splice wire rope end to end brands

As a rigger or end-user of wire rope, it’s important to understand the types of terminations, or treatments, that can be used at the ends of a length of wire rope. These terminations are usually made by forming an eye or attaching a fitting, and are designed to be a permanent end termination on the wire rope where it connects to the load.

Wire rope is an extremely versatile mechanical device that can be used to help support and move an object or load. In the lifting and rigging industries, wire rope is attached to a crane or hoist and fitted with swivels, shackles or hooks to attach to a load and move it in a controlled matter. It can also be used to lift and lower elevators, or as a means of support for suspension bridges or towers.

In this article, we’ll explain what some of the following terms mean and how the can be used to terminate the end of a wire rope cable:Wire rope sockets—spelter sockets, swaged sockets, and wedge sockets

When you understand the construction and specifications of the wire rope you need, as well as the right type of end termination you need, you’ll be able to select the best performing and longest-lasting wire rope for the job at hand.

There are essentially two techniques that can be used to create a termination on a length of wire rope or cable:You can form an eye, or loop, in the wire rope

Eyes, or loops, can be created at one end of a length of wire rope by using a mechanical splice with a swaged sleeve, a hand-tucked splice, or wire rope clips.

A swaged socket is applied to the end of a wire rope cable and is then forced into place using special dies and a hydraulic machine called a swager. When properly applied with the correct sized fitting, swaged sockets have an efficiency rating of 100% of the breaking strength of the rope.

A poured socket, commonly referred to as a spelter socket, attaches a termination fitting onto the end of a wire rope cable by pouring molten zinc or resin into a socket that then hardens and holds the fitting onto the end of the cable.

Due to the rigidity of this type of termination, the wires of the rope are subject to fatigue where the wires enter the socket, if the poured socket is subject to constant vibration.

Wedge sockets secure the rope to the end attachment by passing it around a grooved, wedge-shaped piece of steel and pulling it down under load into the bowl of the fixture.

Wedge sockets are popular because they can be installed in field and adjusted in field – providing 80% efficiency of rope breaking strength. Wedge sockets are popular in applications where the wire rope may be subjected to abuse and abrasion—particularly in construction and mining applications.

Wire rope clips can be used to form a load bearing eye at the end of a cable or wire rope, or to connect two cables together with a lap splice. Wire rope clips are popular because they can be installed in the field and provide 80% efficiency of the rope breaking strength.

However, the use of wire rope clips is heavily regulated by ASME B30.26 Rigging Hardware. When using wire rope clips, the end user must account for the following:When using U-bolt wire rope clips, the saddle shall be placed on the live end of the wire rope, with the U-bolt on the dead-end side—NEVER SADDLE A DEAD HORSE!

After installation, the connection shall be loaded to at least the expected working load. After unloading, the wire rope clips shall be re-tightened to the torque specifications of the manufacturer or a Qualified Person.

This type of wire rope clip is essentially a U-bolt, two nuts, and a metal base (saddle) that can be made from forged steel or cast iron. Careful consideration and attention must be given to the way U-bolt type wire rope clips are installed.

The base of the wire rope clip is made from forged steel. Forged clips are heated and hammered into the desired shape—resulting in a consistent grain structure in the steel. Forged wire rope clips are used for critical, heavy-duty, overhead loads such as winch lines, crane hoist lines, support lines, guy lines, towing lines, tie downs, scaffolds, etc.

Malleable wire rope clips are used for making eye termination assemblies only with right regular lay wire rope and only for light duty uses with small applied loads, such as hand rails, fencing, guard rails, etc. The base of the wire rope clips is made from malleable cast iron, which may fracture under heavy use and does not have the desirable metal properties of steel, or the beneficial grain structure that a forged base has.

Double saddle wire rope clips consist of two saddles, each with a leg, and two nuts—one used on the top and one on the bottom. Double saddle wire rope clips can be used in either direction, so they take the guesswork out during installation when applying to the live end and the dead end of a piece of wire rope.

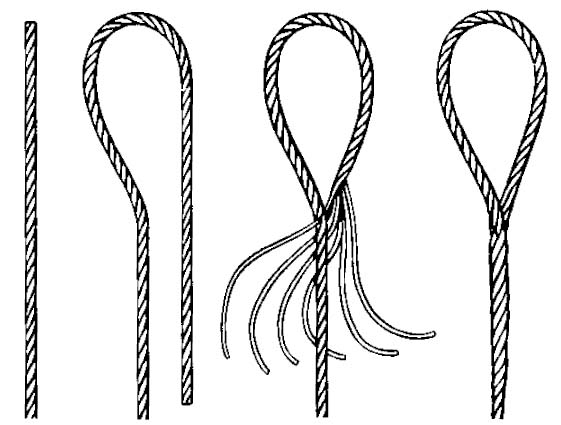

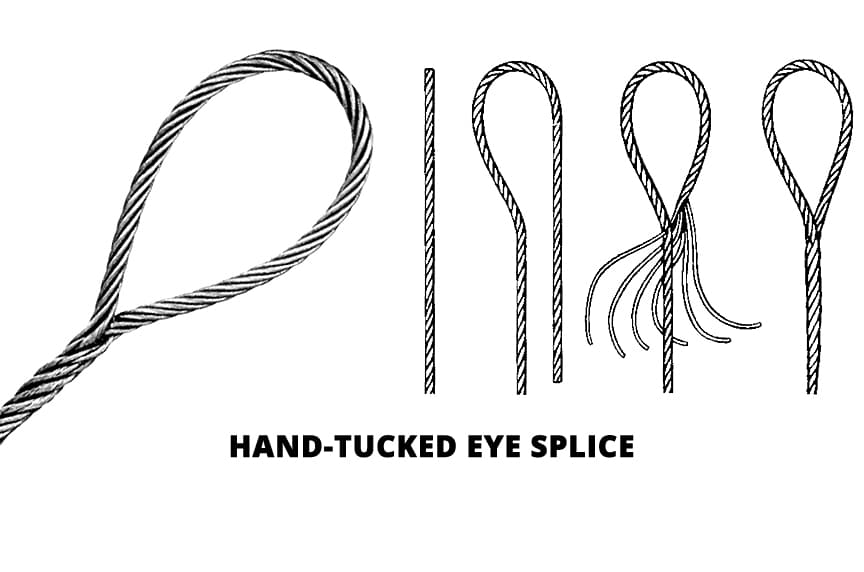

An eye splice may be used to terminate the loose end of a wire rope when forming a loop. The strands of the end of a wire rope are unwound and then the wire is bent around, and the unwrapped strands are then weaved back into the wire rope to form an eye.

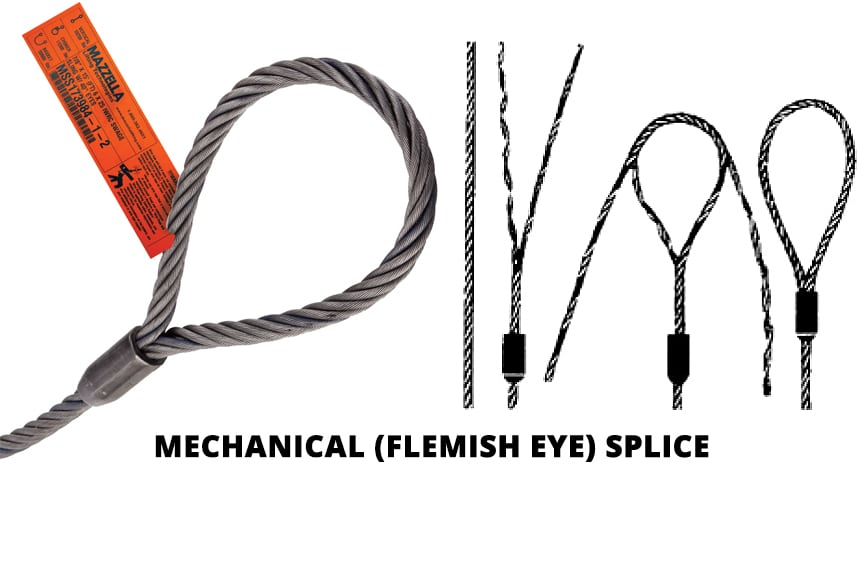

A Flemish eye splice is created when the wire rope is opened, and the strands are laid out into two parts. The two strands are looped in opposite directions and then laid back together—forming an eye, or loop, at one end of the wire rope cable. The strands are then rolled back around the rope body and a metal sleeve fitting is slipped over the splice and swaged using hydraulic machinery. This splicing method provides the most efficient use of rope capacity and is highly economical.

A hand tucked splice is formed when the shorter “dead” end is tucked into the longer “live” end of the wire rope—forming an eye. These types of splices allow for easy inspection of the wire rope wires and strands.

When the end of a rope is turned back and formed into an eye, a thimble is often used to keep the shape of the eye, prevent the rope from being crushed, and keep the rope from being bent at a diameter smaller than the rope manufacturer’s recommendations.

The table below will explain the efficiencies of the different types of wire rope end terminations for both independent wire rope core (IWRC) and fiber core (FC) wire rope configurations. Rope efficiency is described as the ratio of a wire rope’s actual breaking strength and the aggregate strength of all individual wires tested separately—usually expressed as a percentage.IWRCFC

*Spelter sockets in smaller rope sizes (usually less than 7/16”) may not always develop 100% efficiency and are not recommended by some rope manufacturers.

When you need to order a replacement wire rope, understanding the right type of end termination will help to make sure you get a direct replacement rope so you can get your project back on track. We hope this article gives you a better understanding of terms related to sockets, wire rope clips, and eye splices and that you understand what type of end termination may be best for your application.

At Mazzella, we offer all different kinds of wire rope from all of the leading manufacturers. We sell the highest-quality domestic and non-domestic rigging products because product quality and operating safety go hand-in-hand. We have one of the largest and most complete inventories of both domestic and non-domestic rigging and lifting products to suit your lifting needs.

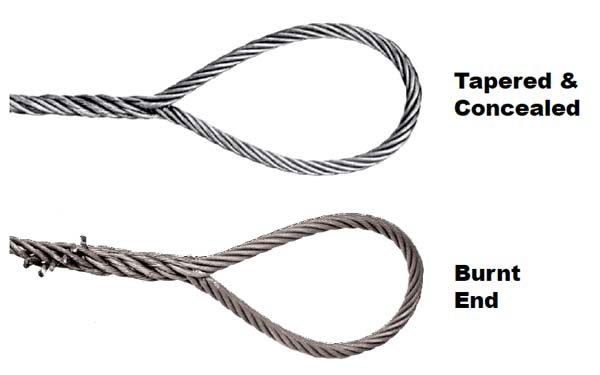

The end of a single-part hand spliced wire rope sling is bent back along the rope to form the eye, and strands are hand-tucked into the body of the rope in what is called a burnt end splice. With Burnt End splices, the ends of strands are left exposed and cut off with a torch.

Upon special request, a premium splice known as a tapered and concealed splice can be provided. Slings with rope bodies larger than 1″ diameter are made only with Burnt End splices.

Engineering wire rope slings for your application is a highly specialized field – with exacting standards – that we gladly live by. A Union sling can meet or exceed the most exacting specifications. We apply thorough design and production controls – including an extensive ISO-controlled process. And our traceability process tracks every component through completion of the assembly and into the field.

A mechanical-spliced wire rope sling is constructed when eyes are formed using the Flemish eye splice. Ends are then secured by pressing a metal sleeve over the ends of the strands of the splice. Pull is directly along the centerline of rope and eye. This splicing method gives the most efficient use of rope capacity and proves to be economical.

We custom manufacture wire rope assemblies (endless loop) for conveyor lines. Our specialty is the Long splice. The Long splice is used to create a continuous or endless loop of wire rope cable frequently utilized on conveyor systems. The splice is a difficult multi-step labor intensive process in which two wire rope cable ends are joined end to end and the strands are intertwined to merge the two individual wire rope cable ropes ends.

Our proven experience can be viewed first hand in the quality of our wire rope cable splices we perform regularly for diverse clientele in the Unites States and around the world. For assistance with your unique wire rope conveyor cable splicing needs, please complete theor call us directly at

The Wallis Splice utilizes tension in the rope body to secure strands where they are tucked back into the rope. Needs no metal sleeve to assure firm anchoring. When “tapered and concealed”, ends of strands are tucked inward and concealed inside the rope.

![]()

There are many methods of using Splices and Socket Attachments in forming loops in wire rope, and attaching fittings and terminals. The methods most widely used and which have proven best for wire rope slings are explained below. Some attachments lower the strength of the sling more than others. Different splices have different characteristics. Mechanical splices, while very strong, sometimes cannot be tolerated because of their size. The best splice is the one that will handle your specific requirement best. The same is true for terminals and fittings. The application and need for maximum safety should dictate these requirements.

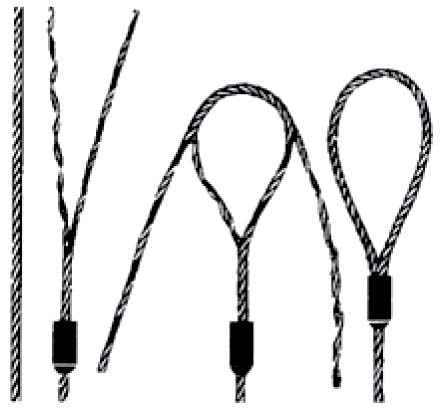

Mechanical splices are used to form loops and thimble splices, or to splice two ends of a General Purpose or Cable-Laid Body together to form an endless sling. Metal sleeves are bonded to the wire rope by compression under great pressure in a hydraulic press. Metal of the sleeve cold flows around the rope and strands.

A Titan Roll Splice is a “Flemish” splice with the strand ends secured to the body of the sling by a metal sleeve. The Titan Roll Splice is the most effective splice available as it combines the advantages of a hand splice and a mechanical splice for double assurance. Our practice is to separate the strands into two groups: 3 strands, and 3 strands plus the core. The strands are then re-laid to form the loop. A seamless metal sleeve is positioned over the strand ends and compressed sunder great pressure in a hydraulic press. The sleeve metal cold flows around the rope strands and wires, developing maximum holding power. The Titan Roll Splice assures a strong and evenly balanced splice. There are no dangerous wire ends exposed. Titon Roll Splices are used to form loops (eyes) and thimble splices on both General Purpose and Cable-Laid Slings.

This is the simplest mechanical splice, with the rope bending back on itself to form the eye. Attach-ment is made by compressing a sleeve over the junction.

Hand Splices are formed by “weaving” the strands of the rope end into the body to form a loop, or to join two ends of a rope to form a continuous loop. Inspection is easy, and hand splices are frequently used on applications where it is necessary to pull the sling out from under a load.

A “Liverpool” splice is a flexible, basic hand splice used for wire rope. It may be used to form loops or thimble splices. A Liverpool splice may be covered with a serving of wire to protect against exposed ends.

The Hidden or Wailes Splice is hand made and very smooth in appearance. All strand ends and wire ends are tucked in. This is the preferred Hand Splice for slings used on applications where wire ends could be a hazard to men working with the sling. Hidden Splices are used only to form eyes on General Purpose Body style with Fiber Core.

Sockets and other fittings can be attached to the ends of the sling body by swaging. The metal in the shank of the socket or terminal is bonded to the wire rope by compressing it under great pressure in a hydraulic press. The metal cold flows around the strands and wires forming a secure bond. These fittings can develop the catalog breaking strength of IWRC rope. Swaged Sockets are normally attached to General Purpose Slings only. This type of end attachment provides excellent resistance to vibration fatigue.

The socket of fitting is firmly attached to the carefully prepared end of a wire rope by filling the basket of the fitting with molten zinc. The zinc fills the basket and surrounds the broomed out wires to form both a mechanical and chemical bond. This type of attachment, when properly installed, will develop the catalog breaking strength of the rope body. Spelter Sockets are attached to General Purpose Slings only.

For more than 135 years, users in industries around the world have relied on products, services, and expertise from Columbus McKinnon to address needs in the workplace. From individual

hand tools to sophisticated crane systems, the wide range offered by Columbus McKinnon is unsurpassed in the market. We carry many CM products including: hoists, trolleys,

Wire rope splicing is essentially the formation of a knot between two parts of the same rope or between two separate ropes by separating and unravelling the strands and interweaving the threads together to produce a strong joint. Splicing forms a very strong knot which stays secure even if exposed to water.

There are different types of wire rope splicing. The two more common ones areBack or end splicing – This is a type of splicing where rope end strands are directly spliced without making a loop. With this wire rope splicing, rope ends are drawn to a close to prevent fraying.

Eye splicing – This a more popular type of wire rope splicing which involves taking the working end of the rope to form a loop at the end. The end of the rope strands are unraveled, then passed over and under against the lay of the rope to interweave it back into the main length of the rope.

Wire rope splicing maintains almost 95% of the wire rope’s strength. You can employ splicing in three-strand braided ropes, or even in over 12-strand braided ropes.

Splicing lets you create a new rope of any length, alter an existing rope to suit a changing application, or repair a damaged wire rope. There are two main disadvantages to splicing – the expanding thickness of the line at the joint and the distortion in the shape of the rope.

Check the wire rope tools and accessories section of this website for more tools or fill out the enquiry form and let us help with your wire rope splicing needs.

We were established in 1961 and since then Sahm-Seilklemmen has produced and distributed products complementing the mechanical splicing of wire ropes. Today we are a leading supplier for wire rope end terminations to the rigging industry and in addition to ferrules, we can supply appropriate accessories and the most diverse services.

Our product range includes ferrules made from aluminium, copper, steel and stainless steel, all manufactured exclusively by us in Germany and USA. As a system supplier, we can provide you not only with the correct ferrule for your application, but also a large range of swaging machines, test beds, cutting & annealing machines and differenttools.

Our in house machine building department ensures the highest quality standards for all our machines combined with the flexibility to react to your requirements quickly.

Since 2015 we operate under the name SAHM SPLICE GmbH. In cooperation with our affiliated firms SAHM SPLICE Ltd in Great Britain, SAHM France S.A.R.L. in France and various distribution partners we sell our products globally.

The Flemish eye splice is popular. The rugged and durable sleeves secure the ends of the strands around the body of wire rope slings. For the construction industry and the majority of industrial sling applications, this is the preferred method.

Flemish eye splice is only performed on six-strand ropes. Loop end terminations used for non- and rotation-resistant wire ropes, as well as ropes with more than six strands, require aluminum or turn-back steel sleeves. If the sleeves are made from regular carbon or aluminum metal, an electrochemical reaction between the two metals has the potential to speed up deterioration. This can be accelerated if the slings are used in corrosive environments or saltwater.

The fabrication of this splice involves forming a loop eye and pressing an aluminum sleeve over both rope parts. As for strength, this is dependent on the pressed sleeve’s integrity. For non-rotating rope types, as well as 8-, 9-, and 10-strand ropes, thimbles at the ends are typically requested.

This method is almost identical to the aluminum turn back splice with the exception that it is fabricated with steel sleeves of a somewhat smaller diameter. Also available in stainless steel, this termination can be used on stainless steel ropes of a larger diameter. With this method, the rope loops back into a swaged sleeve, forming a permanent load-bearing bond between the two parts of the rope.

For the termination on these wire rope slings, the rope inserts into the fitting bore, followed by being swaged onto the rope. This is the preferred method for open and closed sockets, buttons, and threaded studs and to attach a load hook directly onto the rope. This method works great for all rope constructions, and it produces a high-efficiency bond.

Some people do not believe that spelter socket terminations are true sling fittings. Traditionally, this type of end termination was used to determine the breaking strength of wire rope slings. Considered 100 percent of the true actual rope strength, all other end terminations are compared to spelter sockets.

This download sets out the instructions for the correct execution of splice eyes on 12 strands rope with jacket. These instructions are applicable for the execution of splice eyes on 12 strands ropes with jacket and describe the traditional splice tucked 10 ½ times, with jacket. This splice is suitable for braiding one over one.

8613371530291

8613371530291