splice wire rope end to end free sample

Want to do your own rigging and splicing of ropes? We have made more than 30 rope splicing instruction videos. For example, how to make an eye-splice in modern ropes? Or how to make soft shackles from ropes with Dyneema® fibers? Watch our video"s! The reference numbers correspond to the chapters of "Handbook Splicing Modern Ropes".

Want to start with splicing? Check out our wide range of splicing tools. And do you already have our Rope Splicing App on your phone? All splicing instructions in your pocket and easy to use off-line!

If your rope does not hold in jammers or clutches, splice an extra cover or add an extra core. Chafing covers from Technora or Dyneema®are great to extend the life of your ropes.

Splicing modern braided ropes of super fibres is quite fun and easy to learn. Premiumropes has uploaded various splicing tutorials, such as eye-splices, soft shackles, taper sheets or make a continuous furler line. Make sure you have enough space to work and an anchoring point for your rope. If you are on board, you can use a winch in case you need extra force. Choose a fid that matches the diameter of the rope, or even one that is slightly thinner. Never use pliers to pull out a fid from the rope - you will damage it! Do you know what the construction of your rope is? Check our table what splicing technique to choose for which type of rope. The core material largely determines the type of splice, whether it is core dependend or if you need to use the cover in the eye-splice too.

A splice is a way of terminating a rope or joining two ends of rope together without using a knot. Apart from being bulky and unsightly, even a correctly tied knot can cause significant loss of strength to a rope. At Marlow our splicing team have over 150 years of combined splicing knowledge and experience and we offer a splicing service to our trade and commercial customers for bespoke rope assemblies, slings and strops. For sailors and boat owners, we always recommend using your local rigging professional to splice and install your ropes. Find your local Marlow Rigging professional here.

For those wishing to splice their own ropes, we have produced a comprehensive splicing guide and range of splicing tutorials (scroll down to view) detailing a range of splicing methods. For hands-on splicing demonstrations, visit the Marlow stand at any of our shows and exhibitions throughout the year, or sign up to attend a Marlow Rope-Show held across the UK at sailing clubs once per month.

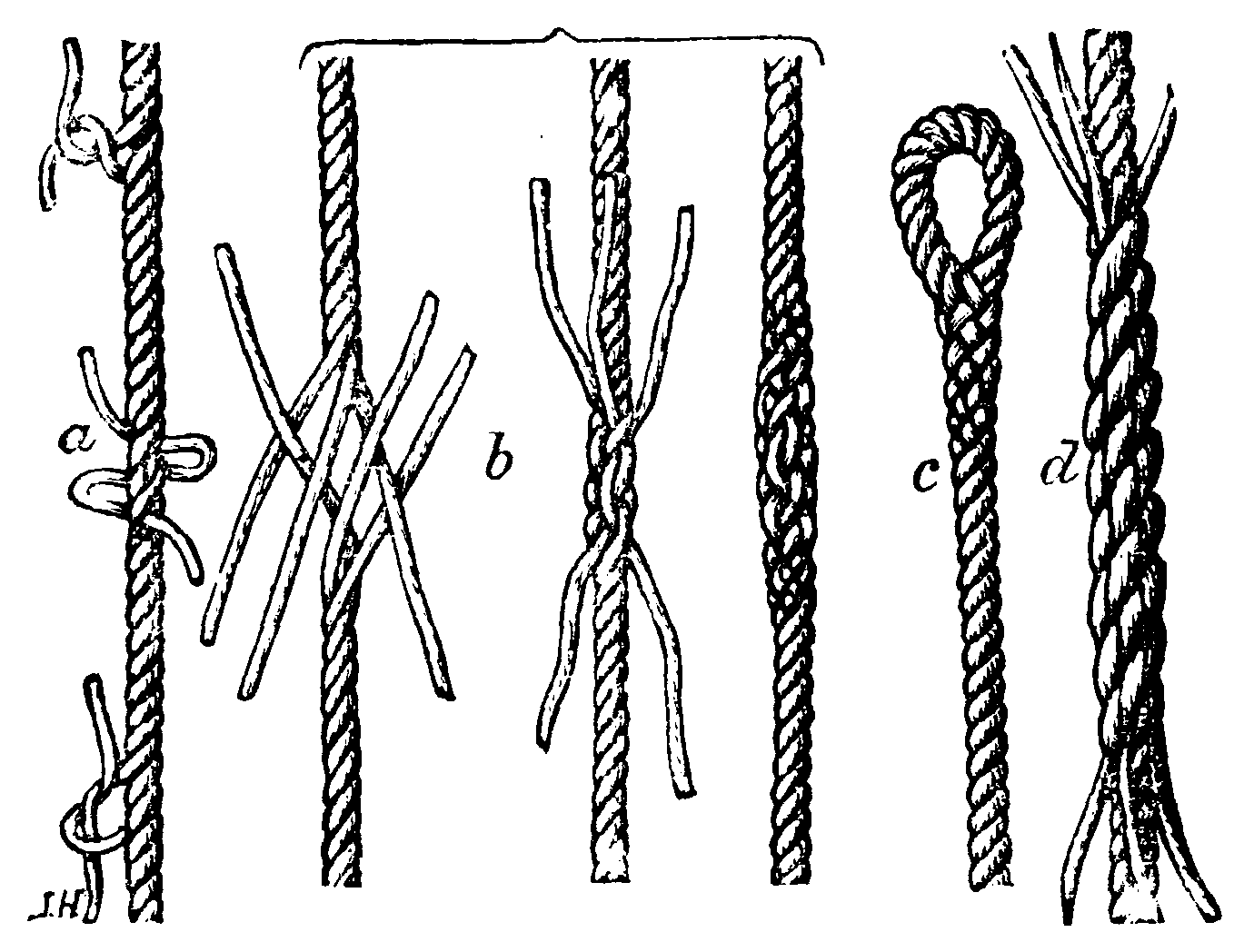

Rope splicing in ropework is the forming of a semi-permanent joint between two ropes or two parts of the same rope by partly untwisting and then interweaving their strands. Splices can be used to form a stopper at the end of a line, to form a loop or an eye in a rope, or for joining two ropes together.

back splice (or end splice) – A splice where the strands of the end of the rope are spliced directly back into the end without forming a loop. It is used to finish off the end of the rope to keep it from fraying. The end of the rope with the splice is about twice the thickness of the rest of the rope. With nylon and other plastic materials, the back splice is often no longer used; the rope strands are simply fused together with heat to prevent fraying.

cut splice (originally cunt splice) – A splice similar to the eye splice. It is typically used for light lines (e.g. the log-line) where a single splice would tend to come undone, the rope being frequently wet.bowdlerised to "cut splice".

long splice – A splice used to join two rope ends forming one rope the length of the total of the two ropes. The long splice, unlike most splice types, results in a splice that is only very slightly thicker than the rope without the splice, but sacrifices some of the strength of the short splice. It does this by replacing two of the strands of each rope end with those from the other, and cutting off some of the extra strands that result. The long splice allows the spliced rope to still fit through the same pulleys, which is necessary in some applications.

short splice – Also a splice used to join the ends of two ropes, but the short splice is more similar to the technique used in other splices and results in the spliced part being about twice as thick as the non spliced part, and has greater strength than the long splice. The short splice retains more of the rope strength than any knots that join rope ends.

Splices are often tapered to make the thicker splice blend into the rest of the line. There are two main types of tapering, the standard and the "West Coast Taper".

Standard tapers progressively remove a portion of each remaining strand – one-third at a time is typical, resulting in a taper of two additional tucks beyond the splice – thus making each successive tuck produce a narrower splice. This is only practical with laid-lines – those made up of numerous strands laid side by side.

A fid is a hand tool made from wood, plastic, or bone and is used in the process of working with rope. A variety of fid diameters are available depending on the size of rope being used. Styles of fid designs include:

A Marlinspike is a tool, usually made of steel and often part of a sailor"s pocketknife, which is used to separate strands of rope from one another. They can range in size anywhere from 3 inches to 5 feet long, with a round or flattened point.

Splicing Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NOTE* ! * ! * ! * ! BACK IN STOCK ! * ! * ! * ! Basic Braided Splices - Book 5 of the Working Rope Field Guides by Brion Toss

Brion"s new most favorite tool - HM Shears for cutting all High Modulus Rope - cuts like butter. If you can get these shears around the rope - you can cut it. check them out - very bottom of this page.

Braided and High Modulus (aka Parallel-Core) Rope splicing can be a daunting, frustration task, if you are using conventional tools and instructions. That"s why the Splicing Wand was invented, a tool that makes quick, easy work of tucking.

The Splicing Wand is basically a long tube containing a hidden snare. You slide the tool into the rope, grab the end you want to tuck, and slide the tool out. There"s a specially-shaped tip on the tube, to keep you from snagging yarns along the way, an ingenious mechanism in the handle, to hold the tube in place while you work. You can clamp the tool in a vise if you want, leaving both hands free to deal with the rope, there"s no taping or un-taping, no fid lengths to decipher,and very little physical effort needed to tuck.

The Splicing Wand comes in six sizes - the inches noted are for rope diameter. The smallest we make is Micro, then Small, Medium, Large, X Large...and extra long/ but with a medium width tube -Arborist. (This is a very specialized size for a very specialized set of splices...most arborists will do well with our regular wands). You can get an idea of the diameter of each of the wands by looking at the photo above - I put a pencil and a ruler in the photo to give perspective.

Arborist Splicing Wand - which is a Medium diameter wand cut extra long and which works rope 5/16" - 1/2" in diameter. This wand is especially good for split tail arborist splices. (12 ounce)

For 3-Strand & Mega Braid rope. This is the world"s second most expensive fid; the most expensive being those fids that cut and disturb your rope as you use them!

The Phid is round and polished with no sharp edges to damage the rope fibers. It is easy to enter, even into hard-laid rope. The Phid is designed with an artful �cutaway 148;, so you can leave it in the rope while tucking the strand; no more yanking and dragging to get the strand home.

The Phid is truly a beautiful tool, a marvel of functional elegance. The Point Hudson Phid comes in two sizes - Small works rope 5/16-5/8; Large works rope 3/4-1 1/8

"Tarred Seine Twine is the ideal string. It is fairly chaif resistant, extemely weather resistant, and does not slip. It can be used for service, seizings, lanyards, lashings, emergency repairs, gaskets making of lost wax jewelry, and fishing to name a few. "

In this volume of the Working Rope series, Brion Toss and Margie McDonald bring to you the distilled results of decades of experience with thousands of splices.

Here are the tips, techniques, and shortcuts that professionals use, along with valuable information on the characteristics of each type of rope you�ll be splicing.

There are no confusing �fid lengths� here, just dimensions based on rope diameter, or on marks braided into the rope at the factory. And the purpose or every mark is explained, so you can comprehend each splice, from start to finish.

You�ll find instructions for splicing conventional ropes, like Dacron and Nylon. But this volume also covers splices for the new High-Modulus lines like Spectra and Vectran. There are even instructions for making High-Modulus rope grommets.

Make no mistake, splicing is still an art, requiring patience and dedication on the part of the splicer. But with these instructions, you�ll be taking a giant step towards mastering braided rope splicing.

We are happy to autograph your book. Please state clearly to whom you would like the dedication, i.e. a person, a couple, a boat, a company, etc. You can indicate this in the comment field when you check out

Great splice for running and standing rigging, life lines, slings, outhauls and more...Properly done, this splice will approach 100% efficiency in strength and security.

A sturdy 6 inch spike of the Best quality steel, with duck bill point for smooth insertion. Small enough for tiny line, strong enough for splicing steel wire. Solid wood varnished handle.

"A 4 inch version of our popular hand spike of the BEST quality steel, with duck bill point for smooth insertion. Small enough for tiny line, strong enough for splicing steel wire. Solid wood handle - shaped to your hand & varnished

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. The Micro ( x small ) wand requires a special snare - stiffened to allow it to be threaded through the rod."

Keep your rope ends from fraying - finish the job - whip them with a palm and needle whipping or a double constrictor knot (pg. 78 in the Rigger"s Apprentice). Mark them distinctly and traditionally with your choice - Dark Red, Dark Green, Deep Blue, White, or Gold. Also great for tying up very small packages.

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. These are our new heavier weight snares for Medium and Large - they will last much longer!"

"Replacing your Spectra snare on the Brion Toss Splicing Wand is easy now. These are our new heavier weight snares for Medium and Large - they will last much longer!"

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

8613371530291

8613371530291