splice wire rope end to end in stock

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:You can form an eye, or loop, in the wire rope

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

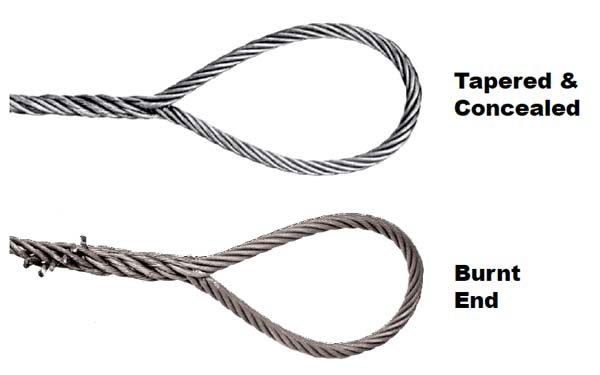

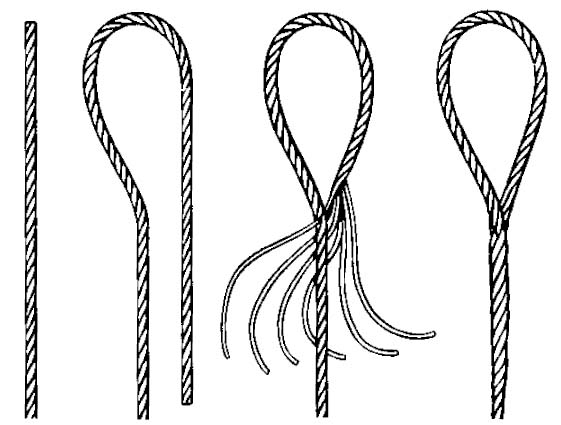

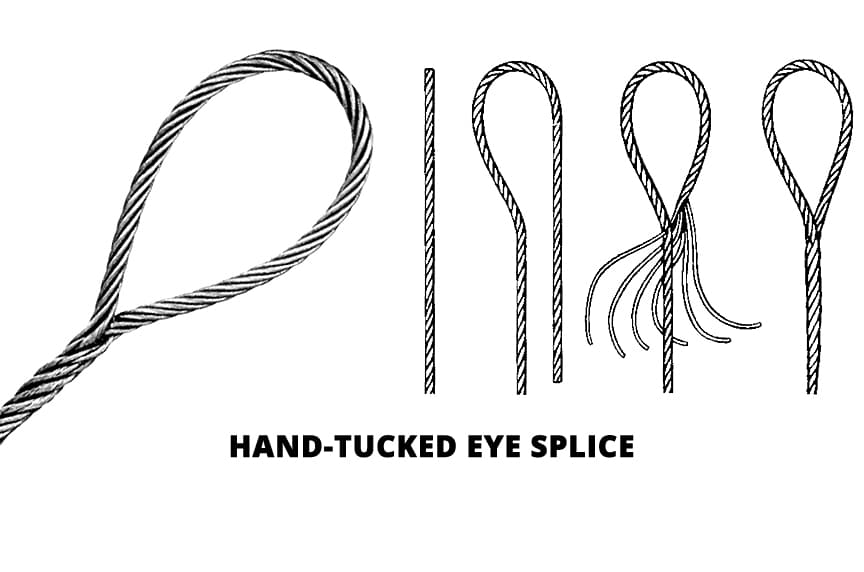

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

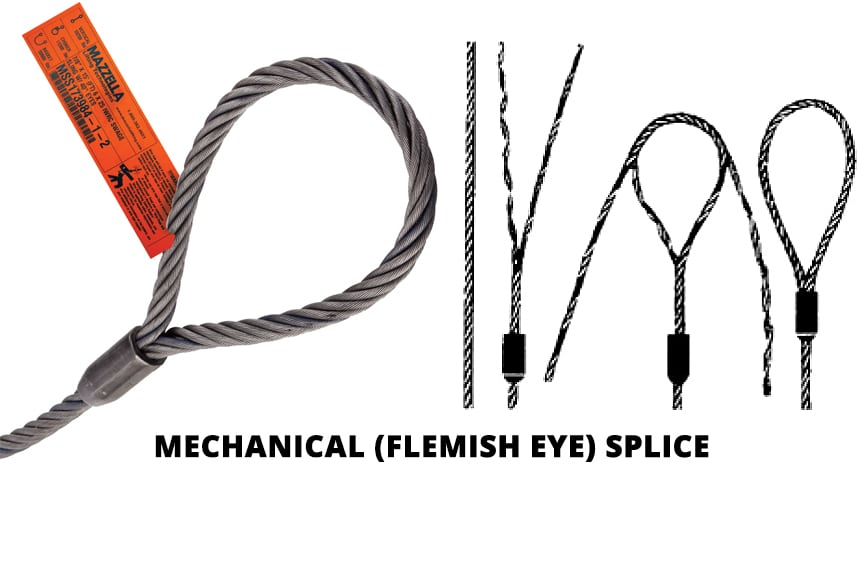

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.IWRCFC

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

Splicing arborist ropes is a fun and useful skill which allows you to make your own custom tree slings, eye splices, prusiks, and more. Below you will find everything you need to learn to splice arborist ropes. 12-strand and double braid ropes are easily spliced with the appropriate tubular aluminum fids and fid pushers. Splicing 16-strand ropes requires a bit more effort, and that"s where tools like the Brion Toss splice wand really shine. If you have any questions about the tools require for rope splicing, feel free to call and our splicers can help you out.

We have created complete rope splicing kits for both 16-strand and double braid ropes. Check out our rope clearance page for discounted rope perfect for splicing project. You"ll find free rope splicing instructions for Samson arborist ropes available to download.

This durable manual features user-friendly directions for the latest splicing techniques. A full-color Samson rope identification chart features 52 different ropes and their corresponding construction and class designation. This is one of the best splicing manuals available, and is the go-to for enthusiasts and pros alike. It has information on so many different types of splices that it benefits splicers in all fields: industrial, marine, arborist, equestrian, etc. 158 pages of 30 different splices grouped by 7 types of rope constructions. Laminated, fold-out cover.

These fids are designed to splice all Samson ropes according to their splicing instructions. Measurements are determined in “fid-lengths”, so you will want to purchase the splicing fid that corresponds to the rope diameter you are splicing. You will also want the appropriate fid pusher.

For rope sizes above 1" in diameter, Samson recommends a wire fid. Keep in mind that while the tubular fids are 100% scale for Samson"s splicing instructions, the wire fids are 1/2 scale, and the length of the tool is 1/2 the actual fid length for the corresponding rope diameter.

Samson fid pushers are used in rope splicing to push the tubular fids attached to the rope through the rope to complete the bury, and also can be used to help extract core fibers when beginning the splice. Choose the size of fid pusher corresponding to the rope diameter you want to splice. Made in the USA by Samson Ropes for use with their rope splicing instructions.

Chock full of useful splicing tools. Contains one small pusher, one each of 1/4”, 5/16”, 3/8”, 7/16”, and 1/2” aluminum fids. A great way to save money if you want to splice a wide range of ropes from 1/4” to 1/2”. The splicing tools in this kit will be useful for splicing 12-strands like Tenex as well, up to 1/2” in diameter. We recommend picking up the Splicing Manual for full instructions.

This kit provides the fids and pushers needed to splice common climbing and rigging lines used in tree work. Includes Samson Small and Large Pushers, 7/16”, 1/2”, 5/8”, and 3/4” fids. These tools allow you to splice according Samson"s proven rope splicing methods. You will want to also pick up some masking tape and a sharpie for marking strands.

Order this kit for the fids and pushers you need to splice the most commonly-used lines in arboriculture, and then head on over to our Samsonrope splicing instructions page to download and print the free instructions you need to get started splicing, or buy the complete set of Samson rope splicing instructions in the durable Samson Splicing Manual below.

Polished stainless steel fids have a unique design with a catch on the inside, which grabs the strand and removes the need to tape the rope to the fid. These Norwegian-designed fids are popular around the world for splicing marine lines, and will work great on hollow braid 12-strand, double-braid, and 3-strand ropes.

This set of 5 Selma fids contains fids with inside diameters of 4.0, 5.5, 7.5, 10.0, and 13.0 mm. Each fid fits inside the next larger fid, making storage convenient and compact.

Packed full of professional tools most useful for arborist ropes. This compact splicer kit from Yale will get you splicing your own prusiks and climb lines.

This new fid from Yale is designed to make splicing 12-strand hollow braids like Tenex and AmSteel-Blue a snap. The wire basket on the fid works just like a Chinese finger trap: use your fingers to bunch up the wire basket, then slide the rope end in and pull. The basket closes on the rope, allowing you to easily complete the splice and bury. When done, simply bunch up the wire, and remove the rope. A great time-saver for anyone splicing 12-strand hollow braids up to 5/8” diameter.

Marlow"s stainless steel wire loop on 3mm Excel Pro cord makes a great tool for easy pulling when splicing small cords. As with the New England Fids, the Marlow Wire is great for tight crossovers and is a nice, minimal wire fid for people who don"t want to use the piano wire/clamp method.

These high-quality steel needles can be used for lock-stiching or whip-stitching a splice in larger ropes. Ideal for working on Tenex or large diameter double-braid splices.

The larger of the two sailmakers" needles can be used similarly to a Marlin Spike to extract the core of a rope in a pinch, but over time is not an ideal substitute.

Leather palm slips over the hand and puts the metal socket in the middle of the palm, so that this can protect the hand when the palm is used to push needles through a splice. Right and left hand versions.

These bands have been re-purposed from their veterinary use to make a captive, tight-eye on our 5" eye-splices. This helps keep the carabiner properly positioned. They can also be used to make speedline slings by keeping nylon runners properly positioned on an oval carabiner. Use the banding tool to quickly apply a band to make any loop or eye a captive eye.

Thimbles preserve more of the breaking strength of a rope when used with a knot or an eye splice by maintaining a large bend radius and protecting the rope.

Thimbles preserve more of the breaking strength of a rope when used with a knot or an eye splice by maintaining a large bend radius and protecting the rope.

This plastic thimble has high sides to help it stay in place inside a spliced eye, with open edges to allow removal (tools required) after splicing if needed. Fits rope from 7/16" to 1/2". Not recommended for heavy-duty needs/rigging applications.

Thimbles preserve more of the breaking strength of a rope when used with a knot or an eye splice by maintaining a large bend radius and protecting the rope.

Thimbles preserve more of the breaking strength of a rope when used with a knot or an eye splice by maintaining a large bend radius and protecting the rope. These steel thimbles from DMM are compatible with wire or textile ropes, have open-sided rope channels to allow for easy rope inspection.

These stainless steel thimbles from DMM are compatible with wire or textile ropes and have open-sided rope channels to allow for easy rope inspection. The added tab in the eye makes this thimble useful in constructing friction savers, as it gives the retrieval ball something to catch on.

Tenex Tec (Two-End-Carrier) is a high-strength, low-stretch rope ideal for splicing slings. The two-ends per carrier construction gives more allows Tenex Tec to conform more to the surface of the tree than standard single-braid ropes, giving it better grip. Tenex Tech is Samthane-coated for enhanced wear life. Easily to splice.

Stable Braid is an all-polyester double-braid rigging line which is a standard in tree rigging. Uncoated Stable Braid is left untreated with Samthane (a coating which enhances wear-resistance) so it is softer to the hand than coated Stable Braid. Uncoated Stable Braid is often used by folks making custom animals leads, and it is fine for rigging.

Pro-Master is a soft-lay 3-strand rope which is super easy to splice, making it a popular material for all manner of slings, leads, tool tethers, and other rope tools.

Nylon chafe sleeve for the protection of arborist ropes and slings. You may order chafe sleeve by the foot here for your own spliced products, or request it on any spliced product we make that will fit the sleeve. Often used to reinforce spliced eyes or as a movable chafe sleeve on fliplines, winch lines, etc.

Splicing Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NOTE* ! * ! * ! * ! BACK IN STOCK ! * ! * ! * ! Basic Braided Splices - Book 5 of the Working Rope Field Guides by Brion Toss

Brion"s new most favorite tool - HM Shears for cutting all High Modulus Rope - cuts like butter. If you can get these shears around the rope - you can cut it. check them out - very bottom of this page.

Braided and High Modulus (aka Parallel-Core) Rope splicing can be a daunting, frustration task, if you are using conventional tools and instructions. That"s why the Splicing Wand was invented, a tool that makes quick, easy work of tucking.

The Splicing Wand is basically a long tube containing a hidden snare. You slide the tool into the rope, grab the end you want to tuck, and slide the tool out. There"s a specially-shaped tip on the tube, to keep you from snagging yarns along the way, an ingenious mechanism in the handle, to hold the tube in place while you work. You can clamp the tool in a vise if you want, leaving both hands free to deal with the rope, there"s no taping or un-taping, no fid lengths to decipher,and very little physical effort needed to tuck.

The Splicing Wand comes in six sizes - the inches noted are for rope diameter. The smallest we make is Micro, then Small, Medium, Large, X Large...and extra long/ but with a medium width tube -Arborist. (This is a very specialized size for a very specialized set of splices...most arborists will do well with our regular wands). You can get an idea of the diameter of each of the wands by looking at the photo above - I put a pencil and a ruler in the photo to give perspective.

Arborist Splicing Wand - which is a Medium diameter wand cut extra long and which works rope 5/16" - 1/2" in diameter. This wand is especially good for split tail arborist splices. (12 ounce)

For 3-Strand & Mega Braid rope. This is the world"s second most expensive fid; the most expensive being those fids that cut and disturb your rope as you use them!

The Phid is round and polished with no sharp edges to damage the rope fibers. It is easy to enter, even into hard-laid rope. The Phid is designed with an artful �cutaway 148;, so you can leave it in the rope while tucking the strand; no more yanking and dragging to get the strand home.

The Phid is truly a beautiful tool, a marvel of functional elegance. The Point Hudson Phid comes in two sizes - Small works rope 5/16-5/8; Large works rope 3/4-1 1/8

"Tarred Seine Twine is the ideal string. It is fairly chaif resistant, extemely weather resistant, and does not slip. It can be used for service, seizings, lanyards, lashings, emergency repairs, gaskets making of lost wax jewelry, and fishing to name a few. "

In this volume of the Working Rope series, Brion Toss and Margie McDonald bring to you the distilled results of decades of experience with thousands of splices.

Here are the tips, techniques, and shortcuts that professionals use, along with valuable information on the characteristics of each type of rope you�ll be splicing.

There are no confusing �fid lengths� here, just dimensions based on rope diameter, or on marks braided into the rope at the factory. And the purpose or every mark is explained, so you can comprehend each splice, from start to finish.

You�ll find instructions for splicing conventional ropes, like Dacron and Nylon. But this volume also covers splices for the new High-Modulus lines like Spectra and Vectran. There are even instructions for making High-Modulus rope grommets.

Make no mistake, splicing is still an art, requiring patience and dedication on the part of the splicer. But with these instructions, you�ll be taking a giant step towards mastering braided rope splicing.

We are happy to autograph your book. Please state clearly to whom you would like the dedication, i.e. a person, a couple, a boat, a company, etc. You can indicate this in the comment field when you check out

Great splice for running and standing rigging, life lines, slings, outhauls and more...Properly done, this splice will approach 100% efficiency in strength and security.

A sturdy 6 inch spike of the Best quality steel, with duck bill point for smooth insertion. Small enough for tiny line, strong enough for splicing steel wire. Solid wood varnished handle.

"A 4 inch version of our popular hand spike of the BEST quality steel, with duck bill point for smooth insertion. Small enough for tiny line, strong enough for splicing steel wire. Solid wood handle - shaped to your hand & varnished

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. The Micro ( x small ) wand requires a special snare - stiffened to allow it to be threaded through the rod."

Keep your rope ends from fraying - finish the job - whip them with a palm and needle whipping or a double constrictor knot (pg. 78 in the Rigger"s Apprentice). Mark them distinctly and traditionally with your choice - Dark Red, Dark Green, Deep Blue, White, or Gold. Also great for tying up very small packages.

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. These are our new heavier weight snares for Medium and Large - they will last much longer!"

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. These are our new heavier weight snares for Medium and Large - they will last much longer!"

Samson recommends splicing as the preferred rope termination method. Knots can significantly decrease a ropes strength while, in most cases, splicing maintains 100% of the specified rope strength. Splice terminations are used in all our ropes to determine new and unused tensile strengths.

For more than 135 years, users in industries around the world have relied on products, services, and expertise from Columbus McKinnon to address needs in the workplace. From individual

hand tools to sophisticated crane systems, the wide range offered by Columbus McKinnon is unsurpassed in the market. We carry many CM products including: hoists, trolleys,

Want to do your own rigging and splicing of ropes? We have made more than 30 rope splicing instruction videos. For example, how to make an eye-splice in modern ropes? Or how to make soft shackles from ropes with Dyneema® fibers? Watch our video"s! The reference numbers correspond to the chapters of "Handbook Splicing Modern Ropes".

Want to start with splicing? Check out our wide range of splicing tools. And do you already have our Rope Splicing App on your phone? All splicing instructions in your pocket and easy to use off-line!

If your rope does not hold in jammers or clutches, splice an extra cover or add an extra core. Chafing covers from Technora or Dyneema®are great to extend the life of your ropes.

Splicing modern braided ropes of super fibres is quite fun and easy to learn. Premiumropes has uploaded various splicing tutorials, such as eye-splices, soft shackles, taper sheets or make a continuous furler line. Make sure you have enough space to work and an anchoring point for your rope. If you are on board, you can use a winch in case you need extra force. Choose a fid that matches the diameter of the rope, or even one that is slightly thinner. Never use pliers to pull out a fid from the rope - you will damage it! Do you know what the construction of your rope is? Check our table what splicing technique to choose for which type of rope. The core material largely determines the type of splice, whether it is core dependend or if you need to use the cover in the eye-splice too.

Scope. This section applies to slings used in conjunction with other material handling equipment for the movement of material by hoisting, in employments covered by this part. The types of slings covered are those made from alloy steel chain, wire rope, metal mesh, natural or synthetic fiber rope (conventional three strand construction), and synthetic web (nylon, polyester, and polypropylene).

Basket hitch is a sling configuration whereby the sling is passed under the load and has both ends, end attachments, eyes or handles on the hook or a single master link.

Cable laid endless sling-mechanical joint is a wire rope sling made endless by joining the ends of a single length of cable laid rope with one or more metallic fittings.

Cable laid grommet-hand tucked is an endless wire rope sling made from one length of rope wrapped six times around a core formed by hand tucking the ends of the rope inside the six wraps.

Cable laid rope sling-mechanical joint is a wire rope sling made from a cable laid rope with eyes fabricated by pressing or swaging one or more metal sleeves over the rope junction.

Choker hitch is a sling configuration with one end of the sling passing under the load and through an end attachment, handle or eye on the other end of the sling.

Female handle (choker) is a handle with a handle eye and a slot of such dimension as to permit passage of a male handle thereby allowing the use of a metal mesh sling in a choker hitch. (See Fig. N-184-1.)

Master coupling link is an alloy steel welded coupling link used as an intermediate link to join alloy steel chain to master links. (See Fig. N-184-3.)

Master link or gathering ring is a forged or welded steel link used to support all members (legs) of an alloy steel chain sling or wire rope sling. (See Fig. N-184-3.)

Diagam howing Two slings with indicators for sling width, overall length, bearing to bearing length, and fabric length. Further indicators point to both male handles, handle eye, female handle, and slot depth

Diagram indicates Forms of Hitch and Kind of Sling. Eye&Eye Vertical Hitch. Eye&Eye Choker Hitch. Eye&Eye Basket Hitch (Alterates have identical load rations). Endless Vertical Hitch. Endless Choker Hitch. Endless Basket Hitch (Alternateve have identical load ratings). Notes: Angles 5 deg or less from the veritcal may be considered vertical angles. For slings with legs more than 5 deg off vertical, the actual angle as shown in Figure N-184-5 must be considered. Explanation of Symbols: Minimum Diameter of Curvature. Represents a contact surface which shall have a diameter of curvature at least double the diameter of the rope from which the sling is made. Represents a contact surface which shall have a diameter of curvature at least 8 times the diameter of the rope. Represents a load in a choker hitch and illustrates the rotary force on the load and/or the slippage of the rope in contact with the load. Diameter of curvature of load surface shall be at least double the diameter of the rope.

Diagram indicates Form of Hitch and Vertical Hitch. Kind of Sling. Eye&Eye Vertical Hitch Not Applicable. Eye&Eye Choker Hitch Not Applicable. Eye&Eye Basket Hitch (Alternates have identical load ratings). Endless Vertical Hitch Not Applicable. Endless Choker Hitch Not Applicable. Endless Basket Hitch (Alternates have identical load ratings). Notes: For vertical angles of 5 deg or less, refer to Figure N-184-4 ""Basic Sling Configurations with Vertical Legs"". See Figure N-184-4 for explanation of symbols.

Proof test is a nondestructive tension test performed by the sling manufacturer or an equivalent entity to verify construction and workmanship of a sling.

Reach is the effective length of an alloy steel chain sling measured from the top bearing surface of the upper terminal component to the bottom bearing surface of the lower terminal component.

Strand laid endless sling-mechanical joint is a wire rope sling made endless from one length of rope with the ends joined by one or more metallic fittings.

Strand laid grommet-hand tucked is an endless wire rope sling made from one length of strand wrapped six times around a core formed by hand tucking the ends of the strand inside the six wraps.

Strand laid rope is a wire rope made with strands (usually six or eight) wrapped around a fiber core, wire strand core, or independent wire rope core (IWRC).

Employers must not load a sling in excess of its recommended safe working load as prescribed by the sling manufacturer on the identification markings permanently affixed to the sling.

Hooks, rings, oblong links, pear shaped links, welded or mechanical coupling links or other attachments shall have a rated capacity at least equal to that of the alloy steel chain with which they are used or the sling shall not be used in excess of the rated capacity of the weakest component.

In addition to the inspection required by paragraph (d) of this section, a thorough periodic inspection of alloy steel chain slings in use shall be made on a regular basis, to be determined on the basis of

Safe operating temperatures. Employers must permanently remove an alloy steel-chain slings from service if it is heated above 1000 degrees F. When exposed to service temperatures in excess of 600 degrees F, employers must reduce the maximum working-load limits permitted by the chain manufacturer in accordance with the chain or sling manufacturer"s recommendations.

Sling use. Employers must use only wire-rope slings that have permanently affixed and legible identification markings as prescribed by the manufacturer, and that indicate the recommended safe working load for the type(s) of hitch(es) used, the angle upon which it is based, and the number of legs if more than one.

Cable laid and 6 × 19 and 6 × 37 slings shall have a minimum clear length of wire rope 10 times the component rope diameter between splices, sleeves or end fittings.

Safe operating temperatures. Fiber core wire rope slings of all grades shall be permanently removed from service if they are exposed to temperatures in excess of 200 °F. When nonfiber core wire rope slings of any grade are used at temperatures above 400 °F or below minus 60 °F, recommendations of the sling manufacturer regarding use at that temperature shall be followed.

All welded end attachments shall not be used unless proof tested by the manufacturer or equivalent entity at twice their rated capacity prior to initial use. The employer shall retain a certificate of the proof test, and make it available for examination.

Sling marking. Each metal mesh sling shall have permanently affixed to it a durable marking that states the rated capacity for vertical basket hitch and choker hitch loadings.

Sling testing. All new and repaired metal mesh slings, including handles, shall not be used unless proof tested by the manufacturer or equivalent entity at a minimum of 1½ times their rated capacity. Elastomer impregnated slings shall be proof tested before coating.

Safe operating temperatures. Metal mesh slings which are not impregnated with elastomers may be used in a temperature range from minus 20 °F to plus 550 °F without decreasing the working load limit. Metal mesh slings impregnated with polyvinyl chloride or neoprene may be used only in a temperature range from zero degrees to plus 200 °F. For operations outside these temperature ranges or for metal mesh slings impregnated with other materials, the sling manufacturer"s recommendations shall be followed.

Once repaired, each sling shall be permanently marked or tagged, or a written record maintained, to indicate the date and nature of the repairs and the person or organization that performed the repairs. Records of repairs shall be made available for examination.

Sling use. Employers must use natural and synthetic fiber-rope slings that have permanently affixed and legible identification markings stating the rated capacity for the type(s) of hitch(es) used and the angle upon which it is based, type of fiber material, and the number of legs if more than one.

Safe operating temperatures. Natural and synthetic fiber rope slings, except for wet frozen slings, may be used in a temperature range from minus 20 °F to plus 180 °F without decreasing the working load limit. For operations outside this temperature range and for wet frozen slings, the sling manufacturer"s recommendations shall be followed.

Splicing. Spliced fiber rope slings shall not be used unless they have been spliced in accordance with the following minimum requirements and in accordance with any additional recommendations of the manufacturer:

In manila rope, eye splices shall consist of at least three full tucks, and short splices shall consist of at least six full tucks, three on each side of the splice center line.

In synthetic fiber rope, eye splices shall consist of at least four full tucks, and short splices shall consist of at least eight full tucks, four on each side of the center line.

Strand end tails shall not be trimmed flush with the surface of the rope immediately adjacent to the full tucks. This applies to all types of fiber rope and both eye and short splices. For fiber rope under one inch in diameter, the tail shall project at least six rope diameters beyond the last full tuck. For fiber rope one inch in diameter and larger, the tail shall project at least six inches beyond the last full tuck. Where a projecting tail interferes with the use of the sling, the tail shall be tapered and spliced into the body of the rope using at least two additional tucks (which will require a tail length of approximately six rope diameters beyond the last full tuck).

For all eye splices, the eye shall be of such size to provide an included angle of not greater than 60 degrees at the splice when the eye is placed over the load or support.

Removal from service. Natural and synthetic fiber rope slings shall be immediately removed from service if any of the following conditions are present:

Attachment of end fittings to webbing and formation of eyes. Stitching shall be the only method used to attach end fittings to webbing and to form eyes. The thread shall be in an even pattern and contain a sufficient number of stitches to develop the full breaking strength of the sling.

Diagram depicting three of six types of sling constructions. Type I Triangle Choker typer. Contains Triangle Fitting, measured pull to pull when flat, choker slot, choker fitting, and fitting eye. Type II Triangle Triangle. Length Measured pull to pull when flat. Type III Eye and Eye with Flat Eyes. Length between Lap and Eye.

Diagram depicting the final three types of six of sling constructions. Type IV Eye and eye with Twisted Eyes. Length measured Eye Perpendicular to Sling Body. Type V Endless Type. Type VII Return Eye.

Each repaired sling shall be proof tested by the manufacturer or equivalent entity to twice the rated capacity prior to its return to service. The employer shall retain a certificate of the proof test and make it available for examination.

RM2H669FJ–Looking up at the underside of exposed floor joists resting, with packing on wall plate with simple pegged tenoned mitre splice in old timber framed

RF2B8XXCM–Los Angeles, California, USA - 24 March 2020: Splice app logo on phone screen close up with website on background with icon, Illustrative Editorial

RF2A367AD–Electric wire connecter for fasten low-voltage electrical conductors. Connector splice wires together with a wire nut. Connecting end caps on electric

RFT5XDW6–Eye splice is the end of the rope is unlaid and the strands are bent upon the body of the rope, vintage line drawing or engraving illustration.

RF2A367A2–Splice electrical wires using wire connectors. Electric wire connectors are twist-on or wire nuts. End caps for electrical wires are wire caps or wire

RFT5YWT6–Short Splice is the most common description of splice is when a rope is lengthened by another of the same size, vintage line drawing or engraving illu

RF2AH7DRE–Collectible mineral strontianite specimen; radial splice of white crystals isolated on a black background; Mine number 5, Long Mountain, village Vishn

RFKG187G–View from the side of a sailing boat. In the foreground in focus - a tight shroud with eye splice. The middle plan is the slightly blurred face of the

RF2A7N5R9–Splicing electric wires in a electrical box of a ceiling chandelier using a spring-loaded lever terminal block. An electrician mounts a wiring of a li

RFT5X4JH–Eye Splice in Three Steps which is a sort of eye or circle formed by splicing the end of a rope into itself, vintage line drawing or engraving illustr

RFMNXG3F–Technicians put it Optical cable and wire in fiber optic splice tray. Close up, selective focus. Modern and fast internet and network concept

RFT61FN3–Double Strop Made with one piece of rope the splice being brought as usual to the crown of the block, vintage line drawing or engraving illustration.

RMJAAPEY–A cricket bat has white tape near the splice at Lynton & Lynmouth Cricket Club during an annual friendly match at the club based inside the Valley of Rocks, North Devon.

The Flemish eye splice is popular. The rugged and durable sleeves secure the ends of the strands around the body of wire rope slings. For the construction industry and the majority of industrial sling applications, this is the preferred method.

Flemish eye splice is only performed on six-strand ropes. Loop end terminations used for non- and rotation-resistant wire ropes, as well as ropes with more than six strands, require aluminum or turn-back steel sleeves. If the sleeves are made from regular carbon or aluminum metal, an electrochemical reaction between the two metals has the potential to speed up deterioration. This can be accelerated if the slings are used in corrosive environments or saltwater.

The fabrication of this splice involves forming a loop eye and pressing an aluminum sleeve over both rope parts. As for strength, this is dependent on the pressed sleeve’s integrity. For non-rotating rope types, as well as 8-, 9-, and 10-strand ropes, thimbles at the ends are typically requested.

This method is almost identical to the aluminum turn back splice with the exception that it is fabricated with steel sleeves of a somewhat smaller diameter. Also available in stainless steel, this termination can be used on stainless steel ropes of a larger diameter. With this method, the rope loops back into a swaged sleeve, forming a permanent load-bearing bond between the two parts of the rope.

For the termination on these wire rope slings, the rope inserts into the fitting bore, followed by being swaged onto the rope. This is the preferred method for open and closed sockets, buttons, and threaded studs and to attach a load hook directly onto the rope. This method works great for all rope constructions, and it produces a high-efficiency bond.

Some people do not believe that spelter socket terminations are true sling fittings. Traditionally, this type of end termination was used to determine the breaking strength of wire rope slings. Considered 100 percent of the true actual rope strength, all other end terminations are compared to spelter sockets.

8613371530291

8613371530291