator 802180 WRL sling with ratchet, grease quick disconnects and 802251 1.063 27 1.122 28,5 802280 1 1⁄16 27 adapter ittings. 1) Model for ordering in the US. 802221 1.124 28,6 1.183 30,1 802281 1 1⁄8 28,6 2) Model for ordering in Germany. 802253 1.187 30,2 1.246 31,7 802282 1 3⁄16 30 802212 1.249 31,8 1.309 33,3 802283 1 1⁄4 31,8 802255 1.313 33,3 1.372 34,8 802284 1 5⁄16 33,3

1) See WRL installation guide, form number 801975A section J3 3A, for wire rope measuring instructions to ensure correct it 2) Recommended spare parts

Groove cleaner Designed to complement the Lincoln wire Groove cleaner and separating bushing kit rope lubricator, the groove cleaner removes dirt and used grease from the rope before it passes through the lubricator. Utilizing the cleaner improves the penetration of new grease and enhances corrosion protection to extend wire rope service life. Each groove cleaner is produced individu- ally based on rope speciications to make sure that the device proile matches Separating bushing accurately with the strands. The groove cleaner unit consists of a groove cleaner device, as well as separating bushings and a separating bushing support to minimize wear. The cleaner is manufac- tured from thermoplastic polyurethane elastomer (TPU) for durability.

Advantages: Separating bushing support • Extends service life of wire rope • Improves penetration of new grease • Enhances corrosion protection • Easy to install and use

5Groove cleaner and separating bushing identiication codesFor the correct selection of a groove cleaner and separating bushing, the user must determine the accurate dimensions and type of wire.We recommend the following steps:

Measure the real diameter (A) of the wire rope Identify the number of outer strands. Determine the lay (right or left) of the wire ropewith a caliper. strands.

Order no. Code Nominal wire rope diameter Description minimum maximum

802332 S - 19/32" - 3/4" 19/32 15.1 3/4 19 For wire rope diameters 19/32" - 3/4" 802333 S - 3/4" - 29/32" 3/4 19.1 29/32 23 For wire rope diameters 3/4" - 29/32" 802334 S - 29/32" - 1 1/16" 29/32 23.1 1 1/16 27 For wire rope diameters 29/32" - 1 1/16" 802335 S - 1 1/16" - 1 7/32" 1 1/16 27.1 1 7/32 31 For wire rope diameters 1 1/16" - 1 7/32"

802336 S - 1 7/32" - 1 3/8" 1 7/32 31.1 1 3/8 35 For wire rope diameters 1 7/32" - 1 3/8" 802337 S - 1 3/8" - 1 17/32" 1 3/8 35.1 1 17/32 39 For wire rope diameters 1 3/8" - 1 17/32" 802338 S - 1 17/32" - 1 11/16" 1 17/32 39.1 1 11/16 43 For wire rope diameters 1 17/32" - 1 11/16" 802339 S - 1 11/16" - 1 27/32" 1 11/16 43.1 1 27/32 47 For wire rope diameters 1 11/16" - 1 27/32"

802340 S - 1 27/32" - 2" 1 27/32 47.1 2 51 For wire rope diameters 1 27/32" - 2"

Order no. Code Nominal wire rope diameter Description minimum maximum

802341 F - 19/32" - 2" 19/32 15.1 2 50,8 For wire rope diameters 19/32" - 2" without 13 ft (4 m) ratchet sling 802342 FS - 19/32" - 2" 19/32 15.1 2 50,8 For wire rope diameters 19/32" - 2" with 13 ft (4 m) ratchet sling

66 The groove cleaner is designed and manufactured in accordance with the exact size of the wire rope. In order to request the product, the client must provide the rope speciication, or send a sample. To ensure an effective cleaning, the groove cleaner must be tightened with a breeze T-bolt (included).

Groove cleaner element with breeze T-bolt clamp Groove cleaner element with breeze T-bolt clamp For rope strands with left lay For rope strands with right lay

Order no. Code Wire rope No. of Order no. Code Wire rope No. of diameter rope diameter rope strands strands

© SKF Group 2018The contents of this publication are the copyright of the publisher and may not be reproduced (evenextracts) unless prior written permission is granted. Every care has been taken to ensure the accuracyof the information contained in this publication but no liability can be accepted for any loss or damagewhether direct, indirect or consequential arising out of the use of the information contained herein.PUB LS/P2 17901 EN · May 2018Certain image(s) used under license from Shutterstock.com.This publication supersedes publication PUB LS/P2 16063 EN.

Proper lubrication of wire rope will extend operational life and increase safety. Done correctly, it lubricates exterior surfaces as well as the inside wires and core. Proper lubrication will help reduce friction as the individual wires move over each other, and provide corrosion protection.However, lubricating wire ropes can be difficult. Manual lubrication via drip, brush, spatula or rubber glove method is a messy, time-consuming maintenance task and can be hazardous to the environment.

The Viper Wire Rope Lubricator is a much better solution. The Viper Mid MK II provides fast, effective one-pass lubrication of wire ropes from 5/16 in (8 mm) to 2 5/8 in (67 mm) in diameter, at speeds up to 6,670 ft (2,033 m) per hour. It eliminates the slow, labor-intensive task of manual lubrication, at the same time achieving more thorough results by forcing LE’s robust wire rope lubricant under high pressure (up to 5,500 psi) right to the core of the wire rope.

The Viper Wire Rope Lubricator can be used in any application where wire rope can be drawn through the collar of the lubricator, including the following typical applications:

The Viper Wire Rope Lubricator consists of a lubricator collar assembly that houses polyurethane seals suited to a specific wire rope size. The assembly is clamped around the rope and anchored to a fixed point. The rope is then pulled through the collar. The steel scraper plates pre-clean the rope by scraping dirt, debris and old lubricant from the rope and protect the seals from loose strands, flattening them out before new lubricant is applied.

As the lubricant is applied with the high-pressure, high-flow grease pump, it forces the lubricant between the strands to the wire rope core. The result is a fully lubricated wire rope with a smooth minimal film of lubricant on the outer strands.

The collar is the heart of the Viper MK II. Constructed from high-grade cast aluminum with a robust protective coating, the collar is completed with stainless steel hardware to provide maximum corrosion protection. The MK II collar has built-in handles, making it easy to carry in one hand. One person can easily attach the Viper to the rope.

LE carries the complete standard kit and all necessary components for operation. Configuring the kit is simple. The selection of the seals and scraper plates is based on wire rope size. If you have more than one wire rope size, additional scrapers and seals can be purchased.

We also carry some of the best wire rope lubricants found in the market to provide you with an entire solution. We recommend that you use Wirelife® Almasol® Coating Grease (452-453) with the Viper Wire Rope Lubricator

Wirelife Almasol Grease is available in NLGI 00 (452-PL, 452-QD, 452-DR) and NGLI 0 (453-PL, 453-QD, 453-DR) grades, both of which are extremely tacky and water resistant and have exceptional penetrating ability. They provide EP protection and exceptional corrosion protection, even in underwater applications

In addition to wire rope lubrication, LE is happy to offer lubricant and reliability recommendations for a variety of industries and applications, and to provide product-specific data on all of our items to help you make the right decision.

To learn more about the Viper Wire Rope Lubricator or about LE’s enhanced lubricants, lubricant training, oil analysis, filtration, lube rooms, breathers, sight glasses or other lubricantreliability solutions, please contact us today.

The service tool has been designed to deliver highly effective lubrication in virtually any application using wire rope, including oil and gas rigs, wharf and ship cranes, deck winches, ship hoists, remotely operated vehicles and winding machines in mines. Used as part of the maintenance cycle, the Lincoln WRL can enhance the steel wire rope life by as much as eight times that of a wire rope that has not been lubricated in this way, while also dramatically reducing downtime.

Supporting all lubricants typically used with wire rope, the system ensures optimum lubrication by applying the exact amount of grease required and distributing it evenly onto the rope’s surface. The lubricator forces the grease into the rope’s core, thus reducing friction and heat generation, while protecting against corrosion. As a result, it reduces lubrication time by up to 90 per cent compared with manual lubrication, as well as eliminating excessive waste and environmental contamination.

The easy to use wire rope lubrication system comes to the market following extensive field testing. It is ultra-reliable and features an extremely robust design, making it ideal for long-term use in even the most challenging environments and harsh conditions.

Commenting on the new Lincoln WRL, Tim Veal, Lubrication Systems Business Manager at SKF, said: “The launch of this highly efficient lubrication tool enhances our maintenance and friction management product family and brings to the market an effective solution that is ideal for most wire rope applications. It provides users with time and labour savings, while reducing grease consumption and, most importantly, significantly increases the life cycle of wire ropes.

Corelube designs, engineers & manufactures state-of-the-art, wire rope lubricators/lubricator & wire rope cleaning tools. Corelube has been solving wire rope maintenance problems for over 40 years.

The key to maintaining wire ropesis protecting the interior core wires from corrosion and wear with protecting the exterior from the elements and extreme wear conditions. Corelube Equipment has designed wire rope lubrication systems that address both of these issues.

We believe there is no one size fits all solution when it comes to wire rope lubrication. With 40 years of designing wire rope lubrication systems, we believe our systems are the most advanced/environmentally friendly systems out there.

Wire rope lubricants with good penetrating properties are key to preventing internal corrosion & wear. Corelube highly recommends wire rope lubricants that transition from penetrating oil to grease.

8613371530291

8613371530291